Professional Documents

Culture Documents

Framed Steel Member Conection

Uploaded by

Raju SharmaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Framed Steel Member Conection

Uploaded by

Raju SharmaCopyright:

Available Formats

Raju Sharma

Assistant Professor

Chandigarh University

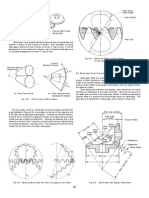

Seat connection

Two types of seat connection are used

Un-stiffened seat connection

Stiffened seat connection

UNSTIFFENED SEAT CONNECTION

Angle is provided below the beam flange and is designed to transfer the

end reactions of beam to the column through connections.

The seat angle also provides a surface on which the beam flange may rest

during erection, eliminating erection bolts.

Generally the outstanding (seating) leg is taken as 100 mm

which is sufficient to check the web crippling of the beam

Minimum two rivets required for the connection of seat angle

to beam flange

10-15 mm clearance should be made between the beam and

column. Seat is assumed to be flexible

Angle is provided at the upper flange of the beam and this is

called cleat or clip angle. provide later support

to the compression flange of the beam at this point only and

is assumed to carry no load.

Clit Angle

Conventional design assumed

Does not restrain the rotation at the beam end in the

vertical plane and the end reaction is the only force to be

considered

When the beam tends to rotate ,the cleat angle bends away

from the column as well as the beam Flexible beam seats

are the simplest and most desirable because the thickness

of the seat angle provides the only resistance against

bending in the outstanding leg.

Stiffened Seat Connections

The outstanding leg is stiffened by angles thus the seat

does not remain flexible.

Why stiffened Seat Connections are required ?

The outstanding leg of seat angle must be stiffened when the

reaction to be transferred to the column is too large

When the seating leg of 100 mm cannot provide the required

bearing area

Due to large reaction the number of rivets required to join the

connecting leg with the column may be large

The rivets can be accommodated on an additional angle called

a stiffener angle. packing equal to the thickness of the seat

angle are used between the column flange and the stiffener

angle.

The rivets connecting the column flange to the

outstanding legs are not tack riveted two stiffener angles,

bending moment (R act independentally .in this case the

rivets connecting the stiffener angle with the column

flange are designed for shear, bending moment (Rexx) and

twisting moment (Reyy), where exx, eyy are the eccentricities of

the reaction parallel to the outstanding legs and connected legs

respectively

Design of Unstiffened seat Connection

A seat angle is chosen suitably on the following

consideration:

The seat angle is assumed to have a length B, equal to the

width of the beam flange.

On the basis of web crippling of the beam length of the

outstanding leg of the seat angle may be calculated. The

seat length is kept more than the calculated bearing length.

b = (R/p x t) - 3h2

Above equation can give negative value of b for a large

beam with a small reaction. Therefore minimum bearing

length is

b < .5 (R/p x t)

R = end reaction in N

p = permissible bearing stress in Mpa (.75 fy)

t = thickness of the web of the beam in mm

h2 = depth of the root of fillet from extreme fibre of

flange for the beam in mm.

The connected leg is so chosen that at least three horizontal

rows of rivets can be accommodated. It can be assumed to

be 150 mm or more as desirable.

The thickness of seat angle is chosen such that the

outstanding leg does not fail in bending on a section at the

toe of the fillet.

Let

e1 = the distance from the critical section to the reaction

acting at the center of the bearing length (Fig 1)

= 10 + b/2 -t- radius of root of fillet

M= moment at the critical section (Re1)

B = length of seat angle (equal to the width of beam

flange)

bc = bending stress in compression assumed to be

equal to the bending stress in slab base i.e 185 N/mm

T= 6Re1/(B bc )

The angle thickness is assumed and the M.O.R is

computed, which should be more than the moment at

the critical section.

Two or more horizontal rows of rivets are provided to

connect the seat angle with the column flange

These are subjected to direct shear forces. rivets dia is

assumed and number of rivets required to connect the seat

angle with the flange of column are determined. The

outstanding leg of the seat angle is connected to the beam

flange with two rivets of the same dia as provided on the

connected leg

N = (end reaction/rivet value) n is number of rivets

A cleat angle of normal size is provided on the top flange of

beam and is connected by two rivets.

