Professional Documents

Culture Documents

Toyota Tundra 20% Front Seat FMVSS 207/210 - April-07-05: Analysis Results Summary

Uploaded by

api-19817003Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Toyota Tundra 20% Front Seat FMVSS 207/210 - April-07-05: Analysis Results Summary

Uploaded by

api-19817003Copyright:

Available Formats

ANALYSIS RESULTS SUMMARY:

Toyota Tundra 20% Front Seat

FMVSS 207/210 – April-07-05

Work Order: 233.41860.001.G

FEA Design Level #: 14

Load Case Iteration #: 35,36

Template Revision: 1 Analyst (Employer): Ashish (Altair)

Revision Date: 01/01/05

April/07/05 1 W.O. # 233.41860.001.G

Seat: Toyota Tundra 20% Front Seat FEA Design Level #: 14

Load Case: FMVSS 207/210 Load Case Iteration #: 35,36

I. Conclusions and Recommendations

Design 14 Iteration 35

• The Toyota Tundra 20% front seat withstands the 207/210 load case.

• No structural failure observed under the 207/210 load case.

• Maximum torque on right side recliner is 2888 Nm, where as maximum torque on left side recliner is 1045 Nm.

Design 14 Iteration 36

• The Toyota Tundra 20% front seat withstands the 207/210 load case.

• No structural failure observed under the 207/210 load case.

• Maximum torque on right side recliner is 2266 Nm, where as maximum torque on left side recliner is 912 Nm.

April-07-2005 2 W.O. # 233.41860.001.G

Seat: Toyota Tundra 20% Front Seat FEA Design Level #: 14

Load Case: FMVSS 207/210 Load Case Iteration #: 35,36

II. Design Level and Model Description

Design Level 14 and Iteration 35

From the design 14 Iter 32 model: following changes has been done

1) CG loading change as per New FMVSS with distribution bar .

2) Lap block change to narrow mga lap block.

L-shaped steel channel 40x40xt4.

April-07-2005 3 W.O. # 233.41860.001.G

Seat: Toyota Tundra 20% Front Seat FEA Design Level #: 14

Load Case: FMVSS 207/210 Load Case Iteration #: 35,36

II. Design Level and Model Description

Design Level 14 and Iteration 36

From the design 14 Iter35 model: following changes has been done

1) The shoulder and lap belt load reduce to 100% of FMVSS standard (from 120%). (13500N)

2) The CG load reduce to 100% of FMVSS standard (from 120%).(3551 N)

April-07-2005 4 W.O. # 233.41860.001.G

Seat: Toyota Tundra 20% Front Seat FEA Design Level #: 14

Load Case: FMVSS 207/210 Load Case Iteration #: 35,36

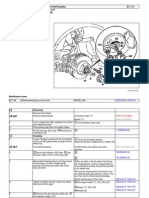

Design 14:

Welds between outer and inner RH cushion bracket

added as per design11 iteration 19.

