Professional Documents

Culture Documents

Acido 2

Uploaded by

Pablo SotoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Acido 2

Uploaded by

Pablo SotoCopyright:

Available Formats

Completion Fluid Damage Treatment

Options.

Damage Mechanism

Solids invasion

Clay swelling

Clay mobilisation

Water block

Emulsion block

Wettability damage

Precipitation of solids

Treatment Options

HCl:mud acid Solids dependent

HCl:mud acid

HCl:mud acid

Surface Tension Reduction

Dependent on emulsion external

phase.

Mutual Solvents and or

Surfactants

Solids dependent

Formation Damage Treatment

Options

for Different Drive Mechanisms.

Formation Damage Mechanism

Water Drive

Accelerated water production after

acidizing.

Asphaltene damage

Water production

Scale formation

Gas Drive

Water block

Paraffin damage

Treatment

Selective acidizing

Paravan/Solvent soaks

Aquatrol 1,2 or 3, Direxit

Depends on composition

Reduce surface tension

Paravan/Sovent soaks

Formation Damage Mechanism

Solution Drive

Water block

Inadequate formation pressure

Organic formation damage

Combination Drive

Treatment

Reduce surface tension

Carbon Dioxide or Nitrogen

Paravan/Sovent soaks

All of the above

Formation Damage Treatment Options

for Different Drive Mechanisms.

Temperature Considerations

150F

L

L

U

L

L

L

L

U

L

L

165F

L

L

U

L

L

L

L

U

L

L

170F

M

M

U

M

2

L

L

L

U

L

M

180F

M

M

U

M

2

L

M

M

U

L

M

185F

M

M

U

M

2

L

M

M

U

L

M

200F

U

M

M

U

L

M

M

M

3

M

U

240F

U

U

L

U

L

U

U

M

3

M

U

Situation

Emulsion Blocks

Organic Deposition

Asphaltene Coking

Bacteria

CaCO

3

Scale

BaSO

4

Scale

CaSO

4

Scale

Chlorination of Mutual

Solvents

Rigid Emulsion Film

Are Retarded HF

Systems Economical

Temperatures

Treatment Options for Formation Damage Caused by Indigenous Minerals

Siderite,

Hematite

Iron Hydroxide

Precipitation

Acidize - Standard HCl/HCl:HF with

properly evaluated sequesterants

Pyrite Iron Hydroxide

Precipitate.

Asphaltene

Sludging

Mobile Fines

Formation

Fines

(Feldspars,

Quartz, Etc)

High Flow Rates Preflush - 7.5% HCl

Acidize - 7.5:1.5 HCl:HF + Boric

Acid (Volume as required).

Overflush - as required.

Calcite,

Dolomite

>18% - HCl Only.

<18% - Standard HCl/HCl:HF

Calcium

Fluoride

Precipitation

Contact of

calcium ion with

HF Acid.

Oxygen Rich

Systems

Oxygen Rich

Systems

Preflush - 25 Gal/ft Xylene + 10%

Acetic

Acidize - Standard HCl/HCl:HF with

properly evaluated sequesterants

Mineral Potential

Problems

Treatment Options What To

Avoid

Mineral Potential

Problems

Treatment Options What To

Avoid

Kaolinite Mobile Fines Rate Control.

<5%-Acidize - Standard HCL/HCL:HF

>5% - Evaluate for Stress Pack

High Flow Rates

Illite Mushing Permeability > 120 Md Acidize -

Standard HCl/HCl:HF

Permeability < 120 md reduce

surface tension to 30 Dynes/Cm

2

Fresh Water

Systems

Swelling Acidize - Standard HCl/HCl:HF

Perform Immersion Tests to see if

alcohol/acid blends or other

additives are necessary to prevent

swelling

(Montmoril-

Smectite

lonite)

Fresh Water

Systems

Chlorite Iron Hydroxide

Precipitate,

Hydrous Silicates

Amorphous

Alumino Silicate

Acidize - Standard HCl/HCl:HF with

properly evaluated sequestering

agents, boric acid volume as

required. Overflush as required

Oxygen Rich

Systems: Ph>2.8

Inadequate

Sequesterant.

