Professional Documents

Culture Documents

Marine Auxiliary Machinery: 4 Positive Displacement Pumps

Uploaded by

Joshua HicksOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Marine Auxiliary Machinery: 4 Positive Displacement Pumps

Uploaded by

Joshua HicksCopyright:

Available Formats

1

Marine Auxiliary

Machinery

Chapter 1 Lesson 4

Positive Displacement Pumps

By Professor Zhao Zai Li

05.2006

2

Learning objectives

After successfully completing this lesson, you will be

familiar with:

1: The operation of a reciprocating pumps

2: Single and double acting reciprocating pumps

3: The operation of several different rotary positive

displacement pumps

4: The relief valve In positive displacement pumps.

3

Rotary

Reciprocating

Basic design

Positive displacement pumps have one of two basic designs either

Reciprocating or Rotary.

4

Positive Displacement Pumps

versus Centrifugal Pumps

Positive displacement pumps differ from centrifugal pumps in

that they use mechanical energy to transfer fluid. If the

displacement is on the forward stroke only, then the pump is

single acting.

This pump is double acting because it displaces liquid both on

the forward and return stroke.

5

Positive Displacement Pumps

versus Centrifugal Pumps

Positive displacement pumps differ from

centrifugal pumps in that they use

mechanical energy to transfer fluid. If the

displacement is on the forward stroke only,

then the pump is single acting.

This pump is double acting because it

displaces liquid both on the forward and

return stroke.

6

Key features - reciprocating pump

design

High pressures Self-priming

External Priming

Cgnnectign

Pressure Fluctuatigns

Damper

7

Key features - reciprocating pump

design

High pressures

Positive displacement pumps are capable of delivering very

high pressures.

These pressures can be much in excess of the design

pressure and so a relief valve must protect the pump.

8

Key features - reciprocating pump

design

Self-priming

Positive displacement pumps are self-priming as the suction

and delivery are positively separated during pumping.

9

Key features - reciprocating pump

design

Self-priming

Positive displacement pumps are self-priming as the suction

and delivery are positively separated during pumping.

10

Key features - reciprocating pump

design

Damper Valve Relief valve

External Priming

Cgnnectign

However, in order to reduce wear and ensure quick starting, an external

priming connection from above the pump should be available.

11

Key features - reciprocating pump

design

Damper Valve Relief valve

Pressure Fluctuatigns

Reciprocating pumps can produce pressure fluctuations in the

discharge pipelines.

12

Key features - reciprocating pump

design

A damper, either gas or air filled, can help to even out the

pressure fluctuations. The damper stores some of the energy

as the pressure rises, and releases this energy as the pressure

falls.

Damper

13

Quick quiz

14

Rotary pumps

Most positive displacement pumps in use

are of the rotary type.

Rotary pumps operate in a circular motion

and displace a constant amount of liquid

with each revolution of the pump shaft.

This is accomplished by the pumping

elements moving in such a way as to expand

volumes to allow liquid to enter the pump.

These volumes are contained by the pump

until the geometry causes the elements to

move to reduce the volume and force the

liquid out

The clearances of the elements within the

pump separate the suction from the

discharge and are critical for efficient

operation.

15

Radial and Axial Piston

Rotary piston type positive displacement pumps

are found in hydraulic systems. There are two

types: radial piston and axial piston

16

Operation of the radial piston

pump

You can see that the pistons rotate

eccentrically to the rotor axis. This causes

the cylinder volume to increase as the

pistons pass the suction port,and decrease

as the pistons pass the delivery port.

In some applications such as steering gear

applications,the pump can have a variable

discharge .This is achieved by increasing

and decreasing the eccentricity of the

pistins thereby changing the amount of

cylinder volume increase.

The nature of the ports can also change by

moving the piston eccentricity past the

pump centre line.

17

Operation of the axial piston pump

2. and are forced back

in at outlet

1. Pistons withdraw

from bore at inlet.

PISTON

DRME

SWASH

OUTLET PORT

An axial piston pump is sometimes known as a swash plate pump.

The principle is the same as for the Radial type.

An axial piston pump can also be used as a variable delivery pump.

