Professional Documents

Culture Documents

New Microsoft Office PowerPoint Presentation

Uploaded by

Prosenjit Chatterjee0 ratings0% found this document useful (0 votes)

44 views29 pagesPPT FOR PLC&SCADA

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentPPT FOR PLC&SCADA

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

44 views29 pagesNew Microsoft Office PowerPoint Presentation

Uploaded by

Prosenjit ChatterjeePPT FOR PLC&SCADA

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 29

PRESENTED BY:PROSENJIT CHATTERJEE(ROLL NO:68)

DEPARTMENT OF ELECTRICAL ENGINEERING(SKFGI)

WHAT IS PLC

INTRODUCTION OF PLC

HISTORICAL BRACKGROUND

PROGRAMMBLE CONTROLLER DEVELOPMENT

LEADING BRANDS OF PLC

AREA OF APPLICATION

PLC SIZE

MAJOR COMPONENTS OF A COMMON PLC

TYPES OF PLC CONSTRUCTION

PLC LADDER DIAGRAM INSTRUCTIONS

PLC HARDWARE DESIGN

BASIC PLC PROGRAMMING

WHAT IS SCADA

INTRODUCTION OF SCADA

SCADA PRINCIPLES OF OPERATION

APPLICATION OF SCADA

SCADA FUNCTION

HARDWARE IMPLEMENTATION OF SCADA

CONCLUSION

REFERENCE

Programmable Logic Controllers are solid

state devices that can be programmed to

performed sequential and discrete state

operation on external equipment

They are designed to perform the logic

functions previously accomplished by

electromechanical relays, drum switches,

mechanical and electronic timers and

counters, standalone digital PID

controllers etc.

Advantages of PLCs:

Flexible

Faster response time

Less and simpler wiring

Solid-state and no moving parts

Modular design and easy to repair

Handles much more complicated systems

sophisticated instruction sets available

Less expensive

Communications Capability:

The Hydromantic Division of the General

Motors Corporation specified the design

criteria for the first programmable controller in

1968 .

To eliminate the high costs associated with

inflexible, relay-controlled systems.

1968: Programmable logic controller developed

1969: Hardware CPU controller with logic instruction,1K

of memory and 128 I/O points

1974: Use of several processors with in PLC-timers and

counters, arithmetic operation,12K of memory and

1024 I/O points

1976: Remote input /output systems introduced

1977: Microprocessor based PLC introduced

1980: Intelligence I/O module developed

1983 :Low cost small PLC introduced

1985 ON: Networking of all level of PLC,computer

and machine using SCADA software.

AMERICAN:

1. Allen Bradley

2. Gould Modicon

3.Texas Instruments

4. General Electric

5. Cutter Hammer

6. Square D

EUROPEAN:

1. Siemens

2. Festo

3.Telemechanique

JAPANESE:

1.Toshiba

2.Omron

3.Fanuc

4.Mitsubishi

Manufacturing / Machining

Food / Beverage

Metals

Power

Mining

Petrochemical / Chemical

1.SMALL: It covers units with up 128 I/Os ports

and memories up to 2 Kbytes.

2.MEDIUM: Have to 2048 I/Os and memories up

to 32 Kbytes.

3.LARGE: The most sophisticated units of the

PLC family. They have to 8192 I/Os and

memories up to 750 Kbytes. Can control

individual production process.

PROCESSOR

INPUT

MODULE

POWER

SUPPLY

PROGRAMMING

DEVICE

OUTPUT

MODULE

i. Compact PLC

ii. Modular PLC

iii. PLC Plug-in Card

I. Compact PLC:

Figure 1: Compact PLC

II.Modular PLC:

Figure 2: Modular PLC

III.PLC Plug-in Card:

Figure 3: PLC Plug in Card

1) Relay,

2) Timer and counter,

3) Program control,

4) Arithmetic,

5) Data manipulation,

6) Data transfer, and

7) Others, such as sequencers.

ON : TRUE, contact closure, energize, etc.

OFF: FALSE, contact open , de-energize, etc.

A

R1

PB1

PB2

R1

R1

start

emergency stop

Rail

Rung

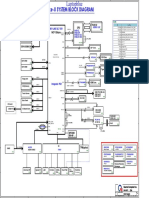

Microprocessor

/ CPU

ROM

RAM

Input

Output

Data BUS

Control Bus

Address Bus

Figure 4: Design of Basic Microcomputer

L2 L1

N.O

C

CONTACTOR

L2

L1

O:4

0

CONTACTOR

L1

L2

Supervisory Control and Data Acquisition

Supervisory

Operator/s, engineer/s, supervisor/s, etc

Control

Monitoring

Limited

Telemetry

Remote/Local

Data acquisition

Access and acquire information or data from the

equipment

Sends it to different sites through telemetry

Analog / Digital

SCADAsystems are usually designed to be fault-tolerant

systems with significant redundancy built into the

system architecture.

