Professional Documents

Culture Documents

S.T.B.S. College of Diploma Engg, Surat

Uploaded by

Alfredo Nunes da SilvaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

S.T.B.S. College of Diploma Engg, Surat

Uploaded by

Alfredo Nunes da SilvaCopyright:

Available Formats

NAME: AKSHAY J GHEEWALA.

VRAJ C GANDHI.

EN.NO.: 10-9052 & 10-9050

SEMINAR: WATER JET MACHINING

SUBJECT: MANUFACTRING PRACTICE

CLASS: 1051 (MECH-C)

S.T.B.S. COLLEGE OF DIPLOMA

ENGG,SURAT

Abrasive Waterjet

Machining

A water jet cutter is a tool capable of slicing into

metal or other materials using a jet of water at high

velocity & pressure, or a mixture of water & an

abrasive substance.

Water jet cutter

The cutter is commonly connected to a high pressure

water pump where the water is then ejected from the

nozzle, cutting through the material by spraying it

with the jet of high speed water. Additives in the form

of suspended grit or other abrasives, such as garnet

and aluminum oxide can assist in this process.

Working principle

Fastest growing machining process

One of the most versatile machining processes

Compliments other technologies such as milling,

laser, EDM, plasma and routers

True cold cutting process no HAZ, mechanical

stresses or operator and environmental hazards

Not limited to machining food industry

applications

Introduction to WaterJet

Pure cuts soft materials cardboard, disposable

diapers, tissue papers, automotive interiors

Very thin stream (0.004-0.010 dia).

Very little material loss due to cutting.

Can cut thick, soft, light materials like fiberglass

insulation up to 24 thick or thin, brittle materials.

Very low cutting forces and simple fixturing.

Pure WJ Cutting

Water inlet pressure

between 20k-60k psi

Forced through hole in

jewel 0.007-0.020 dia

Sapphires, Rubies with

50-100 hour life

Diamond with 800-2,000

hour life, but they are

pricey

Pure WJ Cutting cont.

Used to cut much harder materials

Water is not used directly to cut material as in Pure,

instead water is used to accelerate abrasive particles

which do the cutting

80-mesh garnet (sandpaper) is typically used though

50 and 120-mesh is also used

Standoff distance between mixing tube and workpart

is typically 0.010-0.200 important to keep to a

minimum to keep a good surface finish

Abrasive WJ Cutting

Evolution of mixing tube

technology

Standard Tungsten Carbide lasts 4-

6 hours (not used much anymore)

Premium Composite Carbide lasts

100-150 hours

Consumables include water,

abrasive, orifice and mixing tube

Abrasive WJ Cutting cont.

Setup

When is it Practical?

The cutter is commonly connected to

a high-pressure water pump, where

the water is then ejected from the

nozzle, cutting through the material

by spraying it with the jet of high-

speed water.

Its practical to use it to cut any kind

of material. In waterjet cutting, there

is no heat generated. This is especially

useful for cutting tool steel and other

metals where excessive heat may

change the properties of the material.

Waterjet cutting does not leave a burr

or a rough edge, and eliminates other

machining operations such as finish

sanding and grinding. It can be easily

automated for production use.

Advantages

Cheaper than other processes.

High cutting speed.

Make all sorts of shapes with only one tool.

No heat generated.

It does not produce dust or particles.

Clean cutting process without gasses or oils.

Modern systems are now very easy to learn.

Are very safe.

No need for resharpening tools.

This part is shaped with waterjet

using one tool. Slots, radii, holes,

and profile in one 2 minute setup.

Disadvantages

One of the main disadvantages of water

jet cutting is that a limited number of

materials can be cut economically. While

it is possible to cut tool steels, and other

hard materials, the cutting rate has to be

greatly reduced, and the time to cut a part

can be very long. Because of this, water jet

cutting can be very costly and outweigh

the advantages.

Another disadvantage is that very thick

parts can not be cut with water jet cutting

and still hold dimensional accuracy. If the

part is too thick, the jet may dissipate

some, and cause it to cut on a diagonal, or

to have a wider cut at the bottom of the

part than the top. It can also cause a rough

wave pattern on the cut surface.