April-07-2005 5 W.O. # 233.41860.001.G

Seat: Toyota Tundra 20% Front Seat FEA Design Level #: 14

Load Case: FMVSS 207/210 Load Case Iteration #: 35,36

Design 14 Iteration 35

Material and Thickness information for Major Components

April-07-2005 6 W.O. # 233.41860.001.G

Seat: Toyota Tundra 20% Front Seat FEA Design Level #: 14

Load Case: FMVSS 207/210 Load Case Iteration #: 35,36

2-D seat belt

Back tube

Retractor mounting bracket

Belt routing over retractor mtg. bracket, back tube and wire belt exit

April-07-2005 7 W.O. # 233.41860.001.G

Seat: Toyota Tundra 20% Front Seat FEA Design Level #: 14

Load Case: FMVSS 207/210 Load Case Iteration #: 35,36

III. Detailed Analysis Results Pictures shown after structure is stabilized at 100% loading.

Design 14 Iteration 35

Deformed Shape of Seat Deformation plot with un-deformed geometry

FMVSS 207/210 load results

April-07-2005 8 W.O. # 233.41860.001.G

Seat: Toyota Tundra 20% Front Seat FEA Design Level #: 14

Load Case: FMVSS 207/210 Load Case Iteration #: 35,36

III. Detailed Analysis Results Pictures shown after structure is stabilized at 100% loading.

Design 14 Iteration 36

Deformed Shape of Seat Deformation plot with un-deformed geometry

FMVSS 207/210 load results

April-07-2005 9 W.O. # 233.41860.001.G

Seat: Toyota Tundra 20% Front Seat FEA Design Level #: 14

Load Case: FMVSS 207/210 Load Case Iteration #: 35,36

Design 14 Iteration 35

Resultant Deflection contour

FMVSS 207/210 load results

April-07-2005 10 W.O. # 233.41860.001.G

Seat: Toyota Tundra 20% Front Seat FEA Design Level #: 14

Load Case: FMVSS 207/210 Load Case Iteration #: 35,36

X-Component Design 14 Iteration 35 Z-Component

X and Z Deflection contour

FMVSS 207/210 load results

April-07-2005 11 W.O. # 233.41860.001.G

Seat: Toyota Tundra 20% Front Seat FEA Design Level #: 14

Load Case: FMVSS 207/210 Load Case Iteration #: 35,36

Design 14 Iteration 35 Contour shown at stabilized time

The von Mises stress contour of complete seat

FMVSS 207/210 load results

April-07-2005 12 W.O. # 233.41860.001.G

Seat: Toyota Tundra 20% Front Seat FEA Design Level #: 14

Load Case: FMVSS 207/210 Load Case Iteration #: 35,36

Design 14 Iteration 35 Contour shown at stabilized time

The effective plastic strain contour of complete seat

FMVSS 207/210 load results

April-07-2005 13 W.O. # 233.41860.001.G

Seat: Toyota Tundra 20% Front Seat FEA Design Level #: 14

Load Case: FMVSS 207/210 Load Case Iteration #: 35,36

Design 14 Iteration 36

Resultant Deflection contour

FMVSS 207/210 load results

April-07-2005 14 W.O. # 233.41860.001.G

Seat: Toyota Tundra 20% Front Seat FEA Design Level #: 14

Load Case: FMVSS 207/210 Load Case Iteration #: 35,36

X-Component Design 14 Iteration 36 Z-Component

X and Z Deflection contour

FMVSS 207/210 load results

April-07-2005 15 W.O. # 233.41860.001.G

Seat: Toyota Tundra 20% Front Seat FEA Design Level #: 14

Load Case: FMVSS 207/210 Load Case Iteration #: 35,36

Design 14 Iteration 36 Contour shown at stabilized time

The von Mises stress contour of complete seat

FMVSS 207/210 load results

April-07-2005 16 W.O. # 233.41860.001.G

Seat: Toyota Tundra 20% Front Seat FEA Design Level #: 14

Load Case: FMVSS 207/210 Load Case Iteration #: 35,36

Design 14 Iteration 36 Contour shown at stabilized time

The effective plastic strain contour of complete seat

FMVSS 207/210 load results

April-07-2005 17 W.O. # 233.41860.001.G

Seat: Toyota Tundra 20% Front Seat FEA Design Level #: 14

Load Case: FMVSS 207/210 Load Case Iteration #: 35,36

Analysis Outputs Under FMVSS Loading, Steady-State

Conditions - Belt tensions at the attachment points

Design 14 Iteration 35

LH side 16626 N

Lap belt

RH side 8890 N

Shoulder belt Upper Shoulder Belt Tension (Belt Exit Point) 8231 N

Design 14 Iteration 36

LH side 13781 N

Lap belt

RH side 7751 N

Shoulder belt Upper Shoulder Belt Tension (Belt Exit Point) 7118 N

April-07-2005 18 W.O. # 233.41860.001.G

Seat: Toyota Tundra 20% Front Seat FEA Design Level #: 14

