Professional Documents

Culture Documents

Coal Power Plant Layout and Working

Uploaded by

Mohammad Asif0 ratings0% found this document useful (0 votes)

52 views73 pagesThis document provides information about steam power plants and the process of converting coal to electricity. It discusses:

1) The general layout of a steam power plant, including the coal handling, boiler, turbine, condenser and other key components.

2) The three stage process of (1) burning coal in a boiler to produce steam, (2) using the steam to power a turbine, and (3) generating electricity via a generator rotated by the turbine.

3) Details on the coal combustion process, energy conversion efficiencies, and factors contributing to thermal inefficiencies in steam power plants.

Original Description:

thermal power sector

Original Title

29315004 Steam Power Plants

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides information about steam power plants and the process of converting coal to electricity. It discusses:

1) The general layout of a steam power plant, including the coal handling, boiler, turbine, condenser and other key components.

2) The three stage process of (1) burning coal in a boiler to produce steam, (2) using the steam to power a turbine, and (3) generating electricity via a generator rotated by the turbine.

3) Details on the coal combustion process, energy conversion efficiencies, and factors contributing to thermal inefficiencies in steam power plants.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

52 views73 pagesCoal Power Plant Layout and Working

Uploaded by

Mohammad AsifThis document provides information about steam power plants and the process of converting coal to electricity. It discusses:

1) The general layout of a steam power plant, including the coal handling, boiler, turbine, condenser and other key components.

2) The three stage process of (1) burning coal in a boiler to produce steam, (2) using the steam to power a turbine, and (3) generating electricity via a generator rotated by the turbine.

3) Details on the coal combustion process, energy conversion efficiencies, and factors contributing to thermal inefficiencies in steam power plants.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You are on page 1of 73

Energy Conversion Engineering

Steam Power Plants

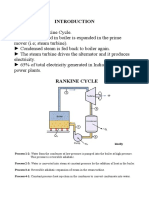

General layout of steam power plant

Boiler

Ash handling

plant

Ash storage

Coal handling

plant

Coal storage

Air preheater

Economizer

Super heater

Turbine Generator

Condenser

Air

Flue gases

To chimney

To power grid

Flue

gases

Steam

Super heated

Steam

Main

valve

Feed

water

Condensate

extraction pump HP heater

LP heater

Boiler feed

pump

Cooling tower

Circulating

water pump

River or Canal

Coal

Ash

Air

Water

Flue gases

Steam

Cooling water

LEGEND

Schematic diagram of coal based steam power plant

The conversion from coal to electricity takes place in three stages.

Stage 1

The first conversion of energy takes place in the boiler. Coal is burnt in the boiler

furnace to produce heat. Carbon in the coal and Oxygen in the air combine to

produce Carbon Dioxide and heat.

Stage 2

The second stage is the thermodynamic process. The heat from combustion of

the coal boils water in the boiler to produce steam. In modern power plant,

boilers produce steam at a high pressure and temperature. The steam is then

piped to a turbine. The high pressure steam impinges and expands across a

number of sets of blades in the turbine. The impulse and the thrust created

rotates the turbine. The steam is then condensed to water and pumped back into

the boiler to repeat the cycle.

Stage 3

In the third stage, rotation of the turbine rotates the generator rotor to produce

electricity based of Faradays Principle of electromagnetic induction.

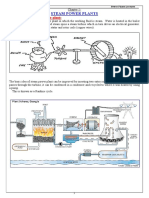

How coal power plants produce electricity

The different types of systems and components used in steam

power plants are:

High pressure boiler

Prime mover

Condensers and cooling towers

Coal handling system

Ash handling system

Draught system

Feed water treatment plant

Pumping system

Air preheater, super heater, feed water heater

General layout of coal based steam power plant

Though each plant is unique in itself in terms of specific features

and functionalities, there are four main circuits in any thermal power

plant:

1. Coal & Ash Circuit This circuit deals mainly with feeding the

boiler with coal for combustion purposes and taking care of the ash

that is generated during the combustion process and includes

equipment and peripherals that is used to handle the transfer and

storage of coal and ash.

2. Air & Gas Circuit Since lots of coal is burnt inside the boiler it

needs a sufficient quantity of air which is supplied using either

forced draught or induced draught fans. The exhaust gases from the

combustion are in turn used to heat the incoming air and water

through heat exchangers before being let off in the atmosphere.

The equipment which handles all these processes fall under this

circuit.

General layout of coal based steam power plant

3. Feed Water & Steam Circuit This section deals with supplying

of steam generated from the boiler to the turbines and to handle

the outgoing steam from the turbine by cooling it to form water in

the condenser so that it can be reused in the boiler plus making

good any losses due to evaporation etc.

4. Cooling Water Circuit This part of the thermal power plant

deals with handling of the cooling water required in the system.

Since the amount of water required to cool the outgoing steam

from the boiler is substantial, it is either taken from a nearby water

source such as a river, or it is done through evaporation if the

quantity of cooling water available is limited.

A power plant using steam as working substance works basically on

Rankine cycle. For plants operating with steam at subcritical pressures

(less than 221 bar) and steam temperatures of 570 C, the Rankine cycle

efficiency is around 43 %. For the state of the art plants running at greater

than supercritical pressure and steam temperatures near to 600 C, the

efficiency is around 47 %.

General layout of coal based steam power plant

Why is the efficiency low for thermal plant?

The heating value or the energy available in the coal, is in the range of

10,500 kJ/kg to 27,000 kJ/kg. A heating value of 20,000 kJ/kg is equivalent

to 5.56 kwh of electrical energy. In practice the effective conversion is only

around 43% to 47% of the theoretically possible value.

Reasons for low thermal efficiency:

Due to practical limitations in heat transfer, all the heat produced by

combustion is not transferred to the water; some is lost to the atmosphere

as hot gases. Moisture in coal vapourises taking latent heat from the

combustion heat and exits the boiler along with the hot gases. This is a loss.

