Professional Documents

Culture Documents

Lessons From Montara and BP Blowouts

Uploaded by

Eduardo GuajardoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lessons From Montara and BP Blowouts

Uploaded by

Eduardo GuajardoCopyright:

Available Formats

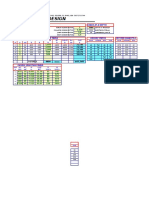

O I L S E A R C H L I M I T E D

1

Barriers to flow

Surface or seabed

Shallow casings set to prevent

hole collapse or losses of mud

Sandstone containing oil

and gas

Cement to seal around casing,

prevent leak to surface

Pressure from heavy mud prevents

gas / oil flowing into well

Wellhead and BOP allow closing in at

surface or seabed if flow occurs

O I L S E A R C H L I M I T E D

Lessons from Montara and BP

blowouts update on

implications to OSL

L Bundesen / C Fraser

26

th

August 2010

O I L S E A R C H L I M I T E D

3

Before blowout caught fire

O I L S E A R C H L I M I T E D

4

Montara well diagram suspension

Sea level

Seabed

ormation

top

!his bo" indicates #mud line hanger$

Casing #shoe track$

%& &/'$ casing cemented in %( )$ hole

* +/'$ casing in %, -$ hole

Blowout preventers removed during suspension and casings removed to seabed

Pressure.containing corrosion cap on * +/'$

Brine left in * +/'$

B/00120S 0234156 O57

%8 Cemented * +/' inch

,8 Brine left in * +/' inch

&8 Pressure containing corrosion cap

O I L S E A R C H L I M I T E D

5

Causes of Montara Blowout

Inquiry results not yet released, however

ver!dis"la#ed a$ter % &/'( #e)ent *o+, leaving "ath $or oil

and /or gas to $low u" the inside o$ the #asing

,id not #ondu#t "ressure test o$ the #e)ent *o+ a$ter that

Inadequate +arriers in "la#e -+rine that )ay have +een too

low a density. sealing #orrosion #a"/ and re)oved the

#orrosion #a" without having B0s installed

A$ter a "eriod o$ hours, the well #o))en#ed $lowing1

2u)an errors, la#3 o$ review, #utting #orners1

O I L S E A R C H L I M I T E D

6

Causes of BP Blowout:

Inquiries and ata Sources

Full in$or)ation is not yet availa+le. in$or)ation here is

+ased on a nu)+er o$ sour#es, )ainly B0 and 4ranso#ean

dra$t investigations availa+le on internet. 56 6enate su+!

#o))ittee inquiry letter to B0 and 780 day( re"ort +y the

56A ,e"t o$ Interior to the 56A 0resident1

In$o on ne9t slides is +ased on a B0 dra$t do#u)ent. they

show an overview o$ what the #riti#al $a#tors were1

4he in#ident o##urred during dis"la#e)ent o$ )ud +y

seawater "rior to setting the $inal -shallow/ #e)ent "lug

+e$ore dis#onne#ting the B0 and riser and leaving the

lo#ation -with intention o$ #o)ing +a#3 later to #o)"lete

the well as an oil "rodu#er/1

O I L S E A R C H L I M I T E D

7

Causes of BP Blowout:

O!er!iew of Critical "actors

Criti#al Fa#tors

11 Loss o$ Integrity o$ the % :/'( 9 :( #asing

#reated a "ath $or hydro#ar+on -2C/ in$lu9

21 5nre#ogni;ed well #onditions

< In$lu9 unre#ogni;ed ! Integrity test $ailed

to identi$y #o))uni#ation with the

reservoir

< "erations allowed 2C in$lu9 to enter and

)ove u" the well +ore < well became

capable of flowing

< =es"onse $ailed to #ontrol the well

81 B0 > ?)ergen#y 6yste)s $ailed to isolate the

2C sour#e

@1 Aas "lu)e ignited

Criti#al Fa#tors

11 Loss o$ Integrity o$ the % :/'( 9 :( #asing

#reated a "ath $or hydro#ar+on -2C/ in$lu9

21 5nre#ogni;ed well #onditions

< In$lu9 unre#ogni;ed ! Integrity test $ailed

to identi$y #o))uni#ation with the

reservoir

< "erations allowed 2C in$lu9 to enter and

)ove u" the well +ore < well became

capable of flowing

< =es"onse $ailed to #ontrol the well

81 B0 > ?)ergen#y 6yste)s $ailed to isolate the

2C sour#e

@1 Aas "lu)e ignited

upper annular

lower annular

LMRP connector

Riser

blind shear

case shear

Top of Wellhead

mudline 5,067

T!"#,$60

BOP

%ariable pipe ram

9 7/8 x 7 Casing

Wellbore fuid

Seal Assembly

Floa Collar

Cemen

!rillsring

O I L S E A R C H L I M I T E D

8

Critical "actor # Loss of Integrit$ of

Casing

Loss of Integrit$ of %&'()* + '* Casing

< Ce)ent $ailed to isolate the

reservoir

< 4he $loat #ollar -1/ or the seal

asse)+ly -2/ lea3ed

Loss of Integrit$ of %&'()* + '* Casing

< Ce)ent $ailed to isolate the

reservoir

< 4he $loat #ollar -1/ or the seal

asse)+ly -2/ lea3ed

O I L S E A R C H L I M I T E D

9

BP Blowout Causes: Casing Cementing

Losses during drilling hole, oil / gas +earing

Internal B0 ris3 review #onsidered the o"tion o$ running and

#e)enting a liner, thus allowing an additional dee" set +arrier -liner

to" "a#3er/, then tying +a#3 with #asing to sea+ed1 B0 re*e#ting that

o"tion and #hose instead to run a $ull string o$ -ta"ered/ #asing +a#3

to the sea+ed1 It is alleged that this de#ision was solely to #ut #ost

B0 used a $oa) #e)ent to )ini)ise losses. 4ranso#ean alleges it

would ta3e @' hours to develo" reasona+le strength1

Alleged not enough #e)ent "u)"ed, % atte)"ts to a#tivate the $loat

valves, other #e)enting issues

Casing was not as well #entralised as re#o))ended +y 2alli+urton

verall, the #e)ent *o+ design had an in#reased ris3 o$ hydro#ar+on

in$lu9 during #e)ent setting1

O I L S E A R C H L I M I T E D

10

,ellhead rawing Showing Seal

-ssembl$ and Loc.down

O I L S E A R C H L I M I T E D

11

BP Blowout Seal -ssembl$

4he other "otential lea3 "ath identi$ied +y B0 is u" the annulus and

"ast the 7seal asse)+ly(

B0 says 76et and test o$ seal asse)+ly was nor)al(

4he letter $ro) the 6enate 6u+!Co))ittee to B0 alleges 7$ailure to

se#ure the wellhead with a lo#3down sleeve(1 Also alleged +y

4ranso#ean who also question whether 7outer lo#3 ring( was run on

the #asing hanger1

4ranso#ean allege the "ressure was su$$i#ient to 7$loat( the #asing -li$t

hanger and seal asse)+ly o$$ nor)al "osition/1 6u""osition is that the

seal asse)+ly and/or #asing hanger )oved u" and wedged a#ross the

B0Bs, "reventing the) $ro) e$$e#tively #losing to seal o$$ the well

4ranso#ean #o))ent that all B0 tests were done / "assed1

O I L S E A R C H L I M I T E D

12

Critical "actor /:

0nrecognised ,ell Conditions

Integrity test $ailed to identi$y #o))uni#ation with the

reservoir (plug bumped, casing pressure test to

2500psi was reported to be successful)

"erations allowed 2C in$lu9 to enter and )ove u" the

well +ore < well became capable of flowing

(see later comments about the operation of displacing

mud with seawater)