Load Case: FMVSS 207/210 Load Case Iteration #: 35,36

Design 14 Iteration 35

April-07-2005 19 W.O. # 233.41860.001.G

Seat: Toyota Tundra 20% Front Seat FEA Design Level #: 14

Load Case: FMVSS 207/210 Load Case Iteration #: 35,36

Design 14 Iteration 36

April-07-2005 20 W.O. # 233.41860.001.G

Seat: Toyota Tundra 20% Front Seat FEA Design Level #: 14

Load Case: FMVSS 207/210 Load Case Iteration #: 35,36

Maximum Bolt forces at floor mounting locations

RH cushion rear Design 14 Iteration 35

A = 39044 SR = 10710

LH cushion rear

A = 49586.4 SR = 12842

RH cushion front

A = 42071 SR = 5531.42

LH cushion front

A = 34625 SR = 4023.27

A = axial force, SR = shear resultant

April-07-2005 21 W.O. # 233.41860.001.G

Seat: Toyota Tundra 20% Front Seat FEA Design Level #: 14

Load Case: FMVSS 207/210 Load Case Iteration #: 35,36

Maximum Bolt forces at floor mounting locations

RH cushion rear Design 14 Iteration 36

A = 36771 SR = 10061.3

LH cushion rear

A = 46537 SR = 11745

RH cushion front

A = 38835 SR = 4800

LH cushion front

A =33398.3 SR = 3828.51

A = axial force, SR = shear resultant

April-07-2005 22 W.O. # 233.41860.001.G

Seat: Toyota Tundra 20% Front Seat FEA Design Level #: 14

Load Case: FMVSS 207/210 Load Case Iteration #: 35,36

IV. Test Set-up and Acceptance Criteria

Design 14 Iteration 35,36

Generic JCI shoulder

block

Belt exit point

Generic JCI shoulder clevis

Retractor

mounting point.

Generic JCI lap block

CG bars

Load Distribution bar

Note: The “narrow mga lap block” is used for the center lap block

April-07-2005 23 W.O. # 233.41860.001.G

Seat: Toyota Tundra 20% Front Seat FEA Design Level #: 14

Load Case: FMVSS 207/210 Load Case Iteration #: 35,36

Design 14 Iteration 35

16200 N

4261 N

• Seatback in design position.

• Load levels shown are at FMVSS+ 20% (16200N). In the analysis, the applied

loads are held FMVSS + 20% load level.

• The shoulder and lap belt loading =13500x1.2=16200 N

• The CG loading =(20xgxmass)x1.2=(20x9.81x18.1 kg)x1.2=4261 N

Acceptance Criteria:

• Seat must hold FMVSS + 20% loads without any part fracture.

April-07-2005 24 W.O. # 233.41860.001.G

Seat: Toyota Tundra 20% Front Seat FEA Design Level #: 14

Load Case: FMVSS 207/210 Load Case Iteration #: 35,36

Design 14 Iteration 35

13500 N

3551 N

• Seatback in design position.

• Load levels shown are at FMVSS (13500N). In the analysis, the applied loads are

held FMVSS.

• The shoulder and lap belt loading =13500 =13500 N

• The CG loading = 20xgxmass= 20x9.81x18.1 kg = 3551 N

Acceptance Criteria:

• Seat must hold FMVSS loads without any part fracture.

April-07-2005 25 W.O. # 233.41860.001.G

Seat: Toyota Tundra 20% Front Seat FEA Design Level #: 14

Load Case: FMVSS 207/210 Load Case Iteration #: 35,36

Design 14 Iteration 35,36

April-07-2005 26 W.O. # 233.41860.001.G

Seat: Toyota Tundra 20% Front Seat FEA Design Level #: 14

Load Case: FMVSS 207/210 Load Case Iteration #: 35,36

Design 14 Iteration 35,36

April-07-2005 27 W.O. # 233.41860.001.G

Seat: Toyota Tundra 20% Front Seat FEA Design Level #: 14

Load Case: FMVSS 207/210 Load Case Iteration #: 35,36

V. Analysis Methods Summary

The following standardized JCI methods were used for this analysis iteration(s):

Revision

JCI Analysis Method Comments/Exceptions

Level

207/210 General Analysis

1

Procedure (1/1/05)

(207210_Analysis_Procedure.pdf)

207/210 Body Block Positioning

Procedure 1

(1/1/05)

(Belt_Lengths_and_Body_Block_Positioning

_Procedure.pdf)

Dyna General Procedure 1

(Dyna_General.pdf) (1/1/05)

Forming Mapping Procedure 1

(Mapping_Forming_Results.pdf) (1/1/05)

Material Property Curves

0

(10/1/04)

Detailed Bolt Modeling Macro 2

(01/21/05)

April-07-2005 28 W.O. # 233.41860.001.G

You might also like

- Toyota Tundra 20% Front Seat FMVSS 207/210 - April-07-05: Analysis Results SummaryDocument16 pagesToyota Tundra 20% Front Seat FMVSS 207/210 - April-07-05: Analysis Results Summaryapi-19817003No ratings yet

