Professional Documents

Culture Documents

Mix Design

Uploaded by

Ashok Rajanavar0 ratings0% found this document useful (0 votes)

79 views75 pagesConcrete Mix Design

Original Title

135250791-Mix-Design-ppt

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentConcrete Mix Design

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

79 views75 pagesMix Design

Uploaded by

Ashok RajanavarConcrete Mix Design

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You are on page 1of 75

BUILDING TECHNOLOGY AND MANAGEMENT

CONCRETE MIX DESIGN

INTRODUCTION

Concrete is obtained by mixing cement, fine aggregate, coarse

aggregate, water and admixtures in required proportions. The

mixture when placed in forms and allowed to cure becomes

hard like stone.

The hardening is caused by chemical action between water and

the cement due to which concrete grows stronger with age.

It is the most widely-used man-made construction material in

the world.

2 CONCRETE MIX DESIGN

CONCRETE MAKING MATERIALS

Cement

Aggregates

Water

Admixtures

3 CONCRETE MIX DESIGN

CEMENT

Cement and water forms the active component of concrete, while

the inactive group comprises the fine and coarse aggregates.

The cement and water form a paste that hardens and bonds the

aggregates together.

Types of Cement

Although around 18 types of cements are recognized by BIS, more

commonly used ones are:

Ordinary Portland Cement 33, 43, & 53 grade OPC,

Blended Cements (PPC and PSC).

Sulphate Resisting Cement (SRC),

Low Heat Portland Cement (LHPC),

Hydrophobic Portland Cement,

Colored Cement (White Cement).

4 CONCRETE MIX DESIGN

AGGREGATES

They are cheaper than cement and impart greater volume

stability and durability to concrete.

The main purpose is to provide bulk to the concrete.

Some of the aggregates may be chemically active.

CLASSIFICATION

Geological origin natural and artificial

Size fine, coarse and all-in

Shape rounded, irregular, angular, flaky and elongated

Unit weight normal-weight, heavyweight and lightweight

5 CONCRETE MIX DESIGN

WATER

The most important and least expensive ingredient of concrete.

One part of the water is used in the hydration of cement to form

the binding matrix.

The remaining water affords lubrication and workability to the

concrete.

Water-cement ratio depends on the grade of concrete, its

workability, durability, nature and type of aggregates etc.

Potable water is ideal for concreting.

Seawater may be used in PCC.

6 CONCRETE MIX DESIGN

ADMIXTURES

Added to the concrete immediately or during mixing to modify its

properties in the fresh or hardened state.

Types:

Accelerators - speed up the initial set of concrete.

Retarders delay the setting time of concrete mix.

Plasticizers and Super-plasticizers - water reducers.

Air entraining admixtures

Water proofers

Pigments

Corrosion-inhibiting chemicals

Antifungal admixtures

7 CONCRETE MIX DESIGN

TYPES OF CONCRETE MIXES

1. NOMINAL MIX

Mixes of fixed proportions, IS:456-2000 permits nominal mixes

for concretes of strength M20 or lower

2. DESIGN MIX

Designed on the basis of requirements of the concrete in

fresh and hardened states.

8 CONCRETE MIX DESIGN

TRIAL MIXES

Prepared to verify whether the Design Mix would perform as

per the assumptions. If appreciable variation exists, the

available alternatives are:

1. directly employ the trial mix proportions at the site

2. modify the trial mix proportions on the basis of intuition and

employ the revised proportions at the site

3. prepare further trial mixes incorporating changes in the

proportions based on the feedback generated from the

previous mix.

9 CONCRETE MIX DESIGN

CONCRETE MIX DESIGN

DEFINITION

Mix Design is the science of determining the relative

proportions of the ingredients of concrete to achieve the

desired properties in the most economical way.