Buffered Acids

Treatment Options for Formation Damage Caused by Indigenous Minerals

Chamosite Iron Hydroxide

Precipitate

Oxygen Rich

Systems: Ph>2.8

Acidize - Standard HCl/HCl:HF with

properly evaluated sequesterants

Mineral Potential

Problems

Treatment Options What To

Avoid

Swelling Acidize - Standard Hcl/Hcl:Hf Mixed Layer

Illite/ Smectite

Fresh Water

Systems

Feldspars Silica

Precipitation

> 20%- 7.5% HCl, 7.5:1.5 HCl:HF

< 20%- Standard HCl/HCl:HF

High % of HF Acid

Treatment Options for Formation Damage Caused by Indigenous Minerals

Acid Treating Volumes Based on

Permeability

Average Permeability

w/o Damage

Ku (md).

< 0.1 md

0.1 - 1.0 md

1.0 - 10 md

10- 50 md

> 50 md

Normal HCl

Range Gal/ft

(L/M)

15-25

(185-310)

25-50

(310-620)

35-75

(430-930)

50-100

(620-1240)

50-100

(620-1240)

Normal HCl:HF

Range Gal/ft

(L/M)

Not Recommended

35-50

(430-620)

75-100

(930-1240)

100-150

(1240-1865)

100-200

(1240-2480)

Recommended Treating Volume of

HCl:HF in

Gallons Per Square Foot of Pay

GALLONS PER FOOT OF TREATED INTERVAL

T

R

E

A

T

I

N

G

R

A

D

I

U

S

(

F

t

)

0 100 200 300 400 500 600 700 800 900

0

1

2

3

4

5

6

7

20 gallons

per sq.ft

15 gallons

per sq.ft

10 gallons

per sq.ft

5 gallons

per sq.ft

Volume of 12:3 HCl:HF Required

to Treat a 3.0 Inch Damage Zone -

Gallons Per Foot of Pay.

Temperature

100 F

Gal/ft

70

50

50

50

50

50

50

150 F

Gal/ft

80

65

55

50

50

50

50

200 F

Gal/ft

100

75

65

55

50

50

50

250 F

Gal/ft

120

80

75

65

50

50

50

Pump Rate

BPM/ft

0.001

0.005

0.010

0.025

0.050

0.100

0.200

Volume of 12:3 HCl:HF

Required to Treat a 6.0 Inch

Damage Zone - Gallons Per

Foot of Pay.

Temperature

100 F

Gal/ft

350

275

225

175

140

130

150 F

Gal/ft

350

350

300

250

200

160

200 F

Gal/ft

350

350

350

325

260

210

250 F

Gal/ft

350

350

350

350

320

260

Pump Rate

BPM/ft

0.005

0.010

0.025

0.050

0.100

0.200

Gallons Per Foot of Treating Fluid

for

Differing Porosities.

B

A

R

R

E

L

S

P

E

R

F

O

O

T

O

F

S

A

N

D

T

H

I

C

K

N

E

S

S

0 1 2 3 4 5 6 7

0

20

40

60

80

100

120

140

160

180

200

220

240

260

280

300

320

340

360

380

400

35 %

Porosity

100 %

Porosity

RADIUS DISTANCE IN FEET FROM WALL OF 7 INCH WELLBORE

G

A

L

L

O

N

S

P

E

R

F

O

O

T

O

F

S

A

N

D

T

H

I

C

K

N

E

S

S

9

8

7

6

5

4

3

2

1

0

5.0 %

Porosity

15 %

Porosity

25 %

Porosity

Acid Selection Based On %Carbonate

& Temperature.

