Professional Documents

Culture Documents

Supply Chain Mangement

Uploaded by

Soumya MohapatraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Supply Chain Mangement

Uploaded by

Soumya MohapatraCopyright:

Available Formats

-Chocolate that loves you back

By-

Nithin Reddy

Soumen Kundu

Soumya Mohapatra

Suhail Afzal

Shashank Reddy

Mukesh Kumar

Soma Sandeep

Description of Chocolate

Chocolate is made from

cocoa beans found on the

cacao tree.

The cacao tree was first

discovered in the South

American rainforest.

The three main

ingredients in chocolate

are chocolate liquor, cocoa

powder, and cocoa butter.

Different kinds of

chocolate use varying

amounts of these 3

ingredients.

Picture of the Cacao Tree

Raw material suppliers

The main raw materials required for this industry is

Sugar

Cocoa Beans{butter}

Pea nuts

Rasins, Almonds

Vanilin

Honey

Beans

Raw materials are collected from the different whole sale

dealers, Cocoa growers, cooperatives etc

Cocoa is also imported mainly from West Africa.

How Chocolate is Made

Cocoa pods are

harvested

Pods are crushed and

fermented.

Cocoa beans are taken

out of the pods and then

dried.

Beans are roasted,

graded, and then ground.

Grinding the beans

creates a liquid called

chocolate liquor.

Chocolate liquor - made

mostly of fat called cocoa

butter.

Cocoa butter is extracted.

Cocoa powder is also

created when beans are

ground.

Process creates chocolate

liquor, cocoa powder,

and cocoa butter.

Ingredients are blended

back together to create

different kinds of

chocolates.

The Chocolate Making Process

Production starts at the cocoa factory where the top quality cocoa beans are

processed to produce the cocoa mass - which contains 53% cocoa and cocoa butter -

the basis for all chocolate products.

When chocolate is made, the 'mass' goes straight to our factories.

Fresh full cream milk is collected and condensed and transported to the factories.

Sugar is added to the cocoa mass, making a rich creamy chocolate liquid, which is

then evaporated to make chocolate crumb

As these ingredients are cooked together, the special rich creamy taste of Cadbury

chocolate is produced. Each year, 22,000 tonnes of crumb is produced at Claremont

to be made into chocolate.

On arrival at the chocolate factory, the crumb is passed through a pin mill and

mixed with cocoa liquor and cocoa butter, as well as special chocolate flavouring.

The amount of emulsifiers added depends on the consistency of the chocolate

required. Thick chocolate is needed for moulded blocks, while a thinner consistency

is used for assortments and covering bars.

Both milk and dark chocolate undergo the same final special production stages -

refining, conching and tempering - which produce the famous smoothness, gloss

and snap of chocolate.

Conching involves mixing and beating the semi-liquid mixture to develop the

flavour, removing unwanted volatile flavours and reducing the viscosity and

particle size.

Tempering is the final crucial and complex stage which involves mixing and

cooling the liquid chocolate under carefully controlled conditions to ensure that the

fat in the chocolate crystallises in its most stable form

Tempered chocolate is used in a number of ways to produce our famous brands.

Blocks of solid chocolate, including bars with added ingredients such as nuts and

raisins, are known in the industry as 'moulded' products. Tempered chocolate is

poured into bar-shaped moulds, shaken and cooled, then the moulded blocks

continue to high speed wrapping plants.

Our plants are potentially expected to produce 700 blocks per minute

Types of Chocolate

Sweet Chocolate

Contains no milk solids

Cannot contain less than

15% chocolate liquor

Dark Bittersweet Chocolate

Contains the most chocolate

liquor.

It is sweet chocolate that

cannot contain less than

35% chocolate liquor.

Semi Sweet Chocolate

Similar to dark bittersweet

chocolate.

Baking Chocolate

Contains no sweeteners and

no milk.

Types of Chocolate

Milk Chocolate

Contains milk and sugar,

which differs from

bittersweet and semisweet

chocolate.

