Professional Documents

Culture Documents

Aggregate Planning

Uploaded by

Sourabh NandaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aggregate Planning

Uploaded by

Sourabh NandaCopyright:

Available Formats

Aggregate Planning

6

Aggregate Planning

Goal: Specify the optimal combination of

production rate

workforce level

inventory on hand

Product group or broad category (Aggregation)

Medium-Range: 6-18 months

7

Aggregate Planning

Terminology

Production Rate

Workforce Level

Inventory on Hand

Inputs

A forecast of aggregate demand covering the selected

planning horizon (6-18 months)

The alternative means available to adjust short- to

medium-term capacity, to what extent each

alternative could impact capacity and the related costs

The current status of the system in terms of

workforce level, inventory level and production rate

Outputs

A production plan: aggregate decisions for each

period in the planning horizon about

workforce level

inventory level

production rate

Projected costs if the production plan was

implemented

Strategies

Matching Demand (Chase Demand)

Level Capacity (Constant Production Rate)

Buffering with inventory

Buffering with backlog

Buffering with overtime or subcontracting

Hybrid strategies ( Mixed Policy)

Matching Demand Strategy

Capacity (Production) in each time period is varied to

exactly match the forecasted aggregate demand in

that time period

Capacity is varied by changing the workforce level

Finished-goods inventories are minimal

Labor and materials costs tend to be high due to the

frequent changes

Level Capacity Strategy

Capacity (production rate) is held level (constant)

over the planning horizon

The difference between the constant production rate

and the demand rate is made up (buffered) by

inventory, backlog, overtime, part-time labor and/or

subcontracting

Developing and Evaluating

the Level Production Plan

Assume that the amount produced each period is

constant, no hirings or layoffs

The gap between the amount planned to be produced

and the forecasted demand is filled with either

inventory or backorders, i.e., no overtime, no idle

time, no subcontracting

Developing and Evaluating

the Level Production Plan

The primary costs of this strategy are inventory

carrying and backlogging costs

Period-ending inventories or backlogs are determined

using the inventory balance equation:

EI

t

= EI

t-1

+ (P

t

- D

t

)

Aggregate Plans for Services

For standardized services, aggregate planning may be

simpler than in systems that produce products

For customized services,

there may be difficulty in specifying the nature and

extent of services to be performed for each

customer

customer may be an integral part of the production

system

Absence of finished-goods inventories as a buffer

between system capacity and customer demand

8

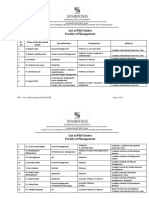

Aggregate Planning Example

Keepdry, a small manufacturing company (200 employees),

produces umbrellas. The company, founded in 1991 produces the

following three product lines: 1) the Executive Line, 2) the Durable

Line and 3) the Compact line shown in the following figure.

Executive

Line

Durable

Line

Compact

Line

9

Aggregate Demand

(Executive Line)

Number of working days:

Jan 22

Feb 19

Mar 21

Apr 21

May 22

Jun 20

11

Examples

Cost I nformation

Materials $5/unit

Holding costs $1/unit per mo.

Marginal cost of stockout $1.25/unit per mo.

Hiring and training cost $200/worker

Layoff costs $250/worker

Labor hours required .15 hrs/unit

Straight time labor cost $8/hour

Beginning inventory 250 units

Productive hours/worker/day 7.25

Paid straight hrs/day 8

12

Determining Straight Labor Costs and Output

Jan Feb Mar Apr May Jun

Days/mo 22 19 21 21 22 20

Hrs/worker/mo 159.5 137.75 152.25 152.25 159.5 145

Units/worker 1063.33 918.33 1015 1015 1063.33 966.67

$/worker $1,408 1,216 1,344 1,344 1,408 1,280

13

Chase Strategy

(Hiring & Firing--meet demand)

