Professional Documents

Culture Documents

Design and Analysis of Aircraft Propulsion Systems

Uploaded by

SandeepRajOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design and Analysis of Aircraft Propulsion Systems

Uploaded by

SandeepRajCopyright:

Available Formats

DESIGN AND ANALYSIS OF

PROPULSION(POWER

PLANT)

By:

Sandeep raj

Contents :

Propulsion

Aircraft engine

Types of Aircraft engine

Aero piston engine

Gas turbine engine

Brayton cycle

Other engines

Electronic Fuel Injection

Propulsion

Propulsion is an energy which creates force from

the engine to make the aircraft move forward.

On airplanes, thrust is usually generated through

some application of Newton's third law of action

and reaction. A gas, or working fluid, is

accelerated by the engine, and the reaction to

this acceleration produces a force on the engine.

Aircraft engine

An aircraft engine is the propulsion unit(power

plant) which generates thrust and pushes the

aircraft to move forward direction to reach

higher level.

Most of the aircraft engines are either run by

the piston engine and gas turbines.

The aircrafts which are powered by piston

engines comes under (Light civil aviation).

Reciprocating engine or IC engine

Most of the piston engines

consists of reciprocating

engines.

It consists of cylinders ,

piston , sparkplug ,crank case

, connecting rod , valves.

Reciprocating engines

operate on a four-stroke

cycle, where each piston

travels from one end of its

stroke to the other four times

.

The cycle is composed of four

operations:

-Intake,

-Compression,

-Expansion (or power),

-Exhaust.

With ignition taking place late

in the compression stroke

and combustion of the fuel-

air charge occurring early in

the expansion.

The reciprocating engines

work on the Otto power

cycle.

Otto Cycle:

Process 1-2 is an adiabatic

compression.

Process 2-3 is a heat

addition at constant

volume(isochoric).

Process 3-4 is an adiabatic

expansion.

Process 4-1 is a heat

rejection at constant

volume.

Types of reciprocating engines

In 1903 after the wright brothers first

successful flight ,the making aircraft engine

has been started.

Basically there are three types of reciprocating

engines.

Rotary engine

In 1918 in world war I where aircrafts were first

being used for military purposes.

It is an early type of IC engine.

It is designed with no. of cylinders per row,

crankshaft remains stationary, entire cylinder

block rotates around it the entire engine rotates

with the propeller which drives plenty of air inside

for cooling purpose.

It can generate up to 80 HP and gave good power

to weight ratio .

Major disadvantage was it became difficult to fly

as it consumed large amount of castor oil .

V shaped

The cylinders were aligned in

two separate planes from each

other tilted at an angle of 30-60

degree, where the crank shaft

holds the both pistons .

Rolls Royce was first to design

the V shaped engines for

aircraft .

V shaped designs gives high

power to weight ratio and high

reciprocating torque or mass .

The famous V12 engine played a

major role in world war II.

Radial

It is similar to the rotary engine where it has

one more set of rows of rotating cylinders

attached to the main crank case .

It gave a favorable power to weight ratio and

smooth running and radials also tends to

cool down the engine evenly.

But the lower cylinders under the crankcase

collected more oil when the engine is

stopped and due its large frontal area ( blunt

shaped ) nose it gave a insufficient

aerodynamics efficiency.

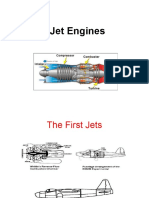

Gas Turbine engines

After world war II

designers dreamed to

invent an engine which

can break the sound

barrier (speed of sound) ,

which led to the discovery

of gas turbine engines

which was called as Jet

engine.

Gas turbine engines work

on Brayton power cycle.

The air enters the compressor gets compressed

and the compressed air enters in to the

combustion chamber,where the fuel and air are

mixed and burnt and passes through the turbine,

exit through nozzle with high acceleration.

Brayton Cycle

Since fresh air enters the compressor at the

beginning and exhaust are thrown out at the end,

this cycle is an open cycle.

By replacing the combustion process by a constant

pressure heat addition process, and replacing the

exhaust discharging process by a constant pressure

heat rejection process, the open cycle described

above can be modified as a closed cycle, called ideal

Brayton cycle. The ideal Brayton cycle is made up of

four internally reversible processes.