The steam is condensed for re-use. During this process the latent heat of

condensation is lost to the cooling water. This is the major loss and is

almost 40 % of the energy input. Losses in the turbine blades and exit

losses at turbine end are some of the other losses.

The Rankine cycle efficiency is dictated by the maximum temperature of

steam that can be admitted into the turbine. Due to metallurgical constraints

steam temperatures are at present limited to slightly more than 600 C.

Various auxiliary equipment like pulverizers, fans, pumps and precipitators

in large power plants consume around 6 % of the generator output for

internal consumption.

Fuels used for steam generation

The primary fuels which are burned to release heat and generate

steam in boilers are the fossil fuels coal, fuel oil and natural

gas.

Besides these, industrial wastes like blast furnace gas, coke

oven gas, refinery gas, bagasse, saw mill wood dust, rice husk

etc. are also used to boost primary fossil fuels in the form of

combination firing.

Coal

In India, coal is the main source of energy because of its large

deposits and availability.

Coal originates from millions of years old vegetable matter

transformed by subterranean heat and soil pressure. The

vegetable decay first produces peat bogs, which after distillation

of its moisture by subterranean forces hardens to brown coal or

lignite. Continuing metamorphosis produces higher grade coals.

Fuels used for steam generation

Coal (contd..)

According to geological order of formation, coal may be of the following

types with increasing carbon content:

Peat

Lignite

Sub-bituminous

Bituminous

Sub-anthracite

Anthracite

Graphite

Each type of coal has a certain set of physical parameters which are

mostly controlled by moisture, volatile content (in terms of aliphatic or

aromatic hydrocarbons) and carbon content.

Peat contains up to 90% moisture and is not attractive as a utility fuel.

Coal Ranking is a measure of carbon content in the coal. Lignite is

considered to be low rank and anthracite to be high rank.

Coal analysis

Coal ranking is made based on coal analysis. Basically there are two

types of coal analysis:

Proximate analysis

Ultimate analysis

Proximate analysis

The objective of coal proximate analysis is to determine the amount of

fixed carbon (FC), volatile matters (VM), moisture (M), and ash (A) within

the coal sample.

FC + VM + M + A = 100% by mass

The variables are measured in weight percent (wt. %) and are calculated

in several different bases as follows.

As Received (AR)

Air Dried (AD)

Dry Basis (DB)

Dry Ash Free (DAF)

Dry Mineral Matter Free (DMMF)

Coal analysis

Proximate analysis Unit AR AD DB DAF

Moisture (wt. %) 3.30 2.70

Ash (wt. %) 22.10 22.20 22.80

Volatile Matter (wt. %) 27.30 27.50 28.30 36.60

Fixed Carbon (wt. %) 47.30 47.60 48.90 63.40

AR (as-received) basis is the most widely used basis in industrial applications.

It takes all variables into consideration and uses the total weight as the basis of

measurement.

AD (air-dried) basis neglects the presence of moisture other than inherent

moisture.

DB (dry-basis) leaves out all moistures, including inherent moisture.

DAF (dry, ash free) basis neglects all moisture and ash constituent in coal

DMMF (dry, mineral-matter-free) basis leaves out the presence of moisture and

mineral matters in coal like quartz, pyrite, calcite, etc.

A typical proximate analysis of coal looks like this:

Coal analysis

Coal rank compared with proximate analysis

Figure below shows the trend in moisture, volatile matter and fixed

carbon expressed on DAF basis.

With increasing rank, there is an increase of heating value and carbon

content with a corresponding decrease of moisture and VM.

Lower rank coals also contain greater oxygen, which helps combustion

Coal analysis

Ultimate analysis

Similar to coal proximate analysis, the objective of coal ultimate

analysis is to determine the constituent of coal, but in a form of its basic

chemical elements.

The ultimate analysis determines the amount of carbon (C), hydrogen

(H), oxygen (O), sulphur (S), and other elements within the coal sample.

These variables are also measured in weight percent (wt. %) and are

calculated in the bases explained above.

C + H + O + N + S + M + A = 100% by mass

A typical ultimate analysis of coal looks like this:

Ultimate analysis Unit AR AD DB DAF

Carbon (C) (wt. %) 61.1 61.5 63.2 81.90

Hydrogen (H) (wt. %) 3.00 3.02 3.10 4.02

Nitrogen (N) (wt. %) 1.35 1.36 1.40 1.81

Total Sulphur (S) (wt. %) 0.40 0.39 0.39

Oxygen (O) (wt. %) 8.80 8.80 9.10

Coal ranking

Rank of Coal

Fixed

Carbon*

Volatile

Matter* Moisture*

Lignite 29 26 46

Subbituminous 42 34 23

Low-rank/volatile

bituminous 47 41 12

Medium-rank/volatile

bituminous 54 41 5

High-rank/volatile

bituminous 65 32 3

Low-rank/volatile

semibituminous 75 22 3

Semianthracite 86 12 3

Anthracite 96 1.2 3

* Figures indicate weight by percentage

Boilers

Boiler is an apparatus to produce steam. Thermal energy

released by combustion of fuel is transferred to water, which

vapourises and gets converted to steam at the desired

temperature and pressure.

The performance of a boiler is measured in terms of its

evaporative capacity which is also called as Boiler Power. It is

defined as the amount of steam produced in kg/hour. It may also

be expressed in kg of steam per kg of fuel burnt or kg/hr/m

2

of

heating surface.

Boilers are classified according to the following criteria:

According to flow of water and hot gases.

Water tube

Fire tube

According to flow of water and hot gases.

Water tube

Fire tube

According to position of furnace

Internally fired

Externally fired

According to the position of the principle axis

Vertical

Horizontal

Inclined

According to application

Stationary

Mobile (Marine, Locomotive)

According to circulating water

Natural circulation

Forced circulation

According to steam pressure

Low pressure

Medium pressure

High pressure

Boilers

Water Tube Boilers

In water tube boilers, water is circulated through tubes and hot

products of combustion flow over these tubes

Water Tube Boilers

Water tube boilers can further be classified as follows:

Horizontal straight tube boilers

Bent tube boilers

Cyclone fired boilers

Water tube boilers have the following advantages:

High pressures (about 140 kg/cm

2

) can be

obtained

Large heating surfaces can be obtained by use of

large number of tubes therefore steam can be

generated easily.

