Professional Documents

Culture Documents

Gas Turbine Course

Uploaded by

Mgn San100%(1)100% found this document useful (1 vote)

121 views54 pagesThis document provides an overview of a gas turbine course, outlining 13 topics that will be covered including fundamentals, components, lubrication systems, and maintenance. It also includes diagrams of the gas turbine system, describing the main components like the compressor, combustion chamber, turbine, and supporting systems. Key aspects of the lubrication oil system are explained, such as the main and auxiliary pumps, filters, heat exchangers, and monitoring devices.

Original Description:

gas turbine

Original Title

gasturbinecourse-130129063149-phpapp02

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides an overview of a gas turbine course, outlining 13 topics that will be covered including fundamentals, components, lubrication systems, and maintenance. It also includes diagrams of the gas turbine system, describing the main components like the compressor, combustion chamber, turbine, and supporting systems. Key aspects of the lubrication oil system are explained, such as the main and auxiliary pumps, filters, heat exchangers, and monitoring devices.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

121 views54 pagesGas Turbine Course

Uploaded by

Mgn SanThis document provides an overview of a gas turbine course, outlining 13 topics that will be covered including fundamentals, components, lubrication systems, and maintenance. It also includes diagrams of the gas turbine system, describing the main components like the compressor, combustion chamber, turbine, and supporting systems. Key aspects of the lubrication oil system are explained, such as the main and auxiliary pumps, filters, heat exchangers, and monitoring devices.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You are on page 1of 54

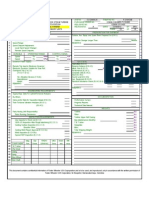

GAS TURBINE COURSE

1. GAS TURBINE FUNDAMENTALS

2. GAS TURBINE COMPONENTS

3. LUBRICATION OIL SYSTEM

4. HYDRAULIC OIL SYSTEM

5. TRIP OIL SYSTEM

6. VARIABLE INLET GUIDE VANES, IGV

7. STARTING SYSTEM

GAS TURBINE COURSE

8. FUEL SYSTEM

9. COOLING & SEALING AIR SYSTEM

10. COOLING WATER SYSTEM

10. ATOMIZING AIR SYSTEM

11. FIRE PROTECTION SYSTEM

12. COMPRESSOR WATER WASHING

13. GAS TURBINE MAINTENANCE

STEAM TURBINE

LOAD

HP/IP LP

STEAM

GENERATOR (BOILER)

MW

STEAM

GAS TURBINE (OPEN CYCLE)

TURB

COMPRESSOR

HIGH PRESSURE

AIR

HIGH TEMPERATURE/PRESSURE GAS

FUEL

COMBUSTION

CHAMBER

LOAD

MW

AIR INLET

HEAT ENGINE

A DEVICE THAT CONVERTS HEAT

INTO WORK IS KNOWN AS HEAT

ENGINE

EXAMPLE :

- Petrol Engine

- Diesel Engine

- Gas Turbine Engine

- Steam Engine

HEAT ENGINE

Heat Engine

Output

High Temperature Source

Heat Sink

W

Otto Cycle

Pressure (P)

1

2

3

4

Volume (V)

1 - 2 Compression

2 - 3 Combustion

3 - 4 Expansion

4 - 1 Exhaust

DIESEL CYCLE

1

2

3

4

Pressure (P)

Volume (V)

1 - 2 Compression

2 - 3 Combustion

3 - 4 Expansion

4 - 1 Exhaust

BRAYTON CYCLE

(Constant Pressure Cycle)

1

2

3

4

Pressure (P)

Volume (V)

1 - 2 Compression

2 - 3 Combustion

3 - 4 Expansion

4 - 1 Exhaust

Fundamental of Gas Turbine

AIR

FUEL

GENERATOR

c

t

b

c = compressor

b = burners

t = turbine

1

2

3

4

When the Brayton Cycle is worked out for a steady flow

process, we have a simple gas turbine cycle.

In a simple gas turbine cycle, combustion & exhaust occur

at constant pressure and compression & expansion occur

continuously.

General Description of GE 9001E

The Model Series 9001E gas turbine is a 3000

rpm, single shaft with a 14 combustor, reverse-

flow combustion system, simple-cycle power

package that basically requires only fuel & fuel

connections, generator breaker and AC power

source for turbine start-up.

The MS9001E is also available in a combined-

cycle configuration for application utilizing a Heat

Recovery Generator or similar device

Gas Turbine Unit

The gas turbine unit consists of a 17-stage axial flow

compressor and a 3-stage power turbine.

