Professional Documents

Culture Documents

FRP Presentation

Uploaded by

Khairul AnwarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FRP Presentation

Uploaded by

Khairul AnwarCopyright:

Available Formats

Dual Laminated Fiberglass Reinforced

Polymer (FRP)

MAXAR Pipe & Fittings

SAUDI KKEM

ENGINEERING SERVICE COMPANY

What is Dual Laminated FRP Piping?

Materials

Design & Fabrication Details

Application and Operational Parameters

Inspection

Advantages of Dual Laminated over Lined Steel

pipe.

OUTLINE

A dual laminate bonded pipe is one where the FRP has been bonded

to the liner to overcome vacuum and the different coefficients of

thermal expansion.

Concentration of stresses can be prevented and the potential of

mechanical damage due to expansion is eliminated.

Thermoplastics temperature and pressure handling capabilities are

enhanced due to the FRP bonding.

What is Dual Laminated FRP Piping?

Materials

1. Liner

Seamless Fluorinated Ethylene Propylene

(FEP) Teflon

Meet requirements of ASTM D2116 Type III

Physical properties:

PROPERTIES VALUE TEST

Specific Gravity 2.13-2.15 ASTM D-792

Tensile Strength 3800-4100 PSI ASTM D-638

Elongation 280-330% ASTM D-638

Materials

2. Bonding Layer

Seamless knit fiberglass (reinforced vinyl ester) sock is

melt-bonded and partially embedded on the OD surface

of the liner.

Bond strength between FEP liner & reinforced vinyl ester

is minimum 35 in*lb/in. (ASTM D1781).

Materials

3. Outer Structure

Reinforced by:

Filament Winding method or

Hand Lay-up Vinyl Ester Fiberglass

Winding thickness:

Specification as per STD-300 and STD-304

Hand Lay-up:

Specification as per ASTM C582 Type II, Class V.

Premium grade vinyl ester resins are used with glass

reinforcement & UV stabilizer exterior gel coat.

Reinforcement Method

Filament Winding

Hand Lay-up

Design & Fabrication Details

Pipe and fittings fabrication tolerances are as follows:

Design & Fabrication Details

Dimensional drawings of standard MAXAR FEP

products:

SPEC-300 Piping Specification

STD-101 Flange Dimensions

STD-300 Pipe Dimensions. Pipe and Fittings Weights (1 thru

12 )

STD-304 Pipe Dimensions, Pipe and Fittings Weights (14 thru 24

)

STD-301 Fitting Dimensions (1 thru 4 )

STD-305 Fitting Dimensions (6 thru 24

Application & Operational Parameters

MAXAR Liner can be operated up to 250F BUT

operation temperature above 180F need to

evaluate by RPS Engineering either the process is

acceptable or not.

Pressure Ranges:

full vacuum for 150 PSI for 1 up to 12 *

full vacuum to 100 PSI for 14 up to 24 *

Continuous full vacuum services require bonded flange.

Application & Operational Parameters

Thermal Expansion:

CTE for MAXAR Pipe ~1.7 x 10

-5

in/in/F*

Chemical Resistance (liner):

All acids including HF, HCl, H

2

SO

4

and Aqua Regia (nitric

acid hydrochloride)

All chloride organic &inorganic

All sulfate organic & inorganic

All bleach solution

All solvents, caustic, phenols and peroxides.

Application & Operational Parameters

Chemical Resistance:

Vinyl ester structure is inherently corrosion resistance.

Open air and direct burial installation in harsh chemical

environments.

Gel coat exterior contains UV stabilizer.

Fire retardant available.

For other requirements, consult manufacturer.

Application & Operational Parameters

Gas permeation:

MAXARs bonding technology eliminates air gap between

FEP liner & vinyl ester structure.

Vinyl ester structure permeates higher rate than the FEP

liner. (eliminates condensation between liner & structure)

No weep holes are required and internal corrosion of the

structure is eliminated.

Application & Operational Parameters

Insulation qualities:

MAXARs vinyl ester casing yields a heat conduction factor

(k) of 1.5 Btu*in/FT2/hr/F.

Heat Tracing:

Capable of handling dry heat trace applications up to

180F.

