Professional Documents

Culture Documents

Example of Different DC Motors

Uploaded by

fieraminaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Example of Different DC Motors

Uploaded by

fieraminaCopyright:

Available Formats

DC Motor

Presented by

SRIKANT PATI

CENTRAL TOOL ROOM AND TRAINING

CENTER

Example of Different Motors

DC (brushed)

Stepper

RC Servo

Solenoid

DC (brushed) Motor

DC (brushed)

Stepper

RC Servo

Solenoid

Workhorse, high power

Simple to use, two wires

Torque proportional to

current, steady state

constant-load speed

proportional to voltage

Requires gearing

Requires feedback

Stepper Motors

DC (brushed)

Stepper

RC Servo

Solenoid

Useful for low-torque

applications with no

surprises

No feedback required

One step per pulse

More involved driving circuit

RC Servo Motors

DC (brushed)

Stepper

RC Servo

Solenoid

High torque, useful for

positioning applications

Feedback and gearing built in

Position commanded by

persistent pulse train

Limited motion (less than 1

revolution)

Solenoid

DC (brushed)

Stepper

RC Servo

Solenoid

For on-off applications

Simple to use

Short stroke

Powered in only one

direction; requires external

spring for return

DC Motors

Lorentz Force Law:

F = I x B

F = force on wire

I = current

B = magnetic field

Right hand rule:

index finger along I,

middle finger along B,

thumb along F

N S

Inside a DC Motor

DC Motors

V = IR + L (dI/dt) + k

e

w

t = k

t

I

V voltage

I current

R resistance

L inductance

w speed

t torque

k

e

electrical constant

k

t

torque constant

2 - permanent magnet

3 - housing (magnetic return)

4 - shaft

5 - winding

w

t

speed-torque curves

for two voltages

DC Motor Specs

Driving a DC Motor

Switches and relays

Transistors

Linear push-pull stage with op amp

Ideally: H-bridge and PWM

H-bridge and PWM

PWM: Rapidly switch between

S1-S4 closed and S2-S3 closed

Averages to effective voltage

across motor between -V and

+V depending on time spent in

S1-S4 and S2-S3 states

Switch control signals are simply

digital signals

Use an H-bridge chip or build out

of transistors

L293 H-bridge chip

Practical Issues

flyback diodes for inductive kick

heat sinks for transistors

capacitors to smooth voltage spikes

other noise issues, isolation

Gears

Gear ratio G

w

out

= w

in

/ G

t

out

= h G t

in

(h = efficiency)

Many types

spur, planetary, worm, lead/ball screw, bevel,

harmonic...

Encoder Feedback

Another option:

potentiometer

US Digital

Feedback Control

Proportional (Integral-Derivative) Control

Multiply position/velocity error by a gain to get control

signal (and perhaps add integral and derivative of

that error multiplied by other gains)

Usually implemented on computer

Can be implemented with op amps

Stepper Motor

Bipolar: 4 wires

Unipolar: 5 or 6 wires

+V

alternately ground one

end of coil or other

1 4 2 3

A B

A B

R R

R

R L

L

L L

L

L R

R

R

L

Animation of Unipolar

Taken from http://www.cs.uiowa.edu/~jones/step/

Driving a Stepper

Use logic on/off signals at 2, 7, 10, 15.

RC Servo Motor

3 wires: power, ground, control

Control signal sets the position.

High pulse every ~20 ms determines

set angle; pulse width between

~0.5 ms and ~2 ms, indicating the

two ends of angle range

Internal gearing, potentiometer, and

feedback control.

Solenoid

Plunger attracted or repelled by current

through a coil.

May be driven by a relay or transistor.

