Professional Documents

Culture Documents

Good Manufacturing Practices PP

Uploaded by

Free Escort ServiceOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Good Manufacturing Practices PP

Uploaded by

Free Escort ServiceCopyright:

Available Formats

Good Manufacturing

Practices

Developed by

Agenda

Good Manufacturing Practices

Contamination

General Employee Hygiene

Food Handling Practices

Good Manufacturing Practices

Deal with contamination

by people

by food materials

by packaging materials

by hazardous materials

by miscellaneous materials

General Employee

Hygiene

Hygiene

All employees working in direct contact with

food, food contact surfaces and food

packaging must conform to hygienic practices.

This protects against food contamination by

microorganisms or unwanted material.

Prevent contamination

Careless employee practices can cause

product contamination.

The best way to avoid contamination is to

prevent it.

How do we prevent

contamination?

Any behavior that could result in food

contamination such as eating, use of

tobacco, chewing gum or other

unhygienic practices, is not allowed in

food handling areas

Hygiene and Communicable Diseases

clothing

hair

personal habits

hand washing

personal effects and

jewelry

illness and disease

injuries

visitors

training

Production employees

Bathe daily

No perfume, aftershave, fragrant creams

No jewellery

No false nails or nail polish

Fingernails should be trimmed short

Use metal detectable bandages covered with gloves

No eating, drinking or chewing gum

Clothing

Everyone must wear pants and covered sleeves.

Separate shoes (no open toes or high heels) are to

be worn in the factory.

Personal belongings and street clothing must be

stored in locker rooms.

Illness

Doctors certificate on hiring

Inform your supervisor or HR if you are ill with

symptoms that could contaminate ingredients or

products

No medication allowed in factory

Ensure that a clean bandage covers any open

wounds

Hand washing

All employees must wash their hands thoroughly:

when they enter food handling areas

before starting work

after handling contaminated materials

after breaks

after using toilet facilities

Food Handling Practices

Personnel

Do not leave gloves, masks, etc. lying

around while on break or at shift end.

Crates, boxes, containers or buckets must not

be placed directly on the floor.

Store brooms and dust pans at stations

provided.

Product

Keep hand contact with ingredients to a minimum.

Check ingredients for expiration dates to ensure

that fresh ingredients are used.

Cooling product should always be kept covered.

Equipment, containers and utensils

Use white or brown

containers to store

ingredients and rework.

Use gray

containers for

garbage. Garbage

containers must be

kept covered.

Ensure that all containers, including those

holding rework, are properly labelled and are

kept covered.

Cloths

Use white cloths to wipe

hands regularly and

dispose of soiled cloths

immediately. No moist

cloths are to be left in the

production area.

Use yellow cloths to

clean the floor and

objects (e.g. step stools)

that come into contact

with the floor.

Utensils

Scrapers for moulds and tabletops are not to be

used on the floor.

Production equipment/utensils must be thoroughly

cleaned and sanitized with alcohol after use.

Premises

Keep unscreened doors and windows closed.

Report any pests or evidence of pests such as

flies, insects, mice droppings.

Equipment

Return tools and attachments to their proper place

after use.

Check product surfaces before starting

equipment. Remove any foreign objects or dirt.

Replace brushes that lose bristles.

Personnel Practices

Do not lean, sit or step on product surfaces.

Do not handle ingredients or products with either

cut or infected hands.

Do not engage in horseplay.

Keep hand contact with ingredients and product

to a minimum.

Sanitation

Keep contact surfaces clean and free of

contamination from tools, cords, cleaning

utensils, machine parts, lubricants and paper.

Clean all spills promptly.

Keep everything off the floor and the area

clean and floors swept.

Work areas should be cleaned regularly

throughout the shift.

Keep your immediate working area swept or dust

mopped. Wipe or mop up spilled liquids promptly.

Scrape the floor around the work area after

completing a job.

Leave your work area clean at the end of your

shift.

Receiving and Storage

Ensure that all pallets and materials are kept at

least 18 away from the walls.

Inspect torn bags and boxes and then repair if

appropriate.

Brush off bags and boxes before opening

them.

Store ingredients and products at the

appropriate temperature.

Receiving & Storage

Use ingredients in the proper rotation (oldest

stock first)

Handle ingredients or products carefully to

avoid spilling

Do not return products or ingredients to the

production line after they have touched the

floor or any other surface that is not clean.

Maintenance and Repairs

Ensure area is segregated from production by

use of tarps.

Do not leave maintenance supplies in the

product zone.

Return all tools and attachments to their proper

place after use.

