Professional Documents

Culture Documents

Impression Materials: by Bibin Bhaskaran

Uploaded by

Priyanka SinghOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Impression Materials: by Bibin Bhaskaran

Uploaded by

Priyanka SinghCopyright:

Available Formats

Impression materials

by

Bibin bhaskaran

Impression materials

Definition :- (GPT):

1) A negative likeness or copy in reverse of the

surface or object.

2) An imprint of the teeth and adjacent

structures for use in dentistry

Impression material:-

Any substance or combination of substances

used for making an impression or negative

reproduction.

Impression technique:-

A method and manner used in making a

negative likeness.

inelastic or

rigid

elastic

material use material use

Chemical

reaction

(irreversible)

plaster of Paris Edentulous

ridge

Alginate

hydrocolloid

Teeth and

soft tissues

zinc oxide-eugenol Interocclusal

records

Non aqueous

elastomers

Polysulfide,polyet

her

Condensation

silicone

Addition silicones

classification

Thermally

induced

Physical

reaction

(reversible)

Compound wax

Preliminary

impression

Agar

TEETH &

SOFT

TISSUES

Classification

Based on rigidity : Rigid

eg Plaster,Zincoxide eugenol

impression compound

Elastic

eg Alginate,polyether,silicone

Based on setting of the material: 1.) Chemical reaction(irreversible)

eg plaster of paris,zincoxide eugenol

alginate,additon and condensation silicones

2 ) Physical change of state(reversible)

eg agar

Based on viscosity : Mucostatic

eg impression plaster,agar,

light body elastomer

Mucocompressive

eg Impression compound,alginates

Pseudoplastic

eg addition silicones

Based on interaction with saliva

and water : Hydrophobic

eg polysulfide ,condensation

silicones

Hydrophilic

eg putty,impression plaster

Based on use :

Primary

impression material

eg impression compound,alginate

Secondary

Impression material

eg Zoe,medium bodied elastomers

Duplicating

material

eg agar

Based on

Chemical composition : impression plaster

impression compound

metal oxide(zinc oxide eugenol)

pastes

agar hydrocolloid

alginate hydrocolloid

polysulfides

condensation silicones

addition silicones

polythers

light curing polyether

(urethane dimethacrylate)

Desirable qualities

Pleasant odor taste and color

Absence of toxic irritants

Adequate shelf life

Economical

Easy to use

Setting that meet clinical requirements

Satisfactory consistency

Readily wet oral tissues

Elastic

Adequate strenght

Dimensional stability

Compatiblity with cast and die materials

Accuracy

Disinfection

Impression plaster

ADA

specificat

ion

Composit

ion

Uses Mixing

time

Working

time

Setting

time

Advanta

ges

Disadvan

tages

No 25 Calcined

caso4

Anti

expansio

n agents

k2so4

Accelera

tors

k2so4

Retarder

borax

Gelatin

Gum

tragnath

Starch

Alizarin

red

Primary

impressio

n material

Seconda

ry

impressio

n material

60 sec Altered

by use of

additives

same Good

deatail

reproduct

ion

Inexpens

ive

Easy to

handle

Non

toxic

Increase

d shelf

life

Setting

time can

be

controlle

d.

Requires

separatin

g medium

Dry

sensation

to

patients

mouth

Impression plaster

The impressions are very accurate

Being hydrophilic it has got intimate contact with oral

tissues by absorbing surface moisture

Impression compound

ADA

specificatio

n

Compositi

on

Uses Flow Advantage

s

Disadvanta

ges

Disinfectio

n

No 3

Type 1-

Impression(

low fusing)

Type 2-

Tray(high

fusing)