=ig #rew res"onse to well $low $ailed to #ontrol the well1

O I L S E A R C H L I M I T E D

13

isplacement of Mud b$ Seawater

1# of /2

B0 internal do#s say the #asing was su##ess$ully "ressure tested to

2&00"si

Ce9t ste" was trans$erring )ud to a +oat while dis"la#ing the )ud

with seawater -in "re"aration $or setting shallow #e)ent "lug then

dis#onne#ting the B0 and riser/

B0 ad)its that the )ethod o$ trans$erring )ud did not allow

)onitoring $or 3i#3s

4hey also ad)it that the o"eration was #on$using as regards the

"ressure over+alan#e or under+alan#e #reated in the well1 4here

were une9"lained "ressures during the o"eration1

At one "oint the #rew +led o$$ "ressure, +ut )ay have ta3en a 3i#3

-B0 inter"retation/

O I L S E A R C H L I M I T E D

14

isplacement of Mud b$ Seawater

1/ of /2

4hey )onitored "ressures at the #e)ent unit. Ce)enter said

the well #ontinued to $low and s"urted. shut 3ill line and

"ressure +uilt1

A$ter )onitoring, #rew were satis$ied the well was dead -+ut B0

later inter"retation was that an in$lu9 was in #asing or annulus/

4hey o"ened the annular B0 and #ontinued with dis"la#e)ent

o$ the well to seawater, #he#3ed that there was no oil sheen,

then "u)"ed over+oard -$ro) that "oint, they had no )easure

o$ $low out/1

Later #he#3s o$ the dis"la#e)ent rates and return $low rates

show that the well was $lowing -B0 in$o/, +ut this was not

dete#ted at the ti)e1

O I L S E A R C H L I M I T E D

15

Critical "actor 3 BOP failed to seal

A#tion to a#tivate the B0 on#e well #ondition was

re#ogni;ed, $ailed to isolate the sour#e

?)ergen#y ,is#onne#t 6yste) $ailed to se#ure the well

-when a#tivated $ro) +ridge a$ter e9"losion/1 4he ?,6

$un#tion #an +e a#tivated $ro) either the +ridge or drill

$loor Its $un#tion is to seal the well and dis#onne#t the

vessel $ro) the well1

ADF/,ead!)an $ailed to se#ure well1 4he ADF is an

e)ergen#y sequen#e that should a#tivate the +lind shear

ra)s to seal the well1

6u+sequent =E interventions $ailed to se#ure the well

O I L S E A R C H L I M I T E D

16

Lessons for Oil Search from

Montara and BP blowouts

0ro+le)s during #e)enting a##ount $or &0F o$ +lowouts -in$o

given to Dontara Inquiry/

< i))ediate #ause o$ Dontara +lowout and )ost li3ely root #ause on

the B0 one

0rogra)s with )ini)al and un#onventional +arriers

< 6us"ension o$ Dontara well would not have satis$ied 6L +arrier "oli#y

$or two inde"endently tested )e#hani#al +arriers

6eries o$ #hanges o$ "lan -short#uts/ without ris3 assess)ent1

Changes to +arriers and "rogra)s -without "ro"er ris3

assess)ent, "ro#edures, #ontingen#y "lans and understanding o$

"ersonnel on site/

< =eview and #ontrol $ro) the o$$i#e is #riti#al1 Dorning o"s )eetings

and regular "eer reviews are standard "ra#ti#e in 6L

-Dontara/ La#3 o$ understanding o$ site "ersonnel that they had a

#e)enting "ro+le). no thorough #he#3 o$ re"orts +y line

)anage)ent or "eer review

-B0/ La#3 o$ #are or understanding o$ site "ersonnel during

dis"la#e)ent o$ )ud < did not realise they had well 3i#3ing then

$lowing1

O I L S E A R C H L I M I T E D

17

Oil Search Blowout Pre!ention in place

4horough drilling design and "rogra))ing with "eer review and

line )anage)ent #he#3

< 0eer and )anage)ent reviews and sign o$$ at )anage)ent level

6u""orted +y very detailed "rogra)s $or ea#h se#tion o$ well.