Ensure the production area is clear of all tools

and hazards before production starts

Retail store

Monitor and maintain proper temperatures

Rotate ingredients using FIFO and check for expired items.

Check best before dates and the quality of the food before

using.

Refrigerate cold foods immediately upon receipt.

Sanitize equipment, cutting boards, work surfaces and

utensils.

Always wash hands after handling money.

Visitors to Production Areas

Should always be accompanied.

Must be appropriately dressed - hair coverings,

booties over street shoes, gloves, sleeve covers,

etc.

Quiz

Spot the Hazards:

Good Manufacturing Practices

Practical application

On the job.....

Think about food safety as you work

Watch for hazards and remove any that you find

Questions ?

You might also like

- The Worldwide Impacts of SchizophreniaDocument10 pagesThe Worldwide Impacts of SchizophreniaMadusha PereraNo ratings yet

- Sanitation SOP PDFDocument2 pagesSanitation SOP PDFbetterthandrugsNo ratings yet

- ISO 22716 Good Manufacturing Practices (Cosmetics)Document33 pagesISO 22716 Good Manufacturing Practices (Cosmetics)Chiekoi Pasaoa100% (1)

- Merchant Accounts Are Bank Accounts That Allow Your Business To Accept Card Payments From CustomersDocument43 pagesMerchant Accounts Are Bank Accounts That Allow Your Business To Accept Card Payments From CustomersRohit Kumar Baghel100% (1)

- Iso 13690 1999 FR PDFDocument8 pagesIso 13690 1999 FR PDFAlfonso RecioNo ratings yet

- Mineral Claim Purchase and Sale Agreement FinalDocument5 pagesMineral Claim Purchase and Sale Agreement Finaldaks4uNo ratings yet

- Batch Production RecordDocument83 pagesBatch Production Recordsina yadegari100% (1)

- Inclusions in Gross IncomeDocument2 pagesInclusions in Gross Incomeloonie tunesNo ratings yet

- GMP TrainingDocument34 pagesGMP TrainingRohith100% (1)

- Processing of Dehydrated FruitsDocument74 pagesProcessing of Dehydrated FruitsJenina Rosa P. LlanesNo ratings yet

- Cleaning and Sanitation PPDocument28 pagesCleaning and Sanitation PPchemist_tmaNo ratings yet

- SOP For Food ProductionDocument3 pagesSOP For Food ProductionANGELOU SAGARAL50% (2)

- Induction Training - 2021Document95 pagesInduction Training - 2021Fajar PrasetyoNo ratings yet

- 039-Itp For Embedded Plate PDFDocument7 pages039-Itp For Embedded Plate PDFKöksal PatanNo ratings yet

- GMP Inspection ChecklistDocument5 pagesGMP Inspection ChecklistJon MarkNo ratings yet

- PNS BAFS Feed Pellet MillDocument26 pagesPNS BAFS Feed Pellet MillCiel ParkNo ratings yet

- Breweries: Process Wastewater TreatmentDocument8 pagesBreweries: Process Wastewater TreatmentJonathan Quispe TNo ratings yet

- Hygienic and Sanitary Practices For Bakery - Basic LevelDocument76 pagesHygienic and Sanitary Practices For Bakery - Basic LevelTrishitmandas100% (2)

- GMP's For Ice MakingDocument6 pagesGMP's For Ice MakingmailmeaeNo ratings yet

- SC Wheat-Soya Blend With Sugar 1.5Kg - 3KgDocument10 pagesSC Wheat-Soya Blend With Sugar 1.5Kg - 3Kgfaheem ulislamNo ratings yet

- Aui2601 Exam Pack 2016 1Document57 pagesAui2601 Exam Pack 2016 1ricara alexia moodleyNo ratings yet

- Answer Key: Entry TestDocument4 pagesAnswer Key: Entry TestMaciej BialyNo ratings yet

- Cold Chain TransportationDocument6 pagesCold Chain TransportationGokul David100% (1)

- Reverse LogisticsDocument37 pagesReverse Logisticsblogdogunleashed100% (7)

- Food Safety Chap 4Document27 pagesFood Safety Chap 4Sherina Leona AgellonNo ratings yet

- Citrus CommercializationDocument23 pagesCitrus Commercializationannacarmelaaa100% (1)

- Model SsopDocument5 pagesModel SsopCaecilia Jessica UnarsoNo ratings yet

- Good Hygiene PracticesDocument1 pageGood Hygiene Practiceswaziri maulidiNo ratings yet

