Professional Documents

Culture Documents

Tablet Coating - Final 2

Uploaded by

kayes_abuOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tablet Coating - Final 2

Uploaded by

kayes_abuCopyright:

Available Formats

Coating Defects

By

Abu Kayes

TABLET COATING

Tablet coating is defined as covering the tablets

with one or more layers of mixture of film forming

agents, inactive and insoluble filler, sugar,

plasticizer, polyhydric alcohol ,waxes , authorized

color and some times flavor .

Why We Coat?

To protect the tablet from its environment

To mask taste/odor/color

Avoid irritation of stomach

Improve drug stability

Improve product identity

To modify bioavailability (controlled release,

enteric coated)

Components

FILM FORMING AGENT

PLASTICIZERS - LOW MOLECULAR

WEIGHT ORGANIC MOLECULES, CAPABLE

OF MODIFYING THE PHYSICAL

PROPERTIES OF A POLYMER

PIGMENTS DYES

ANTI-TACKING AGENT

Tablet Coating Defects

An ideal coated tablet should be free from

any visual defect or functional defect. But

some imperfections are seen in the tablet

coating for different kinds of reasons.

The imperfections found in tablets coating

are known as tablet coating defects.

Picking and Sticking

It is defect where isolated areas of film are pulled away from

the surface when the tablet sticks together and then part.

Picking does not occur alone it must have another tablet to

be stuck with which called sticking .

Reason:

Over-wetting or excessive film tackiness causes tablets to

stick to each other or to the coating pan.

Remedy:

A reduction in the liquid application rate or

Increase in the drying air temperature and air volume

usually solves this problem.

Picking and Sticking

Bridging

This occurs when the coating materials fills the letter or

logo on the tablet. This defect can be so severe that

the monogram or bisect is completely obscured.

Reason:

Improper application of the solution

Poor design of the tablet embossing

High coating viscosity

High percentage of solids in the solution

Remedy: Increasing the plasticizer content or changing

the plasticizer can decrease the incidence of bridging.

Bridging

Color Variation

The migration of soluble dyes, plasticizers and other additives during

drying may give the coating a mottled or spotted appearance.

Reason :

This problem can be caused by

processing conditions or the formulation.

Improper mixing,

uneven spray pattern and

insufficient coating

REMEDY:

The use of lake dyes eliminates dye migration.

A reformulation with different plasticizers and additives is the best

way to solve film instabilities caused by the ingredients.

Color Variation

Orange Peel

This refers to a coating texture that resembles the

surface of an orange.

Reason:

Inadequate spreading of the coating solution

before drying

It is usually the result of high atomization pressure

in combination with spray rates that are too high.

REMEDY: Thinning the solution with additional

solvent may correct this problem.

Orange Peel

Twinning

This is the term for two tablets that stick

together, and its a common problem with

capsule shaped tablets.

Cause

Coating suspension can not be evaporated.

Remedy:

Solve this problem by balancing the pan speed and

spray rate. Try reducing the spray rate or increasing

the pan speed.

Twinning

Cracking

Small, fine cracks observed on the upper and lower central

surface of tablets, or very rarely on the sidewall are

referred to as Cracks.

Cause

Use of higher molecular weight polymers or polymeric blends

Higher internal stresses in the film ( more than tensile

strength of the film )

Remedy

Use low molecular weight polymer

Adjust the plasticizer & pigment types and concentration to

minimize internal stresses

Cracking

EROSION

This can be the result

Over-wetted tablet surface

Inadequate drying

Lack of tablet surface strength

Remedy

Control drying rate & temperature

You might also like

- Processing ProblemDocument3 pagesProcessing ProblemMeah PachecoNo ratings yet

- 10 Defects of TabletsDocument3 pages10 Defects of TabletsHolihuaChua100% (2)

- Tablet DefectsDocument3 pagesTablet Defectsjeniccax17No ratings yet

- Defects in Tablets and Coated TabletsDocument36 pagesDefects in Tablets and Coated TabletsSunil DarjiNo ratings yet

