Professional Documents

Culture Documents

099S131 Aa06l01

Uploaded by

Rohan ViswanathOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

099S131 Aa06l01

Uploaded by

Rohan ViswanathCopyright:

Available Formats

Inventory Management:

Safety Inventory ( I )

CC

3.0

Inventory Management: Safety Inventory ( I )

1

Safety Inventory

Demand uncertainty

Supply uncertainty

Safety Inventory is inventory carried for the purpose of satisfying

demand that exceeds the amount forecasted for a given period.

Purposes of holding safety inventory

Average

Inventory

Inventory

Time

Safety Inventory

Cycle Inventory

2

Planning Safety Inventory

Appropriate level of safety inventory is determined by

Actions to improve product availability while reducing safety inventory

Uncertainty of both demand and supply

Uncertainty increases, then safety inventory increases.

Desired level of product availability Desired level of product availability

increases, then safety inventory increases.

3

Measuring Demand Uncertainty

k

i=1

D

i

P=

CV= o/

P=KD

D

k

o = O

Coefficient of variation

The total demand during k period is normally distributed with a mean of P

and a standard deviation of O :

If demand in each period is independent and normally distributed with a

mean of D and a standard deviation of o

D

, then

O=

o

i

2

+2 Cov(i,j)

i=1 i>j

k

=

o

i

2

+2 o

i

o

j

i=1 i>j

k

Uncertainty within lead time

Assume that demand for each period i, i=1,.,k is normally distributed

with a mean D

i

and standard deviation o

i

.

o

i

2

i=1

k

+2 o

i

o

j

i>j

D

k

o

4

Measuring Product Availability

Order fill rate

Product fill rate ( f

r

)

Cycle service level (CSL)

The fraction of replenishment cycles that end with all the customer demand being

met

The CSL is equal to the probability of not having a stockout in a replenishment

cycle

A CSL of 60 percent will typically result in a fill rate higher than 60%

The fraction of product demand that is satisfied from product in inventory

It is equivalent to the probability that product demand is supplied from available

inventory

The fraction of orders that are filled from available inventory

Order fill rates tend to be lower than product fill rates because all products must be

in stock for an order to be filled

CoolCLIPS

5

Product fill rate ( f

r

)

Order fill rate

Cycle service level (CSL)

Measuring Product Availability -- Page 5

On-hand

inventory

Order

received

Unfilled

demand

Filled

demand

0

Don't run out of inventory in 6 out of 10

replenishment cycles

An order for a total of 100 palms and has 90 in inventory

Customer may order a palm along with a calculator. The order is filled only if both

products are available.

CSL = 60%

fill rate > 60%

fill rate of 90%

In the 40% of the cycles where a stockout

does occur, most of the customer demand

is satisfied from inventory

Cycle

Microsoft

Microsoft

6

A replenishment policy consists of decisions regarding

When to reorder

How much to reorder.

Continuous review

Inventory is continuously tracked and an order for a lot size Q is placed

when the inventory declines to the reorder point (ROP).

Replenishment Policies

Periodic review

Inventory status is checked at regular periodic intervals and an order is

placed to raise the inventory level to a specified threshold, i.e. order up

to level (OUL) .

Q

P

7

A replenishment policy consists of decisions regarding

When to reorder

How much to reorder.

Continuous review

Inventory is continuously tracked and an order for a lot size Q is placed

when the inventory declines to the reorder point (ROP).

Replenishment Policies

Periodic review

Inventory status is checked at regular periodic intervals and an order is

placed to raise the inventory level to a specified threshold.

Q

P

8

Continuous Review System

Other names are: Reorder point system, fixed order quantity system

Decision rule

The remaining quantity of an item is reviewed each time a withdrawal is

made from inventory, to determine whether it is time to reorder.

Inventory position

IP = inventory position

OH = on-hand inventory

SR = scheduled receipts (open orders)

BO = units backordered or allocated

IP = OH+SR-BO

Whenever a withdrawal brings IP down to the reorder point (ROP), place

an order for Q (fixed) units.

