Professional Documents

Culture Documents

Tipos de Bombas Centrifugas

Uploaded by

frankz89Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tipos de Bombas Centrifugas

Uploaded by

frankz89Copyright:

Available Formats

What is a centrifugal pump?

Three basic

components:

Volute, casing, body

or Diffuser

Impeller

or impellers

Driver (motor)

Centrifugal Pumps

Pump Impeller

Vanes

Direction of

rotation

Centrifugal Pumps

Typical single suction impeller

Centrifugal Pumps

Single suction impeller

Centrifugal Pumps

Impeller Types

Open

Semi-open

Closed

- Single suction

- Double suction

Non-clogging

Axial flow

Mixed flow

Centrifugal Pumps

Full Diameter Impeller

Rotation

Impeller

Blades

V

t

V

r

V

s

V

r

= Radial Velocity

V

t

= Tangential Velocity

V

s

= Vector Sum Velocity

Centrifugal Pumps

Impeller and volute

Suction Eye

Cutwater

Arrows represent the

direction of water flow

Discharge

Nozzle

Centrifugal Pumps

End Suction Pump

Series 1510

26 sizes

To 4400 gpm

To 520 ft TDH

To 150 HP To 8x10

General Purpose

Motor

Centrifugal Pumps

Section View

Bell & Gossett

Series 1510

Standard Construction

Gauge

Taps

Centrifugal Pumps

Close-Coupled Pump

Series 1531 Pump

20 sizes

To 2600 gpm

To 520 ft TDH

To 60 HP

To 6x8

Special Purpose

Motor

Centrifugal Pumps

Large, Line Mounted Pump

Series 80

Close coupled

18 sizes

To 2600 gpm

To 410 ft TDH

To 60 HP

To 8x8

Special Purpose

Motor

Centrifugal Pumps

Multi-stage pumps

Bell & Gossett

Series 3550

Multi-stage, diffuser

design

8 sizes, stainless steel

to 600 gpm

to 1200 ft

to 75 hp, 3500 rpm

many options for suction

and discharge nozzles

Centrifugal Pumps

Multi-stage pump

Bell & Gossett

Series 3550

Diffusers

Centrifugal Pumps

Vertical Turbine

Submersible

48 Models

5 - 14 bowls

40 - 2000 gpm

25 - 300 feet head

Lineshaft

88 Models

5-20 bowls

4 Styles

20 - 10,000 gpm

7 - 200 feet head

Centrifugal Pumps

Double Suction Pump

Bell & Gossett

Series HSC

37 sizes

To 12500 gpm

To 840 ft TDH

To 1000 HP

To 14x18

General Purpose Motor

Centrifugal Pumps

Typical Split Case Pump- Section View

Centrifugal Pumps

Double Suction Pump

Series VSCS

Series VSC

17 sizes

To 8000 gpm

To 400 ft TDH

To 600 HP

To 12x14

General Purpose Motor

Centrifugal Pumps

VSC Pump- Section View

Centrifugal Pumps

Pump Construction

Standard construction, any impeller

Mechanical seal

Internally flushed, seal cavity

Variety of seal materials

Stuffing box construction, any impeller

External flush lines

Compression packing rings

Single flushed mechanical seal

Centrifugal Pumps

Standard construction

Bell & Gossett

Series 1510

Standard

Construction

Centrifugal Pumps

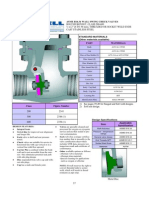

Seals

Shaft

Process

Fluid

Leakage

Environment

Vessel

Wall

Centrifugal Pumps

B&G Pump Construction

Standard construction, any impeller

Mechanical seal

Internally flushed, seal cavity

Variety of seal materials

Centrifugal Pumps

Ceramic Seal Insert

Graphite Seal Ring

Compression Ring

Impeller

Retainer (Sec Seal)

Gasket

Mechanical Seal

Rotary Assy

Stationary Assembly

Secondary Seal (Seal Bellows)

Centrifugal Pumps

Seal Cavity

Centrifugal Pumps

Standard construction

Bell & Gossett

Series 1510

Standard

Construction

Centrifugal Pumps

Limits On Seal Performance

Temperature of the flushing water.