1-2 Isentropic compression (in a compressor)

2-3 Constant pressure heat addition

3-4 Isentropic expansion (in a turbine)

4-1 Constant pressure heat rejection

How propulsion takes place?

Aircraft propellers convert rotary motion from piston

engines or turboprops to provide propulsive force.

The propellers are provided with several rows of

spinning blades called Rotors.

As the airflow goes through each row, the air is

accelerated and compressed.

The air after passing through the several rows of

rotors gets compressed. This stage of the engine is

called the Compressor.

The compressed gas enters a Combustion Chamber

where fuel is added an a spark ignites the fuel/air

mixture and this flame is self-sustaining.

The high pressure, high temperature gases exit

from the combustion chamber and expand in the

turbine to generate enough power .

The exhaust gases leave the turbine.

Gas turbine engines are more powerful

and efficient and produce more thrust.

All modern aircrafts do not use

reciprocating engines they use turbine

engines .

Basically there are three types of gas

turbine engines.

Types

1.Turbo jet - The turbojet

uses a series of fan-like

compressor blades to bring

air into the engine and

compress it.

It works with working

fluid(air) consists of inlet

compressor , combustion

chamber , turbine , nozzle.

Turbo jet gives good

efficiency at higher speeds

(800km/h) and high rate of

climb and un interrupted

power supply.

2.Turbo prop- It is a

combination of

propeller engine and

turbo jet engine.

It consists of a propeller

and reduction gear box

in the front to reduce

the speed of rpm.

Works same as turbo jet

it used by mostly

military and also civil

aviation.

3.Turbo fan - It has one or more rows

of compressor blades extend beyond

the normal compressor blades. The

result is that four times as much air is

pulled into the turbofan engine as in

the simple turbojet.

Most of this excess air is ducted

through by passing around the power

section and out the rear with the

exhaust gases.

The turbofan has greater thrust for

takeoff, climbing, and cruising on the

same amount of fuel than the

conventional turbojet engine.

It has the facility of thrust

augmentation like (afterburner, bleed

burner) turbofan engine has gained lot

more popularity then turbo jet.

4. Ram jet - After the achievement of

turbine engines ,designers, engineers

dreamed of building the engine which

could travel at high speeds and reach at

any point on earth in less time. These led

to the development of ramjet, scramjet

engines.

The ramjet engine is the simplest type of

the all-jet engines because it has no

moving parts.

And works by supersonic air flow at inlet.

The sharp edge acts as a diffuser and the

flow get further compressed inside and

reach the combustion chamber where the

fuel and air is mixed and ignited and exits

through converging nozzle.

It can work only at supersonic speeds not

suitable for less then (Mach no.1).

5.Scramjet Super sonic

combustion ramjet engine

works on oblique shock waves.

The shock waves pass through

inlet and get compressed

through deflections occurred

inside the walls and ignited

with fuel and exit through

nozzle.

It can travel more than Mach

no. 10, suitable for hyper sonic

speeds.

Mostly used in space launch

vehicles , supersonic missiles.

Thank You

You might also like

- Parts Manual NDR 030 AD, NR 035 AD, NR 040AD, NR 045 AD, NS 040 AE, NS 050 AE (B815)Document246 pagesParts Manual NDR 030 AD, NR 035 AD, NR 040AD, NR 045 AD, NS 040 AE, NS 050 AE (B815)Erisson60% (5)

- CNC Maintenance Guide for MachinesDocument206 pagesCNC Maintenance Guide for MachinesArjun M Betageri100% (1)

- Perkins M215C and M185C 1006 SeriesDocument2 pagesPerkins M215C and M185C 1006 SeriesDamian Cid Morales100% (1)

- Jet EnginesDocument32 pagesJet EnginesFelichi Dacumos Balajadia50% (2)

- Jet Engine - 1Document21 pagesJet Engine - 1MuhammedNayeemNo ratings yet

- Aircraft Engines: Reciprocating EngineDocument46 pagesAircraft Engines: Reciprocating EngineBadal Machchhar100% (1)

