Professional Documents

Culture Documents

Pump Technology Training

Uploaded by

kamchorepkCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pump Technology Training

Uploaded by

kamchorepkCopyright:

Available Formats

1

PUMP TECHNOLOGY TRAINING

- CENTRIFUGAL PUMP TECHNOLOGY

- CLASSIFICATION OF PUMP

- CENTRIFUGAL PUMP FUNCTION

- HYDRAULID DESIGN

- IMPELLER DESIGN

- BASIC PUMP HYDRAULIC

- INSTALLATION

2

CENTRIFUGAL PUMP TECHNOLOGY

Pump definition

- Liquid higher pressure

- Deliver liquid

- Energy transfer device

Centrifugal Force

Kinetic Pump

Centrifugal force

Displacement Pump

Changed volume

3

Kinetic Pump Positive Displacement Pump

4

Delivery Gas

Machine that deliver liquids are simply called pump but if gas are involved three

different term are in use

Fan

Pressure rise very small

Blower

Up to 1 atm

Compressor

Above 1 atm

Extract Energy

Machine that extract energy from the fluid

Turbine

5

CLASSIFICATION OF PUMP

Pumps maybe classified on the basis of the applications they serve, the material from

which they are constructed, the liquid they handle, and even their orientation in space.

Application Material Pumping

Medium

Orientation

A basic system of pump classification defines the principle by which energy is added to

the fluid. This system is therefore related to the pump itself and is unrelated to any

consideration external to the pump such as material or orientation of pump.

6

A. Classification of kinetic pump B. Classification of displacement pump

Metering pump

7

API STANDARD

API is the only national trade association that represents all aspects of Americas

oil and natural gas industry. 400 corporate members, from the largest major oil

company to the smallest of independents, come from all segments of the industry.

They are producers, refiners, suppliers, pipeline operators and marine transporters,

as well as service and supply companies that support all segments of the industry.

API 610 Centrifugal Pumps for Petroleum Petrochemical and Natural Gas

IndustriesTenth Edition October 2004

Advocacy Research and

Statistic

Standard Certification Education

8

API 610 Pump classification type identification

9

Pump Type OH1

Foot-mounted single-stage overhung pumps

OH1 does not meet all the requirements of API 610

Pump Type OH2

Centerline-mounted single-stage

overhung pumps, single bearing housing

Pump Type VS4

Vertical suspended,

single-casing volute

line-shaft driven

10

Hydraulic Design

The most common type of centrifugal pump is volute style.

- Shape

- Cross sectional area

A volute is a curved funnel increasing in area

to the discharge port. It is often used with

impeller pumps. As the area of the cross-

section increases, the volute reduces the

speed of the liquid and increases the pressure

of the liquid.

Volute Centrifugal Pump

11

Hydraulic Design

Diffuser style

- increase efficiency

- prevent excessive buildup of pressure

Pump diffuser bracket

Pump diffuser velocity profile Pump diffuser 3D model

12

Hydraulic Design

Classify centrifugal pump by impeller styles

-Fully open; The vanes extend radially from impeller hub with out a back shroud or

front cover plate.

- Semiopen; The vanes project forward from the back shroud, and there is no cover

plate.

- Fully closed; A full back shroud and full front cover plate enclose and support the

vanes.

Fully Open

Semiopen Fully Closed

Efficient

13

Impeller Design/The cause of the pump curve

STEADILY RISING

STEEP FLAT

UNSTABLE

UNSTABLE (saddle-shape)

14

Impeller Design/The cause of the pump curve

Best Efficiency Point (BEP)

The Best Efficiency Point is the point H(Q)), where the pump operates at the maximum

efficiency.

Characteristic curves of a centrifugal pump

in dependence of the flow Q.

Usually the following curve are shown

Head H(Q)

Power P(Q)

Shaft power P2(Q)

Power input P1(Q)

Efficiency

Hydraulic efficiency

Total efficiency

NPSH(Q)

Speed N(Q)

15

Impeller Design/The cause of the pump curve

Characteristic of the impeller affect to the pump curve as the following

1. Impeller width

Changing the widht of the impeller of a centrifugal pump will

usually alter the head-capacity.