225F to 250F

System pH.

7 to 9 for ceramic seals

up to 11 for tungsten carbide seals

Concentration of dissolved solids.

TDS less than 1000 ppm

Concentration of suspended solids.

Less than 20 ppm

Silica, less than 10 ppm

Centrifugal Pumps

Internally Flushed Mechanical Seals

Bell & Gossett

Series HSC

3

Standard

Construction

Centrifugal Pumps

Pump Construction

Stuffing box construction, any impeller

External flush lines

Internal or External Fluid

Compression packing rings

Single flushed mechanical seal

Centrifugal Pumps

Packing

Shaft

Process

Fluid

Leakage

Environment

Vessel

Wall

Centrifugal Pumps

Stuffing box with packing

Centrifugal Pumps

Packing Installation

Centrifugal Pumps

Bypass Flush Line

Bell & Gossett

Series HSC-S

Centrifugal Pumps

Liquid-Abrasives Separator

Centrifugal Pumps

Whats suitable?

Impeller

Single suction or double suction.

Volutes

Base mounted or in-line.

Internally flushed or stuffing box.

Single stage or multi stage.

Packing, seal or wet rotor.

Centrifugal Pumps

Angular Misalignment

Centrifugal Pumps

Parallel or Offset Misalignment

Centrifugal Pumps

Suction Piping Detail

5 dia.

1. Pipe supported

2. Length of suction

piping allows even

impeller loading

RIGHT WRONG

1. Pipe weight hangs

on pump flange.

2. Short suction pipe

results in uneven

impeller loading.

Centrifugal Pumps

Why 5 diameters?

Single Suction

Impeller

Centrifugal Pumps

Installation

Typical installation

Elbow Support

(Anchor to Base)

Solid Base Foundation

Flow

Pump Motor Hoist Beam

Trolley with Manual

Hook-Type Hoist

Triple Duty Valve

Suction Diffuser

Centrifugal Pumps

Vertical Turbine Pump

Driver

Discharge

Head

Column

Bowl

Assembly

Comments?

Questions?

Observations?

You might also like

- 2007 AP Statistics Multiple Choice ExamDocument17 pages2007 AP Statistics Multiple Choice ExamJalaj SoodNo ratings yet

- ITT Gould Pump ManualDocument140 pagesITT Gould Pump ManualTasawwur TahirNo ratings yet

- I.O.M. Diffuser Casing, Multistage, Process Barrel PumpDocument44 pagesI.O.M. Diffuser Casing, Multistage, Process Barrel Pumpsf wNo ratings yet

- 5) Bearing Fundamentals PDFDocument123 pages5) Bearing Fundamentals PDFRizal Gunawan100% (1)

- Hydraulic Power Units Vertical Mount Fixed DisplacementDocument32 pagesHydraulic Power Units Vertical Mount Fixed DisplacementSujata Roy100% (1)

- WhatsApp Chat With Chinnu HeartDocument30 pagesWhatsApp Chat With Chinnu HeartSäi DäťťaNo ratings yet

- Dupont Vespel Cr-6100: Application and Installation Guide For Centrifugal Pump Stationary Wear PartsDocument12 pagesDupont Vespel Cr-6100: Application and Installation Guide For Centrifugal Pump Stationary Wear PartsFernando Tapia GibsonNo ratings yet

- Rotating EquipmentDocument202 pagesRotating EquipmentJithin Rajan Joseph100% (1)

- Internal Gear PumpDocument8 pagesInternal Gear Pumpshivam.nagarNo ratings yet

- Rohm Lathe ChucksDocument91 pagesRohm Lathe ChucksNebojša ObradovićNo ratings yet