these are read through with ,rilling 6u"ervisor and servi#e

#o)"anies

< 0re!"hase )eetings to "revent a)+iguity/)isunderstandings

6tri#t )anage)ent o$ #hange "rin#i"les well understood and

"ra#ti#ed

< 0eer review and ris3 assess)ent o$ any signi$i#ant o"erational #hange

?nsure ,rilling ?ngineering 3ee"s u" with 7what is ha""ening

down holeG(1 It is too late to analyse it a$ter the in#ident

4o" quality ,rilling 6u"ervisors at rigsite

< 6L "ay a "re)iu) $or highly e9"erien#ed wellsite su"ervisors

?qui")ent "ro"erly designed, )aintained, tested every ti)e

6trong #ulture throughout the organisation that sa$ety is not

#o)"ro)ised $or 7"rodu#tion(

You might also like

- Well CompletionDocument82 pagesWell CompletionFlorian Ananias ByarugabaNo ratings yet

- Shallow Gas Guidelines - Kingdom DRL ServicesDocument19 pagesShallow Gas Guidelines - Kingdom DRL ServicesMohamed MahmoudNo ratings yet

- BG - Well Integrity HandbookDocument9 pagesBG - Well Integrity Handbookwalter.tajuNo ratings yet

- API Casing DesignDocument2 pagesAPI Casing DesignJohnNo ratings yet

- Asset Management in A Low Price OilDocument17 pagesAsset Management in A Low Price OilArrif ImranNo ratings yet

- Factors Affecting Casing DesignDocument11 pagesFactors Affecting Casing DesignTharaka DarshanaNo ratings yet

- 22 CompleteWellSummaryDocument4 pages22 CompleteWellSummaryDavide BoreanezeNo ratings yet

- M 2 Prosper AideyanDocument32 pagesM 2 Prosper AideyanJorgito AriasNo ratings yet

- Oilfield Acronym Update Aug 2015Document37 pagesOilfield Acronym Update Aug 2015Eswar PrasadNo ratings yet

- PETE 411: Well DrillingDocument41 pagesPETE 411: Well Drillingshanecarl100% (1)

- Technology Transfer Volumetric StrippingDocument28 pagesTechnology Transfer Volumetric StrippingHüseyin AyazlıNo ratings yet

- Guide casing shoes and drill bitsDocument4 pagesGuide casing shoes and drill bitsUNIISCRIBDNo ratings yet

- Drillpipe Failure and Its PredictionDocument119 pagesDrillpipe Failure and Its PredictionQuality controllerNo ratings yet

- 04 Changing The Way We DrillDocument8 pages04 Changing The Way We DrillRoni Hepson TambunNo ratings yet

- Field Testing Lowers Casing Design FactorsDocument16 pagesField Testing Lowers Casing Design Factorsswaala4realNo ratings yet

- Drilling FluidsDocument19 pagesDrilling FluidsBenjamin HaganNo ratings yet

- Spe 103184 MSDocument7 pagesSpe 103184 MSRamanamurthy PalliNo ratings yet

- Drilling Technology and Costs - Chapter - 6Document51 pagesDrilling Technology and Costs - Chapter - 6zdq02No ratings yet

- SSA 11 Kes Evoy - Workover Well KillDocument7 pagesSSA 11 Kes Evoy - Workover Well KillDavide Boreaneze100% (1)

- Drilling TermDocument3 pagesDrilling TermIzzah IshakNo ratings yet

- Drilling Levels 3 and 4 Syllabus PDFDocument35 pagesDrilling Levels 3 and 4 Syllabus PDFGOKUL PRASADNo ratings yet