- Powerplant: Dimas Arango Emmauel Hincapie AMT 4 2019Document46 pagesPowerplant: Dimas Arango Emmauel Hincapie AMT 4 2019Emanuel Hincapie MorenoNo ratings yet

- Turbine Gas: Oil Nuclear ReactorDocument65 pagesTurbine Gas: Oil Nuclear ReactorDey TandirerungNo ratings yet

- TURBINE ENGINES HISTORY AND TECHNOLOGYDocument61 pagesTURBINE ENGINES HISTORY AND TECHNOLOGYRay-Ray Carino AraoNo ratings yet

- Jet Engine Propulsion in AircraftDocument43 pagesJet Engine Propulsion in AircraftfadyNo ratings yet

- Propulsion Ancillary System and Gas Turbine (PASGT) : 3AE Julie Mar AyumanDocument74 pagesPropulsion Ancillary System and Gas Turbine (PASGT) : 3AE Julie Mar AyumanColeen BattungNo ratings yet

- Turbine System: Indiana Aerospace UniversityDocument29 pagesTurbine System: Indiana Aerospace UniversityKirito kunNo ratings yet

- Powerplant 2 Module 1 Part 1Document19 pagesPowerplant 2 Module 1 Part 1Santos MaineNo ratings yet

- Jet Engine - 1Document21 pagesJet Engine - 1MuhammedNayeemNo ratings yet

- 4-Stroke Petrol Engine History & DesignDocument19 pages4-Stroke Petrol Engine History & Designvivek8194No ratings yet

- Wankel EngineDocument8 pagesWankel EngineMuhammad Qasim JameelNo ratings yet

- Seminar On Jet Engine: Presented by Deepak Kumar ROLL NO-1120854 Section-M7Document27 pagesSeminar On Jet Engine: Presented by Deepak Kumar ROLL NO-1120854 Section-M7an anNo ratings yet

- 6-Aircraft PropulsionDocument32 pages6-Aircraft PropulsionNeeraj K GahlotNo ratings yet

- Diesel PPDocument58 pagesDiesel PPManvendra Pratap Singh Bisht100% (1)

- Chapter 1 and 2 Lecture Notes - IRISDocument111 pagesChapter 1 and 2 Lecture Notes - IRISSsh keys JoshNo ratings yet

- KeshavDocument23 pagesKeshavDhruv SharmaNo ratings yet

- Prop - Unit IDocument64 pagesProp - Unit IsahithiNo ratings yet

- Engine and Motors: Presented by Muhammad Ulul Azmi 10001 Septian Lindhar Listio 10002Document10 pagesEngine and Motors: Presented by Muhammad Ulul Azmi 10001 Septian Lindhar Listio 10002dwi adi santosoNo ratings yet

- Aircraftpropulsion 170811074437 PDFDocument31 pagesAircraftpropulsion 170811074437 PDFHUGO MORANo ratings yet

- Diesel Engine: Aguinaldo, Cellan, Gregorio, MedranoDocument33 pagesDiesel Engine: Aguinaldo, Cellan, Gregorio, MedranoHannah AguinaldoNo ratings yet

- Thermal 1unit3Document178 pagesThermal 1unit3NAGU2009No ratings yet

- Presentation Internal Combustion EngineDocument25 pagesPresentation Internal Combustion EngineAbderrazak ZahirNo ratings yet

- Pertemuan 4 - Turbin Gas (2016)Document53 pagesPertemuan 4 - Turbin Gas (2016)Prabowo WicaksonoNo ratings yet

- Air PropulsionDocument32 pagesAir PropulsionPramodPradhanNo ratings yet

- Lec 2 Best PPT On Jet EnginesDocument25 pagesLec 2 Best PPT On Jet Enginesahmet yıldızNo ratings yet

- Propulsion 2 NotesDocument84 pagesPropulsion 2 NotesTAMILSELVAM NALLUSAMY50% (2)

- Jet Aircraft PropulsionDocument133 pagesJet Aircraft PropulsionShubham Jain100% (2)

- Engine and Motor (4 Stroke Engine and 2 Stroke Engine)Document27 pagesEngine and Motor (4 Stroke Engine and 2 Stroke Engine)Bias PanduNo ratings yet