Temp

F (C)

< 200

(93)

200-250

(93-121)

250-350

(121-177)

>350

(177)

Temp

F (C)

< 250

(121)

250-350

(121-177)

>350

(177)

5.0 to 15%

75 gal/ft

(930 L/M)

15% HCl

followed by

HCl: HF

50 gal/ft

(620 L/M)

7.5% HCl

followed by

HCl: HF

35 gal/ft

(430 L/M)

7.5% HCl +

10% Formic

followed by

Formic:HF

35 gal/ft

(430 L/M)

10% Formic

followed by

Formic:HF

10 to 15%

75 gal/ft

(930 L/M)

15% HCl

then wash

perforations

with

HCl: HF

50 gal/ft

(620 L/M)

7.5% HCl +

10% Formic

35 gal/ft

(430 L/M)

10% Formic

> 15%

100 gal/ft

(1240 L/M)

15% HCl

50 gal/ft

(620 L/M)

7.5% HCl +

10% Formic

35 gal/ft

(430 L/M)

10% Formic

Percentage of Carbonate in the Formation

< 5.0%

50 gal/ft

(620 L/M)

15% HCl followed

by HCl: HF

35 gal/ft

(430 L/M)

7.5% HCl

followed by

HCl: HF

35 gal/ft

(430 L/M)

10% Formic

Formic:HCl

or

Formic:HF

35 gal/ft

(430 L/M)

10% Formic

or Formic:HF

HCl Acid Strength Based on

Formation Solubility

Formation Solubility

(Percentage)

0 -10

10 - 20

20 - 40

Greater than 40

Acid Strength

(Percentage)

3 - 5

5 - 7.5

7.5 - 10

10 - 28

Flow Improvement Ratio of Various

Treating Solutions

in Berea Sandstones

Treating Volume : Gallons Per Square Foot

F

l

o

w

I

m

p

r

o

v

e

m

e

n

t

R

a

t

i

o

K

20.0 0.0 2.5 5.0 7.5 10.0 12.5 15.0 17.5

1.0

1.5

2.0

2.5

3.0

7.5% HCl - 4% HF

15% HCl - 4% HF

15% HCl - 3% HF

15% HCl

15% HCl - 7% HF

15% HCl - 2% HF

Recommended Preflush

Volume in Gallons of 15%

HCl Per Foot of Pay for

Various Radii.

G

A

L

L

O

N

S

O

F

1

5

%

H

C

l

P

E

R

F

O

O

T

O

F

P

A

Y

0 1 2 3 4 5 6

TREATING RADIUS (FEET)

1

10

100

1000

1.0 % HCl Solubility

5.0 % HCl Solubility

10 % HCl Solubility

Selective Acidizing

Treatment Options

Situation

Oil Well - Non Gravel Packed

Oil Well - Gravel Packed

Gas Well

Treatment

SAF Mark II

SAF

65 Quality Foam Preflush

Relative Retarding Action of

Different Systems

Regular

Acid

HCl Acid

HCl:HF

Mixture of

HCl + Organic

Super-Sol

(EQH) Acids

Chemically

Retarded Acid

Sta-Live Acid

Systems

Retarded Mud Sol

Systems. (HCl:HF)

SGMA

Physically

Retarded Acid

Gelled Acids and

Crosslinked Acid.

SRA-3 Emulsified

Acid.

Sandstone Acid

Least Most Retardation

Carbon Dioxide and Nitrogen

Guidelines.

Reservoir Type

Gas.

Low Pressure Gas.

Oil, (Above the Bubble Point).

Oil, (Below the Bubble Point).

Water Injection or Disposal Well.

Nitrogen

Yes

Yes

(3, 4)

Yes

(3, 4)

Carbon Dioxide

Yes (1)

(2)

Yes

Yes

(3, 4)

Injection Rates (Non-Fracturing)

into Permeable Formations at

Various Differential Pressures.

0 100 200 300 400 500 600 700 800 900 1000

D P=2000 PSI

D P=2500 PSI

D P=1500 PSI

D P=1000 PSI

D P= 500 PSI

D P= 200 PSI

0 1000 2000 3000 4000 5000 6000 7000 8000 9000 10000

0

10

20

30

40

50

FORMATION CAPACITY, kh - md.ft.

I

N

J

E

C

T

I

O

N

R

A

T

E

Q

-

B

A

R

R

E

L

S

P

E

R

M

I

N

U

T

E

0

1

2

3

4

5

DARCEY'S EQUATION FOR RADIAL FLOW

Drainage Radius = 5.0 ft

Injected Fluid Viscosity = 1.0 cp

Differential Pressure (D P)

Treating Pressure (+ Plus)

Hydrostatic Column (- Minus)

Reservoir Pressure = psi

Formation Capacity (kh)

Average Effective Permeability

x Thickness of Sand Body = md. ft.