- Om Floaters To Jack Up Rig Offshore SW Java - Technical Reasoning Behind A Cost-Saving MoveDocument15 pagesOm Floaters To Jack Up Rig Offshore SW Java - Technical Reasoning Behind A Cost-Saving MoveHerry SuhartomoNo ratings yet

- UNCONTROLLED KICK CAN LEAD TO A BLOWOUTDocument53 pagesUNCONTROLLED KICK CAN LEAD TO A BLOWOUTRMolina65No ratings yet

- Causes of Oil Well Blowout and Methods of Prevention and ControlDocument23 pagesCauses of Oil Well Blowout and Methods of Prevention and ControlAli KakiNo ratings yet

- Well Integrity Analysis Applied To WorkoDocument8 pagesWell Integrity Analysis Applied To WorkoAdolfo AnguloNo ratings yet

- Slimhole Drilling Paper Revised June 2016 PDFDocument28 pagesSlimhole Drilling Paper Revised June 2016 PDFAbhinav GoyalNo ratings yet

- The Tripping ProcessDocument3 pagesThe Tripping ProcessFabrizioLaVitaNo ratings yet

- Drilling ProblemsDocument14 pagesDrilling ProblemsRohith PgNo ratings yet

- What You Need To Know About Drilling Bit Balling Up and How To Troubleshooting ItDocument3 pagesWhat You Need To Know About Drilling Bit Balling Up and How To Troubleshooting ItShoaib KhalilNo ratings yet

- MR86L - Drilling MontageDocument1 pageMR86L - Drilling MontageGabriel PlazasNo ratings yet

- SPE Rig SelectionDocument8 pagesSPE Rig SelectionEyoma EtimNo ratings yet

- Iadc Bits PDFDocument3 pagesIadc Bits PDFconssu0820No ratings yet

- WellCost Data SheetDocument4 pagesWellCost Data SheetAmirhosseinNo ratings yet

- Drillstring VibrationsDocument4 pagesDrillstring VibrationsLoganBohannonNo ratings yet

- Cutting Description Guidelines2Document18 pagesCutting Description Guidelines2Debbie NovalinaNo ratings yet

- Case History Hydraulics Modeling Software Helps Optimize Drilling and ECD Control With High Degree of Accuracy On Deep, Hot Gulf of Mexico Shelf WellDocument9 pagesCase History Hydraulics Modeling Software Helps Optimize Drilling and ECD Control With High Degree of Accuracy On Deep, Hot Gulf of Mexico Shelf WellElias GonzalezNo ratings yet

- Spe 160429 MS P PDFDocument11 pagesSpe 160429 MS P PDFahmalisha2No ratings yet

- 6th African Rift Geothermal Conference ProceedingsDocument9 pages6th African Rift Geothermal Conference Proceedingszeze_13No ratings yet

- Special ProblemsDocument42 pagesSpecial Problemsdriller22No ratings yet

- Well Test DesignDocument23 pagesWell Test DesignDEAF BOY TOMAHUNo ratings yet

- 00087167Document11 pages00087167JohnSmith100% (1)

- Regaining Sand Control Through RemediationDocument10 pagesRegaining Sand Control Through RemediationChristian PintoNo ratings yet

- SPE 87282 Innovative Completion Technology, Preparation, and Contingency Planning Simplifies Baltim Completions While Increasing Reliability and Reducing Remedial CostDocument9 pagesSPE 87282 Innovative Completion Technology, Preparation, and Contingency Planning Simplifies Baltim Completions While Increasing Reliability and Reducing Remedial Costmoh kadNo ratings yet

- DRILL 09-281 - Unconventional Sandstone HPWBMDocument14 pagesDRILL 09-281 - Unconventional Sandstone HPWBMRick Raynold ClaudiusNo ratings yet

- Master Well Control TechniquesDocument26 pagesMaster Well Control TechniquesJairo Cortes100% (1)

- Drill-String and Casing Design For Horizontal and Extended Reach Wells - Part IDocument0 pagesDrill-String and Casing Design For Horizontal and Extended Reach Wells - Part Iradeon_5055No ratings yet