- Jet Engines: BY:-Karan Prabhakar Aryabhatta CollegeDocument23 pagesJet Engines: BY:-Karan Prabhakar Aryabhatta Collegeمحمد القدوميNo ratings yet

- Jet Engines Explained: Parts, Types & Working PrinciplesDocument3 pagesJet Engines Explained: Parts, Types & Working PrinciplesYemaneDibetaNo ratings yet

- Lecture.6. Агрегаты продувки и наддуваDocument49 pagesLecture.6. Агрегаты продувки и наддуваSea Man MktNo ratings yet

- Aircraft PowerplantsDocument18 pagesAircraft PowerplantsSridhar KanagarajNo ratings yet

- Practical #11: To Study Cutaway Models of Petrol and Diesel Engine Heat EngineDocument9 pagesPractical #11: To Study Cutaway Models of Petrol and Diesel Engine Heat EngineMuhammad Arslan AfzalNo ratings yet

- Aircraft and Jet Propulsion Systems: Ratan Kumar Rout Regd No.:-1221225081 Mechanical Engg. College:-BCETDocument32 pagesAircraft and Jet Propulsion Systems: Ratan Kumar Rout Regd No.:-1221225081 Mechanical Engg. College:-BCETPramodPradhanNo ratings yet

- LEC# 14. I.C EngineDocument43 pagesLEC# 14. I.C EngineAli Murad JokhioNo ratings yet

- Pplant ReviewerDocument7 pagesPplant ReviewerMikaelarae GermanNo ratings yet

- Jet PropulsionDocument45 pagesJet PropulsionPranay SahuNo ratings yet

- Marine Propulsion Systems GuideDocument63 pagesMarine Propulsion Systems GuidetoshugoNo ratings yet

- Ice CH1 2022-2023Document36 pagesIce CH1 2022-2023AS GAMINGNo ratings yet

- Jet EnginesDocument33 pagesJet EnginesntfaNo ratings yet

- Jet EngineDocument50 pagesJet EngineAnand HariNo ratings yet

- Jet Engine Power Point PresentationDocument15 pagesJet Engine Power Point PresentationHarsh GautamNo ratings yet

- Che422: Fuels and Combustion: Dr. Taqi Mehran Scme, NustDocument53 pagesChe422: Fuels and Combustion: Dr. Taqi Mehran Scme, NustKhizAr Hayat KhizArNo ratings yet

- Internal Combustion Engine Chapter 1Document31 pagesInternal Combustion Engine Chapter 1norazwanizaNo ratings yet

- How Does An Internal Combustion Engine Work?Document5 pagesHow Does An Internal Combustion Engine Work?AsraNo ratings yet

- Engines ExplainedDocument64 pagesEngines ExplainedSujithNo ratings yet

- Engines ExplainedDocument40 pagesEngines ExplainedSujithNo ratings yet

- Lecture Jet EngineDocument36 pagesLecture Jet EngineHibbaNo ratings yet

- IC Engines Unit 4 - TDDocument43 pagesIC Engines Unit 4 - TDchincha chuNo ratings yet

- IC EnginesDocument44 pagesIC EnginesIbrahim KhaleelNo ratings yet

- Chapter 2Document41 pagesChapter 2Ibrahim KhaleelNo ratings yet

- 4-Valve Engine Guide: Types, Design & Benefits Over 2-Valves/TITLEDocument37 pages4-Valve Engine Guide: Types, Design & Benefits Over 2-Valves/TITLEtarunskumarNo ratings yet

- How A Turbofan Engine Works: By: Matthew ChmielDocument10 pagesHow A Turbofan Engine Works: By: Matthew ChmielPouryaNo ratings yet

- Internal Combustion Engine ClassificationDocument43 pagesInternal Combustion Engine ClassificationAhmer KhanNo ratings yet

- Chapter 7Document33 pagesChapter 7kuma alemayehuNo ratings yet

- Southern Marine Engineering Desk Reference: Second Edition Volume IiFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IiNo ratings yet