18

Interna! and external gear pumps

Gear pumps rely on the

meshing of gear wheels to

separate the suction and

delivery ports.

They come in two

configurations, either

Internal gear or External

gear.

Internal gear pumps

External gear oumos

19

Internal gear pump

Internal gear pumps use the same principle as the external type.

In this case the driven gear has internal teeth and meshes with

the idler, which has external teeth.

20

External gear pump

The External gear pump has two

gear wheels, one that is driven by

the motor and the second, or idler,

which is driven by the meshing of

the gears.

The gears carry the liquid around

the outside and the meshing of the

teeth cause the liquid to be

discharged.

21

Screw type pumps

Twin-screw pumps Three-screw pumps

Screw type pumps usually have either two or three screws. They

can operate at high speeds and give a smooth discharge with

almost no pulsations.

They come in two configurations, either Twin-screw pump or

Three-screw pump.

22

Twin-screw pumps

Due to the imbalance of forces, this type of pump often has

the suction arranged at the centre of the Shdft screws and

the delivery at either end, and is often driven through timing

gears, which keep the screws from contacting each other.

Due to the imbalance of forces ,this type of pump often has

the suction arranged at the centre of the shaft screws and the

delivery at either end ,and is often driven through timing

gears,which keep the screws from contacting each other.

23

Three-screw pumps

The Three-screw pump is usually

arranged so that the central screw

drives the two outer screws.

24

Progressive cavity pumps

A special type of screw pump is the single screw or progressive cavity

pump. This pump has a single screw rotating in stator. The stator is made of

an elastomer material.

The stator has an internal helix of different pitch to the rotor. The geometry

means that the rotor moves vertically whilst turning, so the meshing of the

rotor and stator causes the cavity to progress to the

discharge.

The screw is an interference fit in the stator, so this pump must always

have liquid present to prevent overheating and failure.

25

Quick quiz

Which part of a progressive cavity pump is called a stator?

Click on the stator.

If you are not sure, go to the previous screen to refresh your memory.

26

Vane pumps

Flexible vane pumps

Vane pumps come in two configurations,

either Flexible Vane Pump or Sliding Vane

Pump.

Sliding vane pumps

27

Flexible vane pumps

The rotor is made of an

elastomer, and as the vanes

pass the cam they deflect,

decreasing the cavity and so

discharging the liquid.

Casing

Rotor

28

Sliding vane pumps

The vanes are a sliding fit

in slots cut in the rotor. The

rotor turns eccentric to the

casing, causing the cavities to

decrease in volume.

Vanes can be forced out by

centrifugal force, use springs

or utilise the pressure of the

discharge liquid.

29

Quick quiz

Where are the vanes located?

Click on the vanes.

If you are not sure, go to the previous screen to refresh your memory.

30

Lesson test

In this test you must answer some questions from the current

lesson. You must take the test to complete the lesson.

Please read the "General rules for tests" if you're not familiar

with taking tests on the computer.

Click the Next-button if you are ready to take the test.

Click the Previous-button if you want to repeat any part of

the lesson before taking the test.

Click the Menu-button if you want to repeat the lesson from

Its beginning.

31

Question 1

In order to pump liquids Positive displacement pumps rely

on?

A) Fast speed of operation

B) Small clearances within the pump

C) Change of volume of the pump chambers

D) Non-return valves

E) I do not know

32

Question 2

Positive displacement pumps can only vary their delivery

rate by changing the speed of the drive motor.

A) True

B) False

C) I do not know

33

Question 3

Positive displacement screw or vane pumps are used for oily

water separator supply because?

A) They are self priming

B) They have a minimum of moving parts

C) They deliver a constant flow

D) They do not cause oil droplet size to change

E) I do not know

34

Question 4

Positive displacement pumps require a relief valve because?

A) It can regulate the delivery pressure.

B) The pump gives a constant flow rate.

C) It allows priming liquid to return to the suction.

D) A high pressure could overload the motor.

E) I do not know.

35

Question 5

Positive displacement pumps require a relief valve because?

A) It can regulate the delivery pressure.