- Service Instructions: Oilgear Type "PVV 540" Open Loop PumpsDocument14 pagesService Instructions: Oilgear Type "PVV 540" Open Loop PumpsAxel LetonaNo ratings yet

- Advance Design of PumpsDocument20 pagesAdvance Design of Pumpsfugga100% (1)

- Technical Catalogue: Pipes Tubes Fittings FlangesDocument121 pagesTechnical Catalogue: Pipes Tubes Fittings FlangesDANIELVENZUELAANo ratings yet

- Comparitive Study of Pile Foundations With Foundations On Stone Column Treated Ground 170704090313Document23 pagesComparitive Study of Pile Foundations With Foundations On Stone Column Treated Ground 170704090313anurag hazarikaNo ratings yet

- HANBOOK Jaw Crushers PDFDocument8 pagesHANBOOK Jaw Crushers PDFfrankz89No ratings yet

- Vertical Bearings: Av, LV & V SeriesDocument7 pagesVertical Bearings: Av, LV & V SeriesSridhar TholasingamNo ratings yet

- Air Sentry - Energy Statement App 3 Dessicant and Filters PDFDocument20 pagesAir Sentry - Energy Statement App 3 Dessicant and Filters PDFEsteban Fernando Meza IbacetaNo ratings yet

- Manual - Dust Collector and Bin VentDocument13 pagesManual - Dust Collector and Bin Ventfrankz89No ratings yet

- Annexure 2 - Requisition For Pipe 4inch & AboveDocument11 pagesAnnexure 2 - Requisition For Pipe 4inch & Abovefrankz89No ratings yet

- Pump Technology Screwpumps l2 Series enDocument11 pagesPump Technology Screwpumps l2 Series enCamiloHernándezNo ratings yet

- E - 7403-9000 - Table of ContentsDocument4 pagesE - 7403-9000 - Table of Contentsraobabar21No ratings yet

- Screw Conveyor O&M ManualDocument20 pagesScrew Conveyor O&M Manualjay b100% (1)

- Structural Health MonitoringFrom EverandStructural Health MonitoringDaniel BalageasNo ratings yet

- Triple Screw PumpDocument7 pagesTriple Screw PumpEfrain Gomez M.No ratings yet

- Warning PDFDocument1 pageWarning PDFPartsGopher.com100% (1)

- Alfa Laval M6: Gasketed Plate Heat Exchanger For A Wide Range of ApplicationsDocument2 pagesAlfa Laval M6: Gasketed Plate Heat Exchanger For A Wide Range of ApplicationsCyrilDepalomaNo ratings yet

- TDZ Hidraulic Vane PumpDocument26 pagesTDZ Hidraulic Vane PumpAndi IshakaNo ratings yet

- Accumalator PDFDocument30 pagesAccumalator PDFmahaveenNo ratings yet

- Technical Manual Centrifugal Axial FanDocument17 pagesTechnical Manual Centrifugal Axial Fanxichengren100% (2)

- Introduction To Psychology (2022)Document642 pagesIntroduction To Psychology (2022)hongnhung.tgdd2018No ratings yet

- FPC Manual PreviewDocument5 pagesFPC Manual PreviewIbrahim Levent AkkoyunluNo ratings yet

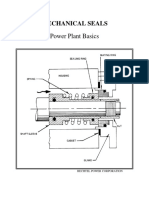

- Mechanical Seals: Power Plant BasicsDocument26 pagesMechanical Seals: Power Plant BasicsService Port100% (1)

- Vacuum PumpDocument10 pagesVacuum Pumptutuli1990No ratings yet

- Noise Reduction in Axial Piston Pumps PDFDocument266 pagesNoise Reduction in Axial Piston Pumps PDFbee140676100% (1)

- Types of PumpDocument32 pagesTypes of Pumpkapun kumar nayakNo ratings yet

- Automatic Fuel Oil Transfer Pump Set - DatasheetDocument5 pagesAutomatic Fuel Oil Transfer Pump Set - Datasheetfrankz89No ratings yet