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Plastic Injection Mold CalculationsDocument10 pagesPlastic Injection Mold CalculationsfieraminaNo ratings yet

- Engineering Drawing Handbook PDFDocument120 pagesEngineering Drawing Handbook PDFRobert Nixon100% (1)

- Cane Sugar PDFDocument633 pagesCane Sugar PDFbernie_bph50% (2)

- Servo MotorDocument11 pagesServo MotorBotlhe SomolekaeNo ratings yet

- All About Steering GearsDocument21 pagesAll About Steering GearsJerome Alojado100% (3)

- Absolute MotionDocument1 pageAbsolute MotionfieraminaNo ratings yet

- Norkontrol Dgu-8800Document198 pagesNorkontrol Dgu-8800Павел100% (1)

- Injection Molding MachineDocument60 pagesInjection Molding Machinefieramina100% (1)

- Auxilary Boiler Basuki Inc)Document56 pagesAuxilary Boiler Basuki Inc)mail_mulyadi5151No ratings yet

- Moog PowerGen Actuator Fail Safe Overview PDFDocument4 pagesMoog PowerGen Actuator Fail Safe Overview PDFdevdownNo ratings yet

- XC709 English Manual-XCMCU UCONTRO PDFDocument91 pagesXC709 English Manual-XCMCU UCONTRO PDFJose Lopez50% (2)

- Ac DC Servo DriveDocument306 pagesAc DC Servo DrivePaun Al100% (2)

- Lecture 5Document80 pagesLecture 5fieraminaNo ratings yet

- Lecture 1Document56 pagesLecture 1fieramina100% (1)

- Action Plan For The Project2Document1 pageAction Plan For The Project2fieraminaNo ratings yet

- Lecture 2Document93 pagesLecture 2fieraminaNo ratings yet

- Lecture 6Document72 pagesLecture 6fieraminaNo ratings yet

- Book Review On Linsu Kim's Imitation To InnovationDocument3 pagesBook Review On Linsu Kim's Imitation To InnovationdonghaoliNo ratings yet

- 8 JoiningDocument7 pages8 Joiningdawoodabdullah56No ratings yet

- Single PhaseDocument23 pagesSingle PhasefieraminaNo ratings yet

- LectureDocument3 pagesLecturefieraminaNo ratings yet

- Design of Parts For Turning: Chuck-ClampedDocument19 pagesDesign of Parts For Turning: Chuck-ClampedfieraminaNo ratings yet

- 3 Phase Induction Machines 1 (Construction)Document75 pages3 Phase Induction Machines 1 (Construction)fieraminaNo ratings yet

- DCDocument25 pagesDCfieraminaNo ratings yet

- AnimatedDocument18 pagesAnimatedfieraminaNo ratings yet

- Three Phase TransformerDocument27 pagesThree Phase Transformerfieramina100% (1)

- Starter MotorDocument15 pagesStarter MotorfieraminaNo ratings yet

- Energy Conversion and Transport: George G. Karady & Keith HolbertDocument32 pagesEnergy Conversion and Transport: George G. Karady & Keith HolbertfieraminaNo ratings yet

- Metals Industry Development Institute Inter Transfer Note: Description Unit of Measure QTY RemarkDocument4 pagesMetals Industry Development Institute Inter Transfer Note: Description Unit of Measure QTY RemarkfieraminaNo ratings yet

- 23 Shaft and Its Design Based On StrengthDocument9 pages23 Shaft and Its Design Based On StrengthPRASAD326No ratings yet

- Engineering DynamicsDocument22 pagesEngineering DynamicsfieraminaNo ratings yet

- 19 Introduction To Design of Helical SpringsDocument12 pages19 Introduction To Design of Helical SpringsPRASAD326100% (3)

- Bags, Boxes, Bowls, and Beyond: Portable Collections ProgramDocument20 pagesBags, Boxes, Bowls, and Beyond: Portable Collections ProgramfieraminaNo ratings yet

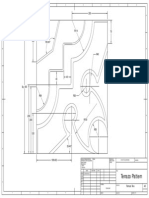

- Terazzo Two - Sheet1 PDFDocument1 pageTerazzo Two - Sheet1 PDFfieraminaNo ratings yet

