Professional Documents

Culture Documents

Gears: Ken Youssefi Mechanical Engineering Dept

Uploaded by

Raghavendra PrasadOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gears: Ken Youssefi Mechanical Engineering Dept

Uploaded by

Raghavendra PrasadCopyright:

Available Formats

Ken Youssefi

Mechanical Engineering Dept.

1

Gears

Ken Youssefi

Mechanical Engineering Dept.

2

Applications of Gears

Control gears long life, low noise, precision gears

kinematic & stress analysis

Aerospace gears light weight, moderate to high load

kinematic & stress analysis

Power transmission long life, high load and speed

kinematic & stress analysis

Appliance gears long life, low noise & cost, low to

moderate load

kinematic & some stress analysis

Toys and Small Mechanisms small, low load, low cost

kinematic analysis

Ken Youssefi

Mechanical Engineering Dept.

3

Types of Gears

Spur gears tooth profile is parallel to

the axis of rotation, transmits motion

between parallel shafts.

Pinion (small gear)

Gear (large gear)

Internal gears

teeth are inclined to

the axis of rotation, the angle provides

more gradual engagement of the teeth

during meshing, transmits motion

between parallel shafts.

Helical gears

Ken Youssefi

Mechanical Engineering Dept.

4

Types of Gears

Bevel gears teeth are formed on a

conical surface, used to transfer motion

between non-parallel and intersecting

shafts.

Straight

bevel gear

Spiral

bevel gear

Ken Youssefi

Mechanical Engineering Dept.

5

Types of Gears

Worm gear sets consists of a

helical gear and a power screw (worm),

used to transfer motion between non-

parallel and non-intersecting shafts.

Rack and Pinion sets a special

case of spur gears with the gear

having an infinitely large diameter,

the teeth are laid flat.

Rack

Pinion

Ken Youssefi

Mechanical Engineering Dept.

6

Gear Design and Analysis

Kinematics of gear teeth and gear trains.

Force analysis.

Design based on tooth bending strength.

Design based on tooth surface strength.

Ken Youssefi

Mechanical Engineering Dept.

7

Nomenclature of Spur Gear Teeth

= (tooth spacing)

driven gear

(tooth thickness)

driver

, measured

on the pitch circle.

Backlash

Pitch circle

gear diam.

Fillet radius

Clearance

Base Circle

Ken Youssefi

Mechanical Engineering Dept.

8

Fundamental Law and I nvolute Curve

Generation of the involute curve

Tangent at the

point of contact

r

G

r

P

r

G

/ r

P

= constant (constant speed ratio)

All common normals have to

intersect at the same point P

Ken Youssefi

Mechanical Engineering Dept.

9

Useful Relations

P = N / d

P = diametral pitch, teeth per inch

N = number of teeth

d = pitch diameter (gear diameter)

m (module, mm) = d / N

Metric system

p (circular pitch) = d / N

Pp =

Ken Youssefi

Mechanical Engineering Dept.

10

Standard Tooth Specifications

Pressure angle

Two mating gears must have the same diametral pitch, P,

and pressure angle, .

Pitch

line

Line of centers

Base

circle

Base

circle

Pitch

circle

Pitch

circle

Pressure angle

Standard pressure angles, 14.5

o

(old), 20

o

, and 25

o

Ken Youssefi

Mechanical Engineering Dept.

11

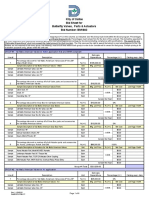

Standard Tooth Specifications

Power transmission, 2 P 16

Ken Youssefi

Mechanical Engineering Dept.

12

Kinematics

(

p

/

g

) = (d

g

/ d

p

) = (N

g

/ N

p

) = VR (velocity ratio)

P = (N

g

/ d

g

) = (N

p

/ d

p

)

Spur, helical and bevel gears

g

d

g

p

d

p

Rack and pinion

Velocity of the rack

Displacement of the rack

is in radians

,

Ken Youssefi

Mechanical Engineering Dept.

