Professional Documents

Culture Documents

Combustion Chambers-Ci Engines

Uploaded by

Srinivas EedaraOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Combustion Chambers-Ci Engines

Uploaded by

Srinivas EedaraCopyright:

Available Formats

Combustion chambers-C.I.

Engines

The most important function of CI engine combustion

chamber is to provide proper mixing of fuel and air in short

time.

In order to achieve this, an organized air movement called

swirl is provided to produce high relative velocity between the

fuel droplets and the air.

Classification of combustion chambers

1. OPEN INJECTION (DI) TYPE :This type of combustion chamber is also

called an Open combustion chamber. In this type the entire volume of

combustion chamber is located in the main cylinder and the fuel is injected

into this volume.

2. INDIRECT INJECTION (IDI) TYPE: In this type of combustion chambers,

the combustion space is divided into two parts, one part in the main

cylinder and the other part in the cylinder head. The fuel injection is

effected usually into the part of chamber located in the cylinder head. These

chambers are classified further into :

a) Swirl chamber in which compression swirl is generated

b) Pre combustion chamber in which combustion swirl is induced

c) Air cell in which both compression and combustion swirl are induced.

DIRECT INJECTION CHAMBERS OPEN COMBUSTION CHAMBERS

An open combustion chamber is defined as one in which the combustion

space is essentially a single cavity with little restriction from one part of the

chamber to the other and hence with no large difference in pressure

between parts of the chamber during the combustion process. There are

many designs of open chamber some of which are shown below

These chambers mainly consist of space formed between a flat

cylinder head and a cavity in the piston crown in different shapes.

The fuel is injected directly into space. The injection nozzles used

for this chamber are generally of multi hole type working at a

relatively high pressure( about 200 bar)

Shallow Depth chamber

In shallow depth chamber the depth of the cavity provided in the piston is

quite small. This chamber is usually adopted for large engines running at

low speeds. Since the cavity diameter is very large, the squish is negligible.

Hemispherical Chamber: This chamber also gives small squish.

However, the depth to diameter ratio for a cylindrical chamber can

be varied to give any desired squish to give better performance

Cylindrical Chamber: This design was attempted in recent diesel engines.

This is a modification of the cylindrical chamber in the form of a truncated

cone with base angle of 30. The swirl was produced by masking the valve

for nearly 1800 of circumference. Squish can also be varied by varying the

depth.

Toroidal Chamber: The idea behind this shape is to provide a powerful

squish along with the air movement, similar to that of the familiar smoke

ring, within the toroidal chamber. Due to powerful squish the mask needed

on inlet valve is small and there is better utilization of oxygen. The cone

angle of spray for this type of chamber is 150 to 160.

IN DIRECT INJECTION CHAMBERS

A divided combustion chamber is defined as one in which the combustion

space is divided into two or more distinct compartments connected by

restricted passages. This creates considerable pressure differences between

them during the combustion process.

Ricardos Swirl Chamber

PRE COMBUSTION CHAMBER

You might also like

- Combustion Chamber in CI EnginesDocument16 pagesCombustion Chamber in CI EnginesDeepak RawatNo ratings yet

- Experiment No.: Title-Combustion Chambers in S. I. & C. I. EnginesDocument10 pagesExperiment No.: Title-Combustion Chambers in S. I. & C. I. EnginesAshutosh KumarNo ratings yet

- Combustion Chambers in CI EnginesDocument24 pagesCombustion Chambers in CI EnginesKLUniveristy100% (2)

- AMTE 130 - Lesson 5 COMBUSTION SECTIONDocument27 pagesAMTE 130 - Lesson 5 COMBUSTION SECTIONCharls CabonataliaNo ratings yet

- AMTE 130 - Lesson 5 COMBUSTION SECTIONDocument27 pagesAMTE 130 - Lesson 5 COMBUSTION SECTIONMervin Adrian A. MonsaludNo ratings yet

- Combustion Chambers in Ci Engines: A Review: Arka GhoshDocument4 pagesCombustion Chambers in Ci Engines: A Review: Arka GhoshJavadNo ratings yet

- Combustion ChambersDocument13 pagesCombustion ChambersMohamed Aqhil AhmedNo ratings yet