- Cabo de Mão GoproDocument1 pageCabo de Mão GoproTiago BorinNo ratings yet

- Briefcases and Bags4 PDFDocument22 pagesBriefcases and Bags4 PDFfieraminaNo ratings yet

- ST Ep DR 86a 1Document2 pagesST Ep DR 86a 1Sergio Trujillo CerroNo ratings yet

- Installation and Operation Manual For Omega Series Amplifiers 3-3-2008Document114 pagesInstallation and Operation Manual For Omega Series Amplifiers 3-3-2008berebgrNo ratings yet

- EGB Installation Manual-03113Document16 pagesEGB Installation Manual-03113Maaz BilgramiNo ratings yet

- BEE20901 MKS 2 ELECTRONICS ENGINEERING LABORATORY II Speed Control SystemDocument26 pagesBEE20901 MKS 2 ELECTRONICS ENGINEERING LABORATORY II Speed Control SystemAnie SaidNo ratings yet

- Ac Servo Driver ManualDocument82 pagesAc Servo Driver ManualAbdulrehman Soomro100% (1)

- Kinetic 5700 Driver ConnectorsDocument144 pagesKinetic 5700 Driver ConnectorsSamuel OliveiraNo ratings yet

- Arduino Based Door Automation System Using Ultrasonic Sensor and Servo MotorDocument10 pagesArduino Based Door Automation System Using Ultrasonic Sensor and Servo MotorRockstar GmailNo ratings yet

- Sinamics - Free Function Blocks - Function Manual-01-2012 - V1.3 - en PDFDocument184 pagesSinamics - Free Function Blocks - Function Manual-01-2012 - V1.3 - en PDFandi1993No ratings yet

- Fuji Servo System: MEH555cDocument8 pagesFuji Servo System: MEH555csunhuynhNo ratings yet

- Technical Report: Project TitleDocument34 pagesTechnical Report: Project TitleMuhammad SalmanNo ratings yet

- MKS MONSTER8 V1.0 Datasheet (Based On Marlin Firmware To Configure Voron 2.4 Machine)Document68 pagesMKS MONSTER8 V1.0 Datasheet (Based On Marlin Firmware To Configure Voron 2.4 Machine)vmvarecloudNo ratings yet

- Mechatronics Boot Camp - May2022Document60 pagesMechatronics Boot Camp - May2022Maryam MehekNo ratings yet

- Technical Description and General Principles of IDE HDD Repair 199704Document37 pagesTechnical Description and General Principles of IDE HDD Repair 199704Ademir PajevicNo ratings yet

- SigmaWin 5.75 Release NotesDocument7 pagesSigmaWin 5.75 Release NotestirawolfNo ratings yet

- CMMB-SY 2017-05 8068715g1Document92 pagesCMMB-SY 2017-05 8068715g1jampukNo ratings yet

- Irjet V6i31240Document7 pagesIrjet V6i31240Ghanvir SinghNo ratings yet

- MR J3 MR J4 Transisition GuideDocument708 pagesMR J3 MR J4 Transisition GuideTAN SAU LIANGNo ratings yet

- DatasheetDocument92 pagesDatasheetNerea GallarNo ratings yet

- mrj2sb SeriesDocument225 pagesmrj2sb Seriesnestor gonzalez de leonNo ratings yet

- A Tutorial On Preview Control SystemsDocument6 pagesA Tutorial On Preview Control SystemsjaquetonaNo ratings yet

- Mesa Motion ControllerDocument2 pagesMesa Motion ControllerArvinder SinghNo ratings yet

- SDE User Manual - V1.01Document242 pagesSDE User Manual - V1.01FehmiturkNo ratings yet

- Parker Aries - ManualDocument174 pagesParker Aries - ManualSomjin Th. MahasarakhamNo ratings yet