13

Kinematics

Worm Gear Sets

N

g

= number of teeth on the helical gear

N

w

= number of threads on the worm,

usually between 2-6

Speed ratio = N

g

/ N

w

Large reduction in one step, but lower

efficiency due heat generation.

Worm

Helical gear

Ken Youssefi

Mechanical Engineering Dept.

14

Kinematics of Gear Trains

Conventional gear trains

2

=

N

2

N

3

4 =

,

4

=

N

4

N

5

,

m

V

= e= train value

Speed ratio

2

=

output

input

=

Reverted gear train output shaft is concentric

with the input shaft. Center distances of the

stages must be equal.

Ken Youssefi

Mechanical Engineering Dept.

15

Kinematics of Gear Trains

Planetary gear trains

gear

=

arm

+

gear/arm

F/arm

=

F

-

arm

,

L/arm

=

L

-

arm

= e (train value)

Ken Youssefi

Mechanical Engineering Dept.

16

Kinematics of Gear Trains

Determine the speed of the sun gear if the arm rotates at 1 rpm.

Ring gear is stationary.

2 degrees of freedom, two inputs are needed to control the system

Ken Youssefi

Mechanical Engineering Dept.

17

Planetary Gear Trains - Example

For the speed reducer shown, the input

shaft a is in line with output shaft b. The

tooth numbers are N

2

=24, N

3

=18, N

5

=22,

and N

6

=64. Find the ratio of the output

speed to the input speed. Will both shafts

rotate in the same direction? Gear 6 is a

fixed internal gear.

Train value = (-N

2

/ N

3

)(N

5

/ N

6

) = (-24/18)(22/64) = -.4583

-.4583 = (

L

arm

) / (

F

arm

) = (0

arm

) / (1

arm

)

arm

= .125, reduction is 8 to 1

Input and output shafts rotate in the same direction

d

2

+d

3

=d

6

d

5

Ken Youssefi

Mechanical Engineering Dept.

18

Harmonic Drive

The mechanism is comprised of three components: Wave Generator, Flexspline,

and Circular Spline.

Wave Generator

Consists of a steel disk and a specially design bearing. The outer surface

has an elliptical shape. The ball bearing conforms to the same elliptical

shape of the wave generator. The wave generator is usually the input.

Flexspline

The Flexspline is a thin-walled steel cup with gear teeth on the outer

surface near the open end of the cup. Flexspline is usually the output.

Circular Spline

Rigid internal circular gear, meshes with the external teeth on the Flexspline.

Ken Youssefi

Mechanical Engineering Dept.

19

Harmonic Drive

Teeth on the Flexspline

and circular spline

simultaneously mesh at

two locations which are

180

o

apart.

As the wave generator travels 180

o

, the

flexspline shifts one tooth with respect

to circular spline in the opposite

direction.

Circular Spline

= 0

Flexspline

= output

Wave Generator

= input

The flexspline has two less teeth than the circular spline.

Gear Ratio = - (N

flex spline

)/ 2

,

,

You might also like

- Gears: Ken Youssefi Mechanical Engineering DeptDocument19 pagesGears: Ken Youssefi Mechanical Engineering DeptSam MagomnangNo ratings yet

- Gears Design MD2Document52 pagesGears Design MD2Faizan MohyuddinNo ratings yet

- Gearboxashu1 150911200033 Lva1 App6891Document80 pagesGearboxashu1 150911200033 Lva1 App6891Jojee MarieNo ratings yet

- Gearbox: Fundamental, Operation & MaintenanceDocument80 pagesGearbox: Fundamental, Operation & MaintenanceGuru VagaNo ratings yet

- Kom Unit 4 NotesDocument68 pagesKom Unit 4 NotesParkunam Randy100% (1)

- Transmission System of Gear BoxDocument86 pagesTransmission System of Gear BoxAmit Kumar Uke100% (4)