( For small volume treatments in partially saturated reservoirs)

Recommended Acid Strengths at Different Temperatures.

Temperature

Up to 180 F (82 C)

180 F to 220 F

(82 C to 104 C)

Above 220 F (104 C)

Maximum

HCl Strength

15%

10%

7.5%

Maximum

HCl:HF Strength

12:3%

9:3%

7.5:1.5%

Common Strengths Of HCl: HF

MIxtures

% HCl

6.0

7.5

12

15

15

% HF

0.5

1.5

3.0

3.0

4.0

Reaction of Acids on Limestone

at Various Concentrations.

Acid

HCl *

Acetic

Formic

Concentration

%

15*

20

25

15*

20

25

15*

20

25

Calcium Carbonate

Dissolved

Per Gallon.

Pounds

1.84

2.50

3.22

1.08

1.43

1.80

1.42

1.90

2.40

Carbon Dioxide

Formed

Per Gallon.

cu.ft.

6.99

9.47

12.20

4.09

5.41

6.82

5.38

7.20

9.09

Calcium Salt

Formed

Per Gallon.

Pounds

2.04

2.75

3.57

1.71

2.25

2.84

1.84

2.47

3.12

Amount of Limestone

Dissolved by 1000 Gallons of

HCl Acid

P

O

U

N

D

S

O

F

L

I

M

E

S

T

O

N

E

D

I

S

S

O

V

E

D

B

Y

1

0

0

0

G

A

L

L

O

N

S

O

F

H

C

l

A

C

I

D

STRENGTH OF HYDROCHLORIC ACID %

0.0

1.0

2.0

3.0

4.0

5.0

6.0

7.0

8.0

9.0

10.0

11.0

12.0

13.0

14.0

15.0

16.0

17.0

18.0

19.0

20.0

21.0

0

500

1000

1500

2000

2500

3000

3500

0 2 4 6 8 10 12 14 16 18 20 22 24 26 28

F

t

3

O

F

L

I

M

E

S

T

O

N

E

D

I

S

S

O

L

V

E

D

B

Y

1

0

0

0

G

A

L

L

O

N

S

O

F

H

C

l

A

C

I

D

Relative Reaction Rates of 15%

HCl with

Limestone Formations at 75 F.

0 5 10 15 20 25 30 35

0

10

20

30

40

50

60

70

80

90

100

* Atmospheric pressure

at sea level

Curve

A

B

C

D

Pressure

psi

14.7 *

400

800

1200

T

o

t

a

l

R

e

a

c

t

i

o

n

,

%

Minutes

D

C

A

B

Relative Reaction Rates of 15% HCl

with

Limestone Formations at 140 F.

Minutes

0 5 10 15 20 25 30 35

0

10

20

30

40

50

60

70

80

90

100

T

o

t

a

l

R

e

a

c

t

i

o

n

,

%

Curve

A

B

C

D

Pressure

psi

14.7 *

400

1200

2000

* Atmospheric pressure at sea

level

A

B

D

C

Relative Reaction Rates of 15%

HCl with

Dolomite Formations at 75 F.

Minutes

0 20 40 60 80 100 120 140

0

10

20

30

40

50

60

70

80

90

100

T

o

t

a

l

R

e

a

c

t

i

o

n

,

%

* Atmospheric pressure at sea

level

Curve

A

B

Pressure

psi

14.7 *

2000

A

B

Relative Reaction Rates of 15% HCl

with

Dolomite Formations at 140 F.

0 10 20 30 40 50 60 70

0

10

20

30

40

50

60

70

80

90

100

T

o

t

a

l

R

e

a

c

t

i

o

n

,

%

Minutes

A

B

C

D

* Atmospheric pressure at sea

level

Curve

A

B

C

D

Pressure

psi

14.7 *

400

1200

2000

You might also like

- Climax-Catalog LUBRICANTES Y SELLANTES PDFDocument30 pagesClimax-Catalog LUBRICANTES Y SELLANTES PDFNini Jhoana Ardila CamachoNo ratings yet

- WCB Waukesha U1 Instruction Manual PDFDocument106 pagesWCB Waukesha U1 Instruction Manual PDFJojaca Xencillo CaqueNo ratings yet