Waterjet lag

Metal cutting

Printed Circuit Boards

Wire Stripping

Food Preparation

Tool Steel

Wood Cutting

Cleaning Applications

Application

Waterjets v/s Lasers

Abrasive waterjets can machine many

materials that lasers cannot. (Reflective

materials in particular, such as Aluminum and

Copper.

Uniformity of material is not very important

to a waterjet.

Waterjets do not heat your part. Thus there

is no thermal distortion or hardening of the

material.

Precision abrasive jet machines can obtain

about the same or higher tolerances than

lasers (especially as thickness increases).

Waterjets are safer.

Maintenance on the abrasive jet nozzle is

simpler than that of a laser, though probably

just as frequent.

After laser cutting

After waterjet cutting

Waterjets vs. EDM

Waterjets are much faster than EDM.

Waterjets machine a wider variety of

materials (virtually any material).

Uniformity of material is not very

important to a waterjet.

Waterjets make their own pierce holes.

Waterjets are capable of ignoring

material aberrations that would cause

wire EDM to lose flushing.

Waterjets do not heat the surface of what

they machine.

Waterjets require less setup.

Many EDM shops are also buying

waterjets. Waterjets can be considered to

be like super-fast EDM machines with less

precision.

Waterjets are much faster than EDM.

Waterjets v/s. Plasma

Waterjets provide a nicer edge finish.

Waterjets don't heat the part.

Waterjets can cut virtually any material.

Waterjets are more precise.

Plasma is typically faster.

Waterjets would make a great compliment to

a plasma shop where more precision or higher

quality is required, or for parts where heating

is not good, or where there is a need to cut a

wider range of materials.

After plasma cutting

After waterjet cutting

Drilling wells

Drilling for oil

Radial tunnels

Future of Waterjet

Edge finishing

Radiusing

De-burring

Polishing

Practical Applications

Relatively new technology has caught on quickly and is

replacing century-old methods for manufacturing

Used not only in typical machining applications, but food

and soft-goods industries

As material and pump technology advances faster cutting

rates, longer component life and tighter tolerances will be

achievable

Paves the way for new machining processes that embrace

simplicity and have a small environmental impact

Conclusion

You might also like

- Water Jet MachiningDocument20 pagesWater Jet MachiningRazvan MargineanNo ratings yet

- Gambheer Singh Mecahnical 4 YearDocument23 pagesGambheer Singh Mecahnical 4 YearMayank RawatNo ratings yet

- Dr. Ufaith H. Qadiri Associate Professor MREC Mechanical EnggDocument24 pagesDr. Ufaith H. Qadiri Associate Professor MREC Mechanical EnggNandam HarshithNo ratings yet

- Presentation Topic: Water Jet CuttingDocument18 pagesPresentation Topic: Water Jet CuttingMayank GargNo ratings yet

- Water Jet CutterDocument16 pagesWater Jet CutterJayant Sisodia0% (1)

- Water and Abrasive Jet MachiningDocument47 pagesWater and Abrasive Jet Machining01fe16bme163No ratings yet

- Abrasive Water Jet MachiningDocument12 pagesAbrasive Water Jet MachiningAbhimanyuPradhanNo ratings yet

- Name: Bharat Ratna Mishra REGD. 0901341092 Guide: Er. Bijay JaiswalDocument17 pagesName: Bharat Ratna Mishra REGD. 0901341092 Guide: Er. Bijay JaiswalSuhana MishraNo ratings yet

- Water Jet CuttingDocument15 pagesWater Jet CuttingMeray Habni AlshehriNo ratings yet

- Water Jet Cutting: Presented byDocument18 pagesWater Jet Cutting: Presented byronyNo ratings yet

- Why Is "Cold Cutting" Superior To Plasma Cutting?Document9 pagesWhy Is "Cold Cutting" Superior To Plasma Cutting?ahmedNo ratings yet