Efficiency is higher because of high velocity of

water in tubes which improves heat transfer.

Fire Tube Boilers

In fire tube boilers, the hot combustion gases pass through the

tubes, which are surrounded by water.

Fire Tube Boilers

Fire Tube Boilers

Fire tube boilers can further be classified as follows:

External furnace

Internal furnace

Fire tube boilers have the following advantages:

Low cost

Fluctuations of steam demand can be easily met

Compact in size

Disadvantage of fire tube boilers is that they contain

more water in the drum and if the flue gas circulation is

poor, they can not quickly meet the steam demand. For

the same output, the outer shell of fire tube boiler is

much larger than the shell of a water tube boiler.

Combustion equipment for burning coal

Coal burning methods are classified into two types:

Stoker firing used for solid coal

Pulverized fuel firing used for pulverized coal

Selection of one of the above methods depends upon

Characteristics of the coal available

Capacity of the plant

Load fluctuations

Efficiency / Reliability of combustion equipments

The boiler furnaces that burn coal can be classified as follows:

Fuel bed furnaces (coarse particles)

Pulverized coal furnaces (fine particles)

Cyclone furnaces (crushed particles)

Fluidized bed furnaces (crushed small particles)

Stoker firing

In small boilers, coal is fed manually on to a

stationary grate. But in large boilers, to attain

uniform operating condition, higher burning rate and

better efficiency, mechanical stokers are employed.

A stoker consists of a power operated coal feeding

mechanism and grate.

Mechanical stokers are of two types:

1. Overfeed stoker

2. Underfeed stoker

Overfeed stoker

Overfeed stokers are used for large capacity boilers where coal

is burnt as lumps (i.e., without pulverization). In this type of

stoker, the fuel bed receives fresh coal on top surface; ignition

plane lies between green coal and incandescent coke.

Overfeed stoker - Processes

In the first layer (top layer), fresh coal is added

Second layer is the drying zone, where coal loses

moisture

Third layer is distillation zone, where coal loses

volatile matter

Fourth layer is the combustion zone, where the fixed

carbon in coal is consumed.

Fifth layer is the ash cooling zone.

Underfeed stoker

In the case of underfeed stoker, the coal is fed into the grate

below the point of air admission, or air entering the stoker

comes in contact with fresh coal before reaching the

incandescent coke.

Types of stokers

Stokers

Overfeed Underfeed

Conveyor Stoker Spreader Stoker

Chain Grate Stoker

Travelling Grate

Stoker

Single Retort Stoker Multi-Retort Stoker

Traveling or chain grate stokers feed coal out onto a

rotating metal belt that supports the fire.

Coal is fed from a hopper.

Grate speed is automatically controlled to maintain

desired steam pressure.

Burning progresses as the belt moves from front to back

of furnace.

Combustion is essentially complete at the back end of

belt, and ash is dumped off into an ash pit.

Can burn all coals, except strongly caking bituminous

coal. Caking coals tend to block the flow of air through

fuel bed and cause loss of carbon in ash.

Travelling or Chain Grate stokers

Chain Grate stokers

Chain Grate stokers

Spreader stokers

Coal from hopper is fed into the path of a rotor by a conveyor, and

is thrown into the furnace by the rotor and the coal is burnt in

suspension.

Spreader stokers can burn any type of coal

Single retort stokers

A screw conveyor or a ram transfers coal to the furnace.

Surrounding the conveyor or ram is the primary air duct.

Multi retort stokers

The stoker consists of a series of sloping parallel troughs called

retorts. Reciprocating rams push the coal into the retort.

Pulverized coal firing system

In the pulverized coal firing

system, the coal is reduced to a

fine powder with the help of

grinding mill and then admitted

into the combustion chamber with

the help of primary hot air.

The primary air also helps to dry

the coal before entering the

combustion chamber.

Secondary air required to

complete the combustion process

is supplied separately to the

combustion chamber.

The resulting turbulence in the

combustion chamber helps in

uniform mixing of fuel and air and

good combustion.

Elements of a pulverized coal firing system

Pulverized coal

Coal is pulverized (powdered) to increase its surface area (and

therefore exposure) thus permitting rapid combustion.

The pulverized coal is obtained by grinding the raw coal in

pulverizing mills. Various types of pulverizing mills are:

Ball mill

Ball and race mill

Hammer mill

Bowl mill

Essential functions of pulverizing mills are:

Drying of the coal

Grinding

Separation of particles of a desired size.

Coal pulverizing mills reduce coal to powder by any (or all) action such as

Impact, Abrasion and Crushing

Ball and race mill for pulverizing coal

Advantages of Pulverized coal firing system

Any grade of coal can be used because coal is powdered before

use.

Rate of feed of fuel can be easily regulated better fuel economy.

Since there is almost complete combustion of fuel, there is

increased rate of evaporation and hence better boiler efficiency.

Greater capacity to meet peak load.

System is free from sagging and clinkering troubles associated

with lump coal.

Practically no ash handling problems.

No moving parts within the furnace that is subjected to high

temperatures.

This system works successfully in combination with gas and oil.

Requires much less air compared to stoker firing

Furnace volume is considerably small.

Disadvantages of Pulverized coal firing system

High capital cost.

Lot of fly-ash in the exhaust removal of fine dust is expensive.

Possibility of explosion is high because pulverized coal burns like

gas.

Maintenance of furnace brickwork is costly because of high

temperatures.

Special equipments required to start the system.

Skilled operators are required.

Separate coal preparation plant is necessary.

Periodic maintenance of pulverized coal dispensing system is

needed.

Pulverized coal firing

Basically, pulverized fuel plants may be

divided into two systems based on the

method used for firing the coal:

Unit System or Direct System

Bin System or Central System

Unit or Direct System: This system works

as follows:

Coal from bunker drops on to the feeder.