- Waste - Guide EPA NSWDocument125 pagesWaste - Guide EPA NSWcaritosfriendsNo ratings yet

- Rice MillDocument73 pagesRice MillJannatul Ferdousi100% (1)

- WFP 0000020110 PDFDocument7 pagesWFP 0000020110 PDFKalpesh RathodNo ratings yet

- Food Product Development Teacher Booklet St5Document35 pagesFood Product Development Teacher Booklet St5Thủy Tiên HồNo ratings yet

- Peanut Plant GMPDocument79 pagesPeanut Plant GMPmohamadkamarudeen50% (2)

- SMEDA Dates Processing PlantDocument27 pagesSMEDA Dates Processing Planttanvirknit100% (1)

- Preventive MaintenanceDocument15 pagesPreventive MaintenancePrincess LumadayNo ratings yet

- Unit6 Equipments and Cleaning Agents-1-1Document14 pagesUnit6 Equipments and Cleaning Agents-1-1pdp786No ratings yet

- OMPECODocument13 pagesOMPECOAnonymous cFAFK1Zof100% (1)

- RELATIVE CLAUSES 1º Bachillerato and KeyDocument3 pagesRELATIVE CLAUSES 1º Bachillerato and Keyrapitanoroel0% (2)

- Plant-Location and Site SelectionDocument39 pagesPlant-Location and Site Selectionअक्षय शर्माNo ratings yet

- MCQs + SEQs Medical Physics Midterm Exam Paper-Fall 2020Document3 pagesMCQs + SEQs Medical Physics Midterm Exam Paper-Fall 2020Ali Nouman100% (1)

- Good Manufacturing Practices PPDocument57 pagesGood Manufacturing Practices PPAlvin Bales100% (1)

- Chapter 1 Introduction To Food Packaging PDFDocument43 pagesChapter 1 Introduction To Food Packaging PDFBernardino VirgilioNo ratings yet

- Ojt HRMDocument7 pagesOjt HRMArlyn Joy NacinoNo ratings yet

- Current Good Manufacturing Practice: Krezza Iries RodriguezDocument14 pagesCurrent Good Manufacturing Practice: Krezza Iries RodriguezQuenneBelocura100% (1)

- Good Manufacturing Practices PPDocument33 pagesGood Manufacturing Practices PPchevypickupNo ratings yet

- Assignment Case Study Pineaple FactoryDocument3 pagesAssignment Case Study Pineaple FactoryMuhammad Azeem Iqbal100% (1)

- Accreditation GuidelinesDocument22 pagesAccreditation Guidelinesjames lacanilaoNo ratings yet

- Flow Chart Coconut VinegarDocument1 pageFlow Chart Coconut VinegarpedailynNo ratings yet

- Concept of ProductionDocument43 pagesConcept of ProductionSweetams QuigamanNo ratings yet

- Peanut Butter 09Document8 pagesPeanut Butter 09jamilvoraNo ratings yet

- Extraction of Cottonseed Oil Expeller Method One Ton Per Day PDFDocument2 pagesExtraction of Cottonseed Oil Expeller Method One Ton Per Day PDFHenryNo ratings yet

- Rejection Handling ProcessDocument4 pagesRejection Handling ProcessSangeeth BhoopaalanNo ratings yet

- Post Harvest Losses in HorticultureDocument2 pagesPost Harvest Losses in HorticultureInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Good Hygiene PracticesDocument30 pagesGood Hygiene PracticesIonut MuscaNo ratings yet

- Project Proposal For Innovation 1Document6 pagesProject Proposal For Innovation 1Mary Paulyn SantillanNo ratings yet

- DPR - Banana Mango Ripening ChamberDocument131 pagesDPR - Banana Mango Ripening ChamberAnonymous EAineTizNo ratings yet

- Lecture Notes Handling & Transportation of F&V 1Document11 pagesLecture Notes Handling & Transportation of F&V 1Jasvir Mann100% (2)

- Food Premises Design and Construction Standards PlainDocument14 pagesFood Premises Design and Construction Standards Plainpanda_yien100% (1)

- Maize & Corn Flour Mill Plant Manufacture, Design, and InstallationDocument3 pagesMaize & Corn Flour Mill Plant Manufacture, Design, and InstallationBelong MachineyNo ratings yet

- Waste Management in Selected Hotels in GoaDocument11 pagesWaste Management in Selected Hotels in GoaSyna SoaresNo ratings yet

- Role of Catering Establishment in Tourism Industry - PRINTDocument3 pagesRole of Catering Establishment in Tourism Industry - PRINTSrinibas JenaNo ratings yet