B) The pump gives a constant flow rate.

C) It allows priming liquid to return to the suction.

D) A high pressure could overload the motor.

E) I do not know.

36

Question 6

Positive displacement pumps are ideal for fuel transfer

duties because?

A) They can deliver high pressures

B) They have very small clearances

C) They can handle large volumes of vapours and gases

D) They require the pumped liquid to be used for

lubrication

E) I dont know

You might also like

- Stan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineFrom EverandStan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineRating: 5 out of 5 stars5/5 (1)

- Operator’S Guide to Centrifugal Pumps: What Every Reliability-Minded Operator Needs to KnowFrom EverandOperator’S Guide to Centrifugal Pumps: What Every Reliability-Minded Operator Needs to KnowRating: 2 out of 5 stars2/5 (1)

- Know and Understand Centrifugal PumpsFrom EverandKnow and Understand Centrifugal PumpsL. BachusRating: 4 out of 5 stars4/5 (1)

- Operator’S Guide to Centrifugal Pumps, Volume 2: What Every Reliability-Minded Operator Needs to KnowFrom EverandOperator’S Guide to Centrifugal Pumps, Volume 2: What Every Reliability-Minded Operator Needs to KnowNo ratings yet

- 2. Forsthoffer's Rotating Equipment Handbooks: PumpsFrom Everand2. Forsthoffer's Rotating Equipment Handbooks: PumpsRating: 1 out of 5 stars1/5 (1)

- Centrifugal Pump Components and ClassificationDocument46 pagesCentrifugal Pump Components and ClassificationRiyadh SalehNo ratings yet

- Centrifugal PumpDocument41 pagesCentrifugal PumpAbdallah MansourNo ratings yet

- Pump and Compressor 2Document52 pagesPump and Compressor 2SaravananRamasamy100% (3)

- Course2a-Energy Efficiency PDFDocument59 pagesCourse2a-Energy Efficiency PDFNazaruddin SinagaNo ratings yet

- Pump TheoryDocument23 pagesPump TheoryYeahkevinrocksNo ratings yet

- Al-Salam Higher Institute For: by Abdelaal Mohamed Khttap Cairo 2014Document28 pagesAl-Salam Higher Institute For: by Abdelaal Mohamed Khttap Cairo 2014عبدوخطابNo ratings yet

- Centrifugal Pumps and SealDocument32 pagesCentrifugal Pumps and SealAnatoli KarpobNo ratings yet

- Manufacturing centrifugal and reciprocating pumpsDocument24 pagesManufacturing centrifugal and reciprocating pumpsumarNo ratings yet

- Industrial Compressors & Pump MaintenanceDocument166 pagesIndustrial Compressors & Pump MaintenancevenkeekuNo ratings yet

- Know Your Equipment - Centrifugal PumpDocument93 pagesKnow Your Equipment - Centrifugal Pumpsgupta_615796100% (1)

- Mep All QuestionsDocument79 pagesMep All QuestionsbabaNo ratings yet

- Chapter 3 Centrifugal Compressors and FansDocument54 pagesChapter 3 Centrifugal Compressors and FansMichael Mesfin100% (1)

- Pump MaintenanceDocument83 pagesPump MaintenanceSiva Kumar Tutika100% (3)

- Pump Installation & MaintenanceDocument116 pagesPump Installation & MaintenanceMohammed El-Shahat100% (8)

- Pump CalculationsDocument6 pagesPump CalculationsAshenafi Gebremeskel MezgeboNo ratings yet

- PUMP TrainingDocument130 pagesPUMP TrainingTirta Budiawan100% (4)

- Pump Troubleshooting: Ahmed Abdullah ZayedDocument514 pagesPump Troubleshooting: Ahmed Abdullah Zayedاشرينكيل مسونكيل0% (1)

- CENTRIFUGAL PUMPS Notes For StudentsDocument35 pagesCENTRIFUGAL PUMPS Notes For Studentsbukboy100% (12)

- Troubleshooting of Rotating EquipmentsDocument4 pagesTroubleshooting of Rotating Equipmentss33d_2010No ratings yet