CONCRETE MIX DESIGN 10

PRINCIPLES OF MIX DESIGN

1 The environment exposure condition for the structure

2 The grade of concrete, their characteristic strengths and

standard deviations

3 The type of cement

4 The types and sizes of aggregates and their sources of supply

5 The nominal maximum sizes of aggregates

6 Maximum and minimum cement content in kg/m

3

7 Water cement ratio

8 The degree of workability of concrete based on placing

conditions

CONCRETE MIX DESIGN 11

9 Air content inclusive of entrained air

10 The maximum/minimum density of concrete

11 The maximum/minimum temperature of fresh concrete

12 Type of water available for mixing and curing

13 The source of water and the impurities present in it.

CONCRETE MIX DESIGN 12

CONCRETE MIX DESIGN 13

IS 456:2000

CONCRETE MIX DESIGN 14

IS 456:2000

CONCRETE MIX DESIGN 15

IS 456:2000

FACTORS DEFINING THE CHOICE OF MIX

PROPORTIONS

1. Compressive Strength

2. Workability

3. Durability

4. Type, size and grading of aggregates

5. Aggregate-cement ratio

CONCRETE MIX DESIGN 16

COMPRESSIVE STRENGTH

Abrams Law

log F = log A

1

x log B

1

where F is the compressive strength

A1, B1 are constants and

x is the w/c ratio by weight

CONCRETE MIX DESIGN 17

WORKABILITY

that property of freshly mixed concrete which determines the

ease and homogeneity with which it can be mixed, placed,

consolidated and finished.

DURABILITY

the resistance to weathering action due to environmental

conditions such as changes in temperature and humidity,

chemical attack, abrasion, frost and fire.

CONCRETE MIX DESIGN 18

REQUIREMENTS AND TESTS OF MATERIALS REQUIRED

FOR MIX DESIGN

ASSIGNMENT # 1 TO BE SUBMITTED BY 07-02-2011

Roll #s 01-21 Cement

Roll #s 22-42 Aggregates

Roll #s 43-63 Water and Admixtures

CONCRETE MIX DESIGN 19

METHODS OF CONCRETE MIX DESIGN

1. American Concrete Institute Committee 211 method

2. Bureau of Indian Standards Recommended method IS 10262-82

3. Road note No. 4 (Grading Curve) method

4. Department Of Environment (DOE - British) method

5. Trial and Adjustment Method

6. Fineness modulus method

7. Maximum density method

8. Indian Road Congress, IRC 44 method

CONCRETE MIX DESIGN 20

American Concrete Institute Method of Mix Design

(a) Data to be collected :

(i ) Fineness modulus of selected F.A.

(ii ) Unit weight of dry rodded coarse aggregate.

(iii ) Sp. gravity of coarse and fine aggregates in SSD condition

(iv ) Absorption characteristics of both coarse and fine

aggregates.

(v ) Specific gravity of cement.

(b) From the minimum strength specified, estimate the average

design strength by using standard deviation.

(c) Find the water/cement ratio from the strength and durability

points of view. Adopt the lower value.

CONCRETE MIX DESIGN 21

(d) Decide the maximum size of aggregate to be used. Generally

for RCC work 20 mm and pre-stressed concrete 10 mm size are

used.

(e) Decide workability in terms of slump for the given job.

(f ) The total water in kg/m

3

of concrete is determined,

corresponding to the selected slump and selected maximum

size of aggregate.

(g ) Cement content is computed by dividing the total water

content by the water/cement ratio.

(h) Select the bulk volume of dry rodded coarse aggregate per unit

volume of concrete, for the particular maximum size of coarse

aggregate and fineness modulus of fine aggregate.

CONCRETE MIX DESIGN 22

( j ) The weight of C.A. per cubic meter of concrete is calculated by

multiplying the bulk volume with bulk density.

(k ) The solid volume of coarse aggregate in one cubic meter of

concrete is calculated by knowing the specific gravity of C.A.

(l ) Similarly the solid volume of cement, water and volume of air is

calculated in one cubic meter of concrete.

(m) The solid volume of FA is computed by subtracting from the

total volume of concrete the solid volume of cement, CA, water

and entrapped air.

(n) Weight of fine aggregate is calculated by multiplying the solid

volume of fine aggregate by specific gravity of F.A.