- Gears: Ken Youssefi Mechanical Engineering DeptDocument19 pagesGears: Ken Youssefi Mechanical Engineering DeptRyan Llona FernandezNo ratings yet

- Gears: Mechanical Engineering Dept. Ken YoussefiDocument19 pagesGears: Mechanical Engineering Dept. Ken YoussefiZahir KhiraNo ratings yet

- 1 Gears Types - ADocument17 pages1 Gears Types - AnethmiNo ratings yet

- Gear Design NhpancholiDocument66 pagesGear Design NhpancholiDINESH KUMARNo ratings yet

- Welcome To International Journal of Engineering Research and Development (IJERD)Document6 pagesWelcome To International Journal of Engineering Research and Development (IJERD)IJERDNo ratings yet

- Gear Trains Simple PDFDocument43 pagesGear Trains Simple PDFYuvaraj GNo ratings yet

- Mech - Ijmperd-Design and Finite Element-Nihad Hasan TalibDocument12 pagesMech - Ijmperd-Design and Finite Element-Nihad Hasan TalibTJPRC PublicationsNo ratings yet

- Gears ReviewDocument28 pagesGears ReviewsharmendrayadavNo ratings yet

- Gears ReviewDocument28 pagesGears ReviewSridhar RaoNo ratings yet

- Gear Trains: (Chapter 6)Document28 pagesGear Trains: (Chapter 6)Suresh ParamuNo ratings yet

- Note On Gear BoxDocument32 pagesNote On Gear BoxanupbagNo ratings yet

- Gear TechnologyDocument31 pagesGear TechnologyRishabh GawriNo ratings yet

- Design of GearsDocument64 pagesDesign of GearsFauiqe Yousaf100% (1)

- Helical Gears: DefinitionDocument29 pagesHelical Gears: DefinitionMuthuvel MNo ratings yet

- Toothed Gearing: (Chapter-12 R.S. KHURMI)Document35 pagesToothed Gearing: (Chapter-12 R.S. KHURMI)Somnath Somadder100% (1)

- Gears - General: Shigley's Mechanical Engineering DesignDocument229 pagesGears - General: Shigley's Mechanical Engineering DesignbasitNo ratings yet

- Chapter 04 - Gear TrainsDocument60 pagesChapter 04 - Gear TrainsMuhammad ZarifNo ratings yet

- Differential Gear Box DesignDocument61 pagesDifferential Gear Box Designramkumar121No ratings yet

- Design of Helical GearsDocument14 pagesDesign of Helical GearsAjay Kumar Reddy KNo ratings yet

- Chapter 4 Design of Power Transmission ElementsDocument43 pagesChapter 4 Design of Power Transmission ElementsMuhamad Arif100% (2)

- Gears: What We Need To Know About Them. 1. Type of Gears 2. Terminologies or Nomenclatures 3. Forces TransmittedDocument35 pagesGears: What We Need To Know About Them. 1. Type of Gears 2. Terminologies or Nomenclatures 3. Forces TransmittedsyampnaiduNo ratings yet

- Gears: 1.module SizeDocument5 pagesGears: 1.module SizeAhmed rehmanNo ratings yet

- Chapter 9 Spur Gear DesignDocument122 pagesChapter 9 Spur Gear DesignJimmy Silvera OtañeNo ratings yet

- Toothed GearingDocument80 pagesToothed GearingArjun RajuNo ratings yet

- Unit-3 Helical GearsDocument38 pagesUnit-3 Helical GearsMarthande100% (1)

- Spur Gear (Treb)Document19 pagesSpur Gear (Treb)diiivadNo ratings yet

- 7 Gear KinematikDocument19 pages7 Gear KinematikiwenNo ratings yet

- Shaft Design ProcedureDocument36 pagesShaft Design ProcedureashiyNo ratings yet

- UNIT-2 Design of Spur GearDocument56 pagesUNIT-2 Design of Spur GearMarthandeNo ratings yet