- b3311 722-2Document7 pagesb3311 722-2Arnaldo BenitezNo ratings yet

- RCE Brochure 05 - 15Document10 pagesRCE Brochure 05 - 15Javier Alejandro Rodriguez MelgozaNo ratings yet

- HANDBOOK Blanket Gas Regulators PDFDocument8 pagesHANDBOOK Blanket Gas Regulators PDFfrankz89No ratings yet

- HANDBOOK Blanket Gas Regulators PDFDocument8 pagesHANDBOOK Blanket Gas Regulators PDFfrankz89No ratings yet

- GearboxDocument6 pagesGearboxedhy_03No ratings yet

- Air Driven, High Pressure Liquid Pumps: Product CatalogDocument24 pagesAir Driven, High Pressure Liquid Pumps: Product CatalogCantora Franciely Viana officialNo ratings yet

- Filters Pressure SF - RFDocument33 pagesFilters Pressure SF - RFoscarn_036No ratings yet

- Bucket Elevator CatalogDocument20 pagesBucket Elevator CatalogLeonardo De la CruzNo ratings yet

- Price List - 2013Document11 pagesPrice List - 2013John MaNo ratings yet

- Sundyne LMC-347: Compressor and Gearbox Cross Section Single Seal ArrangementDocument1 pageSundyne LMC-347: Compressor and Gearbox Cross Section Single Seal ArrangementmohammadNo ratings yet

- Diffuser Versus Volute Casing - PumpsDocument5 pagesDiffuser Versus Volute Casing - Pumpsjanamurali0% (1)

- Low Speed Fans Application Guide MiningDocument20 pagesLow Speed Fans Application Guide MiningsanthoshdonNo ratings yet

- Katalog DS4 2007Document164 pagesKatalog DS4 2007jodandNo ratings yet

- Guia Tecnica de Carbones Marca Helwing Carbon U.S PDFDocument28 pagesGuia Tecnica de Carbones Marca Helwing Carbon U.S PDFmarvin17No ratings yet

- Tubular Casing Pumps by KSBDocument16 pagesTubular Casing Pumps by KSBGogy0% (1)

- SCHROEDER Automatic Recirculation Check ValveDocument14 pagesSCHROEDER Automatic Recirculation Check ValveAli Bari100% (1)

- Centrifugal FanDocument14 pagesCentrifugal FanNiranjanKumarNo ratings yet

- Cavitation and PUmp NPSHRDocument39 pagesCavitation and PUmp NPSHRRaheel Sultan100% (1)

- Acceleration Amplitude Demodulation IN Predictive MaintenanceDocument8 pagesAcceleration Amplitude Demodulation IN Predictive MaintenanceronfrendNo ratings yet

- Pump VSPDocument12 pagesPump VSPMiguel V. PalNo ratings yet

- Drive Shaft - WikipediaDocument5 pagesDrive Shaft - WikipediaMohsen SharifNo ratings yet

- Gear Pump DiscussionDocument2 pagesGear Pump DiscussionSlim ShaddysNo ratings yet

- Cleaning Paper IndustryDocument106 pagesCleaning Paper IndustryLUCERO VILLAMIL FRANCONo ratings yet

- Vacuum ContaminationDocument4 pagesVacuum Contaminationelkin manriqueNo ratings yet

- The Staffa Motor For PDFDocument134 pagesThe Staffa Motor For PDFOMP Hydraulics O Meara PartsNo ratings yet

- OHH OHHL E00697 (Pump Zulzer)Document6 pagesOHH OHHL E00697 (Pump Zulzer)Jose Sosa CojNo ratings yet

- Belt Tracking For Belt ConveyorDocument2 pagesBelt Tracking For Belt ConveyorhadimarviNo ratings yet