9

Time

On-hand

inventory

Order

received

ROP

OH

IP

TBO

2

TBO

3

L

2

L

3

Order

received

OH

Q

IP

Order

placed

ROP = average demand during lead time + safety stock

Continuous Review System

ROP

Order

placed

L

1

TBO

1

10

Time

On-hand

inventory

TBO

2

TBO

3

L

2

L

3

Order

received

OH

Q

IP

Order

placed

ROP = average demand during lead time + safety stock

Continuous Review System

Order

placed

L

1

TBO

1

FIX

Order

received

ROP

OH

IP

11

Time

On-hand

inventory

TBO

2

TBO

3

L

2

L

3

ROP = average demand during lead time + safety stock

Continuous Review System

L

1

TBO

1

Order

received

OH

Q

IP

Order

placed

Order

placed

Order

received

ROP

IP

OH

12

Example

Given the following data

Average demand per week, D = 2,500

Standard deviation of weekly demand, s

D

=500

Average lead time for replacement, L = 2 weeks

Reorder point, ROP = 6,000

Average lot size, Q = 10,000

=ROP-DL=6,000-5,000=1,000 Safety inventory,ss

Cycle inventory

Average inventory

Average flow time

=Q/2=10,000/2=5,000

=5,000+1,000=6,000

= Average inventory / Throughput=6,000/2,500

=2.4weeks

13

Evaluating Cycle Service Level and Safety Inventory

D L L

L DL D o o = = and

CSL=Function ( ROP,D

L

,o

L

)

CSL= Prob (Demand during lead time of L weeks s ROP)

z=F

s

-1

(CSL)

ss=z Lo

D

Demand during lead time is normally distributed with a mean of D

L

and a

standard deviation of o

L

ROP=DL+Z Lo

D

CSL

14

Finding Safety Stock with a Normal Probability

Distribution for an 85 Percent CSL

Safety stock = z

o

L

Average

demand

during

lead time

Probability of stockout

(1.0 - 0.85= 0.15)

ROP

CSL = 85%

?

z

o

L

1

2

3

4:->ROP

15

Evaluating Cycle Service Level and Safety Inventory

D L L

L DL D o o = = and

CSL=Function ( ROP,D

L

,o

L

)

CSL= Prob (Demand during lead time of L weeks s ROP)

z=F

s

-1

(CSL)

ss=z Lo

D

Demand during lead time is normally distributed with a mean of D

L

and a

standard deviation of o

L

ROP=DL+Z Lo

D

16

Example

Given the following data

Q = 10,000

ROP = 6,000

L = 2 weeks

D=2,500/week,

D

=500

2x2,500=5,000 D

L

=DL=

=F(ROP, DL, o

L

)=F(6000,5000,707)

=NORMDIST(6000,5000,707,1)=0.92

= 2 x500=707

CSL=Proability of not stocking out in a cycle

o

L

= L o

D

17

Normal Distribution in Excel

Commands (Page 12)

) ( NORMINV ) (

) 0 , 1 , 0 , ( NORMDIST ) (

) 1 , 1 , 0 , ( NORMDIST or ) ( NORMDIST ) (

Normal Standard

1

p p F

x x f

x x x F

s

s

s

=

=

=

) , , ( NORMINV ) , , (

) 0 , , , ( NORMDIST ) , , (

) 1 , , , ( NORMDIST ) , , (

1

o o

o o

o o

p p F

x x f

x x F

=

=

=

18

Normal Distribution in Excel

(Demo)

19

Example

Given the following data

Q = 10,000

ROP = 6,000

L = 2 weeks

D=2,500/week, oD=500

CSL=0.9

2x2,500=5,000 D

L

=DL=

=F(ROP, DL, sL )=F(6000,5000,707)

=NORMDIST(6000,5000,707,1)=0.92

= 2 x500=707

ss=F

s

-1

(CSL

)

o

L

= L o

D

20

Example

Given the following data

D=2,500/week

o

D

=500

L = 2 weeks

Q = 10,000,

CSL=0.9

2x2,500=5,000 D

L

=DL=

=1.282x707=906

= 2 x500=707

ss=F

s

-1

(CSL)xo

L

=NORMDIST(CSL)xo

L

o

L

= L o

D

ROP=

2x2,500+906=5,906

21

Example

Given the following data

D=2,500/week

o

D

=500

L = 2 weeks

Q = 10,000,

CSL=0.9

2x2,500=5,000 D

L

=DL=

=1.282x707=906

= 2 x500=707

ss=F

s

-1

(CSL)xo

L

=NORMDIST(CSL)xo

L

o

L

= L o

D

ROP=

2x2,500+906=5,906

22

Periodic Review System

Other names are:

fixed interval reorder system or periodic reorder system.