- GMP 2Document18 pagesGMP 2j.k.kumar100% (3)

- 3.3 PFPP-Lab ManualDocument28 pages3.3 PFPP-Lab ManualSB TEKNo ratings yet

- Procedure For Exports of Peanuts and Peanut Products2018Document49 pagesProcedure For Exports of Peanuts and Peanut Products2018alohasabariNo ratings yet

- CassavaDocument7 pagesCassavaAwanisWardaniNo ratings yet

- Good Manufacturing Practices PPDocument32 pagesGood Manufacturing Practices PPAzmee Umam0% (1)

- Good Manufacturing Practices: Pabrikasi ProdukDocument17 pagesGood Manufacturing Practices: Pabrikasi ProdukYashinta Ayu RizkyNo ratings yet

- Good-Qaulity NewDocument34 pagesGood-Qaulity NewShafaat HussainNo ratings yet

- Ard Food Safety Training Good Manufacturing Practices PresentationDocument33 pagesArd Food Safety Training Good Manufacturing Practices PresentationRatna DeepakNo ratings yet

- Bohemia Restaurant Greater NoidaDocument34 pagesBohemia Restaurant Greater NoidaBohemiaNo ratings yet

- Good Manufacturing Practices (GMP'S) PolicyDocument36 pagesGood Manufacturing Practices (GMP'S) PolicyGUB PROJECTNo ratings yet

- Students Prayer For Exam 2014Document2 pagesStudents Prayer For Exam 2014Free Escort ServiceNo ratings yet

- My Resume in Word Format1679Document11 pagesMy Resume in Word Format1679Free Escort ServiceNo ratings yet

- Pharmacological Treatment SchizDocument54 pagesPharmacological Treatment SchizFree Escort ServiceNo ratings yet

- Students Prayer For Exam 2014Document2 pagesStudents Prayer For Exam 2014Free Escort ServiceNo ratings yet

- Mechanism For The Ability of 5Document2 pagesMechanism For The Ability of 5Free Escort ServiceNo ratings yet

- Reliablity Validity of Research Tools 1Document19 pagesReliablity Validity of Research Tools 1Free Escort Service100% (1)

- SchizEdDay Freudenreich - PpsDocument29 pagesSchizEdDay Freudenreich - PpsFree Escort ServiceNo ratings yet

- Inflammation in Schizophrenia and DepressionDocument9 pagesInflammation in Schizophrenia and DepressionFree Escort ServiceNo ratings yet

- Nutraceuticals: Let Food Be Your MedicineDocument32 pagesNutraceuticals: Let Food Be Your MedicineFree Escort ServiceNo ratings yet

- Role of Nutraceuticals in Health Promotion: Swati Chaturvedi, P. K. Sharma, Vipin Kumar Garg, Mayank BansalDocument7 pagesRole of Nutraceuticals in Health Promotion: Swati Chaturvedi, P. K. Sharma, Vipin Kumar Garg, Mayank BansalFree Escort ServiceNo ratings yet

- QBD Definition AnvvvvDocument4 pagesQBD Definition AnvvvvFree Escort ServiceNo ratings yet

- Walid Sarhan F. R. C. PsychDocument46 pagesWalid Sarhan F. R. C. PsychFree Escort ServiceNo ratings yet

- Reliability and ValidityDocument15 pagesReliability and Validityapi-260339450No ratings yet

- HerbaceutclDocument1 pageHerbaceutclFree Escort ServiceNo ratings yet

- Presentation 2Document29 pagesPresentation 2Free Escort ServiceNo ratings yet

- ValidityDocument3 pagesValidityFree Escort ServiceNo ratings yet

- EulaDocument3 pagesEulaBrandon YorkNo ratings yet

- New Pharmacological Approaches To The Treatment of SchizophreniaDocument1 pageNew Pharmacological Approaches To The Treatment of SchizophreniaFree Escort ServiceNo ratings yet

- ResumeDocument3 pagesResumeFree Escort ServiceNo ratings yet

- MBKDocument12 pagesMBKFree Escort ServiceNo ratings yet

- Quality Is Built in by Design, Not Tested inDocument1 pageQuality Is Built in by Design, Not Tested inFree Escort ServiceNo ratings yet

- Nutraceutical Role in Health CareDocument1 pageNutraceutical Role in Health CareFree Escort ServiceNo ratings yet

- Reliablity Validity of Research Tools 1Document19 pagesReliablity Validity of Research Tools 1Free Escort Service100% (1)