- Analysis Results Summary:: Toyota Tundra 20% Front Seat FMVSS 207/210 - May-02-05Document18 pagesAnalysis Results Summary:: Toyota Tundra 20% Front Seat FMVSS 207/210 - May-02-05api-19817003No ratings yet

- Analysis Results Summary:: Toyota Tundra 20% Front Seat FMVSS 207/210 - May-26-05Document18 pagesAnalysis Results Summary:: Toyota Tundra 20% Front Seat FMVSS 207/210 - May-26-05api-19817003No ratings yet

- Toyota Tundra 20% Front Seat FMVSS 207/210 - April-06-05: Analysis Results SummaryDocument36 pagesToyota Tundra 20% Front Seat FMVSS 207/210 - April-06-05: Analysis Results Summaryapi-19817003No ratings yet

- 2010 Ford FusionDocument176 pages2010 Ford FusionAishah Ayoshah100% (3)

- 205-03 Front Drive Axle and Differential - Removal and Installation - Axle Cover BushingDocument3 pages205-03 Front Drive Axle and Differential - Removal and Installation - Axle Cover BushingCARLOS LIMADANo ratings yet

- Print Version - 2006-2014 Fiat Ducato Fuse Box DiagramDocument5 pagesPrint Version - 2006-2014 Fiat Ducato Fuse Box DiagramlogisztikaNo ratings yet

- Work HoursDocument6 pagesWork HoursDennis SetiawanNo ratings yet

- Daily Repair and Maintenance Plan For 1.6.2020Document1 pageDaily Repair and Maintenance Plan For 1.6.2020Ajdin Herc AhmetovicNo ratings yet

- C 6 Tipm 2012 WKDocument2 pagesC 6 Tipm 2012 WKEBER OCHOANo ratings yet

- Dnevni Plan Za 2.6.2020. - Odrzavanje I Popravci: Section 1 EquipmentDocument1 pageDnevni Plan Za 2.6.2020. - Odrzavanje I Popravci: Section 1 EquipmentAjdin Herc AhmetovicNo ratings yet

- BMW f30 Performance KITDocument32 pagesBMW f30 Performance KITPhilNo ratings yet

- Rnym08 1320B 30Document2 pagesRnym08 1320B 30Andrés VRNo ratings yet

- Tractors BenatiDocument79 pagesTractors Benatiomni_partsNo ratings yet

- BMW EBA 2288640 External Eye Kit Retrofit InstructionsDocument14 pagesBMW EBA 2288640 External Eye Kit Retrofit Instructionsburkhill364No ratings yet

- Rnym08 1320B 15Document2 pagesRnym08 1320B 15Andrés VRNo ratings yet

- Dnevne Aktivnosti Održavanja I Popravki: Sekcija 1Document1 pageDnevne Aktivnosti Održavanja I Popravki: Sekcija 1Ajdin Herc AhmetovicNo ratings yet

- 02-Toyota 7FGK 2-3Document4 pages02-Toyota 7FGK 2-3Edwin NgNo ratings yet

- f80 Wheel InstDocument17 pagesf80 Wheel Instgkxb8fhx48No ratings yet

- TOYOTA GENUINE PARTS CLEARANCE - CatalogueDocument63 pagesTOYOTA GENUINE PARTS CLEARANCE - CatalogueKeJeNo ratings yet

- ListPrice - 2021 Jul NewDocument117 pagesListPrice - 2021 Jul NewEleazar PavonNo ratings yet

- Daftar V Belt Dan BearingDocument2 pagesDaftar V Belt Dan BearingEko FebriyantoNo ratings yet

- Att Trans ToolsDocument72 pagesAtt Trans Toolssharawy12No ratings yet

- Bomba de Pistones Fan Armado InglesDocument18 pagesBomba de Pistones Fan Armado InglesAntony Armando Huaylla QuispeNo ratings yet

- Ford Fiesta Body ManualDocument730 pagesFord Fiesta Body ManualkareljpNo ratings yet

- 6 Speed PowerShift Transmission DPS6 RemovalDocument15 pages6 Speed PowerShift Transmission DPS6 RemovalCarlos SerapioNo ratings yet