CONCRETE MIX DESIGN 23

ACI METHOD: DESIGN EXAMPLE

1 Design a concrete mix for the construction of an elevated water

tank. The specified design strength of concrete (characteristic

strength) is 30 MPa at 28 days measured on standard cylinders.

Standard deviation can be taken as 4 MPa. The specific gravity

of FA and C.A. are 2.65 and 2.7 respectively. The dry rodded

bulk density of C.A. is 1600 kg/m3, and fineness modulus of FA

is 2.80. Ordinary Portland cement (Type I) will be used. A slump

of 50 mm is necessary. C.A. is found to be absorptive to the

extent of 1% and free surface moisture in sand is found to be 2

per cent. Assume any other essential data.

CONCRETE MIX DESIGN 24

1 Mean Cylinder Compressive Strength

Assuming 5 per cent of results are allowed to fall below

specified design strength,

The mean strength,

f

m

= f

min

+ ks

= 30 + 1.64 x 4

= 36.5 MPa

2 Water/cement ratio

Strength criteria

Durability criteria

CONCRETE MIX DESIGN 25

CONCRETE MIX DESIGN 26

Strength Criteria

CONCRETE MIX DESIGN 27

Durability Criteria

CONCRETE MIX DESIGN 28

3 Mixing Water Content

Slump = 50 mm

Maximum size of aggregate = 20 mm

Concrete is non air-entrained

CONCRETE MIX DESIGN 29

CONCRETE MIX DESIGN 30

The mixing water content is 185 kg/m

3

of concrete

The approximate entrapped air content is 2%.

The required cement content =185/0.47

= 394 kg/m

3

CONCRETE MIX DESIGN 31

4 Bulk Volume of C.A.

Maximum size of C.A = 20mm

Fineness Modulus of F.A. = 2.80

Find the dry rodded bulk volume of C.A.

CONCRETE MIX DESIGN 32

CONCRETE MIX DESIGN 33

The dry rodded bulk volume of C.A. = 0.62 per unit volume of

concrete

The weight of C.A. = 0.62 x 1600

= 992 kg/m

3

CONCRETE MIX DESIGN 34

5 The first estimate of density of fresh concrete = 2355 kg/m

3

CONCRETE MIX DESIGN 35

The weight of all the known ingredients of

concrete

Weight of water = 185 kg/m

3

Weight of cement = 394 kg/m

3

Weight of C.A. = 992 kg/m

3

Weight of F.A. = 2355 (185 + 394 + 992)

= 784 kg/m

3

6 Weight of FA

CONCRETE MIX DESIGN 36

Alternatively, the weight of F.A. can be determined by the more

accurate absolute volume method

Absolute Volume = weight/(1000) m

3

CONCRETE MIX DESIGN 37

Total absolute volume = 697 x 10

3

cm

3

Absolute volume of F.A. = (1000 697) x 10

3

= 303 x 10

3

Weight of FA = 303 x 2.65

= 803 kg/m

3

CONCRETE MIX DESIGN 38

7 Estimated quantities of materials per cubic meter of

concrete are:

Cement = 394 kg

F.A = 803 kg

C.A = 992 kg

Water = 185 kg

CONCRETE MIX DESIGN 39

8 Proportions

C : F.A : C.A : water

394 : 803 : 992 : 185

1 : 2.04 : 2.52 : 0.47

Weight of materials for one bag mix

in kg = 50 : 102 : 126 : 23.5

CONCRETE MIX DESIGN 40

9 The above quantities is on the basis that both F.A

and C.A are in saturated and surface dry condition

(SSD conditions).