2. Number of Vane

Increasing the number of vanes in an impeller produces a flatter H-Q curve.

3. Warp of vane

A higher-head, lower-flow impeller usually require more warp or sweepback.

Centrifugal Pump Function

1.To raise a liquid from one level to another.

2.To force a liquid into a vessel at a higher pressure by overcoming internal pressure.

3.To force a liquid through a pipe by overcoming piping and fitting friction losses.

16

Basic Pump Hydraulics

The first law of thermodynamics is the basis of all centrifugal pump.

The internal or mechanical energy of a system appears as kinetic, pressure, and

potential energy; these are interchangeable and their sum must remain constant.

Head is a term that expresses the energy of a fluid due to its elevation above

some reference point, its velocity, and its pressure.

- Static Head

- Dynamic Head

P = gh

= water density, 1000 kg/m3

g

= the standard earth gravity, 9.81 m/s

h = depth of water column, m

C

2

/2g

C = fluid velocity, m/s

17

Basic Pump Hydraulics

Static head Velocity or Dynamic head Static head

18

Basic Pump Hydraulics

Continuity equation

The mass flow of fluid per unit of time passing any point is constant

Q= AV

Q = fluid mass flow, m3/s

A = pipe cross section area, m2

V = fluid velocity, m/s

Energy conversion

1.Simple one-dimensional formula

2.Computer simulation, CFD Technique

To construct an elementary theory of the pump performance,we assume

one-dimensional flow and combine idealized fluid velocity vectors through

the impeller with the angular momentum theorem for a control volume.

19

Basic Pump Hydraulics

Apply angular momentum

T= Q(r

2

v

t 2

r

1

v

t1

)

Power delivered to the fluid is

P

LA

= eT

Y

LA

=

P

LA

Q

Specific work

The useful specific work Y

done by the pump is less

than that done by the

impeller because of the

losses in the intake,

impeller, and diffusor.

These losses are

expressed in terms of

efficiency.

Specific work depend on

Contour of the hydraulic components of the

pump, delivery rate, peripheral velocity

20

Basic Pump Hydraulics

Interrelationship between a pump and the pumping plant

Bernoulli Equation

P

s

+ Z

s

g +

c

s

2

g

+ Y =

P

d

+ Z

d

g + c

d

2

Pump suction nozzle Pump

Energy input Energy output

21

Basic Pump Hydraulics

Power, losses and efficiency

Total Efficiency

q= q

v

q

n

q

m

q

v

q

n

q

m

= volumetric efficiency

= hydraulic efficiency

= mechanical efficiency

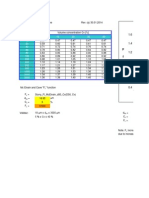

Specific Speed

n

q

= n

Q

H

3

4

The power input required by the pump

P =

Q g H

q

n = speed rpm

P = power, watt

Q = volume flow rate, m3/s

H = head, m

For cold water

q~ 0.82

P = 12 QH

(kW)

22

Basic Pump Hydraulics

Total Head of The Pump

Differential Head; The differential head developed by a centrifugal pump is the

measure of the total energy increase imparted to the liquid by the work done within the

pump.

Total Head; the total head is the discharge head plus or minus the suction head

The head is a unit of energy and corresponds to the total head between the suction

and delivery nozzles as define by Bernoulli. It is independent of the characteristics of

the pumped medium, and for a given pump depends only on the flow rate and the

peripheral speed of the impeller.

23

THE TOTAL HEAD REQUIRED BY A PUMPING PLANT

24

THE TOTAL HEAD REQUIRED BY A PUMPING PLANT

In order to examine total head required by the plant at design flow rate, it is necessary

to consider the energy equation (Bernoulli equation). The flow energy of the pump is

defined in all terms energy per unit mass of pumped fluid.

p

s

+ Z

s

g +

c

s

2

2

+ Y =

p

d

+ Z

d

g +

c

d

2

2

In pump design, it use term of unit weight under gravitational acceleration. It is know

as the head H.