- Unit-I: TO Ic EnginesDocument43 pagesUnit-I: TO Ic EnginesLeo Dev WinsNo ratings yet

- Presentation On Heat ExchangersDocument54 pagesPresentation On Heat ExchangersNagendrababu Mahapatruni100% (1)

- Centrifugal PumpsDocument30 pagesCentrifugal PumpsNitish NairNo ratings yet

- Reciprocating Pump PratishthaDocument13 pagesReciprocating Pump Pratishthamike rosaNo ratings yet

- Centrifugal PumpDocument27 pagesCentrifugal Pumpdivmech1988100% (2)

- Centrifugal Pump OverloadingDocument2 pagesCentrifugal Pump OverloadingAbdul AlimNo ratings yet

- Maintenance of PumpsDocument22 pagesMaintenance of PumpsBhaumik Bhuva100% (2)

- Centrifugal Pump Impeller Design and PerformanceDocument105 pagesCentrifugal Pump Impeller Design and PerformanceMohamed Moataz100% (1)

- Boiler Feed Pump New 1Document39 pagesBoiler Feed Pump New 1789krishnaNo ratings yet

- PumpsDocument80 pagesPumpsMuhammad Nursalam100% (1)

- External Gear PumpDocument9 pagesExternal Gear PumpNaveen Kumar100% (1)

- Learn Basic Hydraulics Concepts in 40 CharactersDocument85 pagesLearn Basic Hydraulics Concepts in 40 CharactersRamesh Babu K KNo ratings yet

- Introduction to Positive Displacement CompressorsDocument30 pagesIntroduction to Positive Displacement CompressorschaitanyaNo ratings yet

- Functions of A PumpDocument178 pagesFunctions of A PumpKetan Sarmalkar50% (2)

- Pump PresentationDocument206 pagesPump Presentationalpha_beta48100% (2)

- BoilerDocument16 pagesBoilerZubair Khan100% (1)

- Pumps, Compressors, Turbines Operation, Maintenance & TroubleshootingDocument2 pagesPumps, Compressors, Turbines Operation, Maintenance & Troubleshootingm_alodat6144100% (1)

- Pump PresentationDocument66 pagesPump PresentationAnonymous K3FaYFlNo ratings yet

- Class 4 Quick Reference For MEP - Motor and General Er Shashwat - 1Document227 pagesClass 4 Quick Reference For MEP - Motor and General Er Shashwat - 1Lovy Singh100% (2)

- Why Centrifugal Pumps Can Overload MotorsDocument4 pagesWhy Centrifugal Pumps Can Overload MotorsKamal UddinNo ratings yet

- Troubleshooting PumpDocument54 pagesTroubleshooting PumpM.nour El-din100% (3)

- Centrifugal Pump MaintenanceDocument32 pagesCentrifugal Pump MaintenancemersiumNo ratings yet

- Hydraulic Resevoir Design Criteria PDFDocument10 pagesHydraulic Resevoir Design Criteria PDF2345421No ratings yet

- On-Line Duralobe Classic SQ RTP Sterilobe Acculobe Tra10 Tra20Document173 pagesOn-Line Duralobe Classic SQ RTP Sterilobe Acculobe Tra10 Tra20kamchorepkNo ratings yet

- Basics of Belt DrivesDocument12 pagesBasics of Belt DrivesSrinivasan RaviNo ratings yet

- Centrifugal Pumps in Scrubbing and FGD SystemsDocument27 pagesCentrifugal Pumps in Scrubbing and FGD SystemsPiyush MalviyaNo ratings yet

- TT 401 Paper: Theory of Machines GearsDocument45 pagesTT 401 Paper: Theory of Machines GearsDurjoy Roy100% (1)

- Overhauling of Centrifugal PumpDocument4 pagesOverhauling of Centrifugal Pumpanil thakur100% (1)

- Mechanical Seal ReplacementDocument21 pagesMechanical Seal ReplacementshahjahanhashimaliNo ratings yet

- Pump Maintenance Procedures 1Document7 pagesPump Maintenance Procedures 1Shraddha Raut100% (1)