Coal is dried in the feeder by passage of hot

air.

The coal then moves to a mill for pulverizing.

A fan supplies primary air to the pulverizing

mill.

Pulverized coal and primary air are mixed and

sent to a burner where secondary air is

added.

It is called Unit System because each burner or a group of burners and pulverizer constitute a unit.

RAW COAL BUNKER

FEEDER

HOT AIR

FAN

PULVERIZING

MILL

SECONDARY

AIR

PRIMARY AIR + COAL

BURNER

FURNACE

PRIMARY

AIR

Pulverized coal firing

Bin or Central System:

Coal from bunker is fed by gravity to a dryer where hot air is admitted to

dry the coal.

Dry coal is then transferred to the pulverizing mill.

Pulverized coal then moves to a cyclone separator where transporting air

is separated from coal.

Primary air is mixed with coal at the feeder and supplied to the burner.

Secondary air is supplied separately to complete the combustion.

RAW COAL BUNKER

Dryer

HOT AIR

FEEDER PULVERIZING

MILL

SECONDARY

AIR

PRIMARY AIR +

COAL

BURNER

FURNACE

PRIMARY

AIR FAN

VENT

FAN

EXHAUST

FAN

CYCLONE

SEPARATOR

CONVEYOR

R

E

T

U

R

N

A

I

R

Equipments for Unit and Bin Systems

RAW COAL

PRIMARY CRUSHER

MAGNETIC

SEPARATOR

COAL DRYER

COAL BUNKERS

FEEDER

CENTRAL BIN

UNIT SYSTEM BIN SYSTEM

SCALE SCALE

PULVERIZER PULVERIZER

BURNERS

BURNERS

Pulverized Coal Burners

Burners are used to burn pulverized coal. Burner configurations

differ in the rapidity with which air-coal mixing (turbulence) takes

place.

Requirements of pulverized coal burners:

Mix coal and primary air thoroughly before secondary air is added.

Deliver air to the furnace in the right proportion and maintain

stable ignition of coal-air mixture.

Control the shape and travel of flame within the furnace. The flame

shape is controlled by the secondary air vanes and their control

adjustments incorporated into the burner. Too much of secondary

air may cool the mixture and prevent ignition.

Control the rate of travel of coal-air mixture away from the burner

to avoid flash back into the burner.

Types of Burners for Pulverized Coal

Various types of burners are used for combustion of pulverized

coal.

Long Flame (U-Flame) Burner: In this burner, air and coal mixture

travels a considerable distance thus providing sufficient time for

complete combustion.

Primary air+Coal

Secondary air

Primary air+Coal

Secondary air

Long Flame Burners

Flame

Flame

Types of Burners for Pulverized Coal

Short Flame (Turbulent) Burner: The burner is fitted in the

furnace wall and the flame enters the furnace horizontally with

great turbulence.

COAL AND

PRIMARY AIR

SECONDARY

AIR

FLOW

CONTROL

FURNACE

Short Flame Burner

FLAME

Types of Burners for Pulverized Coal

Tangential Burner: In this system, one burner is attached at each

corner of the furnace. The inclination of the burners is so made

that the flame produced is tangential to an imaginary circle at the

centre.

Types of Burners for Pulverized Coal

Cyclone Burner: In this system, the cyclonic action whirls coal and

air against the wall of the furnace to facilitate thorough mixing of

coal and air. Advantage of this burner is that it can also use

crushed coal in addition to pulverized coal thus providing an

option. When crushed coal is used, ash is collected in molten form

for easy disposal.

Typical Pulverized Coal Boiler

Oil and Gas Burners

Thermal power plants can also be operated on oil and gas in

addition to coal. Highly volatile petroleum fuels are too expensive

for boiler firing. Therefore, heavy fuel oils (left after refining of

crude petroleum) are used. Schematic of an oil burning system is

depicted below:

Combustion of fuel oil

Because of high viscosity of fuel oil, steam heating coils

are installed in the oil tank to reduce viscosity and

facilitate pumping.

Reciprocating type pumps receive oil from filters and

discharge it to the burners through heaters and a flow

measuring system.

Oil temperature is generally controlled between 65C and

115C for obtaining a good spray pattern. Higher

temperatures may cause vapourization of oil or may lead

to decomposition of oil.

Recirculation of oil is necessary initially to purge the

pipe lines so that heavy oil does not collect and plug the

passages. Usually a light oil is used for some time

during starting and stopping the boiler to wash the pipes

clean of heavy oil.

Oil Burners

The major parts of an oil burner are:

Atomizer

Air register

Oil lines with filters and valves

Atomization of fuel oil exposes more surface area per unit mass,

thus promoting ignition and complete combustion.

Atomization of fuel oil is accomplished mechanically or with

steam or air.

In twin-fluid burners, high pressure steam or air is used to break

up oil drops to fine droplets, enabling better mixing with air

for combustion.

For large boilers, oil burners with pressure atomization are

suitable. Oil under pressure (6 20bar) is atomized by ejecting

the oil through very small oil injector orifices.

Oil Burners

Typical configurations of Steam or Air atomized oil burners

Gas Burners

Burning of gas is easy and clean. There is no need for

atomization. Combustion of 1m

3

of natural gas requires about

20m

3

of hot air. Proper mixing of gas and air can be achieved by

introducing gas into a swirling air flow in the form of thin jets.

Furnace

Ash Handling

Large power plants produce a huge quantity of ash, sometimes as

much as 10 to 20% of the coal burnt per day. Therefore,

mechanical devices are used for effective collection and disposal

of ash.

Ash handling includes:

Removal of ash from furnace

Loading to conveyors and delivery to fill or dump from where

it can be disposed off.

Handling of ash is a problem because it is too hot when it comes

out of furnace, dusty and sometimes poisonous and corrosive.

Ash needs to be quenched before handling due to following

reasons:

Quenching reduces corrosive action of ash

It reduces the dust accompanying the ash

It reduces the temperature of ash

Fused clinkers will disintegrate making it easier to handle

Ash Handling Equipment

A good ash handling equipment should have the following

characteristics:

It should have enough capacity to cope with the volume of ash that

may be produced in a station.