- CRU-83 Combat Edge RegulatorDocument1 pageCRU-83 Combat Edge RegulatorfuccioniNo ratings yet

- Basic HydraulicsDocument64 pagesBasic Hydraulicsedtatel73No ratings yet

- Thermal and Efficiency Characterization of A Low-Backlash Planetary GearboxDocument10 pagesThermal and Efficiency Characterization of A Low-Backlash Planetary Gearboxra maNo ratings yet

- FLENDER Standard CouplingsDocument278 pagesFLENDER Standard Couplingsalfredo_fredo_1No ratings yet

- Power Stream Couplings-Specn SheetsDocument6 pagesPower Stream Couplings-Specn SheetsAmol PatkiNo ratings yet

- The Machine DesignDocument64 pagesThe Machine DesignAnoj pahathkumburaNo ratings yet

- Huber - Folleto - Deshidratador - RoS 3QDocument4 pagesHuber - Folleto - Deshidratador - RoS 3Qenzo_kcrs2787109No ratings yet

- Tipos de Bombas CentrifugasDocument34 pagesTipos de Bombas CentrifugasJorge Fernandez EdelmanNo ratings yet

- Flow Serve PumpsDocument8 pagesFlow Serve PumpsHenry Suarez0% (1)

- Plant 3DDocument1 pagePlant 3Dfrankz89No ratings yet

- Piping MineriaDocument2 pagesPiping Mineriafrankz890% (1)

- Pressure VesselDocument2 pagesPressure Vesselfrankz89No ratings yet

- Piping InstallationDocument1 pagePiping Installationfrankz89No ratings yet

- Industrial PipingDocument1 pageIndustrial Pipingfrankz89No ratings yet

- Overland ConveyorDocument1 pageOverland Conveyorfrankz89No ratings yet

- Piping ArrangementDocument2 pagesPiping Arrangementfrankz89No ratings yet

- Software TankDocument2 pagesSoftware Tankfrankz89No ratings yet

- Gas NaturalDocument7 pagesGas Naturalfrankz89No ratings yet

- Manual Valvula PinchDocument8 pagesManual Valvula Pinchfrankz89No ratings yet

- PV Elite ImagesDocument3 pagesPV Elite Imagesfrankz89No ratings yet

- Valvulas Tipo CuchillaDocument8 pagesValvulas Tipo Cuchillafrankz89No ratings yet

- Pressure Vessel TanksDocument2 pagesPressure Vessel Tanksfrankz89No ratings yet

- Valvulas Tipo CuchillaDocument8 pagesValvulas Tipo Cuchillafrankz89No ratings yet

- CATALOGO Check Criogenica PDFDocument6 pagesCATALOGO Check Criogenica PDFfrankz89No ratings yet

- Valve CatalogueDocument4 pagesValve Cataloguefrankz89No ratings yet

- 06 Mantenimiento de Calderas Industriales BOSCH Fenercom 2013.desbloqueadoDocument43 pages06 Mantenimiento de Calderas Industriales BOSCH Fenercom 2013.desbloqueadoAlex H. De la CruzNo ratings yet

- Vent-O-Mat - Nozzle Check ValveDocument8 pagesVent-O-Mat - Nozzle Check Valvefrankz89No ratings yet

- Tipos de Bombas CentrifugasDocument43 pagesTipos de Bombas Centrifugasfrankz89No ratings yet

- Pipe Systems PDFDocument108 pagesPipe Systems PDFfrankz89No ratings yet

- Cascho Modelo DDocument16 pagesCascho Modelo Dfrankz89No ratings yet

- Valvula Esferica Criogenica TBVDocument20 pagesValvula Esferica Criogenica TBVfrankz89No ratings yet

- Sandwich StoichiometryDocument2 pagesSandwich StoichiometryMaysaa El HarakehNo ratings yet

- Aqa Chm6w W QP Jun02Document18 pagesAqa Chm6w W QP Jun02Diksha KoossoolNo ratings yet