H =

Y

g

Generally the pump draws from a reservoir whouse surface is at a pressure p

e

and

delivers to a second reservoir at a pressure p

a

. The plant head requirement is then

define as

H

A

=

p

a

p

e

g

+ Z

a

Z

e

+

c

a

2

c

e

2

2g

+ H

vs

+ H

vd

H

vs

= total head loss in the intake line

H

vd

= total head loss in the delivery line

25

NET POSITIVE SUCTION HEAD

The total suction head H

H

is the different between total head (static head plus dynamic

head) and the vapour pressure head in the pump intake.

H

H

=

p

ges

p

D

g

If the suction head is referred to the centerline of a horizontal pump then

NPSH =

p

s

abs

p

D

g

+

c

s

2

2g

The NPSH value of the plant defines the total pressure at the pump suction nozzle

for given fluid characteristics at a certain flow rate.

NPSH

avail

=

p

e

abs

p

D

g

+ Z

e

Z

s

+

c

e

2

2g

H

vs

When the pump is operating in the suction mode, Z

e

is negative.

To avoid cavitation

NPSHA > NPSHR

26

SUCTION SPECIFIC SPEED

It is used to described geometrically similar impeller suction designs.

S =

n Q

NPSH

3

4

Note

US unit n / rpm, Q / gpm, NPSH / ft

For cold water and general service applications, suction specific speeds of 8,500

and lower are selected.

2. For boiler feed and condensate applications and for general hydrocarbon service,

values of suction specific speed typically range between 9,000 and 12,000.

3. For a double suction pump the flow is divided by 2 since there are 2 impeller

eyes.

4. Multiply the value in SI unit by 0.8607 to receive US customary.

27

INSTALLATION

-Temporary Alignment

- Installing Foundation Bolt

- Final Alignment

- Grouting

- Adjustment

Foundation and anchor bolts

- Anchor should be accurately set and firmly secured

- Rechecked anchor bolt against the foundation drawing; length, diameter, thread length

- Anchor bolt should be checked for proper projection

- Put grease on the thread

- Plastic or metal anchor bolt sleeves should be used

You might also like

- EnvironmentalDocument277 pagesEnvironmentalkamchorepkNo ratings yet

- Refining Training 01 - CrudeDocument288 pagesRefining Training 01 - CrudekamchorepkNo ratings yet

- On-Line Duralobe Classic SQ RTP Sterilobe Acculobe Tra10 Tra20Document173 pagesOn-Line Duralobe Classic SQ RTP Sterilobe Acculobe Tra10 Tra20kamchorepkNo ratings yet

- NPSH Calculations Explained: Net Positive Suction Head and Pump DesignDocument3 pagesNPSH Calculations Explained: Net Positive Suction Head and Pump DesignEdward YanceNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- A Coriolis Tutorial: Part 2: A Rotating Shallow Water Model, Potential Vorticity and Geostrophic AdjustmentDocument59 pagesA Coriolis Tutorial: Part 2: A Rotating Shallow Water Model, Potential Vorticity and Geostrophic Adjustmenttagne simo rodrigueNo ratings yet

- Determining Friction FactorDocument17 pagesDetermining Friction Factorsaleemdbg100% (4)

- Sơ Đ HTTĐTL CAT 350LDocument2 pagesSơ Đ HTTĐTL CAT 350LDu TrầnNo ratings yet

- Liquid Jet Breakup at Low Weber Number-A SurveyDocument6 pagesLiquid Jet Breakup at Low Weber Number-A Surveytoufik saouchiNo ratings yet

- Oil Recovery by Internal Gas DriveDocument7 pagesOil Recovery by Internal Gas DriveDhiaa LaMiNo ratings yet

- Slurry Flow Functions McElvain, Durand, Weir & Bingham Fluid ModelsDocument14 pagesSlurry Flow Functions McElvain, Durand, Weir & Bingham Fluid ModelsJuan Pablo ApazaNo ratings yet