Decision Rule

Review the items inventory position IP every T time periods. Place an

order equal to (OUL-IP) where OUL is the target inventory, that is, the

desired IP just after placing a new order.

The periodic review system has two parameters: T and

OUL.

Here Q varies, and time between orders (TBO) is fixed.

23

On-hand

inventory

Periodic Review System

OUL

Time

Order

placed

IP

L

T

L L

Order

received

OH

Q

2

IP

Order

placed

Q

1

Q

3

Order

placed

T

Protection interval

OH

IP

1

IP

3

IP

2

OUL

24

The new order must be large enough to make the inventory position, IP,

last not only beyond the next review, which is T periods from now, but

also for one lead time (L) after the next review. IP must be enough to

cover demand over a protection interval of T + L.

OUL =

Finding OUL

+

Safety stock for

protection interval

D

1

s

L T ) CSL ( F D ) L T ( o + + + =

Average demand

during protection

interval

25

Administratively convenient (such as each Friday)

weeks ) 52 (

D

EOQ

T =

weeks 4 or weeks 4.3 ) 52 (

1200

100

= = T

Selecting the Reorder Interval (T )

Example: Suppose D = 1200 /year and EOQ = 100

Approximation of EOQ

26

Example

Given the following data

D=2,500/week

o

D

=500

L = 2 weeks

T= 4weeks

CSL=0.9

(4+2)x2,500=15,000 D

T+L

=(T+L)D=

=1,570

ss=F

s

-1

(CSL)xo

T+L

=F

s

-1

(0.9)xo

T+L

OUL=D

T+L

+ss =

1,5000+1,570=16,570

D

T+L

= T+L oD= (4+2) x500=1,225

27

Periodic System versus Continuous System

Feature

Continuous review

system

Periodic review system

Order quantity Q-constant Q-variable

When to place

order

When quantity on hand

drops to the reorder level

When the review period

arrives

Recordkeeping Each time a withdrawal or

addition is made

Counted only at review period

Size of inventory Less than periodic system Larger than continuous system

Factors driving

safety inventory

Demand uncertainty

Replenishment lead time

Demand uncertainty

Replenishment lead time

Reorder interval

Type of items Higher-priced, critical, or

important items

28

Evaluating Fill Rate Given a Replenishment Policy

f (x) is density function of demand

distribution during the lead time

f

r

=1- =

In the case of normal distribution, we have

ESC

X=ROP

}

=

(X-ROP) f(x)dx

For a continuous review policy

Expected shortage per replenishment cycle (ESC) is the average units

of demand that are not satisfied from inventory in stock per cycle

Q

Q-ESC

Q

ESC

29

Evaluating Fill Rate Given a Replenishment Policy

f (x) is the density function of demand

distribution during the lead time

f

r

=1- =

In the case of normal distribution, we have

ESC

X=ROP

}

=

(X-ROP) f(x)dx

For a continuous review policy

Expected shortage per replenishment cycle (ESC) is the average units

of demand that are not satisfied from inventory in stock per cycle

ESC

Q

Q-ESC

Q

30

Evaluating Fill Rate Given a Replenishment Policy

f (x) is density function of demand

distribution during the lead time

f

r

=1- =

In the case of normal distribution, we have

ESC

X=ROP

}

=

(X-ROP) f(x)dx

For a continuous review policy

Expected shortage per replenishment cycle (ESC) is the average units

of demand that are not satisfied from inventory in stock per cycle

ESC

Q

Q-ESC

Q

31

Evaluating Fill Rate Given a Replenishment Policy

( ) | |

( ) 0 1 0

1 1 0 1

1

, , , /

, , , /

L L

L

L

s L

L

s

ss NORMDIST

ss NORMDIST ss

ss

f

ss

F ss ESC

o o

o

o

o

o

+

=

|

|

.

|

\

|

+

(

|

|

.