Cannot contain less than 12%

milk and cannot contain less

than 10% chocolate liquor.

Can contain other ingredients

but must comply with

regulations.

White Chocolate

Technically not real chocolate

Contains no chocolate liquor,

which is one of the main

ingredients in chocolate.

Its made of cocoa butter,

milk, and sugar.

TARGET MARKET

Particulars Cost Per Unit Total Cost

Raw Material

Sugar = 30,000

Cocoa Butter = 30,000

Peanuts = 32,000

Peanuts = 20,000

Chocolate Coated Rasins = 40,000

Vanilin = 10,000

Almonds = 30,000

Honey = 5,000

Boston Baked Bean = 15,000

Direct Labour = 70,000 1.56 70,000

Carriage on Material = 24,250 0.53 24,250

Prime Cost 7.25 3,26,250

Cost Sheet

For one month

5.16 2,32,000

Total Output = 45,000 units

Factory expenses

Fixed

Depreciation on Plant and M/c = 25,750

Rent = 15,000

Power and Consumable Store = 15,000

Factory Insurance = 15,000

Supervisors Salary = 5,000

Variable

Electricity Charges = 5,000

Power and Consumable Store = 10,000

Running Expenses of Machine = 15,000

Factory Cost 9.60 4,32,000

Office and Administration Expenses 4.40 630,000

Selling & Distribution Expenses 2.00 90,000

Total Cost 16.00 7,20,000

Net Profit (20% on selling price) 4.00 1,80,000

Sales 20.00 9,00,000

2.35 1,05,750

Forward Logistics

The finished chocolates from manufacturing is stored in

the ware houses

Then comes the logistics and distribution where the goods

are packed and moved to various regional distribution

centers.

From RDCs the chocolates are distributed to different

outlets or Retailers

INNOVATIVE PACKAGING

(REVERSE LOGISTICS)

The innovation marks a potentially significant breakthrough for the food

and packaging industries, as it could pave the way for large numbers of

chocolate bars to be wrapped and sold in the stuff of their creation.

Approximately 10 tonnes of cocoa husk waste accounts for every single

tonne of dry cocoa bean produced, or 76% of the fruit itself. The company

says that, unlike other cocoa recycling processes, the paper is made without

burning or gradual degrading of the fibres of the cocoa husk, the finished

light brown paper utilises the cocoa as a natural colourant, avoiding the

need for artificial dyes

Modes of transportation

Transportation is necessary to Move purchased goods from

suppliers to buyers and move finished goods to the customer.

Modes of transport used by supplier

Road transport : It is flexible in nature and can be reached to

any parts of the country and it cost less as compare to other

modes of transport.

Rail carriers : compete most favorably when the distance is long

& the shipments are heavy or bulky.

Air carrier : Very expensive relative to other modes but

also very fast

Water carrier : In flexible and in expensive as compare to

others mode of transport

Demand requirements to design a

warehouse

Is demand high or low?

The new calorie free chocolate analysis shows that the change in calorie free

chocolate consumption occurred for both women (up from 18% in 2000 to

21% in 2010) and men (up from 14% to 19% in the same period).

Still, only about 20% of people are concerned of diet on any given day with

the majority (80%) not maintaining it , the report finds. It included calorie-

free and low-calorie versions

Overall, about half of the population, ages 2 and older, consume fatty things

on any given day. Among boys 2 to 19, 70% consume them while 40% of adult

women consume them.

Hence we can say that the demand for our product is high.

Warehouse design

As our product is not seasonal we have to have a strong warehouse design to

support our production and match our demand in the market. Which can

happen through maintaining proper consolidation and break-bulk, (2) sorting,

and (3) reverse logistics.

Our consolidation is very effective it goes in the following way

The warehouse receives materials, from a number of sources, that are

combined in exact quantities into a large single shipment to a specific

destination.

The benefits of our consolidations are

i. realization of the lowest possible freight rate,

ii. timely and controlled delivery, and

iii. reduced congestion at a customers receiving dock.