Rosin

Copal

resin

Carnauba

wax

Stearic

acid

Talc

Coloring

agent

Type 1-

primary

impression,

peripheral

tracing

Type 2-As

a tray to

support

other

materials

Type 1

flow at

mouth

temp is 6%

Type 2

flow at

mouth

temp is 2%

Non toxic

and non

irritant

Hardens in

reasonably

acceptable

time

Compatibl

e with

gypsum

products

No

separating

medium

required

Although

plastic not

fluid

enough to

record fine

detail

Distorts

over

undercuts

Shrinkage

on cooling

Dimension

al change

on storage

2%alkaline

glutarldehy

de

Impression compound

Fusion temperature of impression compound is 43.5 degree

celesius

Zinc oxide eugenol impression material

ADA

specificat

ion

Composit

ion

Uses Mixing

time

Setting

time

Advanta

ges

Disadvan

tages

Disinfecti

on

No 16

Type1

(hard)

Type 2

(soft)

2 tubes

Tube 1-

ZnO

Veg or

mineral

oil

Tube 2-

Clove oil

or

eugenol

Gum/pol

ymerised

rosin

Filler

silica

Lanolin

Accelera

tors

cacl2,mgc

l2

Impressi

on pastes

Cement

Tempora

ry filling

Root

canal

filling

Bite

registrati

on paste

Tempora

rly reline

material

Surgical

dressing

1 min/30-

40 sec

Type 1-

Initial

3-6min

Final-

10 min

Type 2-

Initial-

3-6min

Final

15 min

Adheres

well to

tray

Sufficien

tly fluid to

record

fine detail

No

dimensio

nal

change in

setting

process

Hard

when set

No

separatin

g medium

required

Non

toxic

Burning

of

eugenol

Persisten

t taste

Adheres

to tissue

Rigid

material

cant be

used

2%

glutarlde

hyde

Zincoxide eugenol impression material

Non eugenol pastes-

One of the chief disadvantages of Zoe pastes is the possible

burning sensation caused by

eugenol.orthoethoxybenzoic acid (EBA) is a valuable

substitute for eugenol in this regard.

Alginate

ADA

specificat

ion

Composi

tion

Uses Mixing

time

Working

time

Setting

time

Advanta

ges

Disadvan

tages

Disinfecti

on

No 18

Type 1

(Fast)

Type 2

(Slow)

Soluble

alginates

Na,K,

Ammonia

Calcium

sulphate

dihydrate

Trisodiu

m

phosphat

e

Diatoma

ceous

earth

Potassiu

m

titanium

fluoride

Flavouri

n agent.

To

record

impressio

ns of

dental

arches

Premilin

ary

impressio

n

Duplicati

ng cast

and

models

Type 1-

45sec

Type 2-

1min

Type 1-

1.25-

2min

Type 2-

3-4.5min

Type 1-

1-2min

Type2

2-4.5min

Non

toxicand

non

irritant

Accepta

ble odor

Compati

ble with

gypsum

Elastic

Sufficien

tly fluid

Dimensi

onally

unstable

Tears if

undercut

s severe

Difficult

to

sterilize

Poor

shelf life

10 min in

sodium

hypochlo

rite

solution

10 min in

iodophor

solution

10 min in

glutarald

ehyde

solution

Alginate

Gelation reaction-

2Na3P04 + 3CaSo4----- Ca3(Po4)2+3 Na2SO4

Recent advances in alginates

Dust free alginates-

De-dusting agent (glycerin or glycol)

Siliconized alginates-

silicon polymers are added to strengthen the material

Alginates containing disinfectants-

eg quaternary ammonium salts or chlorohexamine are added to

alginate powder.

Hard and soft set alginates-

by adjusting the amount of fillers

Reversible hydrocolloid-AGAR

ADA

specificatio

n

Compositi

on

Gelation

temperatu

re

Liquefactio

n

temperatu

re

Advantage

s

Disadvanta

ges

Disinfectio

n

No 11 Agar

Sulfates

(k2so4)

Borax

Alkyl

benzoate

Water

Fillers

(silica)

Plasticizer(

glycerine)

Bactericid

e

(thymol)

colors

37 degree

celesius

To

45 degree

celesius

60 to 70

Degree

celesius

No custom

tray

required

Clean and

pleasant

Easy to

pour

Inexpensiv

e

Good shelf

life

High

accuracy

Re-usable

Requires

conditionin

g unit

Decreased

dimensiona

l stability

Weak inn

deep sulcus

Iodophor

/bleach/glut

arldehyde

Agar

Gelation-

Gelation is accomplished by circulating cold water of

approximately 18-23 degree for not less than 5 min.