|

\

|

=

f (x) is density function of demand

distribution during the lead time

f

r

=1- =

In the case of normal distribution, we have

ESC

X=ROP

}

=

(X-ROP) f(x)dx

For a continuous review policy

Expected shortage per replenishment cycle (ESC) is the average units

of demand that are not satisfied from inventory in stock per cycle

ESC

Q

Q-ESC

Q

32

Proof

=

}

=

=ROP x

dx x f ROP x ESC ) ( ) (

}

+ =

ss D x

D x

L

L

L

dx

L L

e ss D x

2

1

) (

2 2

2 ) ( o

o t

WIKIPEDIA

WIKIPEDIA

33

o

L

dz

Proof

=

}

=

=ROP x

dx x f ROP x ESC ) ( ) (

Substituting Z=(X-D

L

)/o

L

and dx=o

L

dz , we have

}

=

L

ss z

z

L

dz e ss z ESC

o

t

o

/

2 /

2

2

1

) (

}

+ =

ss D x

D x

L

L

L

dx

L L

e ss D x

2

1

) (

2 2

2 ) ( o

o t

34

Proof

}

=

L

ss z

z

L

dz e ss z ESC

o

t

o

/

2 /

2

2

1

) (

=

}

=

=ROP x

dx x f ROP x ESC ) ( ) (

Substituting Z=(X-D

L

)/o

L

and dx=o

L

dz , we have

}

+ =

ss D x

D x

L

L

L

dx

L L

e ss D x

2

1

) (

2 2

2 ) ( o

o t

}

=

=

L

ss z

z

dz ss e

o t /

2 /

2

2

1

}

+

=

L

ss z

z

L

dz z e

o t

o

/

2 /

2

2

1

35

Proof

}

=

L

ss z

z

L

dz e ss z ESC

o

t

o

/

2 /

2

2

1

) (

}

=

=

L

ss z

z

dz ss e

o t /

2 /

2

2

1

}

+

=

L

ss z

z

L

dz z e

o t

o

/

2 /

2

2

1

36

Proof

}

=

L

ss z

z

L

dz e ss z ESC

o

t

o

/

2 /

2

2

1

) (

}

+

=

L

ss z

z

L

dz z e

o t

o

/

2 /

2

2

1

+ = )] / ( 1 [

L s

ss F ss o

}

=

=

L

ss z

z

dz ss e

o t /

2 /

2

2

1

37

Proof

}

=

L

ss z

z

L

dz e ss z ESC

o

t

o

/

2 /

2

2

1

) (

}

+

=

L

ss z

z

L

dz z e

o t

o

/

2 /

2

2

1

+ = )] / ( 1 [

L s

ss F ss o

}

=

=

L

ss z

z

dz ss e

o t /

2 /

2

2

1

}

o =

t

o

2

L

2

2 / ss w

w

L

dw

2

1

e

]

2

1

[ )] / ( 1 [

2

2

1

|

|

.

|

\

|

+ =

L

ss

L L s

e ss F ss

o

t

o o

) 2 / : (note

2

z w =

dw=2zdz/2

dw=zdz

38

Proof

}

=

L

ss z

z

L

dz e ss z ESC

o

t

o

/

2 /

2

2

1

) (

}

+

=

L

ss z

z

L

dz z e

o t

o

/

2 /

2

2

1

+ = )] / ( 1 [

L s

ss F ss o

}

=

=

L

ss z

z

dz ss e

o t /

2 /

2

2

1

}

2

2 /

2

2

1

L

ss w

w

L

dw e

o

t

o

]

2

1

[ )] / ( 1 [

2

2

1

|

|

.

|

\

|

+ =

L

ss

L L s

e ss F ss

o

t

o o

) 2 / : (note

2

z w =

ESC derivation

e

t

e

o e

d e

L

ss

=

}

2

2 /

2

2

1

0

=

2

2 /

2

2

1

L

ss

e

o

e

t

2

) / (

2

1

2

1 L

ss

e

o

t

=

39

Proof

}

=

L

ss z

z

L

dz e ss z ESC

o

t

o

/

2 /

2

2

1

) (

}

+

=

L

ss z

z

L

dz z e

o t

o

/

2 /

2

2

1

+ = )] / ( 1 [

L s

ss F ss o

}

=

=

L

ss z

z

dz ss e

o t /

2 /

2

2

1

}

o =

t

o

2

L

2 / ss w

w

L

2

dw

2

1

e

) 2 / : (note

2

z w =

]

2

1

[ )] / ( 1 [

2

2

1

|

|

.

|

\

|

+ =

L

ss

L L s

e ss F ss

o

t

o o

) / ( )] / ( 1 [

L s L L s

ss f ss F ss o o o + =

40

Evaluating Fill Rate Given a Replenishment Policy

( ) | |

( ) 0 1 0

1 1 0 1

1

, , , /

, , , /

L L

L

L

s L

L

s

ss NORMDIST

ss NORMDIST ss

ss

f

ss

F ss ESC

o o

o

o

o

o

+

=

|

|

.