It should be able to handle large clinkers, boiler refuse, soot etc.,

with little attention from workers.

It should be able to handle hot and wet ash effectively and with

good speed.

It should be possible to minimise the corrosive or abrasive action

of ash.

Operation of the plant should be easy, economical, simple and

noiseless.

It should be able to operate effectively under all variable load

conditions.

It should also remove fly ash and smoke to control air pollution.

Ash Handling Equipment

The commonly used equipment for ash handling in large and

medium size plants may comprise of:

Bucket elevator

Bucket conveyor

Belt conveyor

Pneumatic conveyor

Hydraulic sluicing equipment

Trollies and Rail cars etc.

These are mainly classified into:

Mechanical handling systems

Hydraulic systems

Pneumatic systems

Steam jet systems

Ash Collection and Transportation

Coal Handling System

Furnace firing

Coal delivery

Unloading

Preparation

Transfer

Outdoor storage

Covered storage

In-plant handling

Weighing & Measuring

Rail

Trucks

Ships

Lift trucks

Cranes

Unloading towers

Buckets

Mills

Crushers

Driers

Screw Conveyors

Belt conveyors

Bunkers

Bins

Coal meters

Scales

Equipments

Bucket conveyors / elevators

Coal Handling System

Screw Conveyor

Belt Conveyor

Coal Handling System

Bucket Elevator

225 tons/hr coal

5400 tons/day coal (54 rail cars)

Bottom Ash 108 tons/hr

Fly Ash 432 tons/hr

SOx 228 tons/day

NOx 20 tons/day

Steam 2000 tons/hr

Typical input and output for a 500 MW boiler

Coal and Ash handling in a typical coal fired

power plant

High Pressure Boilers

In all modern power plants, high pressure boilers (> 100 bar) are

invariably used due to their inherent advantages.

If high pressure steam is used, plant efficiency is increased because

lesser quantity of steam is required for generating a given power; i.e.,

work done per unit mass of steam is higher.

Forced circulation of water can be used which helps arrangement of

furnace and water surfaces and reduction of heat exchange area.

Tendency for scale formation is reduced due to high velocity of water.

Danger of overheating id reduced as all parts are more uniformly heated.

Differential expansion is less due to more uniform temperature

distribution thus reducing possibility of gas and air leakages.

Following types of high pressure boilers are generally used:

La Mont Boiler

Benson Boiler

Loeffler Boiler

Schmidt-Hartmann Boiler

Water Circulation in Boilers

FLUE

GAS

S

U

P

E

R

H

E

A

T

E

R

STEAM OUT

WATER IN

C

H

I

M

N

E

Y

B

O

I

L

E

R

E

V

A

P

O

R

A

T

O

R

E

C

O

N

O

M

I

S

E

R

WATER IN

WATER OUT

HEAT

Once through circulation

Natural circulation

Forced circulation

SUPER HEATER

EVAPORATOR

ECONOMISER

FLUE GAS

TO CHIMNEY

SUPER

HEATED

STEAM

WATER IN

DRUM

P

U

M

P

Forced circulation

is generally used in

high pressure boilers

La Mont Boiler

Schematic representation of La Mont Boiler

Water

Air

Super

heated

steam

Circulation

pump

Flue gas

Primary evaporator

Feed water is supplied to the boiler

drum through an economiser.

A pump circulates water at 8 to 10

times the mass of steam evaporated.

The large quantity of water circulated

prevents overheating of tubes.

The pump delivers water to headers

at a pressure of 2.5 bar above the

drum pressure and the distribution

headers distribute the water through

nozzles into the evaporators.

The steam separated in the boiler is

further passed through the super

heater.

This type of boiler can generate 45 to

50 tonnes of superheated steam at

120 bar and 500C

La Mont Boiler

Flow schematic of La Mont boiler

The main difficulty experienced in the La Mont boiler is the formation and

attachment of bubbles on the inner surface of tubes. These bubbles reduce

the heat flow and steam generation as it offers higher thermal resistance

compared to water film.

Benson Boiler

Feed water

pump

Schematic representation of Benson boiler

It is a water tube boiler capable of

producing steam at super critical

pressure (> 225 bar).

At super critical pressure, water flashes

into steam without any latent heat

requirement. Therefore steam

generation is faster.

Above critical point, water transforms

into steam without boiling and without

change in volume. i.e., same density.

Super critical steam generation does

not have bubble formation and

consequent pulsations.

Materials of construction should be

strong to withstand high pressure and

temperature.

130 135 tonnes of steam per hour is

generated at > 225 bar and ~90% thermal

efficiency.

Benson Boiler

Flow schematic of Benson boiler

The main drawback of Benson boiler is deposition of salt and sediment on the

inner surface of water tubes which offers high thermal resistance.

Loeffler Boiler

Schematic representation of Loeffler boiler

Loeffler Boiler

The limitation of Benson boiler is the deposition of salts on water

tube walls. This is solved in Loeffler boiler by evaporation of feed

water by means of superheated steam from the super heater.

Loeffler boiler uses forced circulation and the hot gases from the

furnace are primarily used for superheating purposes.

The high pressure feed pump draws water through the

economiser and delivers it to the evaporating drum.

The steam circulating pump draws saturated steam from the drum

and passes it through convective and radiative superheaters

where steam is heated to required temperature.

From the superheater, about 35% of the superheated steam goes

to the turbine and the remaining 65% passes through water in the

evaporating drum to evaporate feed water.

Loeffler Boiler

Flow schematic of Loeffler boiler

Schmidt-Hartmann Boiler

There are two pressure circuits in this

boiler

Primary circuit

Secondary circuit

Primary circuit uses distilled water that

goes from the drum to primary

evaporator kept at the furnace. Steam

generated is passed through a

submerged heating coil kept inside the

drum. It loses heat to water in secondary

circuit and condenses. A condensate

pump maintains primary water

circulation.