The warehouse enables both the inbound movement from origin and the

outbound movement to destination to be consolidated into a larger size

shipment, which generally results in lower transportation charges per unit

and most often quicker delivery

The design

Bulk breaking

A break-bulk operation receives a single large shipment and arranges for

delivery to multiple destinations. Economy of scale is achieved by transporting

the larger consolidated shipment. The break-bulk warehouse or terminal sorts

or splits out individual orders and arranges local delivery.

Sorting

The basic benefit of sorting is to reconfigure freight as it flows from origin to

destination. Three types of assortmentcross-docking, mixing.

a) cross-docking:

Our objective is to combine inventory from multiple origins into a pre specified

assortment for a specific customer. the jest of cross-docking is on-time delivery

from each manufacturer. The manufacturers, in turn, may have sorted, loaded,

and labeled the appropriate quantity by destination. Product is then literally

moved across the dock from receiving into a truck dedicated to the delivery

destination

Mixing :

mixing is usually performed at an intermediate location between shipment

origin and destination. carloads or truckloads of products are shipped from

origin to mixing warehouses. Upon arrival at the mixing warehouse, shipments

are unloaded and sorted into the combination desired by each customer.

These inbound shipments are planned to minimize inbound transportation

cost.

Reverse Logistics Processing

A great deal of the physical work related to reverse

logistics is performed at warehouses. Reverse logistics

includes the activities to support:

(1) returns management,

(2) remanufacturing and repair,

(3) remarketing,

(4) recycling, and

(5) disposal

LOCATION

The locations probably we select are going to cover would be mostly

the metro politan cities and regions where the IT sector is growing fast

REASONS

a) Less concern on health i.e the diet they take have more fat in it, as our

product is of low calories we may taste success in matching our

demand which is mentioned in the earlier slides

b) They have less time to concentrate on health and

c) Every person now and then picks up a chocolate now and then why

cant it be a lower calorie chocolate.

WAREHOUSE LOCATION

In planning warehouse layout, The most important product variables we

considered in a slotting plan are product velocity, weight, and special storage

requirements.

Product velocity is the major factor for driving our warehouse layout. High-

volume product should be positioned in the warehouse to minimize movement

distance.

As our product is high-velocity products it is positioned near doors, primary

aisles, and at lower levels in storage racks. Our positioning minimizes warehouse

handling and reduces the need for frequent lifting.Our Warehouse will be located

on outskirts of the city area like nearby to our customers i.e outer ring road

HI-TECH city.

PRIVATE WAREHOUSING

we also go with private warehousing the benefits we get

through this type of lay out are

a) control,

b) flexibility,

c) Cost reduction, and

d) a range of intangibles

flexibility provided by this type of warehousing are operating

policies, hours, and procedures can be adjusted to meet specific customer

and product requirements.

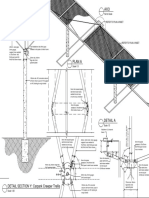

WAREHOUSE DESIGN

Warehouse design must consider product movement characteristics. Three

factors to be determined during the design process are the number of floors to

include in the facility, a cube utilization plan, and product flow.

The ideal warehouse design for us is one-floor building that eliminates the need

to move product vertically (reduces the time).

Our warehouses are designed with 25- to 30-foot clear ceilings, although

selected automated and high-rise handling equipment can effectively use

heights over 100 feet.

It supports straight product flow through the building.

Bill Of Material

Bill of Materials

Team: AMIGOS Date:

for how

many

months: 1 month

Description Qty

Unit of

Meas Unit Price ($) Total Price

Describe the Part

How

Many

Piece,

Inch, Etc. Cost Per Unit

coco beans 1000 kg $500.00 $500,000.00

milk 1000 liters $36.00 $36,000.00

sugar 1000 kg $70.00 $70,000.00

labour 25 humans $15,000.00 $375,000.00

eggs 1000 dozzen $36.00 $36,000.00

coco butter 1000 kg $800.00 $800,000.00

lactose 100

lit

er $200.00 $20,000.00

$0.00

Subtotals: $1,837,000.00

For calculating BOM we considered the materials required

to manufacture our product(for 1 month) and then

estimated the cost for each unit and finally to produce the

products for 1 month we incurred a cost of $1,837,000.00

For each year we have the capacity of producing 22,000

tones

The labors working hours will be 8 to 12 hrs a day.