Elastomeric impression materials

Classification :-

Based on viscosity-

Class 1 heavy body heavy viscosity

Class 2 regular body or medium body

Class 3 light body or low viscosity

Based on chemistry-

Polysulfides

Condensation silicones

Additional slilicones

Polythers

Visible light curable polyether

POLYSULFIDES

ADA

Specific

ation

Composition

Mixing

time

Working

time

Setting

time

Advanta

ges

Disadv

antage

s

Disinfe

ction

No 19

1,Base paste

Liquid polymer

containing

thiol,mercaptan or

polysulfide

polymer.

Filler titanium

dioxide

Plasticizer-DI-n-

butyl phthalate

Sulfur

2,Reactor paste-

Pbo2 or organic

hydroperoxides or

inorganic

hydroxides

Inert oil/plasticizer

Filler -silica

Stearic acid

45 sec-

1min

5-7min 8min No

special

equipme

nt

Superior

strength

Pouring

can be

delayed

to 1 hr

Can be

electropl

ated

Adequat

e shelf

life

Custo

m trays

require

d

Hydro

phobic

Sensiti

ve to

heat

Long

setting

time

High

shrinka

ge

High

perman

ent

deform

ation

2%

glutarld

ehyde

polysulfides

Polysulfide is one of the least stiff or highly flexible of elastomeric

material

For accurate polysulfide impressions-

The cast should be poured immediately after taking impression

Minimise the amount of material used to take impression by using

custom made acrylic trays

ADA

Specific

ation

Composition

Mixing

itime

Workin

g time

Setting

time

Advant

ages

Disadva

ntages

Disinfec

tion

No 19

2 types-

1,Doubl

e mix

type

2,Putty

type

Base paste-

Polydimethyl

siloxane/liquid

silicone polymer

Filler silica

Reactor paste-

Tetra functional

silicates

Tin compound

45 sec Upto

5 min

10 12

min

No

special

equipme

nt

required

Modera

te

strenth

in deep

sulcus

Adequa

te shelf

life

Pleasan

t odor

Custom

tray

required

Difficul

t to

electropl

ated

hydrop

hobic

2%

glutalde

hyde

Condensation silicones

(Double mix type)

Condensation silicones

It is also called room temperature vulcanising silicones(RTV)

Uses

It is widely used in recording dentulous impressions in preparation of

crowns,bridges,inlays,onlays and to some extent for partial dentures

It is also used to record edentulous impressions in preparation of

complete denture

Putty type

Advantages

No custom tray required

No special equipment required

Moderate strength in deep sulcus

Pleasant odor

Adequate shelf life

Disadvantages

Should be poured shortly after removal

Hydrophobic

Difficult to electroplate

Easily distorted

Addition silicones

(Double mix type)