Design of stiffened seat connections

Size of seat angle is assumed on the basis of the bearing length

calculated

b = (R/p x t) - 3h2

Suitable stiffener angles are selected. Outstanding leg of the

stiffener angle must provided the bearing area stiffening leg.

the outstanding leg of the stiffener angle must provided the

bearing area. Also, it should not exceed 16 times its thickness

to avoid local buckling.

Bearing area required= (R/ p )

R= end reaction

p= permissible bearing in Mpa (.75 fy)

Thickness of the stiffner angle should not be less than

the thickness of the web of the beam supported.

seat is rigid so the reaction is assumed to have a greater

eccentricity.

Rivets in connecting leg are subjected to

Direct Shear

Moment

Connection behaves as a bracket connection TYPE II.

Bending moment about the face of the column flange is

determined.

The number of rivets are computed and check similar to

the bracket connection TYPE II is done.

(vf, cal/ vf ) + ( tf,cal/ tf) 1.4

A cleat angle of nominal size is provided and is connected

with rivets of same dia as on the seat angle.Two rivets are

provided on each leg of the cleat angle.

Framed connection

1. The end reaction which the beam has to transfer is

computed.

2. CONNECTION OF FRAMING ANGLE WITH BEAM

WEB

Assumed dia

Find rivet value in double shear and bearing

The number of rivets n, can be computed by

N= (end reaction/rivet value)

3. Connection of outstanding leg of the angle with the

web of the girder.

Assume dia

Rivet value is computed in single shear and bearing.

Number of rivets required n to connect the

outstanding leg with the flange of the beam

n = (end reaction/ rivet value)

4. The size of the framing angle is governed by the

number and row of rivets on connecting and outstanding

leg.

5. The thickness of the angle can be computed as follows

Limited shear stress,.4 fy =(end reaction/ 2x h x t)

Or t= end reaction/ 2h x .4 fy

You might also like

- Knuckle Joints DesignDocument10 pagesKnuckle Joints DesignKvrd Prasad100% (1)

- WErbsen CourseworkDocument562 pagesWErbsen CourseworkRoberto Alexis Rodríguez TorresNo ratings yet

- DCSP Tig Welding of Aa2219 Aluminum AlloyDocument14 pagesDCSP Tig Welding of Aa2219 Aluminum AlloySgk ManikandanNo ratings yet

- Operating: Maintenance ManualDocument18 pagesOperating: Maintenance ManualAnonymous reYe6iCCNo ratings yet

- Sheet Metal StructuresDocument40 pagesSheet Metal StructuresVandane ReyesNo ratings yet

- Mechanicl EngineeringDocument981 pagesMechanicl EngineeringBobby WaltersNo ratings yet

- (B) Testing Machine ToolsDocument100 pages(B) Testing Machine ToolsHyeonggil JooNo ratings yet

- Thread Basics - GO-No GoDocument2 pagesThread Basics - GO-No GoKundan Kumar MishraNo ratings yet

- All About ScrewsDocument19 pagesAll About Screwsbkpaul3107100% (1)

- The Synthesis of Elliptical Gears Generated by Shaper-CuttersDocument9 pagesThe Synthesis of Elliptical Gears Generated by Shaper-CuttersBen TearleNo ratings yet

- Machine Design Lec3Document75 pagesMachine Design Lec3sam0415No ratings yet

- Electric welding guideDocument19 pagesElectric welding guideRaghupatruni SowmyaNo ratings yet

- 4 Cylinder Compressed Air Engine LayoutDocument15 pages4 Cylinder Compressed Air Engine LayoutJitendra BagalNo ratings yet

- Design and Analysis of PROTECTED FLANGE COUPLING Solidworks 2016 and ANSYS WorkbenchDocument27 pagesDesign and Analysis of PROTECTED FLANGE COUPLING Solidworks 2016 and ANSYS Workbenchamu100% (1)