Inspection

Extruded liners are inspected for:

Pinholes

Cracks

Gauges

Nicks

Inclusion of foreign materials

Completed fittings shall be subjected to a 10,000

volts, NDT, electrostatic test to detect pinholes.

Dual Laminate vs. Lined Steel

Advantages of dual laminated over lined steel piping:

NO. ADVANTAGES DESCRIPTION

1 LONGER LIFE

Corrosion resistance on inside and outside minimally

extends piping system life 3x 5x over steel.

2 ELIMINATE FLANGES

From minimally flange to flangeless design, dual laminate

can reduce the flanges which includes cost of nuts, bolts,

gaskets and labor to install.

3 MAINTENANCE FREE

No painting or re-painting needed. Comes in various

external colours to meet client service specifications.

Dual Laminate vs. Lined Steel

Fabrications Advantages (Mechanically Bonded

Format)

1) Bonding greatly reduces the risk of mechanical damage by

redistributing the concentration of stresses.

2) Bonded pipe can withstand higher temperature, vacuum and

differential CTE.

3) Dual laminated can be rated to Full Vacuum at elevated T

and diameters.

Dual Laminate vs. Lined Steel

Eliminate Flanges

NO. ADVANTAGES DESCRIPTION

1 FLANGED

All spools and fittings are flanged according to ANSI

dimensions and specifications.

2 MINIMALLY FLANGED

Reduce the number of flanges by 40% - 60% relying on all

shop joints and retaining bolt up parts in field.

3

FLANGE-LESS

CONSTRUCTION

All flanges are eliminated with exception of connections at

slaves, instrumentation, etc.

Dual Laminate vs. Lined Steel

Installation Advantages

NO. ADVANTAGES DESCRIPTION

1 LESS WEIGHT

Dual laminate pipe is the weight of steel. This greatly

reduces labor and time to install piping systems.

2 LESS FLANGES

The more flanges reduced the less time and money spend

on installation.

3 NO PAINTING

Dual laminate comes with UV resistant gel-coat which can

be specified is various colours to match Client services

requirements.

SAUDI KKEM

ENGINEERING SERVICE COMPANY

Thank you for your time, any question???

SAUDI KKEM

ENGINEERING SERVICE COMPANY

You might also like

- FAB & INSP Guideline - KKVDocument133 pagesFAB & INSP Guideline - KKVSantoshNo ratings yet

- 6-12-0001 Rev 6 General Spec For Pressure VesselsDocument15 pages6-12-0001 Rev 6 General Spec For Pressure Vesselsravi2007No ratings yet

- A Regular ASME Design Checklist - Deconeq Engineering GroupDocument3 pagesA Regular ASME Design Checklist - Deconeq Engineering GroupAmit SharmaNo ratings yet

- KOC-P-002 Part 2 Rev 7Document56 pagesKOC-P-002 Part 2 Rev 7Hari KrishnanNo ratings yet

- Tank ComponentsDocument4 pagesTank ComponentssafwanNo ratings yet

- Storage TanksDocument2 pagesStorage Tanksarif99pakNo ratings yet

- Inbal DG04C Deluge Valve Electric Actuation PDFDocument4 pagesInbal DG04C Deluge Valve Electric Actuation PDFjakkol11No ratings yet

- JMS For Erection of Stiffener Angle With Existing Curb Channel With Erection of Deflector Plate Arrangement For Tank006Document9 pagesJMS For Erection of Stiffener Angle With Existing Curb Channel With Erection of Deflector Plate Arrangement For Tank006AshutoshNo ratings yet

- Shop Fabrication Inspection: 1 Material Receiving Inspection ReportDocument7 pagesShop Fabrication Inspection: 1 Material Receiving Inspection ReportManoj PrabakaranNo ratings yet

- Design Code SummaryDocument12 pagesDesign Code SummaryShane HancockNo ratings yet

- Dry Bulk Storage Tank SpecificationDocument7 pagesDry Bulk Storage Tank SpecificationMohamed Mostafa IbrahimNo ratings yet

- G LIT Aboveground Horizontal TanksDocument4 pagesG LIT Aboveground Horizontal Tankskuati01No ratings yet

- PWTH RequirementDocument2 pagesPWTH Requirementveeru290683_20976731No ratings yet

- HPCL STD Spec For Storage TanksDocument16 pagesHPCL STD Spec For Storage TanksnagtummalaNo ratings yet