FA has surface moisture of 2%

Total free surface moisture in FA = (2/100 x 803)

= 16.06 kg/m

3

Weight of F.A in field condition = 803 + 16.06 = 819.06 kg/m

3

CONCRETE MIX DESIGN 41

Quantity of water absorbed by C.A. = (1/100 x 992) = 9.92 kg/m

3

Weight of C.A in field condition = 992 9.92

= 982 kg/m

3

C.A absorbs 1% water

Water contributed by F.A = 16.06 kg

Water absorbed by C.A. = 9.92 kg

Extra water contributed by aggs. = 16.06 9.92 = 6.14 kg

Total water content = 185.00 6.14

= 179 kg/m

3

Change in Water Content

CONCRETE MIX DESIGN 42

Cement = 394 kg/m

3

F.A. = 819 kg/m

3

C.A. = 982 kg/m

3

Water = 179 kg/m

3

Field density of fresh concrete = 2374

kg/m

3

Quantities of materials to be used in field, corrected for

free surface moisture in F.A and absorption characteristic

of C.A

2. A mix with a mean 28-day compressive strength of 35 MPa and

a slump of 50 mm is required, using OPC. The maximum size

of well shaped, angular aggregate is 20mm, its bulk density is

1600 kg/m

3

and its specific gravity is 2.64. The available fine

aggregate has a fineness modulus of 2.60 and a specific

gravity of 2.58. No air-entrainment is required.

CONCRETE MIX DESIGN 43

Water/Cement ratio

As durability criteria is not

mentioned, consider strength alone

CONCRETE MIX DESIGN 44

Strength Criteria

Water/cement ratio =0.48

CONCRETE MIX DESIGN 45

Slump = 50 mm

Max size of aggregate = 20 mm

Determine water content

CONCRETE MIX DESIGN 46

CONCRETE MIX DESIGN 47

Composition of concrete (kg/m

3

)

Water = 185

Cement = 386

CA = 1020

FA = 738

Density of Concrete = 2329 (kg/m

3

)

CONCRETE MIX DESIGN 48

ROAD NOTE No. 4 METHOD OF MIX DESIGN

Proposed by the Road Research Laboratory, UK (1950)

Procedure:

1. The average compressive strength of the mix to be designed is

obtained by applying control factors to the minimum

compressive strength

2. Water/cement ratio is read from compressive strength v/s w/c

ratio graph

3. Proportion of combined aggregates to cement is determined

from tables, for maximum size 40 mm and 20 mm

4. If the aggregate available differs from the standard gradings,

combine FA and CA so as to produce one of the standard

gradings

CONCRETE MIX DESIGN 49

5. The proportion of cement, water, FA and CA is determined

from knowing the water/cement ratio and the

aggregate/cement ratio.

6. Calculate the quantities of ingredients required to produce 1

m

3

of concrete, by the absolute volume method, using the

specific gravities of cement and aggregates.

CONCRETE MIX DESIGN 50

DRAWBACKS OF ROAD NOTE NO. 4 METHOD

1. Cannot be used directly for the design of air - entrained

concrete

2. No recommendations for durability or strength, regarding the

water/cement ratio

3. The design tables refer to mixes in which the FA and CA are of

the same shape

4. In selecting aggregate/cement ratio, only 3 shapes of

aggregates and 4 gradings are recommended.

CONCRETE MIX DESIGN 51

DOE METHOD OF MIX DESIGN

Can be used for concrete containing fly ash.

PROCEDURE

1. Target mean strength is calculated

2. Select water/cement ratio, from the type of cement and CA.

Compare this with the ratio from durability conditions.

3. Decide the water content for required workability

4. Compare the cement content with the minimum cement content

value and adopt the higher value

5. Find out the total aggregate content

6. Determine the proportion of FA using the appropriate FA% v/s

CA size graph, and find the weight of CA and FA

7. Work out a trial mix.

CONCRETE MIX DESIGN 52

BIS RECOMMENDED MIX DESIGN METHOD

The BIS recommended mix design procedure is covered in IS

10262-82.

In line with IS 456-2000, the first revision IS 10262-2009 was

published, to accommodate some of the following changes:

Increase in strength of cement

Express workability in terms of slump, rather than the

compacting factor

Extend the W/C ratio v/s compressive strength graph

CONCRETE MIX DESIGN 53

CONCRETE MIX DESIGN 54

Modifications in IS 10262-2009

MIX DESIGN BASED ON IS RECOMMENDATIONS

Based on IS 10262:1982

Procedure:

CONCRETE MIX DESIGN 55

1. Target mean strength for mix design:

f

ck

* = f

ck

+ tS

where f

ck

= characteristic compressive strength at 28 days

S = standard deviation

t = a statistical value depending on the risk factor.

