Professional Documents

Culture Documents

Rope Structure and The Application of Anti-Corrosion Methods

Uploaded by

europeancraneOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rope Structure and The Application of Anti-Corrosion Methods

Uploaded by

europeancraneCopyright:

Available Formats

Rope structure and the application

of anti-corrosion methods

Section of wire rope structure and

antiseptic methods

Point-contact round stock, round stock line contact, surface contact round stock, profiled stocks,

single stock does not rotate, such as seals and flat. Where surface contact is by traction round

strand wire rope stranding machine will line contact strand wire drawing die or roller die by pulling

the system. Through die before deformation and after deformation sectional strand.

Oiled antiseptic methods

All wire rope must be oiled. Fiber core immersion oil, grease required to protect the fiber core does

not rot, portal crane jib crane does not rust steel, moist fibers, and lubricate the rope from the

inside. Greased surface so that all the surface of the wire strands are evenly coated with anti-rust

lubricant, in which the friction and enhance a large mine mineral water with a rope, to increased

wear and water resistance coating strong Heiyou fat; alternative use is Strong film-coated, rust

good performance marked fats and require oil thin, easy to keep clean during operation.

Anticorrosive coating method

Galvanized coating, aluminum, coated nylon or plastic. Thick coating of galvanized steel and plated

after first pulling a thin coating and galvanized steel wire after pulling thick coating mechanical

properties than smooth rope has decreased, should be used in severe corrosive environments.

Aluminum wire rope is more resistant to corrosion, abrasion, electromagnetic lifting crane heat-

resistant than galvanized steel wire rope is mainly used for fishing trawl vessels and mines

containing H2S, etc., using the pull after plating production. Coated nylon or plastic coated wire

rope of the two co-rope after rope and coated stocks. The former is used for static rope, which is

used for moving cable.

Precautions when using winch

1 , wire rope reel should be neat , if found around overlapping and oblique , should be shut down rearranged.

Prohibited in the rotation by hand , stepped foot pull rope . Rope allowed to completely release , should be

retained at least three times .

2 , allowed knotted rope , twisted , stainless steel crane hook broken in a pitch more than 10% , should be

replaced.

3 , operation, no person shall cross the rope , after the object ( the object ) to enhance the operator shall not

leave the winch. Object or cage should be lowered to the ground at rest .

4 , operations , drivers, signalers to maintain good visibility with lifting objects , drivers and signalers should

cooperate closely obey signals unified command .

5 , the job situation in case of a power outage , you should cut off the power , will enhance the material down to

the ground.

6 , work to obey the command staff of the signal , the signal is unknown or likely to cause an accident should

suspend operations until after clarifying the situation in order to continue operations.

7 , operations sudden power outage , small electric chain hoist you should immediately pull the knife , will ship

things down.

8 , the operation is completed , you should feed tray floor , lock electrical box .

9 , in the course of rope and mechanical wear. Pyrophoric local corrosion damage is inevitable , should be brushing

time interval to protect the oil .

10 Do not overload use . That is more than the maximum number of hosts tons.

11 , the course should be careful not to appear to tie. Squashed. Arc wounded . Erosion of chemical media .

12 , may not be directly lifting hot objects , objects to the angular care board.

13 , using the process should always check the rope used to achieve the standards should be scrapped

immediately scrapped .

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- CO2 AnsulDocument17 pagesCO2 AnsulJorge RVNo ratings yet

- EI Laying OFC 310107Document21 pagesEI Laying OFC 310107agmtechnical100% (1)

- Method Statement For Cable LayingDocument9 pagesMethod Statement For Cable LayingRavi ManiNo ratings yet

- Cat19579-Tachometer Cable PDFDocument1 pageCat19579-Tachometer Cable PDFshahrol effendy rodziNo ratings yet

- 02 DesistiDocument38 pages02 DesistiRacielMCNo ratings yet

- Slickline and Strand CareDocument10 pagesSlickline and Strand Carehesam abbaszadehNo ratings yet