Beginning workforce level: 7 employees

Jan

Days/mo 22

Hrs/worker/mo 159.5

Units/worker 1,063.33

$/worker $1,408

Jan

Demand 4,500

Beg. inv. 250

Net req. 4,250

Req. workers 3.997

Hired

Fired 3

Workforce 4

Ending inventory 0

14

Jan Feb Mar Apr May Jun

Days/mo 22 19 21 21 22 20

Hrs/worker/mo 159.5 137.75 152.25 152.25 159.5 145

Units/worker 1,063 918 1,015 1,015 1,063 967

$/worker $1,408 1,216 1,344 1,344 1,408 1,280

Jan Feb Mar Apr May Jun

Demand 4,500 5,500 7,000 10,000 8,000 6,000

Beg. inv. 250

Net req. 4,250 5,500 7,000 10,000 8,000 6,000

Req. workers 3.997 5.989 6.897 9.852 7.524 6.207

Hired 2 1 3

Fired 3 2 1

Workforce 4 6 7 10 8 7

Ending inventory 0 0 0 0 0 0

15

Jan Feb Mar Apr May Jun

Demand 4,500 5,500 7,000 10,000 8,000 6,000

Beg. inv. 250

Net req. 4,250 5,500 7,000 10,000 8,000 6,000

Req. workers 3.997 5.989 6.897 9.852 7.524 6.207

Hired 2 1 3

Fired 3 2 1

Workforce 4 6 7 10 8 7

Ending inventory 0 0 0 0 0 0

Jan Feb Mar Apr May Jun Costs

Material $21,250.00 $27,500.00 $35,000.00 $50,000.00 $40,000.00 $30,000.00 203,750.00

Labor 5,627.59 7,282.76 9,268.97 13,241.38 10,593.10 7,944.83 53,958.62

Hiring cost 400.00 200.00 600.00 1,200.00

Firing cost 750.00 500.00 250.00 1,500.00

$260,408.62

16

Level Workforce

(Surplus and Shortage Allowed)

Workforce level: 6 employees

Jan

Demand 4,500

Beg. inv. 250

Net req. 4,250

Workers 6

Production 6,380

Ending inventory 2,130

Surplus 2,130

Shortage

17

Jan Feb Mar Apr May Jun

Demand 4,500 5,500 7,000 10,000 8,000 6,000

Beg. inv. 250 2,130 10 -910 -3,910 -1,620

Net req. 4,250 5,500 7,000 10,000 8,000 6,000

Workers 6 6 6 6 6 6

Production 6,380 5,510 6,090 6,090 6,380 5,800

Ending inventory 2,130 10 -910 -3,910 -1,620 -200

Surplus 2,130 10

Shortage 910 3,910 1,620 200

18

Jan Feb Mar Apr May Jun

Demand 4,500 5,500 7,000 10,000 8,000 6,000

Beg. inv. 250 2,130 10 -910 -3,910 -1,620

Net req. 4,250 5,500 7,000 10,000 8,000 6,000

Workers 6 6 6 6 6 6

Production 6,380 5,510 6,090 6,090 6,380 5,800

Ending inventory 2,130 10 -910 -3,910 -1,620 -200

Surplus 2,130 10

Shortage 910 3,910 1,620 200

Jan Feb Mar Apr May Jun

Labor $8,448 $7,296 $8,064 $8,064 $8,448 $7,680 $48,000.00

Material 31,900 27,550 30,450 30,450 31,900 29,000 181,250.00

Carrying 2,130 10 2,140.00

Stockout 1,138 4,888 2,025 250 8,300.00

$239,690.00

You might also like

- Lundbeck Marketing Mix Optimization HDR NORTHERA 17022017Document12 pagesLundbeck Marketing Mix Optimization HDR NORTHERA 17022017Sourabh NandaNo ratings yet

- List of Guides ManagementDocument5 pagesList of Guides ManagementSourabh NandaNo ratings yet

- ESE Reforms PublicityDocument11 pagesESE Reforms PublicityChirag PatelNo ratings yet