In the secondary circuit, normal water is

pumped to evaporator drum which picks

up heat from steam in submerged coils.

Steam thus produced is superheated

and passed on to the turbines.

FIRE GRATE

SUPER HEATER

SUPER HEATED

STEAM

WATER LINE

C

O

N

D

E

N

S

A

T

E

C

O

O

L

E

R

DRUM

H

E

A

T

I

N

G

S

U

R

F

A

C

E

PUMP

Schmidt-Hartmann Boiler

Flow schematic of Loeffler boiler

Bfw : Boiler feed water

NRV : Non Return Valve

You might also like

- Combustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasFrom EverandCombustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasNo ratings yet

- Steam Power Plant (PLTU)Document5 pagesSteam Power Plant (PLTU)Aldi ErzanuariNo ratings yet

- NTPC (National Thermal Power Corporation) Sipat Boiler-Haxxo24 I IDocument88 pagesNTPC (National Thermal Power Corporation) Sipat Boiler-Haxxo24 I Ihaxxo24100% (1)

- CalderaDocument44 pagesCalderaIvan SanchezNo ratings yet

- Thermal Power Plant Layout and OperationDocument77 pagesThermal Power Plant Layout and OperationAlexNo ratings yet

- Boiler OperationDocument17 pagesBoiler OperationhtrbiNo ratings yet

- Steam Turbine Working & ApplicationsDocument7 pagesSteam Turbine Working & ApplicationsNav Mehra50% (2)

- Performance Analysis of Microturbine SystemDocument5 pagesPerformance Analysis of Microturbine SystemNikhil MhatukadeNo ratings yet

- Steam Power Plants (System)Document58 pagesSteam Power Plants (System)Hafzal Gani100% (1)

- Accidents in Power PlantsDocument6 pagesAccidents in Power PlantsHitesh Navlani100% (1)

- Paper 6 FRF-lube - Oil - MixingDocument34 pagesPaper 6 FRF-lube - Oil - MixingsoorajssNo ratings yet

- Implementation of Energy Conservation Act and BEE Action PlanDocument33 pagesImplementation of Energy Conservation Act and BEE Action PlanRohan PrakashNo ratings yet

- ME 403 Power Plant EngineeringDocument40 pagesME 403 Power Plant EngineeringSadiq AntuNo ratings yet

- EHC - FinalDocument64 pagesEHC - Finalyahya pamungkasNo ratings yet

- Technology BoilerDocument26 pagesTechnology Boilervery sihombing100% (1)

- CONDENSER Air ExtractionDocument2 pagesCONDENSER Air Extractiontrung2iNo ratings yet

- Ennore Thermal Power StationDocument14 pagesEnnore Thermal Power StationRajesh Kumar100% (2)

- Supercritical Boiler: Higher Efficiency Through Advanced DesignDocument26 pagesSupercritical Boiler: Higher Efficiency Through Advanced DesignShaheena Khan100% (2)

- TechnicalDiary SGTPPDocument45 pagesTechnicalDiary SGTPPJoydev GangulyNo ratings yet

- Ultra Supercritical BoilerDocument10 pagesUltra Supercritical Boilerzsuzsapogats04100% (2)

- Emissions Control Thermal Power PDFDocument20 pagesEmissions Control Thermal Power PDFTanzir MusaNo ratings yet

- Turbine & Cooling System: Presented by - AVIJEET PRATAP 07ME12 Iet AgraDocument28 pagesTurbine & Cooling System: Presented by - AVIJEET PRATAP 07ME12 Iet AgraAd Man GeTig100% (1)

- Pulverizers PDFDocument6 pagesPulverizers PDFOscar DorantesNo ratings yet

- Syed Ammal Engineering College Power Plant Engineering Question BankDocument16 pagesSyed Ammal Engineering College Power Plant Engineering Question BankNizam MANo ratings yet

- Presentation On DVR, JS Saroya, CS Singh, 03.12.11Document75 pagesPresentation On DVR, JS Saroya, CS Singh, 03.12.11Amit BiswasNo ratings yet

- Fisher Steam Turbines Application Guide August 2013Document11 pagesFisher Steam Turbines Application Guide August 2013Juan Manuel Pardal100% (1)

- Report #1: Alternating-Current Project: Steam-Electric Power PlantDocument41 pagesReport #1: Alternating-Current Project: Steam-Electric Power PlantKian TecsonNo ratings yet

- Extending the Range of Single-Shaft Combined Cycle Power PlantsDocument12 pagesExtending the Range of Single-Shaft Combined Cycle Power PlantsSrinivasa Rao PallelaNo ratings yet

- Training Report at NFL PanipatDocument22 pagesTraining Report at NFL PanipatKapil AroraNo ratings yet

- Performance Analysis of Surface Condenser in 525MW Thermal Power Plant PDFDocument9 pagesPerformance Analysis of Surface Condenser in 525MW Thermal Power Plant PDFJeeEianYannNo ratings yet

- C&I in CFBC-1Document25 pagesC&I in CFBC-1Prudhvi RajNo ratings yet

- Boiler Heat Transfer Theory-02Document18 pagesBoiler Heat Transfer Theory-02Sai SwaroopNo ratings yet

- Continuum Mechanics For EngineersDocument53 pagesContinuum Mechanics For Engineersshushant kumarNo ratings yet

- Steam TurbinesDocument45 pagesSteam TurbinesHaseeb Bokhari100% (1)

- Hydrogen Leakage and Purity Gek 45941Document10 pagesHydrogen Leakage and Purity Gek 45941rosiNo ratings yet

- NFL ProjectDocument35 pagesNFL ProjectHomi_nathNo ratings yet

- Training ReportPDF PDFDocument42 pagesTraining ReportPDF PDFAman RajNo ratings yet

- 7.summary of Boiler PerfDocument46 pages7.summary of Boiler PerfRAJESH KUMARNo ratings yet

- Heat Required in Kcal For Unit Generation of ElectricityDocument18 pagesHeat Required in Kcal For Unit Generation of ElectricityAyan ChattarajNo ratings yet