ADA

Specifica

tion

Composition

Mixing

itime

Working

time

Setting

time

Advantag

es

Disadvan

tages

No 19

2 types

1,Double

mix type

2, Putty

type

Polymer polyvinyl

siloxane,vinyl

polysiloxane,vinyl

silicones

Cross linking agent-

hydride silicone

Catalyst

chloroplatinic acid

30- 45 sec

Is greater

than

silicones

10-12min

No

special

equipment

Dimensio

naly stable

Good

shelf life

Pleasant

odor

Custom

tray

Hydroph

obic

Expensiv

e

Addition silicones

Addition polysilicones are the most stable of all the existing

materials

It has an excellent recovery of 99.93%

It exhibits pseudoplastic properties.it can be used both as syringe

and tray materials

Putty type

Advantages

No custom tray

No special equipment

Good shelf life

Can be poured more than once

Disadvantages

Extremely hydrophilic

More difficult to pour

Most expensive

Polyether materials

ADA

Specificati

on

Composition

Mixing

itime

Working

time

Setting

time

Advantag

es

Disadva

ntages

No 19

Base plate tube-

Pre polymer-

ethylene amine

Inert filler-silica

Plasticiser

glycolether

Catalyst paste-

Ester derivatives

of aromatic

sulphonic acid

Plasticiszer

phthalate

Thinner-octyl

phthalate

Methyl cellulose

30-45 sec

2-3min

5-6 min

No

special

equipment

Finish line

easily read

Pleasant

odor

Can be

poured

more than

once

Hydrophil

ic

Good

shelf life

Fast

setting

Custom

tray

Very

stiff

Least

tear

strength

More

expensiv

e

Polythers

Uses-

For recording impression in preparation of crowns and

bridges

Cavity preparation for inlays and onlays

For construction of partial and complete dentures

Visible light cured polyether

ADA

Specification

Composition

Advantages

Disadvantages

No 19

Introduced in

1988

Light bodied material=syringe

Heavy body=tubes

Contains

Polyurethane dimethacrylate

resin with sio2 +plasticizer

Polymerises in light

Complete control over

W.T/S.T

Curing time relatively

short

Excellent

physical/mechanical/clini

cal properties

Need for

transparent trays

If delay in

placement

material to be

stored in dark

place

Difficult to cure

remote areas

Should not be

used in patients

allergic to

methacrylates

Light cured polyether

It has excellent elasticity

It has infinite working time and short setting time

The impression can be stored upto two weeks

Disinfection

Most manufacturers recommend a specific

disinfectant,such as iodophor,bleach,or glutaldehyde,for disinfection.

Certain disinfectants may result in gypsum casts that have a lower surface

hardness or diminished surface detail.

The current protocol for disinfecting hydrocolloid impressions recommended

by the centre for disease control is to use house hold bleach(1 to 10

dilutions),iodophor or synthetic phenols as disinfectants

An alternate disinfection method is by immersion,but this should not exceed 10

min.

Duplicating is required for two reasons:-

1, The cast on which the wax pattern of the metal frame work is to be

formed must be made from refractory investment because it must

withstand the casting temperatures required for gold or base metal

alloys

2, The original cast is needed for checking the accuracy of the metal

frame work and for processing the denture base portion of the

partial denture

The most common duplicating materials are agar hydrocolloid

compounds, The primary advantage of agar is their set is

reversible.the disadvantage is it is subject to dimensional

change.The best storage condition is 100% humidity.

Duplicating materials

Tissue conditoners are soft elastomers used to treat an

irritated mucosa supporting a denture.it is used to

provide time for healing of soft tissues

Tissue conditioners are composed of powder containing

poly(ethyl methacrylate)and a liquid containing an

aromatic ester ethyl alcohol.

The properties that make tissue conditioners effective are-

1,viscous behavior which allows adaptation to irritated

denture bearing mucosa

2,viscoelastic behavior which cushions the cyclic forces of

mastication and bruxism

Tissue conditioners

Zardiackas.L.D , Dental materials,Dentla clinics of morth

america,July 2007,vol 51,pg 629-643 .

OBrien.W.J, Dental materials and their selection, 3

rd

edition, Quintessence publications.

Craig.R.G, Dental Materials, 12th edition, Elsevier

publications.

Anusavice, Phillips Science of Dental Materials, 11

th

edition, Saunders publications. Impression materials.

References

You might also like

- Impression MaterialsDocument60 pagesImpression Materialsمحمد احمد محمدNo ratings yet

- Physical Science (Specialization) Reviewer 494 Items With Rationalization PDFDocument118 pagesPhysical Science (Specialization) Reviewer 494 Items With Rationalization PDFKaren DellatanNo ratings yet

- RCC DomesDocument3 pagesRCC Domesvaibhavamore0% (1)

- CRODA Surfactants and Alkoxylated Polyols Overview FEB 2013Document8 pagesCRODA Surfactants and Alkoxylated Polyols Overview FEB 2013Maria Eugenia CiveiraNo ratings yet

- Impression Compounds and AlginatesDocument13 pagesImpression Compounds and Alginatessourav dasNo ratings yet

- Data Sheets - UpdatedDocument267 pagesData Sheets - Updateddurgesh82338114100% (1)