Each section, compressor rotor & turbine rotor is

assembled separately and joined together through bolt

construction.

The assembled rotor is a three bearing design utilizing

pressure-feed elliptical & tilt-pad journal bearings. This

design assures that rotor-critical speed are above the

operating speed for optimum turbine bucket/turbine shell

clearances.

Gas turbine Components

The MS9001E gas turbine assembly consists of

six major section or groups :

1. Air inlet

2. Compressor

3. Combustion system

4. Turbine

5. Exhaust

6. Support system

Gas Path Description

Starting system actuated - ambient air drawn in through inlet plenum -

compress in 17 stages axial compressor - compressed air flow into

annular space surrouding 14 combustion chambers - flows into liners

through metering holes.

Fuel from off-base source divide into 14 equal flows lines - fuel is

equally controlled into 14 nozzles - ignition by spark plugs - flame

propagate through crossfire tubes - combustion chamber pressure

causes spark plug retract from hot flame zone at operating speed.

Hot gas from combustion chamber expand into 14 separate transition

piece - flow through 3-stage turbine section (rows of fixed nozzles &

rotating buckets) - In fixed nozzles (kinetic energy increased &

pressure drop) - In moving buckets (kinetic energy turn to rotor

rotation to generate electrical power)

Gas Path Description - continue

After 3rd. Stage buckets - gases directed into exhaust hood

& diffuser (a series of turning vanes to turn the gases from

axial to radial direction, minimizing exhaust hood losses) -

Gases pass into exhaust plenum - introduced to atmosphere

through exhaust stack.

Accessory Compartment

Several system involved in turbine operation located in this

section :

1. Starting Mean

2. Fuel System

3. Lubrication & Seal Oil System

4. Hydraulic System

5. Cooling Water System

6. Atomizing Air System

Major components - starting motor, torque converter &

accessory drive gear.

Turbine Base & Support

Turbine base - supports the gas turbine & is a structural steel

fabrication of welded steel beam & plates.

Turbine supports - gas turbine is mounted to its base by vertical

supports at three locations :

1. Forward support

2. Two Aft supports (with cooling jacket) - on either side of exhaust

frame

Gib key & Guide Block - Gib key is machined on lower half of turbine

shell & fit into the guide block which is welded to the aft cross beam

of turbine base (prevent lateral & rotational movement & permitting

axial & radial movement for thermal expansion)

Compressor Section

The Axial flow Compressor section consists of :

1. Compressor Rotor

2. Enclosing Casing

Within the compressor casing are Inlet guide Vanes (IGV), 17 stages

of rotor & stator airfoil-shaped blades and exit guide vanes.

The stator (casing) for compressor composed of four major sections :

1. Inlet casing

2. Forward Compressor casing

3. Aft Compressor casing

4. Compressor discharge casing

Combustion System

The combustion system is a reverse-flow type with 14

combustion chambers arranged around the periphery of the

compressor discharge casing.

The major components consists of :

1. Fuel nozzles

2. Spark plug ignition system

3. Ultraviolet flame detector

4. Combustion wrapper

5. Combustion chamber - comb. liners & transition piece

6. Crossfire tubes

Turbine Section

The three-stage turbine section is the area where energy, in

the form of high temperature pressurized gas produced by

the compressor & combustion sections, is converted to

mechanical energy.

Major components in the turbine section are :

1. Turbine rotor - consists of two wheel shafts, the 1st., 2nd. & 3rd.

Stage turbine wheel with buckets & two turbine spacers.

2. Turbine stator - consists of turbine shell and exhaust frame.

Turbine stationary nozzles, diaphragm, shroud, bearing no. 3 &

exhaust diffuser are internally supported from these components.

Bearings

The MS9000 gas turbine unit contain three main journal

bearings used to support the gas turbine rotor & thrust

bearing to maintain rotor to stator axial position & support

thrust load developed on the rotor.

No. Class Type

1 Loaded Tilting pad -thrust equalizing

1 Unloaded Tilting pad - non thrust equalizing

1 Journal Elliptical

2 Journal elliptical

3 Journal Tilting pad.

Lubrication Oil System

The lubricating requirements for the gas turbine

are furnished by a common forced-feed lubrication

system. Lubricating fluid is circulated to the three

main turbine bearings, generator bearings,

reducing gear, accessory gear, as hydraulic oil in

torque converter and also as control, trip oil, high

pressure hydraulic oil & generator seal oil.