- Training On Alignment of Rotating EquipmentDocument21 pagesTraining On Alignment of Rotating EquipmentJayant SagadeNo ratings yet

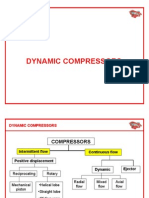

- Dynamic CompressorsDocument48 pagesDynamic Compressorsamrutnerlikar50% (2)

- Sem NomeaDocument2 pagesSem NomeaJoshua HicksNo ratings yet

- DaDocument1 pageDaJoshua HicksNo ratings yet

- Mini Report FormDocument1 pageMini Report FormJoshua HicksNo ratings yet

- Titration TheoryDocument46 pagesTitration TheoryJoshua HicksNo ratings yet

- Siemens Basics of PLCDocument89 pagesSiemens Basics of PLCAlejandro Cortes Bolados100% (1)

- Anleitung Gun (Working)Document288 pagesAnleitung Gun (Working)Joshua HicksNo ratings yet

- Titration LabDocument5 pagesTitration LabJoshua HicksNo ratings yet

- Electrical Study GuideDocument258 pagesElectrical Study GuideHM5100% (1)

- New ZealandDocument35 pagesNew ZealandJoshua HicksNo ratings yet

- Elizabeth IIDocument23 pagesElizabeth IIJoshua HicksNo ratings yet

- Error UncertaintyDocument6 pagesError UncertaintyAdron LimNo ratings yet

- 1 Acid BaseDocument6 pages1 Acid Basekuttyram2005No ratings yet

- Anzac DayDocument15 pagesAnzac DayJoshua HicksNo ratings yet

- New Zealand ParliamentDocument7 pagesNew Zealand ParliamentJoshua HicksNo ratings yet

- Instrumental Analysis Lecture Notes IIIDocument62 pagesInstrumental Analysis Lecture Notes IIIcoolhemakumar100% (1)

- Mahbub Ul HaqDocument6 pagesMahbub Ul HaqJoshua HicksNo ratings yet

- TitrationDocument8 pagesTitrationJoshua HicksNo ratings yet

- New South WalesDocument19 pagesNew South WalesJoshua HicksNo ratings yet

- Aata 20110810Document438 pagesAata 20110810Tram VoNo ratings yet

- Documenting NSW HistoryDocument19 pagesDocumenting NSW HistoryJoshua HicksNo ratings yet

- Soc 0849Document7 pagesSoc 0849Joshua HicksNo ratings yet

- POLI212fall2014 2Document3 pagesPOLI212fall2014 2Joshua HicksNo ratings yet

- USS MaconDocument7 pagesUSS MaconJoshua HicksNo ratings yet

- Yale UniversityDocument29 pagesYale UniversityJoshua HicksNo ratings yet

- Human Development IndexDocument20 pagesHuman Development IndexJoshua HicksNo ratings yet

- BotswanaDocument18 pagesBotswanaJoshua HicksNo ratings yet

- Pengkhianatan G30S:PKIDocument11 pagesPengkhianatan G30S:PKIJoshua Hicks100% (1)

- European Political Development As An Historical and Analytical NarrativeDocument2 pagesEuropean Political Development As An Historical and Analytical NarrativeJoshua HicksNo ratings yet

- HWDocument1 pageHWJoshua HicksNo ratings yet

- Ableton Live Manual JaDocument590 pagesAbleton Live Manual JaHiroyuki SugimotoNo ratings yet

- Et 321 06-23-15Document2 pagesEt 321 06-23-15Shishan AhmadNo ratings yet

- Chapter 12 - LCD and KeyboardDocument27 pagesChapter 12 - LCD and KeyboardAnkit KumarNo ratings yet

- Sharp Lc-46d65u & Lc-52d65u Final LCD TV SMDocument56 pagesSharp Lc-46d65u & Lc-52d65u Final LCD TV SMDan PrewittNo ratings yet

- Case Study Telefonica O2 Germany 116750 PDFDocument4 pagesCase Study Telefonica O2 Germany 116750 PDFGrand OverallNo ratings yet

- HRMS Applicant Assessment FormDocument12 pagesHRMS Applicant Assessment FormDivya KakumanuNo ratings yet