- Common Film Coating Defects and Their CausesDocument2 pagesCommon Film Coating Defects and Their CausesLea Pesigan100% (1)

- Problem Illustration Remidies 1. CappingDocument4 pagesProblem Illustration Remidies 1. CappingMikee MeladNo ratings yet

- Name of DefectDocument3 pagesName of DefectJana EncaboNo ratings yet

- Enteric Materials - Tablets Final Copy 2Document10 pagesEnteric Materials - Tablets Final Copy 2Tulasee ReddiNo ratings yet

- Tablet CoatingDocument50 pagesTablet CoatingNaufal HanifNo ratings yet

- Problems and Remedies For Tablet CoatingDocument7 pagesProblems and Remedies For Tablet CoatingAnowar HossainNo ratings yet

- Processing ProblemDocument3 pagesProcessing ProblemMeah PachecoNo ratings yet

- Minggu 10Document56 pagesMinggu 10lailul apreliaNo ratings yet

- Tablet CoatingDocument51 pagesTablet CoatingsuminderNo ratings yet

- Film DefectDocument3 pagesFilm Defectamitrameshwardayal100% (2)

- Experiment Number 5Document6 pagesExperiment Number 5Ali Hasan RazaNo ratings yet

- PHARDOSE Tablet DefectsDocument2 pagesPHARDOSE Tablet DefectskarenNo ratings yet

- Problems in Tablet ManufacturingDocument8 pagesProblems in Tablet ManufacturingParag MehtaNo ratings yet

- Tablet DefectsDocument2 pagesTablet Defectsophelion2112No ratings yet

- Processing Problems, Pharmaceutical Dosage FormsDocument3 pagesProcessing Problems, Pharmaceutical Dosage FormsFleur Jeizl Perez100% (1)

- Tablet Coating PDFDocument6 pagesTablet Coating PDFAsif Hasan Niloy100% (1)

- 4350 9644 1 PBDocument65 pages4350 9644 1 PBWan MuhamammadNo ratings yet

- Tablet SalutDocument9 pagesTablet SalutRiaaNo ratings yet

- Aqueous Film Coating SeminarDocument38 pagesAqueous Film Coating SeminarYuppie RajNo ratings yet

- CoatingDocument39 pagesCoatingMunna SmileNo ratings yet

- Common tablet defects and remedies under 40 charactersDocument3 pagesCommon tablet defects and remedies under 40 charactersLea PesiganNo ratings yet

- Problems Encountered in Production of TabletsDocument2 pagesProblems Encountered in Production of TabletsLanceNo ratings yet

- Tablet DefectsDocument5 pagesTablet Defectsaloutolentino50% (2)

- Tablet Coating Process ExplainedDocument25 pagesTablet Coating Process ExplainedYuppie RajNo ratings yet

- Common Tablet DefectsDocument2 pagesCommon Tablet DefectsMaiah Dinglasan0% (1)

- 3 PDF Original PDFDocument30 pages3 PDF Original PDFDevang GondaliyaNo ratings yet

- Tablet Formulation Problems, Causes and RemediesDocument16 pagesTablet Formulation Problems, Causes and RemediesSagar SinghNo ratings yet

- Common Tablet Coating Issues And Their SolutionsDocument2 pagesCommon Tablet Coating Issues And Their SolutionsKumar GalipellyNo ratings yet

- T.Shivakumar: Kottam Institute of Pharmacy Jntu, A.PDocument45 pagesT.Shivakumar: Kottam Institute of Pharmacy Jntu, A.PFree Escort ServiceNo ratings yet

- Tablet Coating 2-2Document30 pagesTablet Coating 2-2Abdur RaquibNo ratings yet

- Coating Defects Fitz AtlasDocument73 pagesCoating Defects Fitz AtlasCiprian Iatan100% (2)

- Pharmaceutical Tablet CoatingDocument3 pagesPharmaceutical Tablet Coatingmkarim019No ratings yet