Beans and coca

is mixed in the

factory

Milk+sugar to coca

mass=chocolate

liquid

chocolate liquid

evoprated=chocolat

e crumb

chocolate crumb

cooked to get

cadbury

Crumb to pin

mill mixed with

coco liquor &

butter

Assortments in to

bars

refining,

conching and

tempering

Smoothing of chocolet

wraping Product is ready

Process diagram

PRODUCTION LAYOUT

The layout we use is product layout.

Layout is in following way

PRODUCTION AREA

BEANS STORE AND COLD

ROOM SPRINKLER SYSTEMS

Warehouse sprinkler system

Central Stores Sprinkler System

Overall sprinkler system

Chocolate Craving Theories

Chocolate cravings are a result of the chemical ingredients

found in chocolate.

Chocolate cravings come from the sensory properties of

chocolate = texture, taste, smell, and color.

Chocolate cravings are influenced by culture.

Many theories exist, but there is no conclusive scientific

evidence on what causes people to crave chocolate.

Potential Health Benefits

Chocolate may be good for the heart.

Chocolate contains chemicals like those found in red

wine and green tea.

Helps improve circulation

Helps cut down blood pressure

Chocolate contains flavanols.

Helps in preventing the oxidations of bad cholesterol, which

reduces the stickiness of blood platelets and improve blood

vessel elasticity.

Theobromine, found in chocolate, was found to

treat coughs better than codeine.

AAA into supply chain

Agilitythe ability to respond quickly and cost-effectively to unexpected changeis

critical because in most industries, both demand and supply fluctuate more rapidly

and widely than they used to. In fact, the best companies use agile supply chains to

differentiate themselves from rivals.

Supply-chain agility and resilience no longer imply merely the ability to manage risk.

It now assumes that the ability to manage risk means being better positioned than

competitors to deal withand even gain advantage fromdisruptions. Key to

increasing agility and resilience is building flexibility into the supply-chain structure,

processes, and management.

Adaptability - The best companies tailor their supply chains to the nature of the

markets they serve. They often end up with more than one supply chain, which can be

expensive, but, in return, they secure the best manufacturing and distribution

capabilities for each offering.

All companies must align their supply-chain infrastructure and management with

their underlying value proposition to achieve a sustainable competitive advantage.

That is, they must align the interests of all the firms in the supply network so that

companies optimize the chains performance when they maximize their interests.

Alignment - One way companies align their partners interests with their own is by

redefining the terms of their relationships so that firms share risks, costs, and rewards

equitably. A prerequisite to creating alignment is the availability of information so that

all the companies in a supply chain have equal access to forecasts, sales data, and

plans. Next, partner roles and responsibilities must be carefully defined so that there is

no scope for conflict. Finally, companies must align incentives so that when companies

try to maximize returns, they also maximize the supply chains performance.

FUTURE OF THE PRODUCT

According to KPMG, there are almost two track market, the developed

and the developing. In the developed market a lot more innovation is

needed to grow or maintain the market share. In the developing

market like BRIC countries, manufacturers need to cater to the

specific consumer taste for growth. It also says industries response to

upcoming health regulation could mold the future.

Sustainable sourcing, packaging, and consolidation and outsourcing

chocolate manufacturing will be of growing importance. To grow in

emerging market a global set of local operations is needed. India is

anticipated to grow faster than all emerging markets according to

KPMG. There is an opportunity in new developing markets in eventing

and gifting chocolates, introduction of spices into chocolates can also

gain momentum.

The emergence of health legislation from national government could be

a threat to the industry. The industrys marketing capacity for

communicating the health benefits are yet to be realized by other

chocolatiers but regulation need not become burdensome for us

because we are bringing nutritional benefits in our chocolate.