- TM 5-272 1944 Steel-Treadway Bridge M2Document74 pagesTM 5-272 1944 Steel-Treadway Bridge M2Advocate100% (1)

- Guidelines For Marine Crane LiftsDocument25 pagesGuidelines For Marine Crane LiftsPaulson JosephNo ratings yet

- Manual HoistsDocument71 pagesManual Hoistsfuat0804No ratings yet

- 002-PDS-CON-007 Method Statement For FOC Installation, Splicing & TestingDocument15 pages002-PDS-CON-007 Method Statement For FOC Installation, Splicing & TestingMalik Zaman100% (1)

- Pfeifer Drako - Rope SolutionsDocument52 pagesPfeifer Drako - Rope SolutionsJcruzadoNo ratings yet

- Ariens Model 921013 Deluxe 30 Snow Blower Operator ManualDocument46 pagesAriens Model 921013 Deluxe 30 Snow Blower Operator ManualTim MckennaNo ratings yet

- SH Wire Rope HoistDocument24 pagesSH Wire Rope HoistthomsonNo ratings yet

- Manual SO2164430-i1Document80 pagesManual SO2164430-i1Savinda JanszNo ratings yet

- Feyrer Formula Update-RopeDocument3 pagesFeyrer Formula Update-Ropescsam05No ratings yet

- SEC ApprovedDocument60 pagesSEC ApprovedAnonymous SkU7PyNo ratings yet

- Overhead Crane Hoists eDocument20 pagesOverhead Crane Hoists eAltayeb YassinNo ratings yet

- Macalloy Brochure Tension Structures December - 2017 - V1Document16 pagesMacalloy Brochure Tension Structures December - 2017 - V1Isabel Christina Gonzalez MoralesNo ratings yet

- Dynamic Behavior of Thousand Meter-Scale Cable Stayed Bridge With Hybrid FRP CablesDocument23 pagesDynamic Behavior of Thousand Meter-Scale Cable Stayed Bridge With Hybrid FRP Cableskhawaja AliNo ratings yet

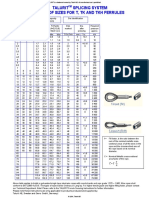

- Talurit Ferrule Table Al PDFDocument1 pageTalurit Ferrule Table Al PDFAndreas SiallaganNo ratings yet

- Aeros Combat 2 Combat LDocument77 pagesAeros Combat 2 Combat LsebastiaanNo ratings yet

- FOSC 450: Gel-Sealed Fiber Optic Splice ClosureDocument32 pagesFOSC 450: Gel-Sealed Fiber Optic Splice Closuremasalgado78No ratings yet

- Lifting Appliances FailureDocument25 pagesLifting Appliances FailurePrakash Alva100% (1)

- Manual Shaw-Box SERIE 700 PDFDocument68 pagesManual Shaw-Box SERIE 700 PDFJavier Isaac Berrocal TorresNo ratings yet

- CIGRE Green Books Overhead Lines - Parte3 PDFDocument258 pagesCIGRE Green Books Overhead Lines - Parte3 PDFFernando Alexander Torres FerrufinoNo ratings yet

- MNS Service Manual Jan 2003Document86 pagesMNS Service Manual Jan 2003HujiLokoNo ratings yet

- Muhammad Shahid Shafi, Jianhui Lu, Zhenpeng Song and Yingqun FuDocument7 pagesMuhammad Shahid Shafi, Jianhui Lu, Zhenpeng Song and Yingqun Fujeremytoh89No ratings yet

- Doble Crane Girder Parts-1Document7 pagesDoble Crane Girder Parts-1Ahmad AlaaNo ratings yet

- Videocon d2h Setup and Reflector Installation GuidelinesDocument68 pagesVideocon d2h Setup and Reflector Installation GuidelinesIndianMascot81% (21)

- Is 14473 (Part - I) Cranes - Inspections GeneralDocument10 pagesIs 14473 (Part - I) Cranes - Inspections GeneralLALATENDU MAHANTANo ratings yet