- Construction and Details of Gears: TopicDocument26 pagesConstruction and Details of Gears: TopicAbhishek HoreNo ratings yet

- Design and Performance Analysis of Helical Gear For Al and Steel Material by Using AnsysDocument10 pagesDesign and Performance Analysis of Helical Gear For Al and Steel Material by Using AnsysankNo ratings yet

- Gears and System of GearsDocument38 pagesGears and System of GearsKristijan HorvatNo ratings yet

- Design of Spur Gear - Fundamentals - 1Document19 pagesDesign of Spur Gear - Fundamentals - 1Dhyan PatelNo ratings yet

- Gears: Mechanical Engineering DeptDocument20 pagesGears: Mechanical Engineering DeptAtikah AbdallaNo ratings yet

- Machine Design-Ii: GearsDocument50 pagesMachine Design-Ii: Gearsmuhammad hamzaNo ratings yet

- 1GEARDocument18 pages1GEARsatheeshkumarNo ratings yet

- ME0403 Ch2 Gear MeasurementDocument42 pagesME0403 Ch2 Gear MeasurementMANOJ M100% (1)

- Gears KinematicsDocument19 pagesGears Kinematicsavinashn12No ratings yet

- Lecture Seven Gears: Common Gear TypesDocument8 pagesLecture Seven Gears: Common Gear TypesShruti SharmaNo ratings yet

- Chapter 9 Spur Gear DesignDocument27 pagesChapter 9 Spur Gear Designagung badoNo ratings yet

- Group 3 Design of Helical Gear. (Autosaved)Document27 pagesGroup 3 Design of Helical Gear. (Autosaved)Absë Thè Hêro'sNo ratings yet

- Functions of A Gear: - Power Transmission - Change Rotational Speed/torque - Maintain Constant Speed RatioDocument16 pagesFunctions of A Gear: - Power Transmission - Change Rotational Speed/torque - Maintain Constant Speed RatioGaurav SinghNo ratings yet

- Gears, Types and ItsDocument22 pagesGears, Types and ItsBravo VermaNo ratings yet

- Gear Theory 1Document164 pagesGear Theory 1suneel kumar rathoreNo ratings yet

- Name:-Yash Shah Enrollment No: - 150120119181 Branch & Class: - Mechanical (7-CG) Subject: - Machine Design (2171909) Topic: - Spur Gear and Design of Spur GearDocument16 pagesName:-Yash Shah Enrollment No: - 150120119181 Branch & Class: - Mechanical (7-CG) Subject: - Machine Design (2171909) Topic: - Spur Gear and Design of Spur GearBossNo ratings yet

- Design of Machine Elements-II: Lecture By: - Engr Aakash Munsif Mechanical Engineering DepartmentDocument37 pagesDesign of Machine Elements-II: Lecture By: - Engr Aakash Munsif Mechanical Engineering DepartmentMuhammad Mubashar FareedNo ratings yet

- ZEIT3700 Notes Gearing 1Document6 pagesZEIT3700 Notes Gearing 1ghufran015580No ratings yet

- 2016 - 1404 - Types of Gears - BearingsDocument78 pages2016 - 1404 - Types of Gears - Bearingspranay kaduNo ratings yet

- Southern Marine Engineering Desk Reference: Second Edition Volume IiFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IiNo ratings yet

- Performance-Based Gear Metrology: Kinematic - Transmission - Error Computation and DiagnosisFrom EverandPerformance-Based Gear Metrology: Kinematic - Transmission - Error Computation and DiagnosisNo ratings yet

- Bearings: A Tribology HandbookFrom EverandBearings: A Tribology HandbookM. J. NealeRating: 3 out of 5 stars3/5 (8)

- Internal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsFrom EverandInternal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsNo ratings yet

- Visvesvaraya Technological University Belagavi, Karnataka-590018Document5 pagesVisvesvaraya Technological University Belagavi, Karnataka-590018Raghavendra PrasadNo ratings yet