Lub. Oil System - continue

Such a system must supply cool, clean and pressurized oil to bearing.

This lub. system includes the following :

1. Lub. oil reservoir in the accessory base (12,490 liter)

2. Main lub. oil pump (shaft driven from accessory gear).

3. Auxiliary lub. oil pump

4. Emergency lub. oil pump

5. Auxiliary & emergency seal oil pump

6. Lub. oil heat exchangers

7. Lub. oil filters.

8. Pressure relief valve VR1 in main pump discharge header (6.9)

9. Bearing header pressure regulator VPR2-1 (1.7 bars)

10. Mist Eliminator

Lub. oil system - control components

Some important operating parameters monitored by Speedtronic Mark

V control system :

1. Oil Level Detection

71 QH = Level detector switch, Alarm when level is high (254 mm)

71 QL = Level detector switch, alarm when level is low ( 432 mm)

2. Pressure & Temperature Protective Devices

63QT-2A & 2B = Pressure switch in lub. oil feed piping to generator

bearings. Trip turbine when < 0.55 bar

63QT-1A & 1B = Temperature switch in lub. oil header.

Trip the turbine if temperature > 79.4

o

C

63 QQ-1 = Differential pressure switch

alarm when pressure across oil filters of 1.03 bar (15 psi)

Lubricating oil Pumps

Main Oil Pump - positive displacement pump mounted on & driven by

the accessory gear, rated 2725 lpm & 7 bar.

Auxiliary Oil Pump - submerged centrifugal pump driven by AC

motor (88QA-1), rated 2460 lpm & 7.5 bar.

Higher pressure for torque converter during slow roll & start-up.

Starts when speed drop below 14HS (90% rated speed) stop when

turbine attains 95% rated speed.

Also when 63QA-1 sense a drop below 4.83 bar.

Emergency Lub. Oil Pump - submerged centrifugal pump driven by a

DC motor (88QE-1).

Rated at 1590 lpm & 1.4 bar. Back-up for AOP when 63QT-2A & 2B

below 0.55 bar.

Seal Oil Pump

The seal oil to the generator bearings is normally supplied

by the main lub. system through a separate line directly to

the seal oil control unit of the generator. This line is

plumbed into the system upstream of VPR2-1. The seal oil

control unit will regulate the seal oil pressure to maintain it

a nominal 0.32 bar above hydrogen gas pressure.

The seal oil pump is driven by two motors :

AC motor - 88QS-1

DC motor - 88ES-1

GE Gas Turbine Device Code - 1st. letter

Q - Lub. oil

H - Hydraulic/heater

A - Air

F - Fuel/flow/fire

D - diesel/divider

C - Clutch/Compressor/Co

2

T - Trip/turbine

P - Purge

W - Water/warm

S - Stop/speed/start

G - Gas

GE Gas Turbine Device Code - 2nd letter

A - Alarm/accessory/air/atomization

B - booster/bleed R - Release/ratio/rachet

C - Cooling/control S - Start

D - Divider/differential T - Turbine/trip/tank

E - Emergency V - Valve/Vane

F - Fuel

G - Gas

H - Heater/high

L - Low level/liquid

M - Middle/medium/minimum

N - Normal

P - Pressure/Pump

Q - Lub. oil

Code designation by figures

12 - Overspeed mechanism 77 - Speed senser

20 - Solenoid valve 88 - Electric motor

23 - Heating device 90 - Modulating valve

26 - Temperature switch 96 - Pressure transmitter

33 - Limit switch

39 - Vibration detector

43 - Manual switch

45 - Fire detector

49 - Overload protection

63 - Pressure switch

65 - Servo. Valve

71 - Level detecting system

Hydraulic Supply System

Hydraulic supply system provides fluid power required for

operating the control components of the gas turbine fuel

system. The fluid furnished the means for opening or

resetting the fuel stop valves, in addition to the variable

turbine inlet guide vanes and the hydraulic control & trip

devices of the gas turbine.

Major system components includes the main hydraulic

pump, an auxiliary supply pump, the system filters, an

accumulator assembly and the hydraulic supply manifold

assemblies.

Trip Oil System

The hydraulic trip oil system is the primary interface

between the turbine protection system circuits of the

Speedtronic Mark V Control System and the the

components on the turbine which open the IGVs and allow

fuel flow to turbine.

The trip oil system contains devices which are eletrically

operated by Speedtronic control signals as well as

completely mechanical devices that operate directly on trip

oil system independent of the turbine control panel.

The trip oil system ensures that fuel flow is halted & the

IGVs close at a unit trip.