There is a threat of decrease in supply of cocoa, which is the main

ingredient of our chocolate, in future.

You might also like

- Production Process in CadburyDocument10 pagesProduction Process in CadburyMeyyappan Siva100% (2)

- Goya Helps Latinos Maintain Mealtime Traditions-SentencesDocument4 pagesGoya Helps Latinos Maintain Mealtime Traditions-SentencespatrickdiemNo ratings yet

- A Detailed Study On Frito Lays PDFDocument12 pagesA Detailed Study On Frito Lays PDFhimanshuNo ratings yet

- CoSt AcCOunting Project RePOrtDocument28 pagesCoSt AcCOunting Project RePOrtsabeen ansari0% (1)

- Philippines Country PulseDocument64 pagesPhilippines Country PulseellochocoNo ratings yet

- Marketing PlanDocument9 pagesMarketing PlanMaher Zain RaufNo ratings yet

- Hershey'S QSPM Matrix: Strategies 1 Key Internal Factors Weights AS StrengthsDocument7 pagesHershey'S QSPM Matrix: Strategies 1 Key Internal Factors Weights AS StrengthsSofiaNo ratings yet

- Imc of CadburyDocument22 pagesImc of Cadburymanoj_yadav_975% (4)

- Production ProcessDocument38 pagesProduction ProcessEdovani PinanditaNo ratings yet

- Statement of The ProblemDocument2 pagesStatement of The ProblemAnthonyNo ratings yet

- Hindalco Industries Ltd000Document19 pagesHindalco Industries Ltd000Parshant Chohan100% (1)

- A Study of Consumer Buying Behavior in Retail Sector Like BIG BAZAARDocument83 pagesA Study of Consumer Buying Behavior in Retail Sector Like BIG BAZAARAlok kumarNo ratings yet

- BR Assignment Complete Print ThisDocument26 pagesBR Assignment Complete Print ThisJing WenNo ratings yet

- C05 - Starbucks - Staying Local While Going Global Through Marketing ResearchDocument2 pagesC05 - Starbucks - Staying Local While Going Global Through Marketing ResearchSafowanNo ratings yet

- SupplyChainManagement - BlueBandDocument22 pagesSupplyChainManagement - BlueBandatif_810% (1)

- Cola WarsDocument6 pagesCola WarsRizal Daujr Tingkahan IIINo ratings yet

- Seria L No. Table of Contents NoDocument14 pagesSeria L No. Table of Contents NoKalwinder Dhillon0% (2)

- Bird's EyeDocument4 pagesBird's EyePranav AnandNo ratings yet

- Economics AssignmentDocument5 pagesEconomics AssignmentPRAVEENKUMAR MNo ratings yet

- Coca Cola External Facto Evaluation Matrix (EFE Matrix) : External Strategic Factor Weight Rating Weighted Score CommentsDocument3 pagesCoca Cola External Facto Evaluation Matrix (EFE Matrix) : External Strategic Factor Weight Rating Weighted Score CommentsNaoman ChNo ratings yet

- Coca Cola PracticumDocument4 pagesCoca Cola PracticumKabunian Dakila Acio IIINo ratings yet

- Sample MissionDocument5 pagesSample MissionDing PolisticoNo ratings yet

- KFC Case StudyDocument4 pagesKFC Case StudyShradha PadhiNo ratings yet

- Marketing Plan HorlicksDocument17 pagesMarketing Plan HorlicksMd. Azad Hossain0% (1)

- Coca ColaDocument7 pagesCoca ColaAnonymous pZ4X8tK8QNo ratings yet

- Case Study Uk EnterDocument3 pagesCase Study Uk EnterUsman KhalidNo ratings yet

- A Submitted in The Partial Fulfillment of The Requirement For The Award of The Degree of Bachelor of Business AdministrationDocument64 pagesA Submitted in The Partial Fulfillment of The Requirement For The Award of The Degree of Bachelor of Business AdministrationdghdgNo ratings yet