- Seminar ON Water Jet Cutting: Raj Kumar Goel Institute of TechnologyDocument17 pagesSeminar ON Water Jet Cutting: Raj Kumar Goel Institute of TechnologyRahul kumarNo ratings yet

- Water Jet CuttingDocument15 pagesWater Jet CuttingDevendar YadavNo ratings yet

- Water Jet Cutting: V.Loganathan M-Tech (PDM)Document34 pagesWater Jet Cutting: V.Loganathan M-Tech (PDM)Hemanth KumarNo ratings yet

- Water JetDocument27 pagesWater Jetvideo uploader dNo ratings yet

- Abrasive WaterjetDocument15 pagesAbrasive WaterjetAniket HardeNo ratings yet

- Abrasive Water Jet MachiningDocument40 pagesAbrasive Water Jet MachiningAnurag Mamgain100% (1)

- Water Jet CutterDocument16 pagesWater Jet CutterSedorfaNo ratings yet

- Abrasive Water Jet Machining ThesisDocument4 pagesAbrasive Water Jet Machining Thesisvtdvkkjbf100% (2)

- Water Jet Cutting: A Technical Seminar OnDocument23 pagesWater Jet Cutting: A Technical Seminar Onprem kumarNo ratings yet

- The Ultimate Guide To WaterjetDocument9 pagesThe Ultimate Guide To WaterjetNsidibe Michael EtimNo ratings yet

- 33 Water Jet CuttingDocument3 pages33 Water Jet CuttingIzaa Cryzza0% (1)

- IENG 475 HO 02 APT Programming NotesDocument20 pagesIENG 475 HO 02 APT Programming NotesHemanth KumarNo ratings yet

- K L E Society'S Polytechnic BAILHONGAL-591 102: "Water Jet Cutting"Document16 pagesK L E Society'S Polytechnic BAILHONGAL-591 102: "Water Jet Cutting"HmwDyNo ratings yet

- Dumkal Institute of Engineering & TechnologyDocument7 pagesDumkal Institute of Engineering & TechnologyabcNo ratings yet

- Advanced Manufacturing - Water Jet Abrasive MachineDocument9 pagesAdvanced Manufacturing - Water Jet Abrasive MachineroseNo ratings yet

- UnconventionalDocument53 pagesUnconventionalÖnder AyerNo ratings yet

- Selecting The Right WaterjetDocument25 pagesSelecting The Right WaterjetFilipe AntunesNo ratings yet

- An Introduction To WaterjetDocument11 pagesAn Introduction To WaterjetGurmeet KangerNo ratings yet

- 7 Hidrodynamic MachiningDocument14 pages7 Hidrodynamic Machiningrangga56No ratings yet

- Milling With Waterjet: Flow InternationalDocument4 pagesMilling With Waterjet: Flow InternationalAadithiyanNo ratings yet

- Thermal and Waterjet Cutting Processes PDFDocument5 pagesThermal and Waterjet Cutting Processes PDFdramiltNo ratings yet

- Water Jet CuttingDocument3 pagesWater Jet Cuttinguday245No ratings yet

- EML2322L-Abrasive Water Jet ProcessesDocument16 pagesEML2322L-Abrasive Water Jet ProcessesTurgut GülmezNo ratings yet

- Waterjet Cutting: Munthasir - T Coaneme038Document17 pagesWaterjet Cutting: Munthasir - T Coaneme038ronyNo ratings yet

- Water Jet Cutting ThesisDocument6 pagesWater Jet Cutting ThesisPayForSomeoneToWriteYourPaperSingapore100% (2)

- Water Jet CuttingDocument3 pagesWater Jet Cuttingnatrajan-ram-379No ratings yet

- Water Jet Cutting AbsDocument12 pagesWater Jet Cutting AbsJagan BabuNo ratings yet

- Water Jet MachiningDocument7 pagesWater Jet Machiningbnnikhil8No ratings yet

- Water Jet Machining Lecture NotesDocument5 pagesWater Jet Machining Lecture Notesselvi6496No ratings yet