- Chapter 7 Shell Tube Heat ExchangerDocument138 pagesChapter 7 Shell Tube Heat ExchangerMinh Hiếu CaoNo ratings yet

- API 510 PC 5mar05 Case Study 2 Thickness CalculationsDocument3 pagesAPI 510 PC 5mar05 Case Study 2 Thickness CalculationsSameh AminNo ratings yet

- Introduction To Storage Tanks & Api650Document12 pagesIntroduction To Storage Tanks & Api650Dhakshina KNo ratings yet

- API 653 PC 07jan08 PTR 4Document3 pagesAPI 653 PC 07jan08 PTR 4Mohammed ShakilNo ratings yet

- Chevron Specification TAM-MN-2Document9 pagesChevron Specification TAM-MN-2Burak GülenNo ratings yet

- Weld Built-Up ProcedureDocument1 pageWeld Built-Up ProcedureMohd Shafuaaz KassimNo ratings yet

- Condenser and Heat Exchanger Tube RestorationDocument6 pagesCondenser and Heat Exchanger Tube RestorationspalaniyandiNo ratings yet

- Name Designation JOB Job Description Crew NoDocument52 pagesName Designation JOB Job Description Crew NoattaullaNo ratings yet

- Tender No: RCC/NR/UPSO-II/ENG/PT-07/19-20 Public Tender:-: Page 76 of 200Document7 pagesTender No: RCC/NR/UPSO-II/ENG/PT-07/19-20 Public Tender:-: Page 76 of 200Shilpa SinghNo ratings yet

- ES-20.02 Quality Requirements PTT Public Co., LTD OF 23 For Pressure Vessel Engineering Standard REV: 01Document23 pagesES-20.02 Quality Requirements PTT Public Co., LTD OF 23 For Pressure Vessel Engineering Standard REV: 01Nikki RobertsNo ratings yet

- FALLSEM2020-21 CHE1014 TH VL2020210101682 Reference Material I 02-Nov-2020 Liquid Fuel Storage-4-96 PDFDocument93 pagesFALLSEM2020-21 CHE1014 TH VL2020210101682 Reference Material I 02-Nov-2020 Liquid Fuel Storage-4-96 PDFJateni GedaNo ratings yet

- Balmoral Bunded Tank InstallationDocument4 pagesBalmoral Bunded Tank InstallationAlberto DiazNo ratings yet

- Gauge - Pole - Cover - For - Floating - Roof - Tanks LR PDFDocument2 pagesGauge - Pole - Cover - For - Floating - Roof - Tanks LR PDFArlen NurlanNo ratings yet

- Fire Hydrant Valve Bs 5041: SpecificationDocument2 pagesFire Hydrant Valve Bs 5041: Specificationirrosel4650No ratings yet

- ControTrace Installation Checklist PipeDocument1 pageControTrace Installation Checklist PipeEnoch TwumasiNo ratings yet

- Ansi Valve Leakage Standards Gemco ValveDocument1 pageAnsi Valve Leakage Standards Gemco ValvenithyaNo ratings yet

- Tank Erection Itp Org ChartDocument34 pagesTank Erection Itp Org Chartvasantha kumar100% (1)

- Repair or Alteration of Pressure VesselsDocument4 pagesRepair or Alteration of Pressure VesselsMSNo ratings yet

- ASMESectionVIIIDivision1 WeldNeckFlangeCalc PDFDocument8 pagesASMESectionVIIIDivision1 WeldNeckFlangeCalc PDFLisa MaloneNo ratings yet

- Engineering Design Guide For Storage TanksDocument107 pagesEngineering Design Guide For Storage Tankssonng.engNo ratings yet

- Scissor Shoe Installation Guide Jan 2005 PDFDocument32 pagesScissor Shoe Installation Guide Jan 2005 PDFMohsen Halweni50% (2)

- Datasheet Floating Roof Tanks Spill Prevention Level Switch SXRLTX A Series1 EnglishDocument4 pagesDatasheet Floating Roof Tanks Spill Prevention Level Switch SXRLTX A Series1 EnglishDylan RamasamyNo ratings yet

- AST Nozzle Repair Req.Document10 pagesAST Nozzle Repair Req.Irvansyah RazadinNo ratings yet