- F 12 PeeyushpDocument2 pagesF 12 PeeyushpSourabh NandaNo ratings yet

- List of Books: XAT FundaDocument1 pageList of Books: XAT FundaSourabh NandaNo ratings yet

- 15 Years Quality Institution: Faculty RecruitmentDocument1 page15 Years Quality Institution: Faculty RecruitmentSourabh NandaNo ratings yet

- Indian Institute of Teghnology Roorkee Centre: No - AHECIS-4 - Gol Dated: March 18,2016Document3 pagesIndian Institute of Teghnology Roorkee Centre: No - AHECIS-4 - Gol Dated: March 18,2016Sourabh NandaNo ratings yet

- 2596notice For Re-Schedule Interview For Asst. Prof.Document1 page2596notice For Re-Schedule Interview For Asst. Prof.Sourabh NandaNo ratings yet

- Faqs IsroDocument3 pagesFaqs IsrosrinivasNo ratings yet

- F 14 ManishsDocument1 pageF 14 ManishsSourabh NandaNo ratings yet

- Proof Identity AddressDocument1 pageProof Identity AddressSourabh NandaNo ratings yet

- Post and EQ-ExpDocument2 pagesPost and EQ-ExpSourabh NandaNo ratings yet

- Splitting A Large SAS Data Set: The %split MacroDocument2 pagesSplitting A Large SAS Data Set: The %split MacroSourabh NandaNo ratings yet

- Admission Notice 2016Document5 pagesAdmission Notice 2016Ranjan SahooNo ratings yet

- ESE Reforms PublicityDocument11 pagesESE Reforms PublicityChirag PatelNo ratings yet

- Provisional List of Recommended Candidates For Admission - 2016 - 17Document1 pageProvisional List of Recommended Candidates For Admission - 2016 - 17Sourabh NandaNo ratings yet

- ADV Oth 062016Document7 pagesADV Oth 062016Amritanshu MishraNo ratings yet

- NMIMS PhD Management Dates 2016Document1 pageNMIMS PhD Management Dates 2016Sourabh NandaNo ratings yet

- Alok Singh3Document1 pageAlok Singh3Sourabh NandaNo ratings yet

- GazetteDocument68 pagesGazetteSourabh NandaNo ratings yet

- Data CleaningDocument10 pagesData Cleaningmrg1212005No ratings yet

- ADDocument1 pageADSourabh NandaNo ratings yet

- ADV Oth 062016Document7 pagesADV Oth 062016Amritanshu MishraNo ratings yet

- ADH and Mineralocorticoids RegulationDocument67 pagesADH and Mineralocorticoids RegulationSourabh NandaNo ratings yet

- Supplier Evaluation and Selection: Laura AITER Cengiz ÇOKAY Güven GÜLDocument38 pagesSupplier Evaluation and Selection: Laura AITER Cengiz ÇOKAY Güven GÜLsrkadaliNo ratings yet

- 1.3 Energy Management & AuditDocument25 pages1.3 Energy Management & AuditEdd GithaeNo ratings yet

- Ahptutorial PDFDocument20 pagesAhptutorial PDFPaijo TengklengNo ratings yet

- Production and Operations ManagementDocument284 pagesProduction and Operations Managementsnehal.deshmukh89% (28)

- Fluid Mechanics Mech Gate Ies NotesDocument21 pagesFluid Mechanics Mech Gate Ies NotesSourabh Nanda50% (2)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Ariva! Events Management, IncDocument18 pagesAriva! Events Management, IncJoeyDeGuzmanNo ratings yet

- Study On Customer Preference and Satisfaction Towards Prismatic Technologies, PatialaDocument14 pagesStudy On Customer Preference and Satisfaction Towards Prismatic Technologies, Patialajagseer singh0% (1)

- Using Social Media Marketing To Pro-Tourism BehaviDocument13 pagesUsing Social Media Marketing To Pro-Tourism BehaviMustāpha KôNo ratings yet

- Slides Strategy Management Pearson Book (3) Visit Us at Management - Umakant.infoDocument29 pagesSlides Strategy Management Pearson Book (3) Visit Us at Management - Umakant.infowelcome2jungle100% (2)