Variable Inlet Guide Vanes (IGVs)

IGVs are used to control the airflow through the

compressor, in turn controlling the airflow through the

entire machine.

The IGVs modulate during the start-up and acceleration of

the gas turbine to rated speed, loading & unloading of the

generator and deceleration of the gas turbine during

shutdown.

This modulation maintains proper flows & pressure, and

thus stresses in the compressor during part-speed

operation, maintains a minimum pressure drop across fuel

nozzles while operating at 100% speed & also maintains

high exhaust temperatures at low generator load level.

Starting System

Like other internal combustion engines, a gas turbine

cannot produce torque at zero speed.

The starting mean system is used to start the gas turbine

rolling, crank it to firing speed and assist the fired turbine

to self-sustaining speed.

This is accomplished by an induction motor starting device

operating through a torque converter coupled to the

accessory gear.

This arrangement provides the cranking torque for turbine

start-up. For shutdown, this continues to rotate the turbine

rotor at slow speed for cool down purposes.

Dual Fuel System

This gas turbine has duel fuel capability. It supplied with

both a natural gas & a liquid fuel (distillate) system.

While operating on gas fuel, if the gas fuel pressure should

drop below a pre-set value, the control system will

automatically transfer to liquid fuel operation.

There is no automatic transfer from liquid to gas, that

transfer must be initiated by operator.

Mechanical fuel handling & electrical control components

are incorporated in the design of capable of burning either

two fuel individually or both fuels simultaneously.

Gas Fuel

The gas fuel system is designed to deliver gas fuel to the turbine

combustion chambers at the proper pressures & flow rates to meet all

of the starting, accelerating, loading requirements of gas turbine

operation. Major components are :

1. Pneumatic block valve VA27-1

2. Y-type strainer

3. Gas stop/speed ratio (VSR) & control (VGC) valve

4. Fuel gas low pressure alarm switch 63FG

5. Gas pressure gauges & vent valves

6. Gas fuel hydraulic trip relay VH5

7. Valve control servo-valves

8. Valve control LVDTs

9. Gas manifolds to Comb. chambers.

10. Fuel metering system

Liquid Fuel

The liquid fuel system pumps and distributes fuel supplied from off-

base fuel forwarding system to the fourteen fuel nozzles of the

combustion system.

The fuel system filters the fuel & divides the fuel flow into 14 equal

parts for distribution to the combustion chamber at the required

pressure & flow rates.

Fuel pump bypass VC3 regulates the amount of fuel input to the

turbine combustion chamber by varying amount of bypassed fuel. If

valve closes, less fuel is circulated around the pump and more fuel

goes to the combustors & vice versa.

The position of the bypass valve is a linear function of the Fuel Stroke

Reference (FSR) generated by the Speedtronic Mark V Control.

Major Components for Fuel System

1. In-line low pressure fuel filter FF1-1

2. Fuel oil stop valve VS1

3. Liquid fuel pump PF1

4. Fuel pump discharge relief valve VR4

5. Fuel bypass Valve VC3

6. Flow divider FD1

7. Selector valve assembly

8. Fuel line check valves

9. Fuel Nozzle assemblies

10. False Start drain valves VA17-1, -2 & -5

Control Devices associated to Fuel System

1. Fuel differential pressure switch 63LF-1

2. Liquid fuel servo valve 65FP

3. Fuel pump clutch solenoid 20CF

4. Permissive limit switches 33FL-1 & -2

5. Hydraulic trip relay VH4

6. LVDTs 96FP-1 & -2

7. Magnetic pickups 77FD-1,-2 & -2

Cooling & Sealing Air system

The cooling & sealing air system provides the necessary air flow from

the compressor to the other parts of the gas turbine rotor & stator to

prevent excessive temperature buildup in these parts during normal

operation and sealing of the turbine bearings. Atmospheric air from

external centrifugal blowers is also used cool the turbine exhaust

frame.

Cooling & sealing function provided by the system are :

1. Sealing of turbine bearings

2. Cooling the internal turbine parts subjected to high temperature

3. Cooling of the turbine outer shell & exhaust frame

4. Providing an operating air supply for air operated valves

5. Compressor pulsation protection

Atomizing Air System

The atomizing air system provides high pressure air to

atomize the liquid fuel as it enters the combustors.

Atomization is necessary to ensure complete and proper

combustion. The ration of atomizing air to compresor

discharge pressure approx. 1.2 or greater.

