Professional Documents

Culture Documents

Aggregate Planning Based On Chase

Uploaded by

prabhupadhiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aggregate Planning Based On Chase

Uploaded by

prabhupadhiCopyright:

Available Formats

Bharat Kantharia

Aggregate Planning

Operations & Supply Management

Semester-II

UnitedWorld, Ahmedabad

Aggregate Planning

Definition

Aggregate Planning is concerned with matching

supply and demand of output over the medium

time range, up to approximately 3 to 12 months

into the future. Term aggregate implies that the

planning is done for a single overall measure of

output (equivalent units) or, at the most, a few

aggregated product categories. Aim of aggregate

planning is to set overall output levels in the near

to medium future in the face of fluctuating or

uncertain demands. Aggregate planning might

seek to influence demand as well as supply

Aggregate Planning

Definition

Aggregate planning has certain prerequired inputs which

are inevitable. They include:

Information about the resources and the facilities

available.

Demand forecast for the period for which the

planning has to be done.

Cost of various alternatives and resources. This

includes cost of holding inventory, ordering cost, cost

of production through various production alternatives

like subcontracting, backordering and overtime.

Organizational policies regarding the usage of above

alternatives.

Bharat Kantharia

Bharat Kantharia

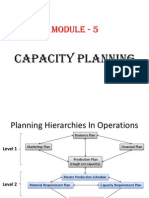

Process planning

Strategic capacity

planning

Sales and operations

(aggregate) planning

Sales

plan

Aggregate

operations

plan

Supply network

planning

Forecasting and

demand management

Master scheduling

Material requirements

planning

Order scheduling

Vehicle capacity

planning

Vehicle loading

Vehicle dispatching

Warehouse

receipt

planning

Weekly

workforce

scheduling

Daily workforce

scheduling

Manufacturing Logistics Services

Long

range

Medium

range

Short

range

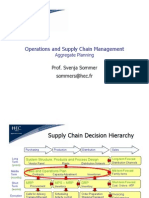

Sales & Operations Planning

Sales & Operations Planning

Long-range planning

Greater than one year planning horizon

Usually performed in annual increments

Medium-range planning

Six to eighteen months

Usually with weekly, monthly or quarterly

increments

Short-range planning

One day to less than six months

Usually with weekly or daily increments

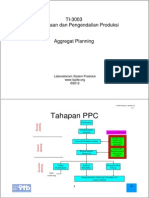

Required Inputs to the Production Planning System

Planning

for

production

External

capacity

Competitors

behavior

Raw material

availability

Market

demand

Economic

conditions

Current

physical

capacity

Current

workforce

Inventory

levels

Activities

required

for

production

External

to firm

Internal

to firm

Key Strategies for Meeting Demand

Chase Strategy: Match production (supply) to demand by

hiring or firing workers

Level strategy: Maintain stable workforce @ constant

output. Shortages/surpluses are absorbed by fluctuating

inventory, order backlog, lost sales. Service levels vary.

Stable workforce- varying work hours: Vary output by

varying no of hours worked thru flexible work schedules &

overtime

Mixed Strategies

Company policies

Usage of two or more control variables eg. Combination

of subcontracting & OT or Inventory & OT

Relevant Costs

Basic Production Costs: Fixed, variable costs

for producing a given product type in a given

time period. Direct & indirect costs

Costs associated with changes in production

rate: Hiring, firing, training : Hiring temporaries

Inventory Holding/Carrying Costs: Capital

tied-up

Backordering costs: cost of expediting, loss of

customer goodwill, loss of sales revenues

Bharat Kantharia

Analyzing Costs

Production Rate Vs Regular

Time Prod. Cost

Workforce Size Vs Regular

time Prod. Cost

Bharat Kantharia

Analyzing Costs

Impact of Cost of overtime &

idle time on Prod. Cost

Incremental Cost of Prod. Vs

Prod. Rate Basis Changing

Workforce

Bharat Kantharia

Analyzing Costs

Aggregate Inventory Level

Inventory, Backorder &

Shortage Costs

Bharat Kantharia

Aggregate Planning Strategies

Top-down approach

Bottoms-up approach Basis Capacity

Requirements Planning

Bharat Kantharia

Aggregate Planning Example : Data

January February March April May June Totals

Demand Forecast 1800 1500 1100 900 1100 1600 8000

No Of Working Days 22 19 21 21 22 20 125

Bharat Kantharia

Title Per Costs /Value

Materials $/Unit 100

Inv. Holding Cost $/ Unit per Month 1.5

Marginal Cost of Stockout $ Per Unit Month 5

Hiring & Training Cost $ Per Worker 200

Layoff Costs $ Per Worker 250

Labour Hrs Reqd. Per Unit Hrs/Unit 5

Straight Time Labour Cost (8 Hrs) $ / Hr 4

Beginning Inventory Units 400

Paid Hrs / Day Hrs /Day 8

Policy: Safety Stock Reqd. Of Monthly

Demand Units 25%

Marginal Cost of Subcontracting $/Unit 20

Overtime Cost /Hr : 150% $/Hr 6

Aggregate Planning : (Chase)