- Architecture Design Handbook - Flashings and Copings - Coping CoversDocument5 pagesArchitecture Design Handbook - Flashings and Copings - Coping CoversDukeNo ratings yet

- Indus Institute of Technology & EngineeringDocument31 pagesIndus Institute of Technology & Engineeringkeval patelNo ratings yet

- Dayton Tech BalllockDocument12 pagesDayton Tech BalllockNaukowyDrpNo ratings yet

- The Art of Centered Eye BendingDocument29 pagesThe Art of Centered Eye BendingKhin Aung Shwe100% (1)

- Metal Joining Methods and Hand ToolsDocument28 pagesMetal Joining Methods and Hand ToolsLinda FondoNo ratings yet

- Riding Mower PartsDocument17 pagesRiding Mower PartsDwight MorrisonNo ratings yet

- 02 Knuckle JointDocument24 pages02 Knuckle JointTeaching ClubNo ratings yet

- Setup and Installation of JDSW51A 5-Axis USB Motion CardDocument36 pagesSetup and Installation of JDSW51A 5-Axis USB Motion Cardabelmil123No ratings yet

- Assy of Ball TurnerDocument1 pageAssy of Ball TurnerAntónio OliveiraNo ratings yet

- ME311 Screws LectureDocument26 pagesME311 Screws LectureantoniodellisantiNo ratings yet

- Bearing ArrangementDocument5 pagesBearing ArrangementSubbarayan SaravanakumarNo ratings yet

- V-Machine Design 1Document37 pagesV-Machine Design 1roamer10No ratings yet

- Pioneer Avh-P3100dvd p3150dvd SMDocument190 pagesPioneer Avh-P3100dvd p3150dvd SMRogerio E. SantoNo ratings yet

- Design and Fabrication of Toggle JackDocument30 pagesDesign and Fabrication of Toggle JackJitendra Rout0% (1)

- Bevel Gear Transmission AnglesDocument6 pagesBevel Gear Transmission AnglesNabende UmarNo ratings yet

- Ralph Patterson Tailstock Camlock 2Document13 pagesRalph Patterson Tailstock Camlock 2supremesportsNo ratings yet

- Climaxportable Lathe Pl3000-EDocument6 pagesClimaxportable Lathe Pl3000-EjpolancosNo ratings yet

- Gears: Drawing Gear Teeth Spur GearsDocument16 pagesGears: Drawing Gear Teeth Spur GearsGvgfhjNo ratings yet

- 149-Workshop Hints & Tips PDFDocument1 page149-Workshop Hints & Tips PDFsyllavethyjimNo ratings yet

- Gear and Gear TrainDocument21 pagesGear and Gear Trainm_er100No ratings yet

- Gear Ratio Calculations PDFDocument4 pagesGear Ratio Calculations PDFrechingatuputamadreNo ratings yet

- Design of Clamps Chapter SummaryDocument54 pagesDesign of Clamps Chapter SummaryKhaled HamdyNo ratings yet

- Gear Teeth: Clocks and ShipsDocument16 pagesGear Teeth: Clocks and ShipsČika BrkoNo ratings yet

- Description of A Standard Bumper JackDocument2 pagesDescription of A Standard Bumper JackDouglas EstradaNo ratings yet

- Design and Modification of Bench Vice by Increasing The Degrees of FreedomDocument4 pagesDesign and Modification of Bench Vice by Increasing The Degrees of FreedomGRD JournalsNo ratings yet

- Mechanics of MaterialDocument3 pagesMechanics of MaterialChhaya Sharma100% (1)

- Baja Suspension ReportDocument3 pagesBaja Suspension ReportheroNo ratings yet

- Dathan Tool and Gauge HandbookDocument32 pagesDathan Tool and Gauge HandbooksamirkaminskyNo ratings yet

- How to calculate bricks or blocksDocument2 pagesHow to calculate bricks or blocksDENCONo ratings yet