- Emerson Process Management - White PapersDocument1 pageEmerson Process Management - White PapersanirbanpoddarNo ratings yet

- Freelance Contract - SampleDocument3 pagesFreelance Contract - SampleVoxsports Voxer50% (2)

- Kotler Chapter 17 MCQ - Direct Marketing - Online AdvertisingDocument11 pagesKotler Chapter 17 MCQ - Direct Marketing - Online AdvertisingyyyNo ratings yet

- Rural Marketing Strategy: Parle G's Approach to Rural IndiaDocument18 pagesRural Marketing Strategy: Parle G's Approach to Rural IndiaChetan WarkariNo ratings yet

- Narrow CastingDocument27 pagesNarrow CastingHuma FarhanNo ratings yet

- Iag Media: Partner ProgramDocument6 pagesIag Media: Partner Programzakaria zakariyaNo ratings yet

- OriflameDocument42 pagesOriflamemanuNo ratings yet

- Copier Catalog Panasonic 2010Document50 pagesCopier Catalog Panasonic 2010Zahid Iqbal100% (1)

- Mushroom Farming Biz Plan 8Document21 pagesMushroom Farming Biz Plan 8Josephine ChirwaNo ratings yet

- Assessing The Six-Station Corporate Identity Model A Polymorphic Model PDFDocument37 pagesAssessing The Six-Station Corporate Identity Model A Polymorphic Model PDFAl PappasNo ratings yet

- Sustainable marketing principlesDocument4 pagesSustainable marketing principlesBashir MureiNo ratings yet

- Nairobi Thrift Stores Business CommunityDocument13 pagesNairobi Thrift Stores Business CommunityGITENE TIBERIUS NYANG'AUNo ratings yet

- Guns Ammo August 2016Document106 pagesGuns Ammo August 2016John50% (4)

- Microeconomics Notes 100 (Mitchell)Document18 pagesMicroeconomics Notes 100 (Mitchell)sasukeNo ratings yet

- MM FEB-UGM MAN 5007 (PRA-MBA) Managerial Economics Bab 3 Kunci JawabanDocument1 pageMM FEB-UGM MAN 5007 (PRA-MBA) Managerial Economics Bab 3 Kunci JawabanDemas HarimurtiNo ratings yet

- Project Report - Social Media MarketingDocument65 pagesProject Report - Social Media MarketingSamrat Singh (Technical Classes)No ratings yet

- Assess Your Information and Make An Action PlanDocument20 pagesAssess Your Information and Make An Action Planeozzypoggy100% (1)

- GBE SukamartDocument25 pagesGBE SukamartDwitya AribawaNo ratings yet

- Department of Management Studies Jnvu Jodhpur: By: Nikhil Vyas Mba-Fs IDocument19 pagesDepartment of Management Studies Jnvu Jodhpur: By: Nikhil Vyas Mba-Fs Ipro educatingNo ratings yet

- Starbucks PESTEL Analysis - Research MethodologyDocument3 pagesStarbucks PESTEL Analysis - Research MethodologySherry Yong PkTian100% (1)

- Value Chain Analysis and Indian Civil AviationDocument12 pagesValue Chain Analysis and Indian Civil AviationShailesh PatelNo ratings yet

- Price CataleDocument36 pagesPrice CataleRavi AnandNo ratings yet

- The Effects of Hallyu On Purchasing BehaDocument15 pagesThe Effects of Hallyu On Purchasing Behacarolyn caiNo ratings yet

- Digital Business PPT Final DoneDocument16 pagesDigital Business PPT Final DoneRoushan Kumar PandeyNo ratings yet

- BK99PUB26 Table of ContentDocument14 pagesBK99PUB26 Table of ContentSyed Mujtaba Ali BukhariNo ratings yet

- Nonprofit Business Model CanvasDocument1 pageNonprofit Business Model CanvasDimitris100% (3)