- The Significance of Andragogy in Present Day Higher EducationDocument5 pagesThe Significance of Andragogy in Present Day Higher EducationInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Contoh Spoof TextDocument7 pagesContoh Spoof TextIndrayaniNo ratings yet

- J Control - DX 9100 Digital ControllerDocument104 pagesJ Control - DX 9100 Digital Controlleramhosny640% (1)

- Lateral Earth Pressures For Seismic Design of Cantilever Retaining WallsDocument8 pagesLateral Earth Pressures For Seismic Design of Cantilever Retaining Wallsredpol100% (2)

- Vet. Medicine Companies in PakistanDocument6 pagesVet. Medicine Companies in PakistanRAO NABEEL AKRAM100% (1)

- Lumascape Lightings CatalogueDocument265 pagesLumascape Lightings CatalogueajlounicNo ratings yet

- CWI TEST FlashcardsDocument30 pagesCWI TEST FlashcardsLuis Jaramillo100% (3)

- Semantics-Based Image Retrieval by Region SaliencyDocument9 pagesSemantics-Based Image Retrieval by Region SaliencyRazzougui SarahNo ratings yet

- Fluid Mechanics CalculationsDocument3 pagesFluid Mechanics CalculationsandreagassiNo ratings yet

- Commander SK Size 2 To 6 Getting Started GuideDocument80 pagesCommander SK Size 2 To 6 Getting Started GuidesunhuynhNo ratings yet

- TLE 9 1st Quarter Exam With Answer Key PDFDocument3 pagesTLE 9 1st Quarter Exam With Answer Key PDFJymaer GeromoNo ratings yet

- BC Zong ProjectDocument25 pagesBC Zong Projectshahbaz awanNo ratings yet

- District Sales Manager or Territory Manager or Regional ManagerDocument3 pagesDistrict Sales Manager or Territory Manager or Regional Managerapi-121327024No ratings yet

- Fireplaces, Mantels, Hearths & InteriorsDocument12 pagesFireplaces, Mantels, Hearths & InteriorsFare NienteNo ratings yet

- Recruitment of Junior Associates (Customer Support & Sales)Document5 pagesRecruitment of Junior Associates (Customer Support & Sales)Revanth TallaNo ratings yet

- Unit 2 StoriesDocument11 pagesUnit 2 StoriesCristina BáezNo ratings yet

- 01 Rude DoctypeDocument215 pages01 Rude DoctypeChristal Rae Tac-anNo ratings yet

- Assignment # La 01 Name: Muhammad Ghufran Siddiqui F.Name: Abdul Sami Class: BSSE (Ii) Section: A Roll No: 32Document5 pagesAssignment # La 01 Name: Muhammad Ghufran Siddiqui F.Name: Abdul Sami Class: BSSE (Ii) Section: A Roll No: 32Mehak AnsariNo ratings yet

- 2-Measuring Innovation in The Australian Public Sector PDFDocument15 pages2-Measuring Innovation in The Australian Public Sector PDFc-felipefxhotmailcomNo ratings yet

- Hydrogen EngineDocument4 pagesHydrogen EnginerajmehaNo ratings yet

- Comprehensive Solid Waste Management OrdinanceDocument19 pagesComprehensive Solid Waste Management OrdinanceAnob EhijNo ratings yet

- Maintenance Handbook On Bonding Earthing For 25 KV AC Traction SystemsDocument46 pagesMaintenance Handbook On Bonding Earthing For 25 KV AC Traction SystemsPavan100% (1)

- FS7M0680, FS7M0880: Fairchild Power Switch (FPS)Document19 pagesFS7M0680, FS7M0880: Fairchild Power Switch (FPS)Arokiaraj RajNo ratings yet

- 15 Step Guide to Build Simple Electric GeneratorDocument13 pages15 Step Guide to Build Simple Electric GeneratorSeindahNyaNo ratings yet

- Caustic Soda Plant 27 000 Tpy 186Document1 pageCaustic Soda Plant 27 000 Tpy 186Riddhi SavaliyaNo ratings yet