- Belt Drive Handout - 05Document3 pagesBelt Drive Handout - 05NkoshiEpaphrasShoopalaNo ratings yet

- Plasma Operations ManualDocument27 pagesPlasma Operations ManualMyk DeVroedeNo ratings yet

- Report FEADocument15 pagesReport FEAamuNo ratings yet

- Bolt Depot CatalogDocument104 pagesBolt Depot Catalogalexmontell100% (2)

- Pipe and Tube Bending PrinciplesDocument5 pagesPipe and Tube Bending PrinciplesPravin SatheNo ratings yet

- Guidelines For Collect DesignDocument24 pagesGuidelines For Collect DesignArun LeleNo ratings yet

- Hand Calculations in Structural AnalysisDocument3 pagesHand Calculations in Structural AnalysisArdalan YazarNo ratings yet

- Glossary of Suspension Terms PDFDocument10 pagesGlossary of Suspension Terms PDFrobinNo ratings yet

- Wear Analysis of Hard Faced Agricultural Equipment - Doc FFDocument15 pagesWear Analysis of Hard Faced Agricultural Equipment - Doc FFSunil BasavarajuNo ratings yet

- Rolling vs Sliding Bearings: Advantages & TypesDocument8 pagesRolling vs Sliding Bearings: Advantages & TypesDebabrat SaikiaNo ratings yet

- Screw Thread MeasurementsDocument77 pagesScrew Thread MeasurementsSridhar SreeNo ratings yet

- Bolted JointsDocument3 pagesBolted JointsGiuseppe GiuseppeNo ratings yet

- Reduction of Stress Concentration in Bolt Nut ConnectorsDocument6 pagesReduction of Stress Concentration in Bolt Nut ConnectorsjtorerocNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Objective Civil Engineering QuestionDocument60 pagesObjective Civil Engineering QuestionRaju Sharma78% (37)

- Industrial Building, Design of Steel Structure Part 2, Types of LoadsDocument36 pagesIndustrial Building, Design of Steel Structure Part 2, Types of LoadsRaju Sharma100% (3)

- Explicit and ImplicitDocument14 pagesExplicit and ImplicitRaju SharmaNo ratings yet

- Solution of Non Linear EquationsDocument29 pagesSolution of Non Linear EquationsRaju SharmaNo ratings yet

- Introduction of Theodolite, Traversing by Theodolite, Error in TraversingDocument26 pagesIntroduction of Theodolite, Traversing by Theodolite, Error in TraversingRaju Sharma81% (27)

- Column Base, Steel Column BaseDocument8 pagesColumn Base, Steel Column BaseRaju Sharma75% (4)

- Laced and Battened Columns, Design of Steel ColumnDocument14 pagesLaced and Battened Columns, Design of Steel ColumnRaju Sharma80% (30)

- Connections of Steel Member by Rivet and BoltDocument13 pagesConnections of Steel Member by Rivet and BoltRaju SharmaNo ratings yet

- Properties of Structure Steel As Per Limit State Method IS 800:2007, Mechanical Properties of SteelDocument19 pagesProperties of Structure Steel As Per Limit State Method IS 800:2007, Mechanical Properties of SteelRaju Sharma75% (4)

- Er Raju Sharma Assistant Professor Department of Civil Engineering CGCDocument21 pagesEr Raju Sharma Assistant Professor Department of Civil Engineering CGCRaju Sharma100% (3)

- Welded Joint, Welded ConnectionsDocument45 pagesWelded Joint, Welded ConnectionsRaju Sharma67% (12)

- MF 5460Document586 pagesMF 5460Maximiliano Hitschfeld100% (2)

- New Membership Application GemsDocument5 pagesNew Membership Application Gemslaguila18No ratings yet

- FSR & FST First Stage Regulator: Maintenance Manual FOR Authorised TechniciansDocument23 pagesFSR & FST First Stage Regulator: Maintenance Manual FOR Authorised TechniciansпавелNo ratings yet

- 9608/21/M/J/15 © Ucles 2015Document57 pages9608/21/M/J/15 © Ucles 2015Asilbek AshurovNo ratings yet