CONCRETE MIX DESIGN 56

CONCRETE MIX DESIGN 57

2. Selection of Water/Cement ratio

CONCRETE MIX DESIGN 58

3. Estimation of Entrapped Air

CONCRETE MIX DESIGN 59

4. Selection of Water Content and Fine to Total Aggregate ratio

CONCRETE MIX DESIGN 60

CONCRETE MIX DESIGN 61

5. Calculation of Cement Content:

cement by mass = Water content/Water cement ratio

To be checked against the minimum cement content for the requirement

of durability and the greater of the two values to be adopted.

CONCRETE MIX DESIGN 62

6. Calculation of aggregate content:

CONCRETE MIX DESIGN 63

7. Actual quantities required for mix

Adjust the mix for deviations from assumed conditions

CONCRETE MIX DESIGN 64

8. Check the calculated mix proportions

DESIGN EXAMPLE: BIS RECOMMENDED METHOD

Grade M20

(a ) Design stipulations

(i ) Characteristic compressive strength

required in the field at 28 days - 20 MPa

(ii ) Maximum size of aggregate - 20 mm (angular)

(iii ) Degree of workability - 0.90 compacting factor

(iv ) Degree of quality control - Good

(v ) Type of Exposure - Mild

(b) Test data for Materials

(i ) Specific gravity of cement - 3.15

(ii ) Compressive strength of cement at 7 days - Satisfies the

requirement of IS: 2691989

(iii ) 1. Specific gravity of coarse aggregates - 2.60

2. Specific gravity of fine aggregates - 2.60

(iv ) Water absorption:

1. Coarse aggregate - 0.50%

2. Fine aggregate - 1.0%

(v ) Free (surface) moisture:

1. Coarse aggregate - Nil

2. Fine aggregate - 2.0%

Design Procedure

1. Target mean strength of concrete

f

ck

* = f

ck

+ tS

CONCRETE MIX DESIGN 67

f

ck

= 20, t = 1.64 , S = 4

f

ck

* = 26.6 MPa

2. Selection of Water/Cement Ratio

CONCRETE MIX DESIGN 68

Durability Criteria: Mild Exposure Conditions

CONCRETE MIX DESIGN 69

W/C ratio from strength considerations = 0.50

W/C ratio from durability considerations = 0.55

Adopt the lower value

CONCRETE MIX DESIGN 70

3. Selection of water and sand content

CONCRETE MIX DESIGN 71

Adjustments in Water and Sand Contents

CONCRETE MIX DESIGN 72

4. Determination of cement content

Water-cement ratio = 0.50

water = 191.6 kg/m

3

CONCRETE MIX DESIGN 73

Cement = 191.6/0.50 = 383 kg/m

3

Is this satisfactory for mild exposure condition?

5. Determination of coarse and fine aggregate contents

Specified max. size of aggregate = 20 mm

Corresponding entrapped air = 2%

CONCRETE MIX DESIGN 74

f

a

= 546 kg/m

3

,

C

a

= 1188 kg/m

3

Final Mix Proportions

Water Cement FA CA

191.6 383 546 1188

0.50 1 1.425 3.10

CONCRETE MIX DESIGN 75

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Pharmacology Review - A Comprehensive Reference Guide For Medical, Nursing, and Paramedic StudentsDocument276 pagesPharmacology Review - A Comprehensive Reference Guide For Medical, Nursing, and Paramedic StudentsfjletonaNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Quality Assurance Hand Book For Rural Roads VolumeIDocument267 pagesQuality Assurance Hand Book For Rural Roads VolumeImadhav_karki_2100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Enzymes Lab ReportDocument8 pagesEnzymes Lab ReportMaizamNo ratings yet