Major components :

1. Main atomizing air compressor (driven by accessory

gear)

2. Starting atomizing air compressor

3. Atomizing air heat exchanger

Cooling Water System

The cooling water system is a closed system designed to

accommodate the heat-dissipation requirements of the

turbine & generator lub. oil system, the atomizing air

precooler, the water cooled flame detector and turbine

support legs.

On-based components includes lub. oil heat exchanger in

accessory base, turbine aft support legs, atomizing air heat

exchanger& heat exchanger of generators air cooling

system.

The hot water of the cooling water system is then cooled

by off-base industrial type water cooling module.

Fire Protection System

The carbon dioxide fire protection system extinguished

fires by reducing the oxygen content of the air in the

compartment from an atmospheric normal of 21% to less

than 15%, an insufficient concentration to support

combustion.

To reduce the oxygen content, a quantity of carbon dioxide

equal or > than 34% of the compartment volume is

discharge into the compartment in one minute and

recognizing the reflash potential of combustibles exposed

to high temperature metal, it provides an extended

discharge to maintain an extinguishing concentration for a

prolong period to minimize likelihood of reflash condition.

Compressor Water Wash System

Gas turbine can experience a loss of performance during operation as

result of deposits of contaminants on internal components. The

deposits of atmospheric contaminants on the compressor parts occur

with the ingestion of air. This contaminants can be removed by

washing with water-detergent solution followed by a water rinse.

Major components for Compressor Water Wash System :

1. On- base Equipment

2. Off-base Equipment

Two type of water wash procedures :

1. Off-line Compressor Wash

2. On-line compressor Wash

Gas Turbine Maintenance

Classification Gas Turbine Maintenance ;

1. Standby Inspection

2. Running Inspection

3. Dis-assembly Inspection

Dis-assembly Inspection can be classified into :

1. Combustion Inspection

2. Hot Gas Path Inspection

3. Major Inspection

You might also like

- GT Various Systems (G)Document62 pagesGT Various Systems (G)shtiwari2002100% (2)

- 3 - Presentation Antisurge Control 2016Document66 pages3 - Presentation Antisurge Control 2016Hayder WasselaNo ratings yet

- CC General DescriptionDocument40 pagesCC General DescriptionKorichiKarim100% (1)

- EPS GT Base PrinciplesDocument32 pagesEPS GT Base PrinciplescdbeardsallNo ratings yet

- Steam TurbinesDocument14 pagesSteam TurbinesArvindPasuparthyNo ratings yet

- Stalling and Surging: Course SeminarDocument12 pagesStalling and Surging: Course SeminarPARMINDERKHOSANo ratings yet

- Gas Turbine System Theory PDFDocument30 pagesGas Turbine System Theory PDFAbdul GafurNo ratings yet

- Inspections, As A Part of A Maintenance Program That Must Be Put in Place With TheDocument29 pagesInspections, As A Part of A Maintenance Program That Must Be Put in Place With TheFrankNo ratings yet

- Gas Turbine Performance: by Rainer KurzDocument16 pagesGas Turbine Performance: by Rainer Kurzthryee100% (1)

- Impulse and Reaction Blading of Gas TurbinesDocument4 pagesImpulse and Reaction Blading of Gas Turbinesapi-271354682100% (3)

- Gas Turbine Lubrication System and WorkingDocument14 pagesGas Turbine Lubrication System and WorkingshaonaaNo ratings yet

- Maintenance Programs of Gas and Steam TurbinesDocument26 pagesMaintenance Programs of Gas and Steam Turbinesmexx4u2nv100% (1)

- 2.3.1 GT FundamentalsDocument30 pages2.3.1 GT FundamentalsSarah CohenNo ratings yet

- Turbine Engine Lubrication SystemDocument55 pagesTurbine Engine Lubrication SystemAkmal FitriNo ratings yet

- Adjust Axial Bently Nevada ProbesDocument3 pagesAdjust Axial Bently Nevada Probesmic-grNo ratings yet

- Pneumatics and Bleed AirDocument9 pagesPneumatics and Bleed AirlouisnathancraigNo ratings yet

- Gas Turbine Performance by Rainer KurzDocument16 pagesGas Turbine Performance by Rainer KurzSulzerRuudNo ratings yet

- M PM 170Document34 pagesM PM 170mahesh_eilNo ratings yet

- Jindal Power Limited.: Design & Feature of 600 MW Steam TurbineDocument70 pagesJindal Power Limited.: Design & Feature of 600 MW Steam TurbineAshish SinghNo ratings yet