- Key Answers of Paper-1Document5 pagesKey Answers of Paper-1Raghavendra PrasadNo ratings yet

- Key Answers of Paper-2Document5 pagesKey Answers of Paper-2Raghavendra PrasadNo ratings yet

- Attendance FormatDocument1 pageAttendance FormatRaghavendra PrasadNo ratings yet

- BTDDocument8 pagesBTDRaghavendra PrasadNo ratings yet

- 1st Year Syllabus Book Setting PDFDocument42 pages1st Year Syllabus Book Setting PDFRaghavendra PrasadNo ratings yet

- AQISManual For Engg CollegesDocument36 pagesAQISManual For Engg CollegesRaghavendra PrasadNo ratings yet

- UNIT-VI Small Scale Industry (SSI)Document30 pagesUNIT-VI Small Scale Industry (SSI)Raghavendra PrasadNo ratings yet

- Multipe Choice Non ConventionalMULTIPLEDocument6 pagesMultipe Choice Non ConventionalMULTIPLERaghavendra Prasad100% (1)

- Subject Code With Syllabus MechanicalDocument100 pagesSubject Code With Syllabus MechanicalRaghavendra PrasadNo ratings yet

- The Payment of Gratuity Act 1972Document13 pagesThe Payment of Gratuity Act 1972KijanjooNo ratings yet

- Karnatka Go On Aicte Engg 6th PayDocument37 pagesKarnatka Go On Aicte Engg 6th PayShankaragoudNo ratings yet

- Thermal PropertiesDocument18 pagesThermal PropertiesRaghavendra PrasadNo ratings yet

- UNIT-1 Casting ProcessDocument23 pagesUNIT-1 Casting ProcessRaghavendra PrasadNo ratings yet

- The Payment of Gratuity Act 1972Document13 pagesThe Payment of Gratuity Act 1972KijanjooNo ratings yet

- 12 Weeks Post Graduate Certificate Course in Thermal Power Plant EngineeringDocument5 pages12 Weeks Post Graduate Certificate Course in Thermal Power Plant EngineeringArun KumarNo ratings yet

- 12 Weeks Post Graduate Certificate Course in Thermal Power Plant EngineeringDocument5 pages12 Weeks Post Graduate Certificate Course in Thermal Power Plant EngineeringArun KumarNo ratings yet

- Chap 17Document20 pagesChap 17Raghavendra PrasadNo ratings yet

- BiogasDocument8 pagesBiogasRaghavendra PrasadNo ratings yet

- UntitledDocument1 pageUntitledRaghavendra PrasadNo ratings yet

- Water Cooling SystemDocument62 pagesWater Cooling SystemRaghavendra PrasadNo ratings yet

- Unit 5 Air CompressorDocument15 pagesUnit 5 Air CompressorRaghavendra PrasadNo ratings yet

- 10me33 1Document1 page10me33 1Raghavendra PrasadNo ratings yet

- Unsteady State Heat TransferDocument4 pagesUnsteady State Heat TransferRaghavendra PrasadNo ratings yet

- Syllabus For Mechanical EngineeringDocument3 pagesSyllabus For Mechanical EngineeringRaghavendra PrasadNo ratings yet

- Supercharger PDFDocument20 pagesSupercharger PDFrishirajtomar87% (30)

- L2 Calendar Blr-Feb12Document4 pagesL2 Calendar Blr-Feb12Raghavendra PrasadNo ratings yet

- Types of Boilers PDFDocument5 pagesTypes of Boilers PDFJosé RubioNo ratings yet

- Midway Space Invader SchematicsDocument3 pagesMidway Space Invader SchematicsThomas C WalkerNo ratings yet

- Jf404e PDFDocument4 pagesJf404e PDFvaskaservNo ratings yet

- User Manual enDocument40 pagesUser Manual enapostucristianNo ratings yet

- ConclusionDocument1 pageConclusionFrancis John DavidNo ratings yet

- How Stuff Works - How Automatic Transmissions WorkDocument21 pagesHow Stuff Works - How Automatic Transmissions WorkKausik DattaNo ratings yet