- Yamaha Gytr Acc 2023Document20 pagesYamaha Gytr Acc 2023Galang Wira SatriadjieNo ratings yet

- 6 Speed PowerShift Transmission DPS6 DisassemblyDocument19 pages6 Speed PowerShift Transmission DPS6 DisassemblyCarlos Serapio100% (2)

- Recommended Parts: Repair DetailsDocument7 pagesRecommended Parts: Repair DetailsAh TeeNo ratings yet

- VBI AmDocument11 pagesVBI AmarfanilyasNo ratings yet

- Technical Sheet KZ 2022 enDocument3 pagesTechnical Sheet KZ 2022 enAdam NasNo ratings yet

- 2 Rev 9Document21 pages2 Rev 9Sidiq PramokoNo ratings yet

- Original BMW Parts and AccessoriesDocument20 pagesOriginal BMW Parts and AccessoriesalexNo ratings yet

- Valve Tappet VolvoDocument2 pagesValve Tappet VolvoFaisalNo ratings yet

- Adjust Wheel Bearing PlayDocument4 pagesAdjust Wheel Bearing PlayDanny SabatoNo ratings yet

- 1Document1 page1maikolNo ratings yet

- Hitachi Tuning Manager: Troubleshooting Guide 08-40-00 Rev01 2016/2/1Document550 pagesHitachi Tuning Manager: Troubleshooting Guide 08-40-00 Rev01 2016/2/1WalterNo ratings yet

- LHYMS30-4F190B-EPY2-80 Spec SheetDocument2 pagesLHYMS30-4F190B-EPY2-80 Spec SheetArielNo ratings yet

- M2 106 TaDocument26 pagesM2 106 TaFERNANDO FERRUSCANo ratings yet

- Configuration: Order DataDocument7 pagesConfiguration: Order Dataclaudiu.gheorghe5710No ratings yet

- Reusable Items of D 13 EngineDocument4 pagesReusable Items of D 13 EngineCwsNo ratings yet

- Reaction Rod Outer VolvoDocument4 pagesReaction Rod Outer VolvoFaisalNo ratings yet

- Partswecan Forklift Parts A Z ToyotaDocument34 pagesPartswecan Forklift Parts A Z ToyotaBubu Bubu100% (2)

- Product Datasheet: HelicalbevelgearedDocument7 pagesProduct Datasheet: Helicalbevelgeared손선호No ratings yet

- BELT TENSIONER - Aj Max EnterpriseDocument30 pagesBELT TENSIONER - Aj Max EnterpriseEleazar PavonNo ratings yet

- PDF - 14 12 23 14 42Document2 pagesPDF - 14 12 23 14 42mirmar2000No ratings yet

- Monroe Catalogue PhilippinesDocument22 pagesMonroe Catalogue PhilippinesJdk SparepartsNo ratings yet

- Precision 6T70 Parts Catalog 2024Document4 pagesPrecision 6T70 Parts Catalog 2024Альфир АптикаевNo ratings yet

- GMA 35 - 35c, IM, 190-00858-11, Rev 3-16Document55 pagesGMA 35 - 35c, IM, 190-00858-11, Rev 3-16esedgar100% (1)

- 1940 432-A - PartlistDocument1 page1940 432-A - Partlist潘学淼No ratings yet

- Hummer Transfer Case TransmissionDocument232 pagesHummer Transfer Case TransmissioneolivariNo ratings yet

- Daily Plan For Equipment: Sekcija 1Document1 pageDaily Plan For Equipment: Sekcija 1Ajdin Herc AhmetovicNo ratings yet

- Golf GTI R32 Jetta Mk4Document50 pagesGolf GTI R32 Jetta Mk4Ioannis Ioannidis100% (3)

- List of Stock Items: 55040-Rework ChargesDocument76 pagesList of Stock Items: 55040-Rework ChargesGanesh Sh100% (1)

- Wheel Install 16x7.5 ET31Document10 pagesWheel Install 16x7.5 ET31Oleg FedchenkoNo ratings yet

- Truck 74 Listino PDFDocument80 pagesTruck 74 Listino PDFclekupreNo ratings yet

- Fuse Box Diagram Peugeot 308 (T7 2007-2013)Document30 pagesFuse Box Diagram Peugeot 308 (T7 2007-2013)tietkop20No ratings yet