- Q 1Document34 pagesQ 1SandeepRajNo ratings yet

- 117.218.49.227 DGCIL Conclusion RohitDocument4 pages117.218.49.227 DGCIL Conclusion RohitSandeepRajNo ratings yet

- Frigate Flyer Dribble ConveyorDocument1 pageFrigate Flyer Dribble ConveyorSandeepRajNo ratings yet

- Microsoft Word - MA - QPDocument16 pagesMicrosoft Word - MA - QPSandeepRajNo ratings yet

- Drawing1 ModelDocument1 pageDrawing1 ModelSandeepRajNo ratings yet

- Marksheet 4th YrDocument1 pageMarksheet 4th YrSandeepRajNo ratings yet

- Mechanical Measurements andDocument29 pagesMechanical Measurements andsrajapratyNo ratings yet

- DMEDocument52 pagesDMESathya KidduNo ratings yet

- Ankit Final RMP ReportDocument3 pagesAnkit Final RMP ReportSandeepRajNo ratings yet

- Drawing1 ModelDocument1 pageDrawing1 ModelSandeepRajNo ratings yet

- Online Application - NSPCL 2015 PDFDocument2 pagesOnline Application - NSPCL 2015 PDFSandeepRajNo ratings yet

- RMP TempleteDocument17 pagesRMP TempleteSandeepRajNo ratings yet

- Experiment No.2Document6 pagesExperiment No.2SandeepRajNo ratings yet

- B 384 K 94 ApplicationformDocument1 pageB 384 K 94 ApplicationformSandeepRajNo ratings yet

- 5 Lathe PDFDocument74 pages5 Lathe PDFPrakash PednekarNo ratings yet

- Feasibility Study of Manufacturing Using Rapid Prototyping FDMDocument8 pagesFeasibility Study of Manufacturing Using Rapid Prototyping FDMSandeepRajNo ratings yet

- Blis-I Semester (Paper B-103 - Library Classification (Practical) ) DuDocument3 pagesBlis-I Semester (Paper B-103 - Library Classification (Practical) ) DuSandeepRaj100% (1)

- Journal of MFGDocument16 pagesJournal of MFGSandeepRajNo ratings yet

- L6 3dtrans PDFDocument12 pagesL6 3dtrans PDFKtk ZadNo ratings yet

- Turn Tapers with Compound Rest, Form Tools, Tailstock OffsetDocument4 pagesTurn Tapers with Compound Rest, Form Tools, Tailstock OffsetSandeepRajNo ratings yet

- 3) 3D TransformationsDocument13 pages3) 3D TransformationsSandeepRajNo ratings yet

- Laser Rapid MFG On Vertical SurfacesDocument11 pagesLaser Rapid MFG On Vertical SurfacesSandeepRajNo ratings yet

- (Firstname) (Middle/Initial) (Lastname)Document3 pages(Firstname) (Middle/Initial) (Lastname)SandeepRajNo ratings yet

- BARC Syllabus 2015 For (CSE, ECE, EEE, Civil, Mechanical Engineering) - Recruitment, Result, Application Form, Admit CardDocument4 pagesBARC Syllabus 2015 For (CSE, ECE, EEE, Civil, Mechanical Engineering) - Recruitment, Result, Application Form, Admit CardSandeepRajNo ratings yet

- After Gate Guide 2015Document100 pagesAfter Gate Guide 2015JaydeepRanipaNo ratings yet

- Engineering Service Examinationsdfgh For Government Job - RailElectricaDocument5 pagesEngineering Service Examinationsdfgh For Government Job - RailElectricaSandeepRajNo ratings yet

- CSIR-UGC NET EXAMDocument9 pagesCSIR-UGC NET EXAMVijay KakaniNo ratings yet

- 1 s2.0 S0960148107001103 MainDocument12 pages1 s2.0 S0960148107001103 MainResearcherzNo ratings yet

- Computer Science Graduate Seeks Entry-Level RoleDocument2 pagesComputer Science Graduate Seeks Entry-Level RoleSandeepRajNo ratings yet

- Victory Rig - LB50-3 ManualDocument75 pagesVictory Rig - LB50-3 ManualLuis CastelanNo ratings yet

- Grove-GMK5275 Product Guide PDFDocument24 pagesGrove-GMK5275 Product Guide PDFMarco Torres HenrriquezNo ratings yet