- IHS PetroChem Collection Listing Aug13Document48 pagesIHS PetroChem Collection Listing Aug13OumorsyNo ratings yet

- Technical Bid Evaluation of Vendor Spring Hanger Offers With PDFDocument3 pagesTechnical Bid Evaluation of Vendor Spring Hanger Offers With PDFAmjadali ChoudhariNo ratings yet

- Product Reference Guide - Oil and GasDocument9 pagesProduct Reference Guide - Oil and GasDavid RodriguesNo ratings yet

- Shell Corena S3 R 68: Performance, Features & BenefitsDocument3 pagesShell Corena S3 R 68: Performance, Features & BenefitsjkamraNo ratings yet

- CP HS 12Document8 pagesCP HS 12aliNo ratings yet

- Seat Leakage Article Valve WorldDocument2 pagesSeat Leakage Article Valve WorldjshadwanNo ratings yet

- Wrapping MethodDocument5 pagesWrapping Methodnnuek67% (3)

- Technical Info FlangesDocument12 pagesTechnical Info FlangesPopescu LeonardNo ratings yet

- Plumbness Inspection ReportDocument3 pagesPlumbness Inspection ReportDoris DorisNo ratings yet

- 3000 Litre Transcube Fuel TankDocument1 page3000 Litre Transcube Fuel Tankyulianus_srNo ratings yet

- 14.052 Rev. 0 - 9PE122 & 9PE123 - ECOPETROL - Cleaning Supervision, Inspection & Repair PDFDocument11 pages14.052 Rev. 0 - 9PE122 & 9PE123 - ECOPETROL - Cleaning Supervision, Inspection & Repair PDFVladimir Rodriguez LeonNo ratings yet

- Vessels LDocument34 pagesVessels LMohammed.abudi1996No ratings yet

- Inspection Test Record (Itr) - A Jacket Pre-Loadout ST08-ADocument1 pageInspection Test Record (Itr) - A Jacket Pre-Loadout ST08-AMomo ItachiNo ratings yet

- Chapter One General Introduction: 1.1 Background StudyDocument32 pagesChapter One General Introduction: 1.1 Background StudyBassey ItaNo ratings yet

- PDO Approved Inspection BodiesDocument15 pagesPDO Approved Inspection BodiesMohammed Rizwan AhmedNo ratings yet

- ESpec Nirma Agosto 30 PP1101 ME SP 7200 005Document29 pagesESpec Nirma Agosto 30 PP1101 ME SP 7200 005jose diazNo ratings yet

- CHAPTER 3: Heat ExchangerDocument54 pagesCHAPTER 3: Heat ExchangerSyamsul Rizal Abd ShukorNo ratings yet

- Acum#2 RoladoDocument1 pageAcum#2 RoladoJuan PabloNo ratings yet

- Dual Laminated Fiberglass Reinforced Polymer (FRP) - MACAR Pipe & Fittings - PresentationDocument21 pagesDual Laminated Fiberglass Reinforced Polymer (FRP) - MACAR Pipe & Fittings - PresentationJulio Humberto Díaz Rondán100% (1)

- Rock Plast Pipe BrochureDocument28 pagesRock Plast Pipe BrochureHusna Mega JayaNo ratings yet

- Novel Technologies For Wear Protection and Monitoring in DredgingDocument23 pagesNovel Technologies For Wear Protection and Monitoring in DredgingRASHEED YUSUFNo ratings yet

- Flexible Duct Insulated & Non InsulatedDocument4 pagesFlexible Duct Insulated & Non Insulatedali faragallahNo ratings yet

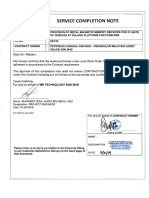

- Service Completion - MRTSBDocument7 pagesService Completion - MRTSBKhairul AnwarNo ratings yet

- Market Review MG 11th July 2014Document8 pagesMarket Review MG 11th July 2014Khairul AnwarNo ratings yet

- NDT Method Summary PDFDocument2 pagesNDT Method Summary PDFKhairul AnwarNo ratings yet

- L1 Manufacturing ProcessDocument17 pagesL1 Manufacturing ProcessKhairul AnwarNo ratings yet