- 8FG10-J35 SpecManual 2302Document66 pages8FG10-J35 SpecManual 2302Patricio CastroNo ratings yet

- HM Training Agenda - Day1: - Automeshing - Surface Less Meshing Techniques - Quality Checking and EditingDocument40 pagesHM Training Agenda - Day1: - Automeshing - Surface Less Meshing Techniques - Quality Checking and Editingapi-19817003No ratings yet

- Hmday 2Document33 pagesHmday 2api-19817003No ratings yet

- 233 41800 001 G 207210 Setup Rev 0Document2 pages233 41800 001 G 207210 Setup Rev 0api-19817003No ratings yet

- Printing - Creating A Macro - HM-8000Document8 pagesPrinting - Creating A Macro - HM-8000api-19817003No ratings yet

- Printing - Tetrameshing A Volume in A Single Step - HM-3230Document7 pagesPrinting - Tetrameshing A Volume in A Single Step - HM-3230api-19817003No ratings yet

- Printing - Defining Composites - HM-4000Document4 pagesPrinting - Defining Composites - HM-4000api-19817003No ratings yet

- Printing - Working With Loads On Geometry - HM-4010Document11 pagesPrinting - Working With Loads On Geometry - HM-4010api-19817003No ratings yet

- Printing - Getting Started With HyperMesh - HM-1000Document28 pagesPrinting - Getting Started With HyperMesh - HM-1000api-19817003No ratings yet

- Printing - Generating 3-D Tetrahedral Elements - HM-3210Document11 pagesPrinting - Generating 3-D Tetrahedral Elements - HM-3210api-19817003No ratings yet

- Printing - Meshing A Part With Hexahedral Elements - HM-3220Document30 pagesPrinting - Meshing A Part With Hexahedral Elements - HM-3220api-19817003No ratings yet

- Printing - Exploring 2-D Mesh Parameter Options in The Automesh Function - HM-3130Document6 pagesPrinting - Exploring 2-D Mesh Parameter Options in The Automesh Function - HM-3130api-19817003No ratings yet

- Printing - Creating A Tria Mesh For Tetrameshing - HM-3190Document17 pagesPrinting - Creating A Tria Mesh For Tetrameshing - HM-3190api-19817003No ratings yet

- Printing - Remeshing 2-D Elements - HM-3110Document6 pagesPrinting - Remeshing 2-D Elements - HM-3110api-19817003No ratings yet

- Printing - Creating A Hexahedral Mesh Using The Solid Map Function - HM-3200Document27 pagesPrinting - Creating A Hexahedral Mesh Using The Solid Map Function - HM-3200api-19817003No ratings yet

- Printing - Splitting and Combining 2-D Elements - HM-3180Document10 pagesPrinting - Splitting and Combining 2-D Elements - HM-3180api-19817003No ratings yet

- Printing - Creating and Optimizing A 2-D Mesh Based On User-Defined Quality Criteria - HM-3150Document4 pagesPrinting - Creating and Optimizing A 2-D Mesh Based On User-Defined Quality Criteria - HM-3150api-19817003No ratings yet

- Printing - Creating 2-D Elements From Surfaces Using The Automesh Function - HM-3100Document22 pagesPrinting - Creating 2-D Elements From Surfaces Using The Automesh Function - HM-3100api-19817003No ratings yet

- Printing - Creating A 2-D Mesh Using Batch Mesher - HM-3160Document25 pagesPrinting - Creating A 2-D Mesh Using Batch Mesher - HM-3160api-19817003No ratings yet

- Printing - Creating 2-D Elements Without Surfaces - HM-3170Document13 pagesPrinting - Creating 2-D Elements Without Surfaces - HM-3170api-19817003No ratings yet

- Printing - 2-D Meshing Around Fixed Points - HM-3120Document4 pagesPrinting - 2-D Meshing Around Fixed Points - HM-3120api-19817003No ratings yet

- Printing - Connecting Components With 1-D Elements - HM-3010Document11 pagesPrinting - Connecting Components With 1-D Elements - HM-3010api-19817003No ratings yet

- Printing - Controlling The 2-D Mesh Concentration in Curved Areas - HM-3140Document5 pagesPrinting - Controlling The 2-D Mesh Concentration in Curved Areas - HM-3140api-19817003No ratings yet