Interface with Physical Devices

Remote terminal unit (RTU)

Intelligent electronic device (IED)

Programmable logic controller (PLC)

Communications

Directly wired (typical for shorter

distances)

Power line carrier (less common)

Microwave (very frequently used)

Radio (VHF, spread spectrum)

Fiber optic (gaining popularity)

Supervisory Control

Data Acquisition

Real Time Database

Graphical Operator Interface

Alarm Processing

Data Historian/Strip Chart Trending

Mapboard Interface

Almost every business in the manufacturing

sector and many in the service sector

Aerospace

Bottling and Canning

Chemicals Plants

Petroleum, Petrochemical

Hardware

Programmable Logic Controllers (PLCs) - Standardized on Allen-

Bradley SLC and Micrologix controllers

MAS/MDS radios and modems for Radio

Communication

Standardized on Rockwell Software

RSLogix for programming

RSLinx for communications

RSView for Operator Interface

RSMessenger for Alarm Paging

LapLink Software allows connection to operator workstation from a

remote computer through a dial-up modem

You might also like

- Training CertificateDocument1 pageTraining CertificateProsenjit ChatterjeeNo ratings yet

- EE Final Upto 4th Year Syllabus April 10, 2013Document62 pagesEE Final Upto 4th Year Syllabus April 10, 2013menilanjan89nLNo ratings yet

- IET Competition Certificate PDFDocument1 pageIET Competition Certificate PDFProsenjit ChatterjeeNo ratings yet

- Transmission Line Applications in P SpiceDocument35 pagesTransmission Line Applications in P SpiceFrancesco CordellaNo ratings yet

- Research Article: An Efficient Gait Recognition With Backpack RemovalDocument8 pagesResearch Article: An Efficient Gait Recognition With Backpack RemovalProsenjit ChatterjeeNo ratings yet

- Bank DetailsDocument1 pageBank DetailsProsenjit ChatterjeeNo ratings yet

- Basic PLCDocument77 pagesBasic PLCrpshvju100% (1)

- Matlab Simulink Based Digital Protection ofDocument5 pagesMatlab Simulink Based Digital Protection ofInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Electrical Interview QuestionDocument7 pagesElectrical Interview QuestionProsenjit ChatterjeeNo ratings yet

- Protection of Power TransformerDocument19 pagesProtection of Power TransformerRitesh Verma100% (2)

- Control Engg. Lab ManualDocument89 pagesControl Engg. Lab ManualZaib RehmanNo ratings yet

- Protection of Power TransformerDocument19 pagesProtection of Power TransformerRitesh Verma100% (2)

- W I P T ?: HAT IS THE Mage Rocessing OolboxDocument1 pageW I P T ?: HAT IS THE Mage Rocessing OolboxProsenjit ChatterjeeNo ratings yet

- Reducing Operation Costs Through SCADA System Modernization: Rmsawwa/Rmwea 2002 Annual ConferenceDocument18 pagesReducing Operation Costs Through SCADA System Modernization: Rmsawwa/Rmwea 2002 Annual ConferenceProsenjit ChatterjeeNo ratings yet

- Able OF OntentsDocument1 pageAble OF OntentsProsenjit ChatterjeeNo ratings yet

- Integration and Automation of Manufacturing SystemsDocument593 pagesIntegration and Automation of Manufacturing SystemsAlejo LalvayNo ratings yet

- Advanced Image Processing With MatlabDocument65 pagesAdvanced Image Processing With Matlabks_proNo ratings yet

- MicroprocessorsDocument24 pagesMicroprocessorsarokiarajNo ratings yet

- Research Article: An Efficient Gait Recognition With Backpack RemovalDocument8 pagesResearch Article: An Efficient Gait Recognition With Backpack RemovalProsenjit ChatterjeeNo ratings yet

- Thesis and ReportDocument27 pagesThesis and ReportProsenjit ChatterjeeNo ratings yet

- Basic PLCDocument77 pagesBasic PLCrpshvju100% (1)

- ComputerArchitecture Chapter1 Introduction ColorDocument94 pagesComputerArchitecture Chapter1 Introduction ColorProsenjit ChatterjeeNo ratings yet

- Lecture PLCDocument30 pagesLecture PLCProsenjit Chatterjee100% (1)

- Chapter 7. PROGRAMMABLE Logic Controller: Dr. T.C. Chang School of Industrial Engineering Purdue UniversityDocument57 pagesChapter 7. PROGRAMMABLE Logic Controller: Dr. T.C. Chang School of Industrial Engineering Purdue UniversityAishwarya Kumar PandeyNo ratings yet

- Industrial Automation Summer Training Report, PLC, SCADA, HMI Instrumentation - ShamsherDocument49 pagesIndustrial Automation Summer Training Report, PLC, SCADA, HMI Instrumentation - ShamsherMd Shamsher86% (28)