- KurkureDocument8 pagesKurkurekushal agrawalNo ratings yet

- EFE... and External AuditDocument21 pagesEFE... and External Auditvicky_00753No ratings yet

- Kellogg's Indian Experience A Failed Business StrategyDocument5 pagesKellogg's Indian Experience A Failed Business StrategyVikrantKumar Pasnoorwar PNo ratings yet

- Group 5 Research ProposalDocument9 pagesGroup 5 Research ProposalxpertseoNo ratings yet

- The Dabbawalas of Mumbai 08Document8 pagesThe Dabbawalas of Mumbai 08ajabrao100% (2)

- Submitted By: Bhoomika Sehgal Bba Iv SemDocument36 pagesSubmitted By: Bhoomika Sehgal Bba Iv SemBhoomikaSehgalNo ratings yet

- Pricing StrategyDocument2 pagesPricing StrategyRupam ChakrabortyNo ratings yet

- Cheetos RepositioningDocument19 pagesCheetos RepositioningMansi ChauhanNo ratings yet

- MC Donald's in Saudi ArabiaDocument15 pagesMC Donald's in Saudi ArabiaSravan SakkhariNo ratings yet

- Business Strategy of Cadbury India Limite1Document4 pagesBusiness Strategy of Cadbury India Limite1Shivam yadavNo ratings yet

- Nescafé With Complete ChartsDocument39 pagesNescafé With Complete ChartsGHGFYGJNo ratings yet

- Short Case Studies - ICBPDocument3 pagesShort Case Studies - ICBPmikamNo ratings yet

- StarbucksDocument5 pagesStarbucksDeepika RastogiNo ratings yet

- McDonald's+Case+Study by Rahul RK (9986510206)Document6 pagesMcDonald's+Case+Study by Rahul RK (9986510206)rahulkmarNo ratings yet

- Ice CreamDocument17 pagesIce CreamPinal KakadiyaNo ratings yet

- Marketing ProjectDocument9 pagesMarketing ProjectkherasiddharthNo ratings yet

- Business AnalysisDocument6 pagesBusiness Analysiskittu111No ratings yet

- Final Soul ShoesDocument64 pagesFinal Soul Shoesadeel100% (3)

- Chapter 1: Consumers RuleDocument28 pagesChapter 1: Consumers RuleKARCHISANJANANo ratings yet

- Farm Record & Balance SheetDocument29 pagesFarm Record & Balance SheetHaikal SapurataNo ratings yet

- IKEA India SeminarPaper2020 Shuporna MEM19 PDFDocument25 pagesIKEA India SeminarPaper2020 Shuporna MEM19 PDFbenNo ratings yet

- Product MixDocument16 pagesProduct Mixvinod_auraNo ratings yet

- Indian Frozen Yogurt MarketDocument14 pagesIndian Frozen Yogurt Marketaakriti aroraNo ratings yet

- Analysis of Retail IndustryDocument11 pagesAnalysis of Retail IndustryVipul ThapaNo ratings yet

- Kelloggs Indian ExperienceDocument9 pagesKelloggs Indian ExperienceanmolNo ratings yet

- Starbucks Supply ChainDocument22 pagesStarbucks Supply ChainXandarnova corpsNo ratings yet

- BritanniaDocument5 pagesBritanniaakanksha1314No ratings yet

- Customer Perception of KFC in BhilaiDocument11 pagesCustomer Perception of KFC in Bhilaipooja raiNo ratings yet

- RefrigeratorsDocument9 pagesRefrigeratorsAbhishek Mahto100% (1)

- HR Practices IntelDocument19 pagesHR Practices IntelKomal Mehta100% (1)

- CadburyDocument11 pagesCadburyArchit AprameyanNo ratings yet

- NestleDocument2 pagesNestleankita1301No ratings yet

- C 17 PDIPR Assignment 2Document9 pagesC 17 PDIPR Assignment 2Sichika LokhandeNo ratings yet

- HAYAT - CLINIC BrandbookDocument32 pagesHAYAT - CLINIC BrandbookBlankPointNo ratings yet