- Automatic Transmission: Group 23ADocument178 pagesAutomatic Transmission: Group 23ADaniel QuisbertNo ratings yet

- Hidraulica - HoyeaDocument3 pagesHidraulica - HoyeaJhoompieer VFNo ratings yet

- Bermad: Electric Pressure Control On-Off Deluge Valve Model FP 400Y - 3DCDocument4 pagesBermad: Electric Pressure Control On-Off Deluge Valve Model FP 400Y - 3DCKhadija MirajNo ratings yet

- PVG 120 SpecificationsDocument6 pagesPVG 120 Specificationsgonzalo andres HernandezNo ratings yet

- NS, PF (Service Kit Catalogue)Document8 pagesNS, PF (Service Kit Catalogue)nicolasNo ratings yet

- Automatic 6-Speed Gearbox 09G PDFDocument96 pagesAutomatic 6-Speed Gearbox 09G PDF19crystiNo ratings yet

- 2-1. Structure and FunctionDocument91 pages2-1. Structure and Functionmarcelo rojas100% (1)

- MK3 Numero de Partes (Frenos)Document15 pagesMK3 Numero de Partes (Frenos)SantiagoAcuñaNo ratings yet

- T-Pattern Globe Valves PDFDocument16 pagesT-Pattern Globe Valves PDFandistwn99No ratings yet

- 480866390Document9 pages480866390Fernando RomeroNo ratings yet

- An Anti-Lock BR-WPS OfficeDocument3 pagesAn Anti-Lock BR-WPS OfficeKaiRae AsakuraNo ratings yet

- Backlash SDPDocument11 pagesBacklash SDPPatrick Cyr GagnéNo ratings yet

- AGMA 1103-H07 Tooth Proportions For Fine - Pitch Spur and Helical Gearing (Metric Edition)Document32 pagesAGMA 1103-H07 Tooth Proportions For Fine - Pitch Spur and Helical Gearing (Metric Edition)simone.castagnetti100% (1)

- Practical Centrifugal PumpsDocument8 pagesPractical Centrifugal PumpsKhemiri Houssem EddineNo ratings yet

- Butterfly ValveDocument4 pagesButterfly ValveghjtyuNo ratings yet

- Rukovodstvo A750E 2Document41 pagesRukovodstvo A750E 2AlzieNo ratings yet

- Part Book D5C LGP-POWER TRAINDocument12 pagesPart Book D5C LGP-POWER TRAINmantoNo ratings yet

- Automatic Transmission F4A41, F4A42, F4A51: Revised PWEE9514-F Jun. 2000 Mitsubishi Motors CorporationDocument118 pagesAutomatic Transmission F4A41, F4A42, F4A51: Revised PWEE9514-F Jun. 2000 Mitsubishi Motors CorporationLuis Eduardo Prada PeñalozaNo ratings yet

- Unitec Parts Part 1Document53 pagesUnitec Parts Part 1coco MPNo ratings yet

- R1 - 100701492-Pro-004 - Uf P&idDocument1 pageR1 - 100701492-Pro-004 - Uf P&idPrashant HuddarNo ratings yet

- Team Turbine GovernorDocument25 pagesTeam Turbine GovernorGanesh Dasara100% (1)

- Lec 3Document48 pagesLec 3Amr AsaadNo ratings yet

- Hand Pump Manual of MaintenanceDocument28 pagesHand Pump Manual of MaintenanceManuel LozanoNo ratings yet

- Hydraulic Pumps: Service Training Manual ECM 720Document10 pagesHydraulic Pumps: Service Training Manual ECM 720victor laraNo ratings yet

- MWSR Parts List ACUATEC...Document4 pagesMWSR Parts List ACUATEC...Jader LeyvaNo ratings yet