- Technical Reference Guide Fastenal K Factor and MoreDocument62 pagesTechnical Reference Guide Fastenal K Factor and Moredlight0No ratings yet

- Guide To Expansion Joints (Choosing and Maintenance)Document16 pagesGuide To Expansion Joints (Choosing and Maintenance)stevebeanNo ratings yet

- HaarslevDocument12 pagesHaarslevjimdacalano1911No ratings yet

- Calculation of Heat and Mass BalanceDocument18 pagesCalculation of Heat and Mass BalanceJitendra Bhatia100% (3)

- EIFS performance standardsDocument40 pagesEIFS performance standardsRyan ClarkeNo ratings yet

- Circulatum MinusDocument2 pagesCirculatum MinusJoshua Arent100% (1)

- Third Quarter Science 8: Content StandardDocument19 pagesThird Quarter Science 8: Content StandardGypsie Ann Pacon100% (1)

- Economics of Methanol Production From Natural GasDocument56 pagesEconomics of Methanol Production From Natural Gaspabel lema0% (1)

- Arun Vishwanath Unhale: Course/Degree Institution Board/University Year Average (%)Document3 pagesArun Vishwanath Unhale: Course/Degree Institution Board/University Year Average (%)Ashok RajanavarNo ratings yet

- Assignment TEDocument2 pagesAssignment TEAshok RajanavarNo ratings yet

- Arun Vishwanath Unhale: Course/Degree Institution Board/University Year Average (%)Document3 pagesArun Vishwanath Unhale: Course/Degree Institution Board/University Year Average (%)Ashok RajanavarNo ratings yet

- Marshall Mix DesignDocument30 pagesMarshall Mix DesignAshok RajanavarNo ratings yet

- Akash RachattteDocument1 pageAkash RachattteAshok RajanavarNo ratings yet

- Undertaking: AmieteDocument5 pagesUndertaking: AmieteAshok RajanavarNo ratings yet

- Assignment TEDocument2 pagesAssignment TEAshok RajanavarNo ratings yet

- FATIGUE ANALYSIS OF 3-LAYER PAVEMENT SYSTEMDocument1 pageFATIGUE ANALYSIS OF 3-LAYER PAVEMENT SYSTEMAshok RajanavarNo ratings yet

- Think Pair Share. Satish B Thalange Engg. Management-IIDocument7 pagesThink Pair Share. Satish B Thalange Engg. Management-IIAshok RajanavarNo ratings yet

- Arun Vishwanath Unhale: Course/Degree Institution Board/University Year Average (%)Document3 pagesArun Vishwanath Unhale: Course/Degree Institution Board/University Year Average (%)Ashok RajanavarNo ratings yet

- IRCTC E-Ticket Details for PNR 4122241070Document2 pagesIRCTC E-Ticket Details for PNR 4122241070Ashok RajanavarNo ratings yet

- SowmyaDocument1 pageSowmyaAshok RajanavarNo ratings yet

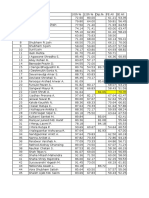

- Walchand Institute Civil Engineering Lab Equipment Rates ComparisonDocument1 pageWalchand Institute Civil Engineering Lab Equipment Rates ComparisonAshok RajanavarNo ratings yet

- Work HDM Format (Chittoor)Document120 pagesWork HDM Format (Chittoor)Ashok RajanavarNo ratings yet

- Minor Junctions-Package-I SL No - Existing Chainag e (KM) Design Chainag e (KM) Type of Intersectio N Categor y Other Features Junction LayoutDocument2 pagesMinor Junctions-Package-I SL No - Existing Chainag e (KM) Design Chainag e (KM) Type of Intersectio N Categor y Other Features Junction LayoutAshok RajanavarNo ratings yet

- QPR ReportDocument76 pagesQPR ReportAshok RajanavarNo ratings yet

- Criteria 03Document1 pageCriteria 03Ashok RajanavarNo ratings yet

- Solar SystemDocument1 pageSolar SystemAshok RajanavarNo ratings yet

- DP CVDocument4 pagesDP CVAshok RajanavarNo ratings yet

- Notification Technl PostsDocument27 pagesNotification Technl PostsShreyas RedNo ratings yet