- Modelling and Simulation of The Three-Phase Induction Motor Using SimulinkDocument10 pagesModelling and Simulation of The Three-Phase Induction Motor Using SimulinkÁron FehérNo ratings yet

- BASF - Prefabricated ProductsDocument4 pagesBASF - Prefabricated ProductsPamela Villanueva0% (1)

- 95 731 01 SilanesSelectorGuideDocument4 pages95 731 01 SilanesSelectorGuideAelya SanNo ratings yet

- Softener, Textile FinishingDocument4 pagesSoftener, Textile FinishingArif NursyabaniNo ratings yet

- MOMENTIVE Silicone in Coating Textile BrochureDocument12 pagesMOMENTIVE Silicone in Coating Textile Brochureoverlord5555100% (1)

- X-Ray Sources Diffraction: Bragg's Law Crystal Structure DeterminationDocument62 pagesX-Ray Sources Diffraction: Bragg's Law Crystal Structure DeterminationSrimanthula SrikanthNo ratings yet

- Cention N PDFDocument15 pagesCention N PDFFabio RibeiroNo ratings yet

- Presented By-Dr - Jyoti Tripathi PG First Year Department of ProsthodonticsDocument48 pagesPresented By-Dr - Jyoti Tripathi PG First Year Department of ProsthodonticsJyoti TripathiNo ratings yet

- Bahan Cetak Elastomer: Etny Dyah HarniatiDocument30 pagesBahan Cetak Elastomer: Etny Dyah HarniatiRenata HazelwayNo ratings yet

- HS PDFDocument15 pagesHS PDFSawa Zayia MichaelNo ratings yet

- Algisium C: ExsymolDocument3 pagesAlgisium C: ExsymolEvelyn Vasquez VasquezNo ratings yet

- Catalogo San NopcoDocument12 pagesCatalogo San NopcopedroNo ratings yet

- Leistritz Compounding ENGDocument9 pagesLeistritz Compounding ENGGustavoNo ratings yet

- Collection For Impression MaterialsDocument3 pagesCollection For Impression Materialselsayed barhomeNo ratings yet

- Impression MaterialsDocument11 pagesImpression Materials050023No ratings yet

- Static RecommendGradeDocument1 pageStatic RecommendGradeJohn BansahNo ratings yet

- TrueDocument12 pagesTrueThree AuNo ratings yet

- Adhesive Classification and Properties: Chapter TwoDocument46 pagesAdhesive Classification and Properties: Chapter TwoFrancisco Javier Salamanca BorreroNo ratings yet

- Clearfil SE BondDocument2 pagesClearfil SE BondSupriya ShuklaNo ratings yet

- AdhesivesDocument22 pagesAdhesivesTanzeel KhanNo ratings yet

- Permabond Flyer Crystal Clear Plastic BondingDocument1 pagePermabond Flyer Crystal Clear Plastic BondingM2 APNo ratings yet

- HeliobondDocument36 pagesHeliobondNg JunnNo ratings yet

- Origin and Early Development of Rubber-Toughened Plastics: I ÎatureDocument11 pagesOrigin and Early Development of Rubber-Toughened Plastics: I ÎatureAsheesh shipra sharmaNo ratings yet

- Belami NYLO Gemini Surfactant CatalogueDocument7 pagesBelami NYLO Gemini Surfactant CatalogueNihar Mango VakilNo ratings yet

- Waterborne PVAc Quick Tack AdhesiveDocument1 pageWaterborne PVAc Quick Tack AdhesiveFacundo SepulvedaNo ratings yet

- ImpressionDocument71 pagesImpressionArpit HalaniNo ratings yet

- Elastic Impression MaterialDocument53 pagesElastic Impression MaterialAriba AsifNo ratings yet

- Galata Fomrez Product GuideDocument1 pageGalata Fomrez Product Guideparijat patelNo ratings yet

- Anti Blocking AdditiveDocument5 pagesAnti Blocking AdditiveSergey TrifonovNo ratings yet