Bharat Kantharia

Comparison of Four Plans

Cost Type Plan1 Chase

Demand

Plan2

Constant

Workforce

Plan3

Constant

Workforce +

SubCon

Plan4

Constant

Workforce +

OT

Hiring 5800 0 0 0

Layoff 7000 0 0 0

Excess

Inventory

0 948 0 1281

Shortage 0 1540 0 0

Subcontract 0 0 60000 0

Overtime 0 0 0 12210

Straight

Time

160000 160000 100000 152000

Totals 172800 162488 160000 165491

Bharat Kantharia

Transportation Method

Demand

Forecast Supply Capacity

Period Units of Demand Regular Time Overtime Subcontract

1 500 700 250 500

2 800 800 250 500

3 1700 900 250 500

4 900 500 250 500

Total 3900

Bharat Kantharia

Initial Inventory Units 100

Desired Final Inventory Units 150

Regular Time Cost Cost/Unit 100

Overtime Cost Cost/Unit 125

Subcontract Cost Cost/Unit 150

Inventory Cost (period) Cost/Unit Time 20

Unused Regular Time Cost Cost/Unit 40

Transportation Method

Bharat Kantharia

Comparison of Different Methods

You might also like

- Book of IQ TestsDocument124 pagesBook of IQ TestsFox Mango100% (4)

- Capacity Requirement PlanningDocument11 pagesCapacity Requirement PlanningVi H ArNo ratings yet

- Microbiological Quality Ice CreamDocument9 pagesMicrobiological Quality Ice CreamocortezlariosNo ratings yet

- Deloitte - Introduction To TS&A - CloudDocument2 pagesDeloitte - Introduction To TS&A - Cloudsatyam100% (1)

- 8D & 7QC ToolsDocument117 pages8D & 7QC ToolsAshok Kumar100% (1)

- Full Download Ebook PDF Introductory Econometrics A Modern Approach 7th Edition by Jeffrey PDFDocument42 pagesFull Download Ebook PDF Introductory Econometrics A Modern Approach 7th Edition by Jeffrey PDFtimothy.mees27497% (39)

- Earth and Life Science, Grade 11Document6 pagesEarth and Life Science, Grade 11Gregorio RizaldyNo ratings yet

- Production Planning and Inventory ManagementDocument23 pagesProduction Planning and Inventory ManagementMuhammad Bilal100% (1)

- Ziarek - The Force of ArtDocument233 pagesZiarek - The Force of ArtVero MenaNo ratings yet

- Capacity PlanningDocument55 pagesCapacity PlanningSatyajeet Chauhan75% (4)

- Aggregate PlanningDocument46 pagesAggregate PlanningSatyajeet ChauhanNo ratings yet

- Aggregate Sales and Operations PlanningDocument30 pagesAggregate Sales and Operations PlanningperuibsNo ratings yet

- Aggregate PlanningDocument134 pagesAggregate PlanningPriya Singh100% (1)

- Aggregate Planning OPCDocument20 pagesAggregate Planning OPCMaithili PrabhuNo ratings yet

- Aggregate Planning ExampleDocument6 pagesAggregate Planning ExampleAbhishek FanseNo ratings yet

- Capacity Planning Module - 5Document54 pagesCapacity Planning Module - 5sreeragsivanNo ratings yet

- Operations and Supply Chain Management: Prof. Svenja Sommer Sommers@Document22 pagesOperations and Supply Chain Management: Prof. Svenja Sommer Sommers@michmich1245No ratings yet

- Strategic Capacity Planning For Products and ServicesDocument33 pagesStrategic Capacity Planning For Products and ServicesGerlyn Briones100% (1)

- Aggregates Sales and Operations PlanningDocument31 pagesAggregates Sales and Operations PlanningIan Kenneth MarianoNo ratings yet

- Aggrigate Planning in TATA MotorsDocument28 pagesAggrigate Planning in TATA Motorsmayurgharat50% (2)

- Tahapan PPC: TI-3003 Perencanaan Dan Pengendalian ProduksiDocument30 pagesTahapan PPC: TI-3003 Perencanaan Dan Pengendalian ProduksiPriscarine PrizNo ratings yet

- AWS Compete CustomerDocument33 pagesAWS Compete CustomerSergeyNo ratings yet

- Objectives of Aggregate Planning Normally AreDocument22 pagesObjectives of Aggregate Planning Normally AreSagar YadavNo ratings yet