- CFD Simulation of Dust Particle Removal Efficiency of A Venturi Scrubber in CFXDocument9 pagesCFD Simulation of Dust Particle Removal Efficiency of A Venturi Scrubber in CFXCristian MartínezNo ratings yet

- Boson India Ventures: Pressure Safety Valve Calculation - Valve Sizing Based On Known Flow RateDocument3 pagesBoson India Ventures: Pressure Safety Valve Calculation - Valve Sizing Based On Known Flow RateRahul AdityaNo ratings yet

- Fluid MechanicsDocument29 pagesFluid MechanicsProf. Avinash Mahale100% (1)

- Fundamentos de Mec Anica de Fluidos Primer Examen Parcial: Figure P1.24Document2 pagesFundamentos de Mec Anica de Fluidos Primer Examen Parcial: Figure P1.24Sergio CorredorNo ratings yet

- Transition in Open Channel FlowDocument13 pagesTransition in Open Channel FlowAdegoke samuel charlesNo ratings yet

- BibleDocument115 pagesBiblePeter TimmsNo ratings yet

- Ghulam Ishaq Khan Institute of Engineering Sciences and Technology, Topi-23460Document3 pagesGhulam Ishaq Khan Institute of Engineering Sciences and Technology, Topi-23460Saad RasheedNo ratings yet

- AREMA Volume 1, Chapter 1, Part 4, Section 4.8 HDPE PDFDocument20 pagesAREMA Volume 1, Chapter 1, Part 4, Section 4.8 HDPE PDFpquiroga2100% (2)

- UntitledDocument18 pagesUntitledadrian_63No ratings yet

- Daftar Isi HydraulicDocument4 pagesDaftar Isi HydraulicYhuto W. PutraNo ratings yet

- Para Calculo de Tirantes ConjugadosDocument122 pagesPara Calculo de Tirantes ConjugadosFlavio Cesar Alvitez VasquezNo ratings yet

- Master1 AM CoursesDocument3 pagesMaster1 AM CoursesParokotil MidhunNo ratings yet

- Negash 1Document5 pagesNegash 1abuabe51No ratings yet

- Steam Trap - Wikipedia, The Free EncyclopediaDocument2 pagesSteam Trap - Wikipedia, The Free EncyclopediaAnbu Ayyappan100% (1)

- Experimental Results For Eppler 387 AirfoilDocument238 pagesExperimental Results For Eppler 387 Airfoilweelad35No ratings yet

- Triangle Velocity For Centrifugal PumpDocument27 pagesTriangle Velocity For Centrifugal PumpWinter NaiNo ratings yet

- SIMPLE Algorithm For Two-Dimensional Channel Flow - Fluid Flow and Heat TransferDocument18 pagesSIMPLE Algorithm For Two-Dimensional Channel Flow - Fluid Flow and Heat TransferCaioPaesNo ratings yet

- Exp6 Air Flow Velocity and Pressure Coefficient Around The 90o Rectangular DuctDocument7 pagesExp6 Air Flow Velocity and Pressure Coefficient Around The 90o Rectangular DuctKawar Abid100% (1)

- Worksheet No. 12 Rheologic Properties MORFE, Erika Grace C. MAY 2021 Group 4Document4 pagesWorksheet No. 12 Rheologic Properties MORFE, Erika Grace C. MAY 2021 Group 4Shannen CostoNo ratings yet

- CFD Analysis of Sloshing Within TankDocument6 pagesCFD Analysis of Sloshing Within TankDipankar NathNo ratings yet

- CIVL3612 Final Exam 2016Document8 pagesCIVL3612 Final Exam 2016neok3No ratings yet

- Density, Viscosity & Drag (Multiple Choice) QPDocument4 pagesDensity, Viscosity & Drag (Multiple Choice) QPSam JoeNo ratings yet

- D07012 EID Parry Vendor ListDocument2 pagesD07012 EID Parry Vendor ListNegama ThullahNo ratings yet