- Shubh AmDocument1 pageShubh AmFree Escort ServiceNo ratings yet

- ABSTRACT (QBD: A Holistic Concept of Building Quality in Pharmaceuticals)Document1 pageABSTRACT (QBD: A Holistic Concept of Building Quality in Pharmaceuticals)Free Escort ServiceNo ratings yet

- Quality by Design On PharmacovigilanceDocument1 pageQuality by Design On PharmacovigilanceFree Escort ServiceNo ratings yet

- M.Pharm Dissertation Protocol: Formulation and Evaluation of Antihypertensive Orodispersible TabletsDocument7 pagesM.Pharm Dissertation Protocol: Formulation and Evaluation of Antihypertensive Orodispersible TabletsFree Escort ServiceNo ratings yet

- Optimizing Quality by Design in Bulk Powder & Solid Dosage: Smt. Bhoyar College of Pharmacy, KamteeDocument3 pagesOptimizing Quality by Design in Bulk Powder & Solid Dosage: Smt. Bhoyar College of Pharmacy, KamteeFree Escort ServiceNo ratings yet

- 2415 14725 4 PBDocument13 pages2415 14725 4 PBFree Escort ServiceNo ratings yet

- Article On Role of Cyberspace in Geopolitics-PegasusDocument5 pagesArticle On Role of Cyberspace in Geopolitics-PegasusIJRASETPublicationsNo ratings yet

- Queen - Hammer To Fall ChordsDocument3 pagesQueen - Hammer To Fall ChordsDavideContiNo ratings yet

- Control Flow, Arrays - DocDocument34 pagesControl Flow, Arrays - DocHARIBABU N SEC 2020No ratings yet

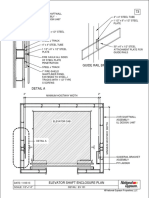

- Module No.3 Prepare Architectual Job Requirements Architectural Working DrawingDocument23 pagesModule No.3 Prepare Architectual Job Requirements Architectural Working DrawingJay S. On100% (1)

- Fish Siomai RecipeDocument12 pagesFish Siomai RecipeRhyz Mareschal DongonNo ratings yet

- WP05 - ACT 01 - Development 1909Document53 pagesWP05 - ACT 01 - Development 1909ramesh9966No ratings yet

- Luigi Cherubini Requiem in C MinorDocument8 pagesLuigi Cherubini Requiem in C MinorBen RutjesNo ratings yet

- Guide Rail Bracket AssemblyDocument1 pageGuide Rail Bracket AssemblyPrasanth VarrierNo ratings yet

- VSL Synchron Pianos Changelog en 1.1.1386Document4 pagesVSL Synchron Pianos Changelog en 1.1.1386RdWingNo ratings yet

- Digital-To-Analog Converter - Wikipedia, The Free EncyclopediaDocument8 pagesDigital-To-Analog Converter - Wikipedia, The Free EncyclopediaAnilkumar KubasadNo ratings yet

- Material List Summary-WaptechDocument5 pagesMaterial List Summary-WaptechMarko AnticNo ratings yet

- Chapter-4 Conditional and Iterative Statements in PythonDocument30 pagesChapter-4 Conditional and Iterative Statements in Pythonashishiet100% (1)

- Engineering ChemistryDocument21 pagesEngineering Chemistryjai kumarNo ratings yet

- 15-3-2020 Chapter 4 Forward Kinematics Lecture 1Document29 pages15-3-2020 Chapter 4 Forward Kinematics Lecture 1MoathNo ratings yet

- I. Matching Type. Write Letters Only. (10pts) : Adamson University Computer Literacy 2 Prelim ExamDocument2 pagesI. Matching Type. Write Letters Only. (10pts) : Adamson University Computer Literacy 2 Prelim ExamFerrolinoLouieNo ratings yet

- W1 - V1 MultipleWorksheets SolnDocument3 pagesW1 - V1 MultipleWorksheets SolnAKHIL RAJ SNo ratings yet

- Case Study StarbucksDocument2 pagesCase Study StarbucksSonal Agarwal100% (2)

- Role of ACT, S & WHO Guidlines For The Treatment of MalariaDocument34 pagesRole of ACT, S & WHO Guidlines For The Treatment of MalariasalmanNo ratings yet

- S L Dixon Fluid Mechanics and Thermodynamics of TurbomachineryDocument4 pagesS L Dixon Fluid Mechanics and Thermodynamics of Turbomachinerykuma alemayehuNo ratings yet

- First Certificate Star SB PDFDocument239 pagesFirst Certificate Star SB PDFPatricia Gallego GálvezNo ratings yet