- Aggregate PlanningDocument55 pagesAggregate PlanningJuvin IcNo ratings yet

- Aggregate PlanningDocument20 pagesAggregate PlanningSidharth GoyalNo ratings yet

- Aggregate Planning: Ragandap, John Paul BDocument17 pagesAggregate Planning: Ragandap, John Paul BJAYPEE bobiasNo ratings yet

- A Presentation On Aggregate PlanningDocument17 pagesA Presentation On Aggregate PlanningAhel Patrick VitsuNo ratings yet

- POM Aggregate PlanningDocument17 pagesPOM Aggregate PlanningAhel Patrick VitsuNo ratings yet

- Aggregate Planning: For Academic Purpose and Private Circulation OnlyDocument28 pagesAggregate Planning: For Academic Purpose and Private Circulation OnlyKushal KapoorNo ratings yet

- PPCDocument94 pagesPPCManoz RijalNo ratings yet

- AggPlanning - PKBDocument47 pagesAggPlanning - PKBAugust LewisNo ratings yet

- Aggregate PlanningDocument29 pagesAggregate Planningj04preetNo ratings yet

- Operations Management: Aggregate PlanningDocument16 pagesOperations Management: Aggregate PlanningArun MishraNo ratings yet

- MPD412 - Ind Org - Lecture-04-AP - Part ADocument20 pagesMPD412 - Ind Org - Lecture-04-AP - Part AMohamed OmarNo ratings yet

- Aggregate PlanningDocument12 pagesAggregate PlanningRahul KukrejaNo ratings yet

- Om Unit IvDocument40 pagesOm Unit Ivvamsi thotaNo ratings yet

- Chapter 5Document57 pagesChapter 5Girma MeleseNo ratings yet

- Sales and Operations PlanningDocument16 pagesSales and Operations PlanningSahil TawdeNo ratings yet

- Aggregate Planning and Its Techniques A P: Ggregate LanningDocument9 pagesAggregate Planning and Its Techniques A P: Ggregate LanningPrashant SinghNo ratings yet

- Aggregate Production PlanningDocument32 pagesAggregate Production PlanningupendraNo ratings yet

- Wk4 Capacity PLGDocument22 pagesWk4 Capacity PLGKausik KskNo ratings yet

- MENG148 - Module 5Document20 pagesMENG148 - Module 5Reimon DoblonNo ratings yet

- Aggregate Sales and Operations PlanningDocument26 pagesAggregate Sales and Operations Planningira_mishra_3No ratings yet

- Aggregate Planning in The Supply ChainDocument15 pagesAggregate Planning in The Supply ChainPrasad GantiNo ratings yet

- OM II - Class 6Document21 pagesOM II - Class 6Ashima AggarwalNo ratings yet

- OM Chapter Four-1Document39 pagesOM Chapter Four-1Getahun MulatNo ratings yet

- Aggregate Planning + MPS +capacity PlanningDocument21 pagesAggregate Planning + MPS +capacity PlanningAnoo PsNo ratings yet

- PPT12 Aggregate Production PlanningDocument12 pagesPPT12 Aggregate Production Planningshivam1992No ratings yet

- Aggregate Sales and Operations PlanningDocument13 pagesAggregate Sales and Operations Planningzakria100100No ratings yet

- Aggregate (Sales & Operations) PlanningDocument23 pagesAggregate (Sales & Operations) Planning199388No ratings yet

- Material Management: Unit IDocument65 pagesMaterial Management: Unit ISownthariya TNo ratings yet

- Aggregate PlanningDocument29 pagesAggregate PlanningkushalNo ratings yet

- Operations Management: Sales and Aggregate PlanningDocument46 pagesOperations Management: Sales and Aggregate PlanningKrishna MurariNo ratings yet

- Week 4 - Capacity MGMTDocument35 pagesWeek 4 - Capacity MGMTHenry TianNo ratings yet

- Aggregateplanning 091012124927 Phpapp02Document21 pagesAggregateplanning 091012124927 Phpapp02نشوان العريقيNo ratings yet

- Aggregate Planning: By, Brijesh R. Ved (70/B)Document22 pagesAggregate Planning: By, Brijesh R. Ved (70/B)a_roy003No ratings yet

- Aggrigate PlanningDocument6 pagesAggrigate PlanningAjit ChoudhariNo ratings yet

- Inventory Is TheDocument16 pagesInventory Is TheEmba MadrasNo ratings yet

- Aggregate PlanningDocument10 pagesAggregate PlanningKetan VishwakarmaNo ratings yet

- Aggregate PlanningDocument28 pagesAggregate PlanningAdil ShaikhNo ratings yet

- Production Planning and ControlDocument28 pagesProduction Planning and ControlSAMRUDA SADANANDNo ratings yet

- Resource PlanningDocument22 pagesResource PlanningIyad KoteichNo ratings yet

- 1 Construction Materials ManagementDocument6 pages1 Construction Materials ManagementSyed ShaheenNo ratings yet