- Chapter Five: Non-Traditional Machining Processes Dawit DebashDocument103 pagesChapter Five: Non-Traditional Machining Processes Dawit Debashchala nigussieNo ratings yet

- 2.2.2. Applications: Me2026 Unconventional Machining Process 12Document6 pages2.2.2. Applications: Me2026 Unconventional Machining Process 12CHARANNo ratings yet

- Chapter 07 - Non-Traditional MachiningDocument34 pagesChapter 07 - Non-Traditional MachiningNurul AsyilahNo ratings yet

- Waterjet CuttingDocument15 pagesWaterjet CuttingMars Marshel100% (1)

- Nontraditional Machining Processes: Mr. D. N. PatelDocument53 pagesNontraditional Machining Processes: Mr. D. N. PatelrrameshsmitNo ratings yet

- My Hobb byDocument8 pagesMy Hobb byJoy RoyNo ratings yet

- ME2026 Uw PDFDocument39 pagesME2026 Uw PDFPrashant Rao MeshramNo ratings yet

- State State of The Art of Precision Abrasive Water Jet Cuttiof The Art of Precision Abrasive Water Jet CuttingDocument22 pagesState State of The Art of Precision Abrasive Water Jet Cuttiof The Art of Precision Abrasive Water Jet CuttingJaveed A. KhanNo ratings yet

- Water Jet MachiningDocument33 pagesWater Jet Machiningjojo258No ratings yet

- Water Jet CutterDocument6 pagesWater Jet CutterVarun Krishna ManneNo ratings yet

- NaveenDocument1 pageNaveennaveenNo ratings yet

- Review On Abrasive Water Jet Cutting: by Sherif ArabyDocument106 pagesReview On Abrasive Water Jet Cutting: by Sherif ArabyVaranasi SrikarNo ratings yet

- Water Jet CutterDocument16 pagesWater Jet CutterRex Delon50% (2)

- Sreedhar 1Document49 pagesSreedhar 1Praveen KumarNo ratings yet

- Mechanical Advanced Machining Processes: Abrasive Jet Machining-AJM Ultrasonic machining-USMDocument31 pagesMechanical Advanced Machining Processes: Abrasive Jet Machining-AJM Ultrasonic machining-USMsajjad NNo ratings yet

- WJM Seminar Report PDFDocument14 pagesWJM Seminar Report PDFpalak mohodNo ratings yet

- Abrasive Water Jet CuttingDocument3 pagesAbrasive Water Jet CuttinghaniNo ratings yet

- High Pressure Water CuttingDocument6 pagesHigh Pressure Water CuttingtimNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Microstructural and Wear Characteristics of Friction Stir Processed Al-7075/Sic Reinforced Aluminium CompositeDocument10 pagesMicrostructural and Wear Characteristics of Friction Stir Processed Al-7075/Sic Reinforced Aluminium Compositekalyanamanohar100% (1)

- Effect of Graphene Addition On The Mechanical Characteristics of AA7075 Aluminium NanocompositesDocument12 pagesEffect of Graphene Addition On The Mechanical Characteristics of AA7075 Aluminium NanocompositeskalyanamanoharNo ratings yet

- Characterization of Al-7075 Metal Matrix Composites: A ReviewDocument10 pagesCharacterization of Al-7075 Metal Matrix Composites: A ReviewkalyanamanoharNo ratings yet

- 1 00833 PDFDocument2 pages1 00833 PDFkalyanamanoharNo ratings yet

- Me2103 m2 NotesDocument34 pagesMe2103 m2 NoteskalyanamanoharNo ratings yet

- AspalDocument104 pagesAspalKholis FindmeNo ratings yet

- 14 A Check Lists - AACDocument3 pages14 A Check Lists - AACVaibhav PatilNo ratings yet

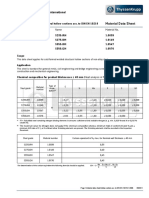

- Product Data: F149 Polyester MatrixDocument4 pagesProduct Data: F149 Polyester MatrixSaidiJalelNo ratings yet