- Natural RubberDocument2 pagesNatural RubbertanuNo ratings yet

- 15ifiziegftenioneers Standard Specification For Surface Preparation and Protective Coating 6-79-0020 Rev. 0Document3 pages15ifiziegftenioneers Standard Specification For Surface Preparation and Protective Coating 6-79-0020 Rev. 0Chinmay DaveNo ratings yet

- BROCHURE Product Range - I&I and Home Care Solutions Europe-BASF-09-18Document19 pagesBROCHURE Product Range - I&I and Home Care Solutions Europe-BASF-09-18Francesco RicciNo ratings yet

- Water-Based Pressure-Sensitive Adhesives For Screen PrintingDocument12 pagesWater-Based Pressure-Sensitive Adhesives For Screen PrintingfaizNo ratings yet

- Chapter I-Impressions (2021)Document15 pagesChapter I-Impressions (2021)Hany NassifNo ratings yet

- Solutions For The Thermoset Composites Industry Flipbook PDF - CompressDocument12 pagesSolutions For The Thermoset Composites Industry Flipbook PDF - Compressmarcela walterosNo ratings yet

- Coupling: SilaneDocument5 pagesCoupling: SilaneAkash YadavNo ratings yet

- Journal of Adhesion Science and TechnologyDocument7 pagesJournal of Adhesion Science and TechnologyDaniel L. FrandsenNo ratings yet

- Construction Solutions: Polymer Emulsions & Specialty ChemicalsDocument9 pagesConstruction Solutions: Polymer Emulsions & Specialty ChemicalsLong An DoNo ratings yet

- Coatosil : Additives For High Performance Coatings and InksDocument8 pagesCoatosil : Additives For High Performance Coatings and InksLong An ĐỗNo ratings yet

- RelyX Ultimate Step by StepDocument16 pagesRelyX Ultimate Step by StepTaylorNo ratings yet

- PUMA RSL V - 06 - 14 Final PDFDocument2 pagesPUMA RSL V - 06 - 14 Final PDFTrinhTruongNo ratings yet

- Plastic RecyclingDocument1 pagePlastic RecyclingkerenpkpNo ratings yet

- PigmentsDocument6 pagesPigmentsAbhinav TayadeNo ratings yet

- Impression Materials - Introduction and Impression Compound - Dr. AnandDocument61 pagesImpression Materials - Introduction and Impression Compound - Dr. AnandDr Anand RajapurNo ratings yet

- Additives For Specialty PolymersDocument8 pagesAdditives For Specialty Polymers吉启周No ratings yet

- Kosmos 19 TdsDocument1 pageKosmos 19 TdsjahdaNo ratings yet

- Spec10 Bitumen RubbersDocument1 pageSpec10 Bitumen RubbersashrafelkhalawyNo ratings yet

- Raw Materials For The Polyurea Industry - Global - EN - May2021Document6 pagesRaw Materials For The Polyurea Industry - Global - EN - May2021Jella NurohmahNo ratings yet

- Cention NDocument14 pagesCention NGiTa TAriganNo ratings yet

- Byk Le-G 1 enDocument11 pagesByk Le-G 1 enHelene Di marcantonioNo ratings yet

- Hasan 2017 IOP Conf. Ser. Mater. Sci. Eng. 213 012048Document10 pagesHasan 2017 IOP Conf. Ser. Mater. Sci. Eng. 213 012048yombexNo ratings yet

- Bituthene 3000 Elastomeric Sheet Tanking and Waterproo NG MembraneDocument1 pageBituthene 3000 Elastomeric Sheet Tanking and Waterproo NG MembraneHen8No ratings yet

- Sodium Hydroxide Product TreeDocument1 pageSodium Hydroxide Product TreeFawait KasyafaniNo ratings yet

- BASF - Sports Flooring 2020Document12 pagesBASF - Sports Flooring 2020Carlitos PrincipeNo ratings yet

- Chemical Inventory Sheet: Name of Company/Production UnitDocument4 pagesChemical Inventory Sheet: Name of Company/Production UnitNur E Alam NuruNo ratings yet