- Super Critical Salient FeaturesDocument16 pagesSuper Critical Salient Featureshanumehrotra100% (1)

- 4 - Silica in BoilerDocument3 pages4 - Silica in BoilerKrishnan ManiNo ratings yet

- 2.final Energy EfficiencyDocument29 pages2.final Energy EfficiencyVandana VanuNo ratings yet

- Overview of NTPC PDFDocument40 pagesOverview of NTPC PDFRahul KediaNo ratings yet

- National Power Training Institute New Delhi: B. TechDocument14 pagesNational Power Training Institute New Delhi: B. TechAditya PandeyNo ratings yet

- Coal To Electricity: K. Bhanu PrakashDocument77 pagesCoal To Electricity: K. Bhanu PrakashAmit MukherjeeNo ratings yet

- Powr PlantDocument10 pagesPowr PlantSajjad Ibraheem100% (1)

- Boiler ParameterDocument2 pagesBoiler ParameterFieNo ratings yet

- Trouble Shooting and Problems of A CFBC Unit PDFDocument72 pagesTrouble Shooting and Problems of A CFBC Unit PDFgangaraoNo ratings yet

- Super Critical Power PlantDocument27 pagesSuper Critical Power PlantPrabir Kumar PatiNo ratings yet

- Report On The Procedures/practices To Minimize The Boiler Tube Leaks in The Thermal Power StationsDocument10 pagesReport On The Procedures/practices To Minimize The Boiler Tube Leaks in The Thermal Power Stationshari gopala charyNo ratings yet

- Doc-2 Training Material On Coal Fired Thermal Power PlantsDocument21 pagesDoc-2 Training Material On Coal Fired Thermal Power PlantsSharan100% (2)

- Technical Specification For Fly Ash Handling System, R0Document7 pagesTechnical Specification For Fly Ash Handling System, R0SumitskbNo ratings yet

- Fossil Fuel Steam GeneratorDocument33 pagesFossil Fuel Steam Generatorchaiya sonwongNo ratings yet

- 2 Telemetry TurbineDocument12 pages2 Telemetry TurbineSamNo ratings yet

- Condensate Extraction Pump: GeneralDocument5 pagesCondensate Extraction Pump: GeneralAnonymous DKv8vpNo ratings yet

- DVC Combustion Modification Package August 2019Document31 pagesDVC Combustion Modification Package August 2019Amitava PalNo ratings yet

- Energy Performance Assessment of Boiler at P.S.S.K. LTDDocument12 pagesEnergy Performance Assessment of Boiler at P.S.S.K. LTDPajooheshNo ratings yet

- "Boiler Tube Failures": Project ReportDocument30 pages"Boiler Tube Failures": Project ReportmdjanNo ratings yet

- Design and Thermal Analysis of CFB and Simple BoilersDocument89 pagesDesign and Thermal Analysis of CFB and Simple Boilersbharathkumar0310No ratings yet

- Academy: U IsingsDocument8 pagesAcademy: U IsingsMohammad AsifNo ratings yet

- Pratiyogita Darpan CatalogueDocument38 pagesPratiyogita Darpan CatalogueMohammad AsifNo ratings yet

- Click Here To Get More Magazines in TelegramDocument3 pagesClick Here To Get More Magazines in TelegramMohammad AsifNo ratings yet

- Indian Economy 1Document90 pagesIndian Economy 1दिव्य सिंहNo ratings yet

- Tariff Determination - Write UpDocument12 pagesTariff Determination - Write UpnikhilkrsinhaNo ratings yet

- GA MCQs 26 May 10 Aug 2017Document41 pagesGA MCQs 26 May 10 Aug 2017Mohammad AsifNo ratings yet

- Integrated Start-Up Procedure for Cold Start-UpDocument39 pagesIntegrated Start-Up Procedure for Cold Start-UpMohammad Asif50% (2)

- Indian Polity and Constitution Multiple Choice QuestionsDocument4 pagesIndian Polity and Constitution Multiple Choice QuestionsMohammad AsifNo ratings yet

- Railtel Recruitment GujaratDocument7 pagesRailtel Recruitment GujaratPraneeta KatdareNo ratings yet

- Disha Publication Goods Service Tax (GST) 2017Document3 pagesDisha Publication Goods Service Tax (GST) 2017Mohammad AsifNo ratings yet

- Multimedia CBTDocument4 pagesMultimedia CBTsesharamanaNo ratings yet

- NobodyDocument1 pageNobodyMohammad AsifNo ratings yet

- Data InterpretationDocument92 pagesData InterpretationMohammad AsifNo ratings yet

- Availabilty Based Generation TariffDocument51 pagesAvailabilty Based Generation TariffMohammad AsifNo ratings yet

- GGGGDocument63 pagesGGGGkumarcv89No ratings yet

- Hi Evryone in This World of Love & Peace, ThankuDocument1 pageHi Evryone in This World of Love & Peace, ThankuMohammad AsifNo ratings yet

- Doc1npti SeatDocument1 pageDoc1npti SeatMohammad AsifNo ratings yet

- 2013edusat Lecture On STEAM PLANTDocument101 pages2013edusat Lecture On STEAM PLANTKishore KrishnaNo ratings yet

- MiptiDocument1 pageMiptiMohammad AsifNo ratings yet

- CGL SYLL SyllabusDocument7 pagesCGL SYLL Syllabusrajupat123No ratings yet

- Syllabus CWCDocument5 pagesSyllabus CWCDowlath BashaNo ratings yet

- Notification SCC Junior Engineer PostsDocument33 pagesNotification SCC Junior Engineer PostsMohammad Asif100% (1)

- How Do You Define Success and How Do You Measure Up To Your Own Definition - HR Interview Questions and AnswersDocument9 pagesHow Do You Define Success and How Do You Measure Up To Your Own Definition - HR Interview Questions and AnswersMohammad AsifNo ratings yet

- Do You Have Any Questions For Me - HR Interview Questions and AnswersDocument8 pagesDo You Have Any Questions For Me - HR Interview Questions and AnswersMohammad AsifNo ratings yet