- Iso 10721-1-1997Document119 pagesIso 10721-1-1997Jagannath SahuNo ratings yet

- Domestic Water Pump Head CalculationsDocument14 pagesDomestic Water Pump Head Calculationsmirza057No ratings yet

- Planning Parameters of Rail ProjectDocument4 pagesPlanning Parameters of Rail ProjectKRDCL Camp Office ErnakulamNo ratings yet

- Multilayer BlownupDocument2 pagesMultilayer BlownupRaghuveer SinghNo ratings yet

- PVC and GMSDocument9 pagesPVC and GMSwickedsinner7No ratings yet

- (01 32 16) Construction Schedule Critical Path Method-CPMDocument7 pages(01 32 16) Construction Schedule Critical Path Method-CPMAmeer JoshiNo ratings yet

- Radiant CoolingDocument25 pagesRadiant CoolingSharmila GangulyNo ratings yet

- James W. P. Campbell - The Study of Bricks (... ) Since Nathaniel Lloyd (2003, Paper)Document11 pagesJames W. P. Campbell - The Study of Bricks (... ) Since Nathaniel Lloyd (2003, Paper)Roger KriegerNo ratings yet

- Paresh Vishnoi - August 2012Document1 pageParesh Vishnoi - August 2012Fayaz HabeebNo ratings yet

- Designing Pressure Relief SystemDocument8 pagesDesigning Pressure Relief SystemvsrslmNo ratings yet

- CSWIP 3 1 PracticalDocument4 pagesCSWIP 3 1 PracticalAhmed Al-Emarah100% (1)

- Mirel Bakessov CVDocument3 pagesMirel Bakessov CVMirelNo ratings yet

- Windloads On Building CanopyDocument5 pagesWindloads On Building CanopyMaryNo ratings yet

- Inspection Poster GilsonDocument2 pagesInspection Poster GilsonJosé Álvarez RoblesNo ratings yet

- Cabinet Based PolesDocument12 pagesCabinet Based Poleseng_waleed2008No ratings yet

- LG 14K BTU Portable Air Conditioner LP1411SHR Owner's ManualDocument48 pagesLG 14K BTU Portable Air Conditioner LP1411SHR Owner's Manualnhutn_15No ratings yet

- pd1185 Fire CodeDocument3 pagespd1185 Fire CodeCamille MangaranNo ratings yet

- 14Document2 pages14codigocarnetNo ratings yet

- Expansion Shell Rock BoltDocument2 pagesExpansion Shell Rock BoltKumarShubhamNo ratings yet

- Copia de Ficha Tecnica 2021-2022 AA 12,18,24,36 T. Solo Frio 410WHIDocument6 pagesCopia de Ficha Tecnica 2021-2022 AA 12,18,24,36 T. Solo Frio 410WHIUlisesSoliherNo ratings yet

- Rules of Thumb Microtunneling Part 1Document1 pageRules of Thumb Microtunneling Part 1mahaprakash0% (1)

- Sitco Profile-2013Document19 pagesSitco Profile-2013api-229248936No ratings yet

- Ammonia Plant Revamp: SPIC, Tuticorin, TamilnaduDocument9 pagesAmmonia Plant Revamp: SPIC, Tuticorin, TamilnaduAl Musabbir LeeonNo ratings yet

- ASP Catalogue 2018 WebDocument104 pagesASP Catalogue 2018 WebRenzo ArangoNo ratings yet

- ATK-31 Completion ReportDocument13 pagesATK-31 Completion ReportRichard PeriyanayagamNo ratings yet

- Activity 2.3.2 Green Building and Sustainable DesignDocument4 pagesActivity 2.3.2 Green Building and Sustainable Designapi-395468565No ratings yet

- Access - Catalog.805b.Color - DP&Casing Tools-46Document1 pageAccess - Catalog.805b.Color - DP&Casing Tools-46RICHARDNo ratings yet

- Pavement Maintenance: DR Nor Faizah BawadiDocument29 pagesPavement Maintenance: DR Nor Faizah BawadiAinur Sya IrahNo ratings yet

- TexSteam DSeriesPlugDocument8 pagesTexSteam DSeriesPlugSIMON S. FLORES G.No ratings yet

- Distribution CatalogDocument41 pagesDistribution Cataloga7mosNo ratings yet