- Tablet Coating With Its DefectsDocument56 pagesTablet Coating With Its Defectsjoshirohan100% (1)

- PharmpediaDocument56 pagesPharmpediaShyam Singh DasNo ratings yet

- Tablet Ingredients: Pharmaceutical Technology I PHARM 2322 byDocument42 pagesTablet Ingredients: Pharmaceutical Technology I PHARM 2322 bySuzie JayNo ratings yet

- Tablet Defects 1660491621Document17 pagesTablet Defects 1660491621Graciela EscobariNo ratings yet

- Tablet Coating: Types, Reasons & ProcessesDocument50 pagesTablet Coating: Types, Reasons & ProcessesdwahyusafriNo ratings yet

- Tablet CoatingDocument33 pagesTablet CoatingJames YenchoNo ratings yet

- Tablet Coating Problems & SolutionDocument3 pagesTablet Coating Problems & Solutionsiddpandit89100% (2)

- An Overview On Tablet CoatingDocument4 pagesAn Overview On Tablet Coatingronahaniifah11No ratings yet

- Lecture (5) Tablet Coating (Spring 2023)Document35 pagesLecture (5) Tablet Coating (Spring 2023)ah1589681No ratings yet

- Paint and Coatings Additivesformulating With MikeDocument7 pagesPaint and Coatings Additivesformulating With Mikerndsb.aopNo ratings yet

- Solid Dosage Form Part 3Document24 pagesSolid Dosage Form Part 3Claire Marie AlvaranNo ratings yet

- Tablet Defects and Coating Defects and Others PDFDocument3 pagesTablet Defects and Coating Defects and Others PDFZinc YuloNo ratings yet

- Processing Problems of Tablets and Methods To OvercomeDocument35 pagesProcessing Problems of Tablets and Methods To Overcomeramyasree29No ratings yet

- DefectsDocument15 pagesDefectssupratik2401No ratings yet

- Glossary of Paint Defect TermsDocument7 pagesGlossary of Paint Defect Terms4romi89No ratings yet

- Tablet processing problems and their remediesDocument16 pagesTablet processing problems and their remediesVikrant SahaneNo ratings yet

- Industrial Pharmacy - CoatingDocument16 pagesIndustrial Pharmacy - CoatingSolomonNo ratings yet

- CIHAN - Trouble Shooting CompressionDocument61 pagesCIHAN - Trouble Shooting CompressionHamidNo ratings yet

- 01.tablets (-I-)Document25 pages01.tablets (-I-)Subha ShankareeNo ratings yet

- Tablet Processing Problems and Their Remedies: Baharul IslamDocument16 pagesTablet Processing Problems and Their Remedies: Baharul IslamEspañola EloiseNo ratings yet

- Lubricants in Pharmaceutical Solid Oral Dosage FormDocument3 pagesLubricants in Pharmaceutical Solid Oral Dosage Formqaz_qazNo ratings yet

- Glass Fusing Design Techniques with Powders on Fiber PaperFrom EverandGlass Fusing Design Techniques with Powders on Fiber PaperRating: 3.5 out of 5 stars3.5/5 (4)

- CFS50 motor feedback installation instructionsDocument1 pageCFS50 motor feedback installation instructionsJavier AlzateNo ratings yet

- Applied Fluid Mechanics: Viscosity of FluidsDocument22 pagesApplied Fluid Mechanics: Viscosity of FluidsMaggie HepditchNo ratings yet

- Dimensions of Physical Quantities DensityDocument100 pagesDimensions of Physical Quantities DensityGerman Rincon UrregoNo ratings yet

- Developing Recycled PET Fiber for Concrete ReinforcementDocument8 pagesDeveloping Recycled PET Fiber for Concrete ReinforcementJunaid Ahmad100% (1)