- S-T1-424-F1-2004 - Framing Plan Level B1 Sheet 004Document1 pageS-T1-424-F1-2004 - Framing Plan Level B1 Sheet 004Marco ReyesNo ratings yet

- Structural Steel VolumeDocument19 pagesStructural Steel Volumedeepa lakshmiNo ratings yet

- Psychrometric Chart & Psychrometry in Air Conditioner SizingDocument8 pagesPsychrometric Chart & Psychrometry in Air Conditioner SizingshoaibNo ratings yet

- Mark III LNG TanksDocument3 pagesMark III LNG TanksEdutamNo ratings yet

- 5158 00 PI SPC 0005 - 1 Specification For ValvesDocument38 pages5158 00 PI SPC 0005 - 1 Specification For Valvesأحمد عبدالنعيمNo ratings yet

- Free SilicaDocument1 pageFree Silicasrinivasu67No ratings yet

- FS Type Fan CoilDocument6 pagesFS Type Fan CoilHamo HamoNo ratings yet

- Society of Automotive Engineers PDFDocument3 pagesSociety of Automotive Engineers PDFShine0% (1)

- La Protection Des Ouvrages en BetonDocument23 pagesLa Protection Des Ouvrages en BetonLotfi KhelifaNo ratings yet

- Mens Bracelet Silver and Glass - Google SearchDocument1 pageMens Bracelet Silver and Glass - Google SearchmontygwennapNo ratings yet

- Cement: Opus CaementiciumDocument12 pagesCement: Opus CaementiciumBasem SalemNo ratings yet

- Hollow Section Acc. To 10219Document3 pagesHollow Section Acc. To 10219Abdul HadhiNo ratings yet

- Documentatie Flowserve Schmidt Armaturen 3 3 Vana Control FlowProDN25 300 PN63 160 DIN Sialco Reprezentanta Flowserve RomaniaDocument28 pagesDocumentatie Flowserve Schmidt Armaturen 3 3 Vana Control FlowProDN25 300 PN63 160 DIN Sialco Reprezentanta Flowserve Romaniajns1606No ratings yet

- CHAPTER 1 FINAL YEAR ProjectDocument5 pagesCHAPTER 1 FINAL YEAR ProjectdejayzNo ratings yet

- Lime in ConstructionDocument7 pagesLime in Constructionsriatul2006No ratings yet

- Monopitch Roof Steel Truss (Ware House) 12345Document5 pagesMonopitch Roof Steel Truss (Ware House) 12345FatihNo ratings yet

- Flexural Members of Special Moment FramesDocument39 pagesFlexural Members of Special Moment FramesJenny MorenoNo ratings yet

- 01 Samss 035 API LinepipeDocument28 pages01 Samss 035 API Linepipemdsazidalam100% (2)

- A New Approach With Prepregs For ReinforcingDocument8 pagesA New Approach With Prepregs For ReinforcingRajesh Kumar SNo ratings yet

- C13 XQ350 Power Module Electrical System: Harness and Wire Electrical Schematic SymbolsDocument4 pagesC13 XQ350 Power Module Electrical System: Harness and Wire Electrical Schematic SymbolsMian MubasharNo ratings yet

- Shelco 4FOS 5FOS Housings1Document2 pagesShelco 4FOS 5FOS Housings1ramonmzaNo ratings yet

- Protection & InterlocksDocument18 pagesProtection & InterlocksSanjay GuptaNo ratings yet

- Lecture-7-Part 1-Strength of Materials - Bending StressesDocument41 pagesLecture-7-Part 1-Strength of Materials - Bending Stressesarno assassinNo ratings yet

- Saes L 100Document13 pagesSaes L 100Honesto Bautista100% (3)

- Advanced Ceramic Components - Materials, Fabrication, and Applications PDFDocument32 pagesAdvanced Ceramic Components - Materials, Fabrication, and Applications PDFDaxel Val100% (1)

- Roof Garden Specification PDFDocument41 pagesRoof Garden Specification PDFKhushbooNo ratings yet