- FPI Freepoint IndicatorDocument1 pageFPI Freepoint IndicatorBayu CiptoajiNo ratings yet

- C7 - Modeling Frac-Fluid Rheology and LeakoffDocument51 pagesC7 - Modeling Frac-Fluid Rheology and LeakoffImam PranadipaNo ratings yet

- Shallow Gas Blowouts: Dangers and Mitigation StrategiesDocument6 pagesShallow Gas Blowouts: Dangers and Mitigation StrategiesYaqoob IbrahimNo ratings yet

- Mud/Gas Separator Sizing and Evaluation: G.R. MacdougallDocument6 pagesMud/Gas Separator Sizing and Evaluation: G.R. MacdougallDiego AraqueNo ratings yet

- ITS Energie Jar and Energizer Operation - Techincal Brochure PDFDocument18 pagesITS Energie Jar and Energizer Operation - Techincal Brochure PDFsaeed65No ratings yet

- Kick Tolerance Calculations For Well Design and Drilling OperationsDocument2 pagesKick Tolerance Calculations For Well Design and Drilling Operationsi oNo ratings yet

- BOP Closing Systems & Equipment GuideDocument64 pagesBOP Closing Systems & Equipment GuideRoby RidoNo ratings yet

- Simulador Well ControlDocument8 pagesSimulador Well Controlivan villabonaNo ratings yet

- Driller's Depth ErrorsDocument2 pagesDriller's Depth Errorsnyanya2007No ratings yet

- SAOGE 2008 - Paper - Full Scale Verification of The Reelwell Drilling MethodDocument10 pagesSAOGE 2008 - Paper - Full Scale Verification of The Reelwell Drilling MethodBep De JongNo ratings yet

- IPTC 17668 Installation of Long Interval Conductor String Across Challenging Offshore Drilling EnvironmentDocument17 pagesIPTC 17668 Installation of Long Interval Conductor String Across Challenging Offshore Drilling EnvironmentAnre Thanh HungNo ratings yet

- Lesson 5A - The Drilling RiserDocument30 pagesLesson 5A - The Drilling RisernaefmubarakNo ratings yet

- The Deepwater Horizon Oil Spill of 2010: A Disaster UnveiledFrom EverandThe Deepwater Horizon Oil Spill of 2010: A Disaster UnveiledNo ratings yet

- Interception of InformationDocument13 pagesInterception of InformationEduardo GuajardoNo ratings yet

- 200 Series User ManualDocument312 pages200 Series User ManualJorge BoaglioNo ratings yet

- Asus 1000 r1.2g SchematicsDocument51 pagesAsus 1000 r1.2g SchematicsEduardo GuajardoNo ratings yet

- Manual CarrierDocument16 pagesManual Carriernedduc20No ratings yet

- The Parts of SpeechDocument60 pagesThe Parts of SpeechRedge Magat AgustinNo ratings yet

- WinServ SetupDocument3 pagesWinServ SetupEduardo GuajardoNo ratings yet

- Weatherford: Drill Pipe SpecificationsDocument1 pageWeatherford: Drill Pipe SpecificationsEduardo GuajardoNo ratings yet

- 065 Spe117109Document9 pages065 Spe117109smahboudiNo ratings yet

- Wild Well Control - Technical Date BookDocument57 pagesWild Well Control - Technical Date Bookgabriel851007No ratings yet

- Geog VG Subsea Wellhead Hybrid 042409 PDFDocument12 pagesGeog VG Subsea Wellhead Hybrid 042409 PDFEduardo GuajardoNo ratings yet

- 14a - Joe Hurt-John Auth Rig Pass PresentationDocument36 pages14a - Joe Hurt-John Auth Rig Pass PresentationEduardo Guajardo100% (1)

- 73 Free Designer Quality Excel Chart Templates - 1Document22 pages73 Free Designer Quality Excel Chart Templates - 1Sujesh Beherain VasudevaNo ratings yet