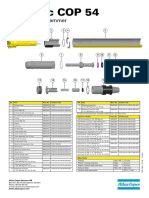

- 9853 1239 01 - COP 54 Service Poster - LOWDocument1 page9853 1239 01 - COP 54 Service Poster - LOWValourdos LukasNo ratings yet

- AASHTO T283-22 Standard Method of Test for Resistance of Compacted Asphalt Mixtures to Moisture-Induced DamageDocument11 pagesAASHTO T283-22 Standard Method of Test for Resistance of Compacted Asphalt Mixtures to Moisture-Induced DamageErnesto Oscar VidelaNo ratings yet

- WATCHDocument9 pagesWATCHGANTORONo ratings yet

- Micron Ezeprox Access Control KeypadDocument4 pagesMicron Ezeprox Access Control KeypadThuy VuNo ratings yet

- Chapter 2 Cast IronDocument9 pagesChapter 2 Cast IronHelen AdugnaNo ratings yet

- 2:4 Decoder: DECODER: A Slightly More Complex Decoder Would Be The N-To-2n Type Binary Decoders. These TypesDocument6 pages2:4 Decoder: DECODER: A Slightly More Complex Decoder Would Be The N-To-2n Type Binary Decoders. These TypesPavithraRamNo ratings yet

- Civil 3 8sem PDFDocument43 pagesCivil 3 8sem PDFG0utham100% (1)

- Michelson Interferometer Na Lamp-1Document11 pagesMichelson Interferometer Na Lamp-1SOHINI KAYALNo ratings yet

- TV Compatibility with Verbatim HDDsDocument2 pagesTV Compatibility with Verbatim HDDsmirciulicacatyNo ratings yet

- Oil Analysis - Ruller and MPC TestDocument81 pagesOil Analysis - Ruller and MPC Testmaidul.islamNo ratings yet

- Filter DesignDocument4 pagesFilter Designhassan11783No ratings yet

- Cassette toilet spare parts guide for models C2, C3 and C4Document21 pagesCassette toilet spare parts guide for models C2, C3 and C4georgedragosNo ratings yet

- UI Sample ResumeDocument6 pagesUI Sample ResumenazeerNo ratings yet

- GD&T Training Levels and ServicesDocument1 pageGD&T Training Levels and ServicesdramiltNo ratings yet

- NUSTian Final July SeptDocument36 pagesNUSTian Final July SeptAdeel KhanNo ratings yet

- January2016page1to36 Layout 1Document36 pagesJanuary2016page1to36 Layout 1c737No ratings yet

- Compact 1NC+1NO limit switch data sheetDocument2 pagesCompact 1NC+1NO limit switch data sheetJose AkinoNo ratings yet

- SHB 2503-3703 en 1000081433Document192 pagesSHB 2503-3703 en 1000081433Alberto100% (1)

- Resume of MD Saiful HyderDocument4 pagesResume of MD Saiful Hyderimtheboss*No ratings yet

- Huawei EHuawei - Erelay - Solution - OverviewRelay Solution OverviewDocument31 pagesHuawei EHuawei - Erelay - Solution - OverviewRelay Solution Overviewtariq8283% (6)

- P1 Conservation and Dissipation of Energy Student Book AnswersDocument11 pagesP1 Conservation and Dissipation of Energy Student Book AnswersjoeNo ratings yet

- Portable Low-Frequency Acoustic Seismic System HMS-620Document2 pagesPortable Low-Frequency Acoustic Seismic System HMS-620AntoNo ratings yet

- Beumer - Pipeconveyor TechnologyDocument51 pagesBeumer - Pipeconveyor TechnologyAli AlatasNo ratings yet

- Inspection and Adjustment of Pump Ls ControlDocument10 pagesInspection and Adjustment of Pump Ls ControlHai Van100% (1)

- Customer Targeted E-CommerceDocument4 pagesCustomer Targeted E-CommercepriyaNo ratings yet

- Node diagnostics report for RBS6601WDocument9 pagesNode diagnostics report for RBS6601WWilson DiazNo ratings yet