- Automatic Transmission Basics PDFDocument34 pagesAutomatic Transmission Basics PDFtambache69100% (1)

- Parker VOAC F11-F12 Technical DocumentDocument44 pagesParker VOAC F11-F12 Technical DocumentPablo Soto100% (1)

- Irp 4 2015Document105 pagesIrp 4 2015Pablo SotoNo ratings yet

- 3 - SPE-98098 Neww Analysis of SRIT For Improved Frac Stim Design PDFDocument17 pages3 - SPE-98098 Neww Analysis of SRIT For Improved Frac Stim Design PDFPablo SotoNo ratings yet

- Abrasive Service Flow MeterDocument2 pagesAbrasive Service Flow MeterPablo SotoNo ratings yet

- External CuttersDocument6 pagesExternal CuttersPablo SotoNo ratings yet

- L-Dens 427 Instruction ManualDocument78 pagesL-Dens 427 Instruction ManualPablo SotoNo ratings yet

- Abrasive Service Flow MeterDocument2 pagesAbrasive Service Flow MeterPablo SotoNo ratings yet

- Bomba W-500 4.5Document2 pagesBomba W-500 4.5Pablo SotoNo ratings yet

- Hydraulic Workover UnitDocument27 pagesHydraulic Workover UnitzenislerNo ratings yet

- Principals of Operation and Sizing: Jeff VotavaDocument12 pagesPrincipals of Operation and Sizing: Jeff VotavaPablo SotoNo ratings yet

- Brandt Screens Solids Control PDFDocument2 pagesBrandt Screens Solids Control PDFPablo SotoNo ratings yet

- Ajuste Valvulas e Inyectores DetroitDocument6 pagesAjuste Valvulas e Inyectores DetroitGabriel Duarte100% (19)

- Acid Properties and Fluid Flow CharacteristicsDocument20 pagesAcid Properties and Fluid Flow CharacteristicsPablo SotoNo ratings yet

- 4 - 107877-Diagnóstico de Fractura Integrado-Función G PDFDocument13 pages4 - 107877-Diagnóstico de Fractura Integrado-Función G PDFPablo SotoNo ratings yet

- Acid Additives and Their UsesDocument25 pagesAcid Additives and Their UsesPablo SotoNo ratings yet

- FRACbookInsert PDFDocument4 pagesFRACbookInsert PDFPablo Soto100% (1)

- Pup Joints Catalog 2012Document4 pagesPup Joints Catalog 2012jesdcp7100% (1)

- 1 - Selección de Arenas ResinadasDocument10 pages1 - Selección de Arenas ResinadasPablo SotoNo ratings yet

- Sj5a Flowline Catalog PDFDocument1 pageSj5a Flowline Catalog PDFPablo SotoNo ratings yet

- Bonnet AssemblyDocument1 pageBonnet AssemblyPablo SotoNo ratings yet

- SPM Full Bore Emergency Unloading Valve Manual PDFDocument9 pagesSPM Full Bore Emergency Unloading Valve Manual PDFPablo SotoNo ratings yet

- 3 - Arenas Curables y ActivadoresDocument52 pages3 - Arenas Curables y ActivadoresPablo SotoNo ratings yet

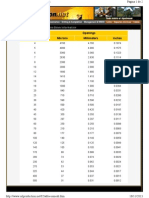

- Sieve Size U.S. Mesh Openings Microns Millimeters InchesDocument1 pageSieve Size U.S. Mesh Openings Microns Millimeters InchesPablo SotoNo ratings yet

- 2 - Arenas CuradasDocument19 pages2 - Arenas CuradasPablo SotoNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Xii Chem MCQSDocument32 pagesXii Chem MCQSLucifer xavierNo ratings yet

- CHE 04 - EN OrganicChemistry IIDocument60 pagesCHE 04 - EN OrganicChemistry IIMadiha RubabNo ratings yet

- ACTIVITY 7 Milk of MagnesiaDocument4 pagesACTIVITY 7 Milk of Magnesiadaven25% (4)

- Chapter 1: Moles and Equations: Homework QuestionsDocument2 pagesChapter 1: Moles and Equations: Homework QuestionsareebNo ratings yet