- Chapter 5 Capacity PlanningDocument78 pagesChapter 5 Capacity PlanningAnthony Royupa100% (1)

- Aggregate Planning Strategies of SCMDocument4 pagesAggregate Planning Strategies of SCMRubaiyat IslamNo ratings yet

- Management Accounting Strategy Study Resource for CIMA Students: CIMA Study ResourcesFrom EverandManagement Accounting Strategy Study Resource for CIMA Students: CIMA Study ResourcesNo ratings yet

- Dove Hair CareDocument5 pagesDove Hair CareprabhupadhiNo ratings yet

- Financial ManagementDocument16 pagesFinancial ManagementprabhupadhiNo ratings yet

- Customer Satisfaction Hyundai MotorsDocument72 pagesCustomer Satisfaction Hyundai MotorsprabhupadhiNo ratings yet

- Customer Satisfaction Hyundai MotorsDocument72 pagesCustomer Satisfaction Hyundai MotorsprabhupadhiNo ratings yet

- TRAVEL POLICY CARLO URRIZA OLIVAR Standard Insurance Co. Inc - Travel Protect - Print CertificateDocument4 pagesTRAVEL POLICY CARLO URRIZA OLIVAR Standard Insurance Co. Inc - Travel Protect - Print CertificateCarlo OlivarNo ratings yet

- Carbonate Platform MateriDocument8 pagesCarbonate Platform MateriNisaNo ratings yet

- Listening Tests 81112Document13 pagesListening Tests 81112luprof tpNo ratings yet

- (Kazantzakis Nikos) Freedom or DeathDocument195 pages(Kazantzakis Nikos) Freedom or DeathTarlan FisherNo ratings yet

- 04 Membrane Structure NotesDocument22 pages04 Membrane Structure NotesWesley ChinNo ratings yet

- Presentación de Power Point Sobre Aspectos de La Cultura Inglesa Que Han Influido en El Desarrollo de La HumanidadDocument14 pagesPresentación de Power Point Sobre Aspectos de La Cultura Inglesa Que Han Influido en El Desarrollo de La HumanidadAndres EduardoNo ratings yet

- Analysis of MMDR Amendment ActDocument5 pagesAnalysis of MMDR Amendment ActArunabh BhattacharyaNo ratings yet

- PPT-QC AcDocument34 pagesPPT-QC AcAmlan Chakrabarti Calcutta UniversityNo ratings yet

- USTH Algorithm RecursionDocument73 pagesUSTH Algorithm Recursionnhng2421No ratings yet

- 0409 Book About Minoru Yamasaki, ReviewDocument4 pages0409 Book About Minoru Yamasaki, RevieweviannNo ratings yet

- Operator'S Manual PM20X-X-X-BXX: 2" Diaphragm PumpDocument12 pagesOperator'S Manual PM20X-X-X-BXX: 2" Diaphragm PumpOmar TadeoNo ratings yet

- Ducati WiringDocument7 pagesDucati WiringRyan LeisNo ratings yet

- ARTS10 Q2 ModuleDocument12 pagesARTS10 Q2 ModuleDen Mark GacumaNo ratings yet

- U2 KeyDocument2 pagesU2 KeyHằng ĐặngNo ratings yet

- 50 Law-Firms Details by Vaibhav SharmaDocument17 pages50 Law-Firms Details by Vaibhav SharmaApoorva NandiniNo ratings yet

- Technical DescriptionDocument2 pagesTechnical Descriptioncocis_alexandru04995No ratings yet

- Course: Introduction To Geomatics (GLS411) Group Practical (2-3 Persons in A Group) Practical #3: Principle and Operation of A LevelDocument3 pagesCourse: Introduction To Geomatics (GLS411) Group Practical (2-3 Persons in A Group) Practical #3: Principle and Operation of A LevelalyafarzanaNo ratings yet

- 2021-01-01 - Project (Construction) - One TemplateDocument1,699 pages2021-01-01 - Project (Construction) - One TemplatemayalogamNo ratings yet

- Ibragimova Lesson 4Document3 pagesIbragimova Lesson 4Dilnaz IbragimovaNo ratings yet

- Teal Motor Co. Vs CFIDocument6 pagesTeal Motor Co. Vs CFIJL A H-DimaculanganNo ratings yet

- Service Letter Service Letter Service Letter Service Letter: Commercial Aviation ServicesDocument3 pagesService Letter Service Letter Service Letter Service Letter: Commercial Aviation ServicesSamarNo ratings yet

- Mahindra First Choice Wheels LTD: 4-Wheeler Inspection ReportDocument5 pagesMahindra First Choice Wheels LTD: 4-Wheeler Inspection ReportRavi LoveNo ratings yet