- Combustion ChambersDocument13 pagesCombustion ChambersMohamed Aqhil AhmedNo ratings yet

- Can Type Combustion Chamber: Group # IiDocument11 pagesCan Type Combustion Chamber: Group # IiDominique San PedroNo ratings yet

- Different Types of Combustion Chambers For CI EnginesDocument8 pagesDifferent Types of Combustion Chambers For CI EnginesM.Bilal noumaniNo ratings yet

- ME-52023 Internal Combustion Engines: Technological University (Hmawbi) Department of Mechanical EngineeringDocument25 pagesME-52023 Internal Combustion Engines: Technological University (Hmawbi) Department of Mechanical EngineeringSi Thu Aung100% (1)

- Types of Combustion ChamberDocument3 pagesTypes of Combustion Chamberfrance9950% (2)

- Combustion ChambersDocument81 pagesCombustion ChambersRavikumar Ningachar0% (1)

- Combustion Chambers in SI EnginesDocument12 pagesCombustion Chambers in SI EnginesKLUniveristy100% (1)

- HSDE - Requirements of C.C-1Document39 pagesHSDE - Requirements of C.C-1Fa CaNo ratings yet

- Squish NotesDocument12 pagesSquish NotesMahesh Babu TalupulaNo ratings yet

- Different Types of Combustion Chamber and TurbineDocument13 pagesDifferent Types of Combustion Chamber and TurbineRonoRoa ZoRen100% (1)

- Internal Combustion EnginesDocument18 pagesInternal Combustion EnginesSameerAhsanNo ratings yet

- Combustion in Ci EngineDocument38 pagesCombustion in Ci EngineAnamul HaqueNo ratings yet

- Module 5 Aircraft Propulsion NotesDocument48 pagesModule 5 Aircraft Propulsion NotesPratham M JariwalaNo ratings yet

- Piston SlapDocument57 pagesPiston SlapRAJU T NNo ratings yet

- Combustion in CI EngineDocument21 pagesCombustion in CI Engineumesh1374No ratings yet

- A Report On Types of Combustion ChamberDocument7 pagesA Report On Types of Combustion ChamberSandip LekhakNo ratings yet

- Combustion Process in SI Engines: What Is Combustion and Conditions Necessary To Be Done ?Document45 pagesCombustion Process in SI Engines: What Is Combustion and Conditions Necessary To Be Done ?ashenafi tesfayeNo ratings yet

- Classification of Combustion ChambersDocument3 pagesClassification of Combustion ChambersNoufal NSNo ratings yet

- Power CyclesDocument66 pagesPower CyclesDomingo PintoNo ratings yet

- Classification of Combustion ChambersDocument3 pagesClassification of Combustion ChambersNoufal NSNo ratings yet

- Chapter 5 - CombustionDocument5 pagesChapter 5 - CombustionAparna RNo ratings yet

- Description and Construction of Cylinder HeadDocument7 pagesDescription and Construction of Cylinder HeadSujithNo ratings yet

- Combustion Chamber LatestDocument95 pagesCombustion Chamber LatestnaveenreddyNo ratings yet

- EconomicsDocument14 pagesEconomicsVinay MaisuriyaNo ratings yet

- 2.direct & Indirect Combustion ChamberDocument15 pages2.direct & Indirect Combustion ChamberSundar MahalingamNo ratings yet

- Air Breathing Propulsion Unit-2Document54 pagesAir Breathing Propulsion Unit-2api-271354682No ratings yet

- The Workings of The Combustion ChamberDocument13 pagesThe Workings of The Combustion ChamberJeffery WilliamsNo ratings yet

- Jet Engine Report - MergedDocument16 pagesJet Engine Report - MergedMohamed Abo BakrNo ratings yet

- Unit 4-Combustion ChamberDocument13 pagesUnit 4-Combustion ChamberADVAITH P SHETTYNo ratings yet

- Gas Turbine Engine Combustion SectionDocument20 pagesGas Turbine Engine Combustion SectionMUHOOZI DENISNo ratings yet

- Mod 1.2 ENGINE PARTSDocument67 pagesMod 1.2 ENGINE PARTSRushikesh PatilNo ratings yet