- Physical vs Chemical ChangesDocument2 pagesPhysical vs Chemical ChangesMidhun Bhuvanesh.B 7ANo ratings yet

- Worksheet - 03 (IUPAC Nomenclature) (BSB Sir)Document4 pagesWorksheet - 03 (IUPAC Nomenclature) (BSB Sir)Daksha SubrhamanyaNo ratings yet

- Improving Aromatic Hydrocarbons Yield From Coal Pyrolysis VolatileDocument6 pagesImproving Aromatic Hydrocarbons Yield From Coal Pyrolysis Volatilebambang_teknikkimiaNo ratings yet

- Borazine - Wikipedia PDFDocument29 pagesBorazine - Wikipedia PDFAhilya GuptaNo ratings yet

- Ocr 33977 PP 09 Jan L Gce 2813 01Document12 pagesOcr 33977 PP 09 Jan L Gce 2813 01Philip_830No ratings yet

- Chap03 CarbonylsDocument10 pagesChap03 CarbonylsAPLCTNNo ratings yet

- Systematic NomenclatureDocument12 pagesSystematic NomenclatureSanjib Mal100% (1)

- Preparation of FormaldehydeDocument14 pagesPreparation of Formaldehydeshiel175No ratings yet

- Chapter 12Document54 pagesChapter 12tanannudt.srNo ratings yet

- Acid and BaseDocument32 pagesAcid and BaseSachin SinghNo ratings yet

- Common Compounds Acids: Chemical Name Chemical Formula Common Name/S CH Cooh CH Cooh H Bo H Co HCL HCN Hno H So 1 Part Hno: 3 Parts HCLDocument3 pagesCommon Compounds Acids: Chemical Name Chemical Formula Common Name/S CH Cooh CH Cooh H Bo H Co HCL HCN Hno H So 1 Part Hno: 3 Parts HCLFrederick FranciscoNo ratings yet

- CM011L - Lab ReportDocument11 pagesCM011L - Lab ReportwahahahhasiafiadgNo ratings yet

- June 2002 Question Paper 1Document20 pagesJune 2002 Question Paper 1Abed AymanNo ratings yet

- Aldehydes Ketones, Carboxylic AcidsDocument11 pagesAldehydes Ketones, Carboxylic AcidsAssishNo ratings yet

- Solutions Acid Base EquilibriumDocument32 pagesSolutions Acid Base EquilibriumNikitaNo ratings yet

- LipidsDocument3 pagesLipidsCamille GrandeNo ratings yet

- Ascotran H 14 (Anti Flash Rust)Document1 pageAscotran H 14 (Anti Flash Rust)Yến HoàngNo ratings yet

- Alcohols, Phenols and Ethers (CBSE)Document25 pagesAlcohols, Phenols and Ethers (CBSE)Vishu Bansal100% (1)

- Determination of Residual Chlorine and Chlorine Demand: Break Point ChlorinationDocument22 pagesDetermination of Residual Chlorine and Chlorine Demand: Break Point Chlorinationনীল জোছনা100% (1)

- Cacl Ca: Seigfred John M. Miranda Che121.1 Laboratory 1Document5 pagesCacl Ca: Seigfred John M. Miranda Che121.1 Laboratory 1Kathleen Caryl PiedadNo ratings yet

- 14) Coordination Chemistry PDFDocument28 pages14) Coordination Chemistry PDFBj Larracas100% (6)

- Making Salts NotesDocument17 pagesMaking Salts NotesLola AdegbonmireNo ratings yet

- Tris and Tris hydrochloride buffer solutionsDocument4 pagesTris and Tris hydrochloride buffer solutionsVanderlei LimaNo ratings yet

- Qualitative Analysis Viva QuestionsDocument5 pagesQualitative Analysis Viva QuestionsKhayati Sharma100% (2)

- LAB Find Out The Bottle ContentsDocument4 pagesLAB Find Out The Bottle ContentschanNo ratings yet

- As Level Chemistry Practical Paper 3 - GCE GuideDocument7 pagesAs Level Chemistry Practical Paper 3 - GCE GuidedeeyamullaNo ratings yet