- Function Mit18086Document3 pagesFunction Mit18086Ria Dwi IzahyantiNo ratings yet

- Notification APSWREIS Teacher PostsDocument14 pagesNotification APSWREIS Teacher PostsRuthvik ReddyNo ratings yet

- I.S.I. C.M.I EntranceDocument6 pagesI.S.I. C.M.I Entrancegaurav kumarNo ratings yet

- New Oscillation Criteria For Second Order Nonlinear Differential EquationsDocument6 pagesNew Oscillation Criteria For Second Order Nonlinear Differential EquationsresearchinventyNo ratings yet

- Simulation Analysis of Compression Refrigeration Cycle With Different RefrigerantsDocument5 pagesSimulation Analysis of Compression Refrigeration Cycle With Different RefrigerantsSpicyNo ratings yet

- Comments Resolution Discharge Filter Coalescer Skid - Foundation - Anchor - CVL ReplyDocument1 pageComments Resolution Discharge Filter Coalescer Skid - Foundation - Anchor - CVL ReplySana UllahNo ratings yet

- Phy131h1 Final Exam Review Questions 3Document6 pagesPhy131h1 Final Exam Review Questions 3hanujahNo ratings yet

- Water DistillerDocument13 pagesWater DistillerjordanrmaNo ratings yet

- A Study of Verbs Compounded With Aus, Ein, Etc., As Contrasted With Those Compounded With Heraus, Hinaus, Herain, Hinein, EtcDocument152 pagesA Study of Verbs Compounded With Aus, Ein, Etc., As Contrasted With Those Compounded With Heraus, Hinaus, Herain, Hinein, EtcEnkindooNo ratings yet

- A Solar Chimney Power Plant TULJAPURDocument16 pagesA Solar Chimney Power Plant TULJAPURDIPAK VINAYAK SHIRBHATE100% (3)

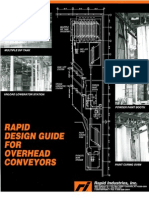

- Design GuideDocument30 pagesDesign Guiderapidindustries100% (6)

- Statistical Mechanics and Out-of-Equilibrium Systems!Document15 pagesStatistical Mechanics and Out-of-Equilibrium Systems!hrastburg100% (1)

- GEOTECH 1 Module 8Document12 pagesGEOTECH 1 Module 8Earl averzosaNo ratings yet

- Load and Stress Distribution in Screw Threads With Modified WashersDocument11 pagesLoad and Stress Distribution in Screw Threads With Modified WashersminakirolosNo ratings yet

- 1 Force and MotionDocument27 pages1 Force and Motion5kfwvjk68bNo ratings yet

- US 0702-3A Design and Execution-F3Document42 pagesUS 0702-3A Design and Execution-F3almirante_andreNo ratings yet

- Ramzan Timetable Grade IX-ADocument1 pageRamzan Timetable Grade IX-AMBJNo ratings yet

- Newtons Laws: By: Armaan NooraniDocument10 pagesNewtons Laws: By: Armaan NooraniArmaan NooraniNo ratings yet

- List of Institutes Engineering (Gujcet)Document20 pagesList of Institutes Engineering (Gujcet)Kumar ManglamNo ratings yet

- Rr211402 Mechanics of SolidsDocument8 pagesRr211402 Mechanics of SolidsSrinivasa Rao GNo ratings yet

- Question PaperDocument1 pageQuestion PaperDeepak PradhanNo ratings yet

- Multiphoton PolymerizationDocument9 pagesMultiphoton PolymerizationMircavid HeydəroğluNo ratings yet

- SBF BK A07025 Accelerating Admixtures For ConcreteDocument53 pagesSBF BK A07025 Accelerating Admixtures For ConcreteSandeep ReddyNo ratings yet

- Notes 2Document65 pagesNotes 2Aamir khanNo ratings yet

- Problem Set No. 1Document2 pagesProblem Set No. 1Zukato DesuNo ratings yet

- FS-l6S: Instruction ManualDocument25 pagesFS-l6S: Instruction ManualFazrulNo ratings yet