- Solar Street LightDocument59 pagesSolar Street LightSiddharth Joon80% (10)

- Electrical Interview QuestionDocument7 pagesElectrical Interview QuestionProsenjit ChatterjeeNo ratings yet

- Thesis and ReportDocument27 pagesThesis and ReportProsenjit ChatterjeeNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- SIWES ReportDocument23 pagesSIWES ReportDaniel Abara93% (15)

- ESD Design PDFDocument39 pagesESD Design PDFarammart100% (2)

- Slides PDF HCI 02 4 CreatingDesignGoalsDocument22 pagesSlides PDF HCI 02 4 CreatingDesignGoalsTuấn Anh LêNo ratings yet

- SS901 DSD 95 DriveDocument4 pagesSS901 DSD 95 DriveSantosh InchalNo ratings yet

- LTSpice Tutorial New PDFDocument10 pagesLTSpice Tutorial New PDFNino NonikashviliNo ratings yet

- Section PlaneDocument38 pagesSection PlaneDeepakDeepNo ratings yet

- Radio Ip AlcatelDocument548 pagesRadio Ip Alcatelcgottoli100% (3)

- FJHJ Volume 85 Issue 1 Pages 320-357Document38 pagesFJHJ Volume 85 Issue 1 Pages 320-357DaliNo ratings yet

- Sample Document - Joining Kit For EPDocument5 pagesSample Document - Joining Kit For EPkish100% (1)

- UNIT 2 OverviewDocument28 pagesUNIT 2 OverviewRohan MehraNo ratings yet

- Cisco Aironet 1140 Series Getting Started GuideDocument34 pagesCisco Aironet 1140 Series Getting Started GuideDmitryNo ratings yet

- Test 17Document23 pagesTest 17Joe StoneNo ratings yet

- Enam Motors - ERP - ProposalDocument11 pagesEnam Motors - ERP - ProposalMainuddin BhuiyanNo ratings yet

- Master Transition Plan DocumentDocument16 pagesMaster Transition Plan Documentrlfisch100% (1)

- COMSOL Simulates Processors For Fiber Optics CommunicationDocument6 pagesCOMSOL Simulates Processors For Fiber Optics CommunicationRodrigo CavalcanteNo ratings yet

- Instant Download Test Bank For Technical Drawing For Engineering Communication 7th Edition PDF ScribdDocument27 pagesInstant Download Test Bank For Technical Drawing For Engineering Communication 7th Edition PDF ScribdNatalieMillersrjf100% (17)

- HGI Catalog PDFDocument33 pagesHGI Catalog PDFYaqien ChusnoelNo ratings yet

- Add or Remove A Digital Signature in Office FilesDocument8 pagesAdd or Remove A Digital Signature in Office Filesmili_ccNo ratings yet

- CSE 451: Operating Systems Semaphores and MonitorsDocument30 pagesCSE 451: Operating Systems Semaphores and MonitorsrinspdNo ratings yet

- LCMDocument100 pagesLCMANSHUMAN MISHRANo ratings yet

- Object Oriented - Design.& .Patterns.2nd - Edition Cay - HorstmannDocument473 pagesObject Oriented - Design.& .Patterns.2nd - Edition Cay - HorstmannPurushotham Bv100% (2)

- 98-366 MTA Networking Fundamental - SlidesDocument232 pages98-366 MTA Networking Fundamental - Slidesharyanto100% (3)

- Analysis of The Exchange Rate in Peru Between January 2020 and December 2021academic Journal of Interdisciplinary StudiesDocument9 pagesAnalysis of The Exchange Rate in Peru Between January 2020 and December 2021academic Journal of Interdisciplinary StudiesVíctor Hugo En Cuarentena Fernández-BedoyaNo ratings yet

- 2014 Cascadia - 2Document3 pages2014 Cascadia - 2Kirk Easom100% (1)

- ZAAA x32 Ironman SK (ZAA) & Captain SK (ZAAA) MB 6L E Version PDFDocument48 pagesZAAA x32 Ironman SK (ZAA) & Captain SK (ZAAA) MB 6L E Version PDFSebastian StanacheNo ratings yet

- Reactor FuncionamientoDocument24 pagesReactor FuncionamientoDaniel BahamondesNo ratings yet

- Expert Systems TypesDocument9 pagesExpert Systems TypesOlaniyiOluwatosinFalomoNo ratings yet

- NN Bhargava Basic Electronics and Linear Circuits PDFDocument169 pagesNN Bhargava Basic Electronics and Linear Circuits PDFJovin Pallickal Thomas50% (2)

- Transcript 870757Document2 pagesTranscript 870757denideni27No ratings yet

- Assessor's Package For HNS - L4Document9 pagesAssessor's Package For HNS - L4bayushNo ratings yet