- Printing - Obtaining and Assigning Beam Cross-Section Properties Using HyperBeam - HM-3020Document14 pagesPrinting - Obtaining and Assigning Beam Cross-Section Properties Using HyperBeam - HM-3020api-19817003No ratings yet

- Printing - Creating 1-D Elements - HM-3000Document5 pagesPrinting - Creating 1-D Elements - HM-3000api-19817003No ratings yet

- Matlab Notes Dundee UnivDocument37 pagesMatlab Notes Dundee Univaakash4380No ratings yet

- Assignment 2 2015 AAiTDocument5 pagesAssignment 2 2015 AAiTMISKIR TADESSENo ratings yet

- DMBF Full en Metric LetterDocument4 pagesDMBF Full en Metric LetterRonaldNo ratings yet

- A 320 Â " A 320M Â " 01 - QTMYMC0WMQDocument7 pagesA 320 Â " A 320M Â " 01 - QTMYMC0WMQhNo ratings yet

- Die-Casting Machines 1913 PDFDocument48 pagesDie-Casting Machines 1913 PDFOceanNo ratings yet

- Design of Shells (Example Problem)Document5 pagesDesign of Shells (Example Problem)AkarshGowdaNo ratings yet

- Separator Sizing and DesignDocument44 pagesSeparator Sizing and DesignKay EenNo ratings yet

- VRV Condensing UnitDocument24 pagesVRV Condensing UnitLeo NgNo ratings yet

- Asb - 407 18 117Document15 pagesAsb - 407 18 117edsel jose diaz sarmientoNo ratings yet

- Acoustic Noise MotorsDocument12 pagesAcoustic Noise MotorsAnonymous kr9TDDmWfJNo ratings yet

- Final 07 Ex2Document4 pagesFinal 07 Ex2Karam FaresNo ratings yet

- BruchM Aufgabenheft - enDocument28 pagesBruchM Aufgabenheft - enIlham HakikiNo ratings yet

- PSC AE QuestionsDocument9 pagesPSC AE QuestionsDipayan MisraNo ratings yet

- Process Flow SheetDocument22 pagesProcess Flow Sheetranger cleetusNo ratings yet

- Hiace Techstream 1st RunDocument3 pagesHiace Techstream 1st RunStephen MasemoNo ratings yet

- C15 Acert Spec SheetDocument4 pagesC15 Acert Spec SheetMalasquez Leon XavierNo ratings yet

- CheatSheet CADocument4 pagesCheatSheet CAAnonymous ypNOeWtsfuNo ratings yet

- Wear of RailsDocument13 pagesWear of RailsMusanif Ahmed FarooqiNo ratings yet

- AnexosDocument99 pagesAnexosGustavo GutoNo ratings yet

- 4301 L 2 - 2006Document23 pages4301 L 2 - 2006Indra H BasriNo ratings yet

- MachineryDocument8 pagesMachineryPalapa 1No ratings yet

- Boiling and Condensation PDFDocument11 pagesBoiling and Condensation PDFYeditha Satyanarayana MurthyNo ratings yet

- Cpi Gtr50 Service ManualDocument43 pagesCpi Gtr50 Service ManualKlara PataiNo ratings yet

- Drainage Pumps: Catalogue Drainage and SewageDocument90 pagesDrainage Pumps: Catalogue Drainage and SewageИбрагим НурмамедовNo ratings yet

- Mondelez-Rework U Mixer - Insepction & Repair ReportDocument9 pagesMondelez-Rework U Mixer - Insepction & Repair ReportTaha ZiaNo ratings yet

- AOS Voltex Hybrid Electric Heat Pump English CANXE50004 - 1015Document2 pagesAOS Voltex Hybrid Electric Heat Pump English CANXE50004 - 1015Pat AuffretNo ratings yet

- ST-101 Data SheetDocument2 pagesST-101 Data Sheetlibrero2014salNo ratings yet

- Refrigerador True-T-49Document12 pagesRefrigerador True-T-49JOHN AGUILARNo ratings yet

- Shear Modulus of GravelDocument9 pagesShear Modulus of GravelSajjadNo ratings yet

- Astm A216Document4 pagesAstm A216salazaralexi100% (1)

- Journal International Analytical and Experimental Seismic Assessment of Irregular BuildingDocument15 pagesJournal International Analytical and Experimental Seismic Assessment of Irregular BuildingBriandoNo ratings yet