- Diccionario Mecanico Ingles-EspañolDocument64 pagesDiccionario Mecanico Ingles-EspañolJhon Fernandez67% (9)

- 55: Brakes Handbrake, Brake Shoes, Replacing: 55: Brakes V70 (00-08), 2004, B5244S2, M56, L.H.D 25/5/2020Document5 pages55: Brakes Handbrake, Brake Shoes, Replacing: 55: Brakes V70 (00-08), 2004, B5244S2, M56, L.H.D 25/5/2020E MakinenNo ratings yet

- PLTMG Prabumulih 18V34SG Rev.3 PendahuluanDocument39 pagesPLTMG Prabumulih 18V34SG Rev.3 PendahuluanOctavianus HarahapNo ratings yet

- Manuals TVS Star City PlusDocument69 pagesManuals TVS Star City PlusdavidNo ratings yet

- NAFEMS Auto Unified CAE Analysis For A Leaf Spring TypeDocument10 pagesNAFEMS Auto Unified CAE Analysis For A Leaf Spring TypeIndranil BhattacharyyaNo ratings yet

- AsideDocument16 pagesAsideStephanie JohnsonNo ratings yet

- MSD Ignition TechDocument132 pagesMSD Ignition Techthis oneNo ratings yet

- Supply and usage report for partsDocument8 pagesSupply and usage report for partsajayNo ratings yet

- Chevrolet Cruze BCMDocument4 pagesChevrolet Cruze BCMAndrés Caleb Blanco GuzmanNo ratings yet

- PC200-8 KomatsuDocument636 pagesPC200-8 Komatsujoao maria100% (1)

- MB W115Document183 pagesMB W115mnbvqwert0% (1)

- Engine All (4xWD, CAR, Light Transporter, Smart)Document7 pagesEngine All (4xWD, CAR, Light Transporter, Smart)Tomica TišljarićNo ratings yet

- 250HP 2T - 2004Document0 pages250HP 2T - 2004Ray Cepeda MenaNo ratings yet

- Valvetronic EngineDocument5 pagesValvetronic EngineHafis SayedNo ratings yet

- Maruti SuzukiDocument19 pagesMaruti Suzukianik jainNo ratings yet

- IRC 30D New Qualified Plug-In Electric Drive Motor Vehicle Credit Internal Revenue ServiceDocument1 pageIRC 30D New Qualified Plug-In Electric Drive Motor Vehicle Credit Internal Revenue ServiceJohnNo ratings yet

- Service and Repair Manual: Ao Avtovaz 2001Document214 pagesService and Repair Manual: Ao Avtovaz 2001Ivan73100% (11)

- Waukesha VHP Series EnginesDocument8 pagesWaukesha VHP Series EnginesJhon SanabriaNo ratings yet

- Axle Shafts RearDocument19 pagesAxle Shafts RearCarlos VelázquezNo ratings yet

- Service Bulletin Trucks: 2140 05 02 03 Valves and Injectors, AdjustmentDocument19 pagesService Bulletin Trucks: 2140 05 02 03 Valves and Injectors, AdjustmentJ JNo ratings yet

- Oshkosh - SandcatDocument16 pagesOshkosh - SandcatUsNdaomanuNo ratings yet

- Dear Customer,: Combilift LTDDocument53 pagesDear Customer,: Combilift LTDВиталийNo ratings yet

- Seatboat Sample ArticleDocument31 pagesSeatboat Sample ArticleJoseph AlimNo ratings yet

- CDC - Heavy Equipment Daily Inspection ChecklistDocument2 pagesCDC - Heavy Equipment Daily Inspection ChecklistJonathan CambaNo ratings yet

- r15.v3 Monstar Indo 2020Document56 pagesr15.v3 Monstar Indo 2020Omar SahadatNo ratings yet

- Ge 41 Kva Eagle Pride Power: Power Your Future ZH4100ZDS Ricardo Generator LG30KFDocument3 pagesGe 41 Kva Eagle Pride Power: Power Your Future ZH4100ZDS Ricardo Generator LG30KFRaniaTortueNo ratings yet