- How Much Salary Do You Expect - HR Interview Questions and AnswersDocument9 pagesHow Much Salary Do You Expect - HR Interview Questions and AnswersMohammad AsifNo ratings yet

- What Are Your Strengths and Weaknesses - HR Interview Questions and AnswersDocument13 pagesWhat Are Your Strengths and Weaknesses - HR Interview Questions and AnswersMohammad AsifNo ratings yet

- What Is The Difference Between Confidence and Over Confidence - HR Interview Questions and AnswersDocument9 pagesWhat Is The Difference Between Confidence and Over Confidence - HR Interview Questions and AnswersMohammad AsifNo ratings yet

- What Is The Difference Between Hard Work and Smart Work - HR Interview Questions and AnswersDocument9 pagesWhat Is The Difference Between Hard Work and Smart Work - HR Interview Questions and AnswersMohammad AsifNo ratings yet

- Tell Me About YourselfDocument25 pagesTell Me About YourselfMohammad AsifNo ratings yet

- AHS System Objectives and CharacteristicsDocument36 pagesAHS System Objectives and CharacteristicsAkash TaradaleNo ratings yet

- 23 ZTE RAN Sharing Solution 200908Document21 pages23 ZTE RAN Sharing Solution 200908Daniel SeungKyu KimNo ratings yet

- Atswa QaDocument400 pagesAtswa QaMelody OkunugaNo ratings yet

- ECS J. Solid State Sci. Technol.-2013-Amanapu-P362-7 - EUV Work With SEMATECHDocument6 pagesECS J. Solid State Sci. Technol.-2013-Amanapu-P362-7 - EUV Work With SEMATECHUmarameshKNo ratings yet

- Zero Full Line Catalog 112255 PDFDocument128 pagesZero Full Line Catalog 112255 PDFvikrampatel1986100% (1)

- Math 3Eng-T Engineering Data Analysis Problem Set #4 Due Date: Sep 24, 2020 (12 NN) Justin M. Marquez BET-Automotive General InstructionsDocument5 pagesMath 3Eng-T Engineering Data Analysis Problem Set #4 Due Date: Sep 24, 2020 (12 NN) Justin M. Marquez BET-Automotive General InstructionsDeniell Joyce MarquezNo ratings yet

- The Mexican Gray WolfDocument3 pagesThe Mexican Gray Wolfanyei nicol curasiNo ratings yet

- Cyborgs and Space by Manfred E. Clynes and Nathan S. KlineDocument5 pagesCyborgs and Space by Manfred E. Clynes and Nathan S. KlineNext DreamhackerNo ratings yet

- JEE 2023 Session-1 24th Jan To 1st Feb 2023Document37 pagesJEE 2023 Session-1 24th Jan To 1st Feb 2023Harshith Reddy GantaNo ratings yet

- Tero Cell Hydrogen GeneratorDocument21 pagesTero Cell Hydrogen Generatorfakiris3100% (1)

- Catalogo Raychem PararrayosDocument12 pagesCatalogo Raychem PararrayosEvertMiguelNo ratings yet

- JOT Cue SheetsDocument53 pagesJOT Cue SheetsMukund KrishnaNo ratings yet

- Gap Analysis Identifies Gaps in Retention Strategy DefinitionsDocument4 pagesGap Analysis Identifies Gaps in Retention Strategy DefinitionsNeotrixnikxNo ratings yet

- Acid Resistance of Ceramic Decorations On Architectural-Type GlassDocument2 pagesAcid Resistance of Ceramic Decorations On Architectural-Type Glassjun floresNo ratings yet

- Slovenia Day Hike: Triglav Lakes ValleyDocument28 pagesSlovenia Day Hike: Triglav Lakes ValleyAnonymous bDCiOqNo ratings yet

- Poser Pro 2012 Reference ManualDocument810 pagesPoser Pro 2012 Reference ManualDwayne WayneNo ratings yet

- Introduction: Need For: MCMT Mapping Course Outcomes Woth Program OutcomesDocument3 pagesIntroduction: Need For: MCMT Mapping Course Outcomes Woth Program OutcomesKalai ArasanNo ratings yet

- Emerald Emerging Markets Case Studies: Article InformationDocument16 pagesEmerald Emerging Markets Case Studies: Article InformationAaqib JokhioNo ratings yet

- SEM TheoryDocument50 pagesSEM TheoryKamiNo ratings yet

- V4200 9 v75 MDocument116 pagesV4200 9 v75 MPeach SzNo ratings yet

- Gastrointestinal Bleeding: Dr. Székely Hajnal 2nd Department of Internal Medicine 2015/16-IDocument74 pagesGastrointestinal Bleeding: Dr. Székely Hajnal 2nd Department of Internal Medicine 2015/16-ISutisna NisaNo ratings yet

- Routine and Emergency Management Guidelines For The Dental Patient With Renal Disease and Kidney Transplant Part 2Document6 pagesRoutine and Emergency Management Guidelines For The Dental Patient With Renal Disease and Kidney Transplant Part 2CristobalVeraNo ratings yet

- Evolution of Intel ProcessorsDocument4 pagesEvolution of Intel Processors이고양No ratings yet

- Oliver Heaviside Physical MathematicianDocument7 pagesOliver Heaviside Physical MathematicianAKHI9No ratings yet

- Script Short FilmDocument9 pagesScript Short FilmKino Go AninangNo ratings yet

- Average England Civil Engineering Costs v1.0 Issued 111108Document4 pagesAverage England Civil Engineering Costs v1.0 Issued 111108mkmusaNo ratings yet

- Theories of PersonalityDocument51 pagesTheories of PersonalityOyedele OluwaseunNo ratings yet

- Chemistry For Engineers 3Document34 pagesChemistry For Engineers 3Audrey VicenteNo ratings yet

- Sar SkinradDocument8 pagesSar SkinradEmf RefugeeNo ratings yet

- Books of DreamsDocument359 pagesBooks of DreamsJennifer LarsonNo ratings yet