- No Curfew for College Dorm StudentsDocument2 pagesNo Curfew for College Dorm Students陳玟蓁No ratings yet

- Safety and Arming Device Timer 6-7-1976Document5 pagesSafety and Arming Device Timer 6-7-1976nguyenhNo ratings yet

- Numerical Simulations of Piano StringsDocument7 pagesNumerical Simulations of Piano StringsMihai DincaNo ratings yet

- Curtis E50 Pump Parts ListDocument8 pagesCurtis E50 Pump Parts ListrobertNo ratings yet

- What Is Creole Language - Definition & PhrasesDocument2 pagesWhat Is Creole Language - Definition & PhrasesGabriel7496No ratings yet

- Introspective Hypnosis Class - 052017 - Antonio Sangio (2745)Document62 pagesIntrospective Hypnosis Class - 052017 - Antonio Sangio (2745)sandra100% (4)

- Event Rulebook Authorsgate 3.0 IEEE SB KUETDocument9 pagesEvent Rulebook Authorsgate 3.0 IEEE SB KUETKUET²⁰²¹No ratings yet

- IQ, OQ, PQ: A Quick Guide To Process ValidationDocument9 pagesIQ, OQ, PQ: A Quick Guide To Process ValidationGonzalo MazaNo ratings yet

- Axion DatabaseDocument25 pagesAxion Databasemacy williamsNo ratings yet

- Snel White Paper 2020Document18 pagesSnel White Paper 2020Zgodan NezgodanNo ratings yet

- Mastercam Book 5 Axis Bai 1Document31 pagesMastercam Book 5 Axis Bai 1tuanvn76100% (3)

- Let's Mingle Chat Invite ExamplesDocument22 pagesLet's Mingle Chat Invite ExamplesCarmen BalbuenaNo ratings yet

- Homebuilding - Renovating-UltimateDesignBuildGuideDocument60 pagesHomebuilding - Renovating-UltimateDesignBuildGuideverivtudawNo ratings yet

- Mock Examination Routine A 2021 NewDocument2 pagesMock Examination Routine A 2021 Newmufrad muhtasibNo ratings yet

- Non-Permanence Risk Report Template (Short Form) : Instructions For Completing TheDocument5 pagesNon-Permanence Risk Report Template (Short Form) : Instructions For Completing Theferrian prabowoNo ratings yet

- Languages and CommunicationDocument17 pagesLanguages and CommunicationDERICK REBAYNo ratings yet

- Vision and Mission Analysis ChapterDocument15 pagesVision and Mission Analysis Chapterzaza bazazaNo ratings yet

- Service Manual 900 OG Factory 16V M85-M93Document572 pagesService Manual 900 OG Factory 16V M85-M93Sting Eyes100% (1)

- 005-012 Fuel Injection Pumps, In-Line: InstallDocument14 pages005-012 Fuel Injection Pumps, In-Line: InstallMuhammad Ishfaq100% (3)

- HydrodynamicsDocument122 pagesHydrodynamicsIustin Cristian100% (2)

- Final Exam - Movie Analysis of Respeto - Sec90 - K. Dela CruzDocument9 pagesFinal Exam - Movie Analysis of Respeto - Sec90 - K. Dela CruzKylie Dela CruzNo ratings yet

- RAN KPI MonitorDocument8 pagesRAN KPI MonitorOmer WaqarNo ratings yet

- Wellmark Series 2600 PDFDocument6 pagesWellmark Series 2600 PDFHomar Hernández JuncoNo ratings yet

- MMA Electrode ClassificationDocument3 pagesMMA Electrode ClassificationRathnakrajaNo ratings yet

- The Stress Relief PrescriptionDocument8 pagesThe Stress Relief PrescriptionRajesh KumarNo ratings yet

- Writing and Reporting For The Media Workbook 12Th Edition Full ChapterDocument32 pagesWriting and Reporting For The Media Workbook 12Th Edition Full Chapterdorothy.todd224100% (23)