- JP Selecta IncubatorDocument5 pagesJP Selecta IncubatorAhmed AlkabodyNo ratings yet

- Liquid Chlorine SdsDocument7 pagesLiquid Chlorine SdsIPKL RS BHAYANGKARA KEDIRINo ratings yet

- Ymrtc LogDocument26 pagesYmrtc LogVinicius Silveira0% (1)

- Progress Report 1Document3 pagesProgress Report 1api-302815786No ratings yet

- TrellisDocument1 pageTrellisCayenne LightenNo ratings yet

- Migne. Patrologiae Cursus Completus: Series Latina. 1800. Volume 51.Document516 pagesMigne. Patrologiae Cursus Completus: Series Latina. 1800. Volume 51.Patrologia Latina, Graeca et OrientalisNo ratings yet

- Lesson Plan SustainabilityDocument5 pagesLesson Plan Sustainabilityapi-501066857No ratings yet

- GTA IV Simple Native Trainer v6.5 Key Bindings For SingleplayerDocument1 pageGTA IV Simple Native Trainer v6.5 Key Bindings For SingleplayerThanuja DilshanNo ratings yet

- Countable 3Document2 pagesCountable 3Pio Sulca Tapahuasco100% (1)

- Q4 Music 6 Module 2Document15 pagesQ4 Music 6 Module 2Dan Paolo AlbintoNo ratings yet

- BS en Iso 06509-1995 (2000)Document10 pagesBS en Iso 06509-1995 (2000)vewigop197No ratings yet

- Understanding The Marshall AttackDocument6 pagesUnderstanding The Marshall Attacks.for.saad8176No ratings yet

- Project Manager PMP PMO in Houston TX Resume Nicolaas JanssenDocument4 pagesProject Manager PMP PMO in Houston TX Resume Nicolaas JanssenNicolaasJanssenNo ratings yet

- Zahid Imran CVDocument4 pagesZahid Imran CVDhia Hadj SassiNo ratings yet

- Homework 1Document8 pagesHomework 1Yooncheul JeungNo ratings yet

- Acampamento 2010Document47 pagesAcampamento 2010Salete MendezNo ratings yet

- LavazzaDocument2 pagesLavazzajendakimNo ratings yet

- BioremediationDocument21 pagesBioremediationagung24864No ratings yet

- Electric Motor Cycle and ScooterDocument9 pagesElectric Motor Cycle and ScooterA A.DevanandhNo ratings yet

- Ed Post Lab Heat of Formation of NaClDocument4 pagesEd Post Lab Heat of Formation of NaClEdimar ManlangitNo ratings yet

- Tetra IntroductionDocument65 pagesTetra Introductionuniversidaddistrital100% (2)

- Ac221 and Ac211 CourseoutlineDocument10 pagesAc221 and Ac211 CourseoutlineLouis Maps MapangaNo ratings yet

- Business CombinationsDocument18 pagesBusiness Combinationszubair afzalNo ratings yet

- The BetterPhoto Guide To Creative Digital Photography by Jim Miotke and Kerry Drager - ExcerptDocument19 pagesThe BetterPhoto Guide To Creative Digital Photography by Jim Miotke and Kerry Drager - ExcerptCrown Publishing GroupNo ratings yet

- Vernacular ArchitectureDocument4 pagesVernacular ArchitectureSakthiPriya NacchinarkiniyanNo ratings yet

- Specialty Coffee Association of Indonesia Cupping Form (ARABICA)Document1 pageSpecialty Coffee Association of Indonesia Cupping Form (ARABICA)Saiffullah RaisNo ratings yet

- Settlement Report - 14feb17Document10 pagesSettlement Report - 14feb17Abdul SalamNo ratings yet

- Properties of LiquidsDocument26 pagesProperties of LiquidsRhodora Carias LabaneroNo ratings yet

- s15 Miller Chap 8b LectureDocument19 pagess15 Miller Chap 8b LectureKartika FitriNo ratings yet