- Unit IIDocument12 pagesUnit IIotakoothanNo ratings yet

- Boiler PerformanceDocument31 pagesBoiler PerformanceIrfan ShaikhNo ratings yet

- Hydraulic Shock AbsorberDocument4 pagesHydraulic Shock AbsorberSUHAIL AHMED KHAN100% (1)

- Combustion ChamberDocument35 pagesCombustion ChamberSujatanu100% (3)

- Vacuum SystemDocument49 pagesVacuum Systemssmith2007100% (3)

- Combustion SectionDocument26 pagesCombustion SectionNicole Deione Morcilla100% (1)

- Combustion in C.I. EnginesDocument24 pagesCombustion in C.I. EnginesAbhishek Dhawan100% (1)

- 03 Combustion ChamberDocument13 pages03 Combustion ChambernareshNo ratings yet

- Phenomenon of KnockingDocument30 pagesPhenomenon of KnockingTrain Placement Cell67% (3)

- Internal Combustion EngineDocument7 pagesInternal Combustion EngineLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLLNo ratings yet

- 22-02-09 Diesel EngineDocument105 pages22-02-09 Diesel EngineA2 Cruxy100% (1)

- Combustion Chamber TypesDocument1 pageCombustion Chamber TypesJacquie JimenezNo ratings yet

- GT - Clase CCDocument39 pagesGT - Clase CCSantiago Ricaurte CamposNo ratings yet

- Combustion Chamber: Aircraft Engines LLDocument6 pagesCombustion Chamber: Aircraft Engines LLSouhaib K Al-AzzawiNo ratings yet

- Combustion Chamber: Aircraft Engines LLDocument6 pagesCombustion Chamber: Aircraft Engines LLSouhaib K Al-AzzawiNo ratings yet

- Aircraft PowerplantDocument93 pagesAircraft PowerplantPranavNo ratings yet

- Stratifistratified Charge EngineDocument14 pagesStratifistratified Charge EngineJay PannaNo ratings yet

- Combustion Chamber Design PrinsiplesDocument11 pagesCombustion Chamber Design Prinsiplesanampb100% (1)

- Turbo Charger PresentationDocument22 pagesTurbo Charger PresentationPragyan Kumar0% (1)

- MAE 570 Aeropropulsion: Gas Turbine CombustorDocument38 pagesMAE 570 Aeropropulsion: Gas Turbine CombustorLuiz Felipe Disconzi LopesNo ratings yet

- Diesel Automotive Engines: Energy and Power Technology TextbookDocument32 pagesDiesel Automotive Engines: Energy and Power Technology TextbookSrinivas EedaraNo ratings yet

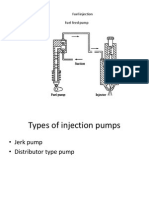

- Types of Injection PumpsDocument9 pagesTypes of Injection PumpsSrinivas EedaraNo ratings yet

- Unit IV Internal Combustion Engines: For Support Notes, Please Visit: WWW - Arpradeep.tk 1Document116 pagesUnit IV Internal Combustion Engines: For Support Notes, Please Visit: WWW - Arpradeep.tk 1Srinivas EedaraNo ratings yet

- Wankel Rotary Engine: Andrew Bakun Brian Menz Ahmad Mahmoud Jacek Foltynski Simon LeeDocument14 pagesWankel Rotary Engine: Andrew Bakun Brian Menz Ahmad Mahmoud Jacek Foltynski Simon LeeSrinivas EedaraNo ratings yet

- Cylinder Blocks 11-00-1 (Hino Engine Type J08etm-Ksda)Document3 pagesCylinder Blocks 11-00-1 (Hino Engine Type J08etm-Ksda)Oecox Cah DjadoelNo ratings yet

- KSuite CarsDocument301 pagesKSuite CarsŁukasz SadowskiNo ratings yet

- Commonrail XeMAN PDFDocument47 pagesCommonrail XeMAN PDFsasa oljacaNo ratings yet

- 2003 SV1000 Repair Manual Part 9: Emission Control InformationDocument17 pages2003 SV1000 Repair Manual Part 9: Emission Control Informationhn7410No ratings yet

- Engine Power Test CodeDocument1 pageEngine Power Test Codezona amrullohNo ratings yet