- Maths N Abstract Algebra - ConnelDocument146 pagesMaths N Abstract Algebra - Connelapi-3709413No ratings yet

- Drilling Rig ComponentsDocument3 pagesDrilling Rig ComponentsEduardo Guajardo0% (1)

- Well Log The Bore Hole ImageDocument15 pagesWell Log The Bore Hole ImageYansyah Oktriono Putra100% (1)

- The Offshore IndustryDocument73 pagesThe Offshore IndustryChan Sek YeongNo ratings yet

- #500 500 - 5 Avenue S.W. Calgary AB. T2P 3L5 Ph. 261-8668: Please Email To: L.evans-Harvey@brinkerhoff - CaDocument2 pages#500 500 - 5 Avenue S.W. Calgary AB. T2P 3L5 Ph. 261-8668: Please Email To: L.evans-Harvey@brinkerhoff - CaEduardo GuajardoNo ratings yet

- UsingDocument16 pagesUsingガンディー サガールNo ratings yet

- Advantage Mud Manual PDFDocument408 pagesAdvantage Mud Manual PDFEduardo Guajardo100% (2)

- 09 Bit Balling Summary GuidelinesDocument1 page09 Bit Balling Summary GuidelinesCerón Niño SantiagoNo ratings yet

- Toro Tool Joint IdentifierDocument9 pagesToro Tool Joint IdentifierEduardo GuajardoNo ratings yet

- (Ebook - PDF - Mathematics) - Abstract AlgebraDocument113 pages(Ebook - PDF - Mathematics) - Abstract Algebrambardak100% (2)

- The Offshore IndustryDocument73 pagesThe Offshore IndustryChan Sek YeongNo ratings yet

- Cameron Type U BOPDocument55 pagesCameron Type U BOProbertlkilgore86% (7)

- Collar WT LB-FT PDFDocument1 pageCollar WT LB-FT PDFEduardo GuajardoNo ratings yet

- ReleaseNotes 3.6.0.23962 Enu PDFDocument24 pagesReleaseNotes 3.6.0.23962 Enu PDFEduardo GuajardoNo ratings yet

- UsingDocument16 pagesUsingガンディー サガールNo ratings yet

- Pump Calculation Cheat SheetDocument12 pagesPump Calculation Cheat SheetEduardo GuajardoNo ratings yet

- Drilling Rig Components Illustration - Komponen Utama PemboranDocument86 pagesDrilling Rig Components Illustration - Komponen Utama PemboranPuji LestariNo ratings yet

- Advanced Well Stimulation TechnologiesDocument42 pagesAdvanced Well Stimulation TechnologiesPeter Mattews100% (1)

- Mearl Oil Company Environmental Impact Targets CaseDocument2 pagesMearl Oil Company Environmental Impact Targets Casedillazzz8642No ratings yet

- Edible Forest Garden: Permaculture For The Great Lakes Bioregion, by Jay TomczakDocument95 pagesEdible Forest Garden: Permaculture For The Great Lakes Bioregion, by Jay Tomczakmitra-sticklen-5631No ratings yet

- CIMA GBC 2015 Case StudyDocument25 pagesCIMA GBC 2015 Case StudyPasanPethiyagodeNo ratings yet

- Loresco DW-1, SC-2 and SC-3 Petroleum Coke BackfillDocument2 pagesLoresco DW-1, SC-2 and SC-3 Petroleum Coke Backfillnever_ever1957No ratings yet

- Rice Bran Oil Production Cost 3Document44 pagesRice Bran Oil Production Cost 3Sai Krishna100% (3)

- Cummins Oil ListDocument5 pagesCummins Oil ListVenkata Ramdas BonamNo ratings yet