- Top 45 Students' Academic RecordsDocument2 pagesTop 45 Students' Academic RecordsAshok RajanavarNo ratings yet

- TicketDocument3 pagesTicketAshok RajanavarNo ratings yet

- ProfileDocument5 pagesProfileAshok RajanavarNo ratings yet

- Field Data StudiesDocument168 pagesField Data StudiesAshok RajanavarNo ratings yet

- Notification Technl PostsDocument27 pagesNotification Technl PostsShreyas RedNo ratings yet

- TrainingDocument44 pagesTrainingAshok RajanavarNo ratings yet

- Soil ResultsDocument12 pagesSoil ResultsAshok RajanavarNo ratings yet

- Number Key Answer Number Key Answer Number Key Answer Number Key AnswerDocument1 pageNumber Key Answer Number Key Answer Number Key Answer Number Key AnswerAshok RajanavarNo ratings yet

- Madan Kumar CVDocument3 pagesMadan Kumar CVAshok RajanavarNo ratings yet

- Edward TellerDocument2 pagesEdward TellerfarshtaschNo ratings yet

- 1 PBDocument12 pages1 PBLela MaelaNo ratings yet

- Estimacion Del AOFDocument12 pagesEstimacion Del AOFPedro Antonio Lea Plaza RicoNo ratings yet

- Computational LaboratoryDocument31 pagesComputational LaboratoryFrendick LegaspiNo ratings yet

- GilbertDocument24 pagesGilbertVibhuti BhargavaNo ratings yet

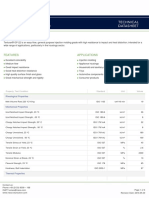

- Terluran GP-22: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesTerluran GP-22: Acrylonitrile Butadiene Styrene (ABS)Mahdi VolgarNo ratings yet

- Formula Ergun Manto LodosDocument22 pagesFormula Ergun Manto LodosReinaldoNo ratings yet

- UTU - B.tech - Project Report FrameworkDocument20 pagesUTU - B.tech - Project Report FrameworkHarShil KotHariNo ratings yet

- Energy and FluctuationDocument10 pagesEnergy and Fluctuationwalid Ait MazouzNo ratings yet

- Cardiac Leads MDT - Cable DéfDocument116 pagesCardiac Leads MDT - Cable DéfRABAH BOUCHELAGHEMNo ratings yet

- GDocument3 pagesGjeas grejoy andrewsNo ratings yet

- NRAC Publication No. 170 An Introduction To Water Chemistry in Freshwater AquacultureDocument4 pagesNRAC Publication No. 170 An Introduction To Water Chemistry in Freshwater AquacultureSk RajNo ratings yet

- Shell Rimula R3 Turbo 15W-40Document2 pagesShell Rimula R3 Turbo 15W-40HUM CIREBON DFLTSNo ratings yet

- Elisa: Enzyme-Linked Immunosorbent AssayDocument12 pagesElisa: Enzyme-Linked Immunosorbent AssayAmitNo ratings yet

- s4 Chemistry Paper 1 Set 1 Marking GuideDocument11 pagess4 Chemistry Paper 1 Set 1 Marking GuideNamuli MercyNo ratings yet

- Chapter 17Document97 pagesChapter 17Marco KrugerNo ratings yet

- DHEA CAPUYAN - Charles's Law Science ExperimentDocument4 pagesDHEA CAPUYAN - Charles's Law Science ExperimentDhea Angela A. CapuyanNo ratings yet

- Timber: Civil Engineering MaterialDocument47 pagesTimber: Civil Engineering MaterialSamirsinh ParmarNo ratings yet

- PLD 105Document8 pagesPLD 105madx44No ratings yet

- David Yu Zhang - Dynamic DNA Strand Displacement CircuitsDocument290 pagesDavid Yu Zhang - Dynamic DNA Strand Displacement CircuitsCogsmsNo ratings yet