- Specifications PDFDocument2 pagesSpecifications PDFseektherunes24No ratings yet

- Ga 16Document142 pagesGa 16Ericsson Via90% (10)

- Data Spesifikasi Pabrik Daihatsu Grand Max: Daya, Torsi, Konsumsi Bahan Bakar Dan Tekanan Efektif RerataDocument20 pagesData Spesifikasi Pabrik Daihatsu Grand Max: Daya, Torsi, Konsumsi Bahan Bakar Dan Tekanan Efektif Reratarinarko rifqiNo ratings yet

- Specifications GeneratorDocument7 pagesSpecifications GeneratorMicky Yuedhy TangkeyNo ratings yet

- Specifications and Repair Procedures For C4.4 Cylinder BlocksDocument8 pagesSpecifications and Repair Procedures For C4.4 Cylinder BlocksMarielis ContrerasNo ratings yet

- Abbreviations LEAP - 1ADocument5 pagesAbbreviations LEAP - 1AwenjukwaxNo ratings yet

- C12 Engine and PumpsDocument2 pagesC12 Engine and PumpsSankar SNo ratings yet

- c15 Inlet and Exhaust Valve InstallationDocument5 pagesc15 Inlet and Exhaust Valve InstallationMUHSIN MTNo ratings yet

- Diesel Fuel : Click On The Applicable Bookmark To Selected The Required Model YearDocument13 pagesDiesel Fuel : Click On The Applicable Bookmark To Selected The Required Model Yearrolly abantoNo ratings yet

- Manual de Partes PDFDocument177 pagesManual de Partes PDFAngela Perez100% (1)

- Wiseco 2019 Catalog AutoDocument130 pagesWiseco 2019 Catalog AutoFelix VeraNo ratings yet

- CAT C 18 Marine Maintenance ScheduleDocument2 pagesCAT C 18 Marine Maintenance ScheduleRuben Gonzales100% (1)

- National Institute of Technology, Rourkela B. Tech. (6 Semester), Mechanical Engineering, Mid-Semester, Spring (2021-22)Document9 pagesNational Institute of Technology, Rourkela B. Tech. (6 Semester), Mechanical Engineering, Mid-Semester, Spring (2021-22)Md. Tariqul Islam MunnaNo ratings yet

- RAIDER R150 High 833-RELOADED (FU150SCD2L6-P31)Document70 pagesRAIDER R150 High 833-RELOADED (FU150SCD2L6-P31)GAYLE GONo ratings yet

- Air Inlet in Jet EnginesDocument39 pagesAir Inlet in Jet EnginesJeevaramnivasNo ratings yet

- HET Yamaha Genuine Parts For Mio Sporty & Mio SoulDocument446 pagesHET Yamaha Genuine Parts For Mio Sporty & Mio Soulnchez67% (3)

- Quasi TurbineDocument30 pagesQuasi TurbineStark288100% (2)

- SKI-DOO 2017 900 ACE - Flat Rate - FR11Y017 - enDocument57 pagesSKI-DOO 2017 900 ACE - Flat Rate - FR11Y017 - enPascal DesmeulesNo ratings yet

- Turbocharger - Inspect: Shutdown SIS Previous ScreenDocument4 pagesTurbocharger - Inspect: Shutdown SIS Previous ScreenbejoythomasNo ratings yet

- ManitouDocument18 pagesManitouAlberto MendesNo ratings yet

- Aerogas TurbineDocument32 pagesAerogas TurbineRakshit GuptaNo ratings yet

- MotoStruct Engine Enhancer - Lighthouse EmporiumDocument6 pagesMotoStruct Engine Enhancer - Lighthouse EmporiumPieter SteenkampNo ratings yet

- Still Steds Diesel Fork Truck Rc40 25 Rc40 30 Parts ManualDocument20 pagesStill Steds Diesel Fork Truck Rc40 25 Rc40 30 Parts ManualMarlon100% (48)

- Grua Electircaribe T-2844Document2 pagesGrua Electircaribe T-2844davidsierraNo ratings yet

- Heat Engines: For SCIENCE Grade 9 Quarter 4 / Week 6Document12 pagesHeat Engines: For SCIENCE Grade 9 Quarter 4 / Week 6HernNo ratings yet