- By Josephine G. Ignacio, MD and Jennifer T. Co, MD, FPOGSDocument9 pagesBy Josephine G. Ignacio, MD and Jennifer T. Co, MD, FPOGSAngela SaldajenoNo ratings yet

- Imteyaz ResumeDocument2 pagesImteyaz ResumeImteyaz AhmadNo ratings yet

- Chapter 4Document6 pagesChapter 4Aung MyatNo ratings yet

- Pulse Production in India: Major Constraints and Way ForwardDocument33 pagesPulse Production in India: Major Constraints and Way ForwardDeus EXNo ratings yet

- Xtra ReportDocument8 pagesXtra ReportTahfeem AsadNo ratings yet

- Pipe Conveyor System: Effective Solutions For Long DistancesDocument8 pagesPipe Conveyor System: Effective Solutions For Long DistancesEugenepaccelli Kolandai SamyNo ratings yet

- Morgan - Electrostatics 2003 (Institute of Physics Conference Series) - Institute of Physics Publishing (2004)Document386 pagesMorgan - Electrostatics 2003 (Institute of Physics Conference Series) - Institute of Physics Publishing (2004)Tsiory RanaivosonNo ratings yet

- Public Places 9 & 10Document2 pagesPublic Places 9 & 10kaka udinNo ratings yet

- California Department of Corrections EmailDocument3 pagesCalifornia Department of Corrections EmailHeidi McCaffertyNo ratings yet

- Review of Documents On Seismic Strengthening of Existing BuildingsDocument12 pagesReview of Documents On Seismic Strengthening of Existing Buildingsm7j7a7No ratings yet

- DGMS Final ReportDocument15 pagesDGMS Final ReportMaverickNo ratings yet

- Itopride HCL Pynetic 50mg TabDocument2 pagesItopride HCL Pynetic 50mg TabAusaf AhmadNo ratings yet

- 1896 - Pearson - Mathematical Contributions To The Theory of Evolution. III. Regression, Heredity, and PanmixiaDocument67 pages1896 - Pearson - Mathematical Contributions To The Theory of Evolution. III. Regression, Heredity, and PanmixiaNilotpal N SvetlanaNo ratings yet

- Forensic Toxicology: A. Classify Toxins and Their Effects On The BodyDocument28 pagesForensic Toxicology: A. Classify Toxins and Their Effects On The BodySajid RehmanNo ratings yet

- Measurement of Poverty and Poverty of Measurement: Martin GreeleyDocument15 pagesMeasurement of Poverty and Poverty of Measurement: Martin GreeleyKule89No ratings yet

- Early Theories On The Origin of Life On Earth: Creation TheoryDocument1 pageEarly Theories On The Origin of Life On Earth: Creation TheoryAngel Elizaga IINo ratings yet

- July 15, 2011 Strathmore TimesDocument24 pagesJuly 15, 2011 Strathmore TimesStrathmore TimesNo ratings yet

- Effect of Different Immediate Dentin Sealing Techniques On The Microtensile Bond Strength PDFDocument6 pagesEffect of Different Immediate Dentin Sealing Techniques On The Microtensile Bond Strength PDFclaudiaNo ratings yet

- SECTION 02892 Traffic Signals Rev 0Document65 pagesSECTION 02892 Traffic Signals Rev 0Abdul HannanNo ratings yet

- Greetings: HVAC Design of Commercial Buildings With TESDocument49 pagesGreetings: HVAC Design of Commercial Buildings With TESchitradevipNo ratings yet

- 1.indentify The Functions of Various Keys On The Key BoardDocument83 pages1.indentify The Functions of Various Keys On The Key BoardMuhammad AbbasNo ratings yet

- Carbonyl Compounds: Unit 4 Rates, Equilibria and Further Organic ChemistryDocument5 pagesCarbonyl Compounds: Unit 4 Rates, Equilibria and Further Organic ChemistryKirusaanth SathiyathasanNo ratings yet