- Some Practical Aspects of Balancing An Ultracentrifuge RotorDocument10 pagesSome Practical Aspects of Balancing An Ultracentrifuge RotorGustavo da SilvaNo ratings yet

- Module 15 ExamDocument119 pagesModule 15 Examمنذر كمالNo ratings yet

- Gas Engine FundamentalsDocument13 pagesGas Engine Fundamentalsherdin56No ratings yet

- Gas Turbine Power PlantDocument16 pagesGas Turbine Power PlantSathya Raj SimiNo ratings yet

- Design and Analysis of Gas Turbine Rotor Blade Using Finite Element MethodDocument22 pagesDesign and Analysis of Gas Turbine Rotor Blade Using Finite Element MethodTJPRC PublicationsNo ratings yet

- Engineering Lesson Guide 11: Gas Turbine TheoryDocument24 pagesEngineering Lesson Guide 11: Gas Turbine TheoryIwan RuhiyanaNo ratings yet

- Antisurge ControllerDocument6 pagesAntisurge ControllerGeorge J AlukkalNo ratings yet

- New Moment WeightDocument16 pagesNew Moment WeightRaj KiranNo ratings yet

- Performance of Industrial GasturbinesDocument28 pagesPerformance of Industrial Gasturbinessomporn duangbuntaoNo ratings yet

- Fans-Their Types, Characteristics, and ApplicationDocument35 pagesFans-Their Types, Characteristics, and ApplicationFarzin SaNo ratings yet

- Gas Turbine BasicsDocument25 pagesGas Turbine Basicsdnageshm4n244No ratings yet

- Turbine Speed & Load ControlDocument32 pagesTurbine Speed & Load Control06nikhil100% (1)

- Gas Turbine NotesDocument21 pagesGas Turbine NotesJohn BlackburnNo ratings yet

- 7230 CompressorDocument57 pages7230 Compressorrobiny100% (1)

- 9.SOP Barring Gear or Turning GearDocument5 pages9.SOP Barring Gear or Turning GearDodik NugrohoNo ratings yet

- V005t15a001 88 GT 150Document13 pagesV005t15a001 88 GT 150Antonio CilindroNo ratings yet

- Api 611 5Th Edition General " Purpose Steam Turbine Existing TurbineDocument1 pageApi 611 5Th Edition General " Purpose Steam Turbine Existing TurbineAlejandro GilNo ratings yet

- Gas Turbine Combustion Chamber Design Aspects & Current TrendsDocument24 pagesGas Turbine Combustion Chamber Design Aspects & Current TrendsPRAVEENNo ratings yet

- 01 - SSE Academy BoolDocument65 pages01 - SSE Academy BoolAmmar AltamimyNo ratings yet

- Speed TronicDocument3 pagesSpeed Tronicscribdkhatn0% (1)

- Compressor Piston Rings & RidersDocument22 pagesCompressor Piston Rings & RidersmauricioNo ratings yet

- Basic Gas Turbines - StartingDocument6 pagesBasic Gas Turbines - StartingCameron KingNo ratings yet

- Description - 9FB Rotor Balancing Description GE Energy - 051025Document9 pagesDescription - 9FB Rotor Balancing Description GE Energy - 051025Emmanuelle YorkNo ratings yet

- 002-Steam Turbines Basics For BeginnersDocument10 pages002-Steam Turbines Basics For BeginnersGeorge J AlukkalNo ratings yet

- Lube Oil System: ١ - ﺖﻳﺰﻟا ﻚﻨﺗ nk Oil Ta) 001 BB 10 MBV (Document15 pagesLube Oil System: ١ - ﺖﻳﺰﻟا ﻚﻨﺗ nk Oil Ta) 001 BB 10 MBV (kamal arabNo ratings yet

- Axial Flow CompressorDocument50 pagesAxial Flow CompressorSunil Panwar100% (1)

- Feed Pumps, Feed Injectors, Feed Regulators, Feed Heaters, Air Heaters and Steam AccumulatorsDocument74 pagesFeed Pumps, Feed Injectors, Feed Regulators, Feed Heaters, Air Heaters and Steam Accumulatorsbanukiran sambojuNo ratings yet

- 3-1 Operation of Cooling TowersDocument12 pages3-1 Operation of Cooling TowersHassan SamiNo ratings yet

- Vibrations in Steam TurbinesDocument11 pagesVibrations in Steam TurbinesAnudeep Chittluri100% (1)