- Bis StandradsDocument121 pagesBis StandradsKarthikeyan ManoNo ratings yet

- Process Indicators For Cellulosic Thermochemical Production of Biofuels Via Pyrolysis/Liquefaction Project TitleDocument11 pagesProcess Indicators For Cellulosic Thermochemical Production of Biofuels Via Pyrolysis/Liquefaction Project TitleSumitAggarwalNo ratings yet

- Futur TBT 4380966 01Document76 pagesFutur TBT 4380966 01Carlos David Obando0% (1)

- New Electrostatic Technology For Desalting Crude OilDocument34 pagesNew Electrostatic Technology For Desalting Crude OilchirinoslaaNo ratings yet

- Cummins 161110083846 PDFDocument18 pagesCummins 161110083846 PDFMuhammad IshfaqNo ratings yet

- 02555E03Document51 pages02555E03rachedNo ratings yet

- Iocl Final ReportDocument57 pagesIocl Final ReportSuhail DastanNo ratings yet

- How shipboard fuel oil blenders mix heavy and light fuelsDocument1 pageHow shipboard fuel oil blenders mix heavy and light fuelsSwarg VibhaNo ratings yet

- A Review of Downhole Separation TechnologyDocument8 pagesA Review of Downhole Separation TechnologyIbrahim NugrahaNo ratings yet

- Astm D323Document10 pagesAstm D323Nayth Andres GalazNo ratings yet

- Chinese Firms Seek Ethiopia Drug JVsDocument42 pagesChinese Firms Seek Ethiopia Drug JVsHemanth RaoNo ratings yet

- Asia Pacific Arb Review 2019 17 31 16Document94 pagesAsia Pacific Arb Review 2019 17 31 16maria de las mercedes teijelo vilaNo ratings yet

- Formation GroupDocument16 pagesFormation GroupAmar BenAmarNo ratings yet

- UTILIZATION OF CORN (ZEA MAYS) COB AS AN ALTERNATIVE OIL ABSORBENT PAPER FOR THE POTENTIAL REDUCTION OF OIL SPILL - Research ProposalDocument31 pagesUTILIZATION OF CORN (ZEA MAYS) COB AS AN ALTERNATIVE OIL ABSORBENT PAPER FOR THE POTENTIAL REDUCTION OF OIL SPILL - Research ProposalBeta KkumaNo ratings yet

- Physical Sciences P2 Additional Exemplar Eng 2008Document22 pagesPhysical Sciences P2 Additional Exemplar Eng 2008quikgoldNo ratings yet

- Rev 2-EIA - NHCTL Vol 1-EIA Report 28.08.2019Document274 pagesRev 2-EIA - NHCTL Vol 1-EIA Report 28.08.2019Dheeraj Chowdary DhanekulaNo ratings yet

- Uganda oil database adds 27 firmsDocument102 pagesUganda oil database adds 27 firmsSolomon BalemeziNo ratings yet

- Solutions For Oil Gaz IndustriesDocument24 pagesSolutions For Oil Gaz Industriessimna bijuNo ratings yet

- TB43-0239 Maintenance in The DesertDocument56 pagesTB43-0239 Maintenance in The DesertdieudecafeNo ratings yet

- G2300 FR3 Operations and Procedures Guide 06-17 (English) - V5Document35 pagesG2300 FR3 Operations and Procedures Guide 06-17 (English) - V5Dominic Santiago100% (2)

- Gas Turbine GEK28143a PDFDocument10 pagesGas Turbine GEK28143a PDFSunario YapNo ratings yet

- PVT Analysis & Eos Modeling: Hesham Mokhtar Ali Senior Reservoir Engineer In/HeshammokhtaraliDocument78 pagesPVT Analysis & Eos Modeling: Hesham Mokhtar Ali Senior Reservoir Engineer In/HeshammokhtaraliRizwan FaridNo ratings yet

- Petroleum Geology and Exploration of The La Creciente Gas Field Lower Magdalena Basin, ColombiaDocument18 pagesPetroleum Geology and Exploration of The La Creciente Gas Field Lower Magdalena Basin, ColombiacasacamNo ratings yet