- Rim and Face AlignmentDocument4 pagesRim and Face AlignmentJJNo ratings yet

- The Steam Turbine: 7.3.3 Rotor BalancingDocument2 pagesThe Steam Turbine: 7.3.3 Rotor BalancingBhavana KewlaniNo ratings yet

- Steam Turbine Governing System: Prepared By: Nimesh GajjarDocument15 pagesSteam Turbine Governing System: Prepared By: Nimesh GajjarKr SantoshNo ratings yet

- Power Plant Familiar Is at Ion V - IIIDocument164 pagesPower Plant Familiar Is at Ion V - IIISiva Kumar Tutika100% (2)

- Gas Turbine PresentationDocument54 pagesGas Turbine Presentationvasanth11kv100% (2)

- GT PresentaionDocument98 pagesGT Presentaionmujeebtalib100% (5)

- GT Frame 9 ManualDocument98 pagesGT Frame 9 ManualSANJAY100% (2)

- Gas TurbineDocument27 pagesGas Turbineghgh140100% (1)

- Turbine Start-Up SOPDocument17 pagesTurbine Start-Up SOPCo-gen ManagerNo ratings yet

- Gas Turbine Start UpDocument131 pagesGas Turbine Start UpBaharudin Bin Kamarul Baharin100% (3)

- Generator Step-Up TransformerDocument24 pagesGenerator Step-Up TransformerعليفاضلNo ratings yet

- Gas Turbine Generator PresentationDocument25 pagesGas Turbine Generator PresentationSagar Naduvinamani100% (2)

- Operator Asset Ownership This Is My Equipment Part 1 98Document7 pagesOperator Asset Ownership This Is My Equipment Part 1 98Mgn SanNo ratings yet

- Countries Plants Products Month DayDocument2 pagesCountries Plants Products Month DayMgn SanNo ratings yet

- Bulletin EQM 89 - 5S PDFDocument23 pagesBulletin EQM 89 - 5S PDFMgn SanNo ratings yet

- Inventário - Pessoal: Item Descrição Do Categoriac ItemDocument8 pagesInventário - Pessoal: Item Descrição Do Categoriac ItemMgn SanNo ratings yet

- 2012 02 Brady 5S HandBookDocument23 pages2012 02 Brady 5S HandBookAlexandruNo ratings yet

- Countries Plants Equipments ProductsDocument3 pagesCountries Plants Equipments ProductsMgn SanNo ratings yet

- 2017 GTS Training Catalog Moz PDFDocument30 pages2017 GTS Training Catalog Moz PDFMgn SanNo ratings yet

- KKC Media 2017 M1Document6 pagesKKC Media 2017 M1Mgn SanNo ratings yet

- Countries Plants Equipments ProductsDocument5 pagesCountries Plants Equipments ProductsMgn SanNo ratings yet

- Countries Plants Products Month: Total Total Total Total Total Total TotalDocument2 pagesCountries Plants Products Month: Total Total Total Total Total Total TotalMgn SanNo ratings yet

- Oil and Gas SeparatorsDocument7 pagesOil and Gas SeparatorsMgn San100% (1)

- PipelinesDocument12 pagesPipelinesSidick DaoussaNo ratings yet

- Countries Plants Equipments ProductsDocument34 pagesCountries Plants Equipments ProductsMgn SanNo ratings yet

- Employee Time Sheet: Employee Name: Etelvino Santiago Department: Start Day: 3/4/2002Document1 pageEmployee Time Sheet: Employee Name: Etelvino Santiago Department: Start Day: 3/4/2002Mgn SanNo ratings yet

- 2013 IntroductiontoPetroleumandNaturalGas NewDocument36 pages2013 IntroductiontoPetroleumandNaturalGas NewMgn SanNo ratings yet

- Disposal and Utilization of Fly Ash To Protect The EnvironmentDocument8 pagesDisposal and Utilization of Fly Ash To Protect The EnvironmentMgn SanNo ratings yet

- Hazard and Operability (HAZOP) Study: Dr. AADocument75 pagesHazard and Operability (HAZOP) Study: Dr. AAjoenediath9345100% (1)

- Cem I CEM II/A 42,5 Çimento TipiDocument8 pagesCem I CEM II/A 42,5 Çimento TipiMgn SanNo ratings yet

- Steam Boiler ProjectDocument32 pagesSteam Boiler ProjectSwastik BhokareNo ratings yet

- TM 3110 Ujian-Tengah-Semester 2021 15 Oktober 2021Document5 pagesTM 3110 Ujian-Tengah-Semester 2021 15 Oktober 2021TM143Adam Putra Pratama ZainuriNo ratings yet

- P02093 02 21 47 3619 - Rev 1Document12 pagesP02093 02 21 47 3619 - Rev 1Veera Venkatesh BandaruNo ratings yet

- Double Volute PumpDocument2 pagesDouble Volute PumpmetropumpsNo ratings yet

- Materi IV Rock CompressibilityDocument9 pagesMateri IV Rock CompressibilityAsriady Dimas AndikaNo ratings yet

- Type Ezr EstancoDocument40 pagesType Ezr EstancoJuan JuanNo ratings yet

- CFD IntroductionDocument13 pagesCFD IntroductionSaeed AbdNo ratings yet

- Hydraulics 1Document82 pagesHydraulics 1Vincent Louie Escover Foronda75% (16)

- Kad03 - 0 Manual de Secador Kad 165Document69 pagesKad03 - 0 Manual de Secador Kad 165Javier GarcíaNo ratings yet

- R F+460 K C+273: 14.7 Psia 101.3 KpaaDocument47 pagesR F+460 K C+273: 14.7 Psia 101.3 KpaaYhelly27No ratings yet

- Lab 3 - Gas Sensor (Iman, Faiz, Anas)Document10 pagesLab 3 - Gas Sensor (Iman, Faiz, Anas)ahmad faizNo ratings yet

- AERO Lab PhotosDocument6 pagesAERO Lab PhotosLiNuNo ratings yet

- MT Assignment - Jan - 2023Document1 pageMT Assignment - Jan - 2023tenguria samriddh100% (1)

- Eiga-36 - 19 (2019)Document120 pagesEiga-36 - 19 (2019)JDNo ratings yet

- Exp 8 Observation of Laminar, Transition and Turbulent FlowDocument6 pagesExp 8 Observation of Laminar, Transition and Turbulent FlowWasi Uddin MahmudNo ratings yet

- Tractor Design & Testing - Lesson 17. Hydraulic System Design ConsiderationsDocument3 pagesTractor Design & Testing - Lesson 17. Hydraulic System Design ConsiderationsCaio GiarettaNo ratings yet

- GEM SeriesDocument180 pagesGEM SeriesZiyadawaliNo ratings yet

- Crowe Cengel CorrguideDocument4 pagesCrowe Cengel CorrguideNg Swee Loong StevenNo ratings yet

- 546 List of Finished Machinery)Document17 pages546 List of Finished Machinery)stelianivan1964No ratings yet

- Vertical Thermosyphon Re Boilers. Maximum Heat Flux and Separation EfficiencyDocument9 pagesVertical Thermosyphon Re Boilers. Maximum Heat Flux and Separation EfficiencyPuskar GuptaNo ratings yet

- Junker's Gas CalorimeterDocument4 pagesJunker's Gas CalorimeterShanti Kiran ZNo ratings yet

- Olympian Plus Plug-In System: General Purpose FiltersDocument1 pageOlympian Plus Plug-In System: General Purpose FiltershoiNo ratings yet

- Fridge System: Vapour-Compression Theoretical GraphsDocument14 pagesFridge System: Vapour-Compression Theoretical GraphsBhargav Krsna GayanNo ratings yet

- FXT SubmittalDocument1 pageFXT SubmittalaekathirNo ratings yet

- JMP Company Profile 2020Document20 pagesJMP Company Profile 2020Jay MarkNo ratings yet

- The New Ansi Centrifufal PumpDocument7 pagesThe New Ansi Centrifufal PumpCésarRenatoCopacondoriCuaylaNo ratings yet

- General Catalog For Compressed Air, Gas and Vacuum SolutionsDocument220 pagesGeneral Catalog For Compressed Air, Gas and Vacuum Solutionsgomera100% (1)

- 7G Particles: Solids, Liquids and GasesDocument3 pages7G Particles: Solids, Liquids and GasesBen PassmoreNo ratings yet

- Process Plant Design - Training Course - 10 and 11 Jan 2018 - Process Line Sizing PDFDocument69 pagesProcess Plant Design - Training Course - 10 and 11 Jan 2018 - Process Line Sizing PDFNgàyMưaNo ratings yet

- G060038 - 2016-10-10 - CECOD Guide For Assessing Zoning For 1999-92-EC Around Dispensers - Rev 3Document33 pagesG060038 - 2016-10-10 - CECOD Guide For Assessing Zoning For 1999-92-EC Around Dispensers - Rev 3Roman MakarNo ratings yet