|

\

|

+

(

|

|

.

|

\

|

=

f (x) is density function of demand

distribution during the lead time

f

r

=1- =

In the case of normal distribution, we have

ESC

X=ROP

}

=

(X-ROP) f(x)dx

For a continuous review policy

Expected shortage per replenishment cycle (ESC) is the average units

of demand that are not satisfied from inventory in stock per cycle

ESC

Q

Q-ESC

Q

41

Example

For a continuous review system with the following data

Lot size ,Q=10,000

D

L

=5,000

o

L

= 707

ss=ROP-DL=6,000-5,000=1,000

ESC= -1,000[1-NORMDIST(1000/707,0,1,1)]

f

r

= =0.9975

10,000

10,000-25

+707xNORMDIST(1000/707,0,1,1)

=25

42

Excel-Demo

For a continuous review system with the following data

Lot size ,Q=10,000

D

L

=5,000

o

L

= 707

ss=ROP-DL=6,000-5,000=1,000

ESC= -1,000[1-NORMDIST(1000/707,0,1,1)]

f

r

= =0.9975

10,000

10,000-25

+707xNORMDIST(1000/707,0,1,1)

=25

43

Factors Affecting Fill Rate

Safety inventory

Fill rate increases if safety inventory is increased. This also increases the

cycle service level.

Lot size

Fill rate increases with the increase of the lot size even though cycle

service level does not change.

44

Factors Affecting Fill Rate -- Page 42

L s

CSL F ss o =

) (

1

) / ( )] / ( 1 [

L s L L s

ss f ss F ss ESC o o o + =

f

r

= 1- ESC/Q

f

r

= 1- ESC/Q

CSL = F(ROP, D

L

, s

L

) is independent of Q

Safety inventory

Fill rate increases if safety inventory is increased. This also increases the

cycle service level.

| | + | , f , , CSL ESC ss

r

Lot size

Fill rate increases on increasing the lot size even though cycle service

level does not change.

45

Evaluating Safety Inventory

Given Desired Fill Rate

|

|

.

|

\

|

+

(

|

|

.

|

\

|

= =

L

s

L

L

s

ss ss

F ss ESC

f

o

o

o

1 250

|

|

|

.

|

\

|

(

(

(

|

|

|

.

|

\

|

+ = 0 , 1 , 1 , 1 250

L

ss

NORMDIST

L

L

ss

NORMSDIST ss

o

o

o

If desired fill rate is fr = 0.975, how much safety inventory should be held?

ESC = (1 - fr)Q = 250

Solve

46

Excel-Demo

47

Evaluating Safety Inventory

Given Desired Fill Rate

|

|

.

|

\

|

+

(

|

|

.

|

\

|

= =

L

s

L

L

s

ss ss

F ss ESC

f

o

o

o

1 250

|

|

|

.

|

\

|

(

(

(

|

|

|

.

|

\

|

+ = 0 , 1 , 1 , 1 250

L

ss

NORMDIST

L

L

ss

NORMSDIST ss

o

o

o

If desired fill rate is fr = 0.975, how much safety inventory should be held?

ESC = (1 - fr)Q = 250

Solve

48

Evaluating Safety Inventory Given Fill

Rate

Fill Rate Safety Inventory

97.5% 67

98.0% 183

98.5% 321

99.0% 499

99.5% 767

The required safety inventory grows rapidly with an

increase in the desired product availability (fill rate).

49

Two Managerial Levers to Reduce Safety Inventory

Safety inventory increases with an increase in the lead time and

the standard deviation of periodic demand.

Reduce the underlying uncertainty of demand ( o

D

)

Reduce the supplier lead time (L)

k

If lead time decreases by a factor of k, safety inventory in the retailer

decreases by a factor of .

If o

D

is reduced by a factor of k, safety inventory decreases by a

factor of k.

The reduction in o

D

can be achieved by reducing forecast uncertainty,

such as by sharing demand information through the supply chain.

It is important for the retailer to share some of the resulting benefits to

the supplier.

50

Impact of Supply (Lead time) Uncertainty on

Safety Inventory

2 2 2

L D L

S D L + = o o

Assume demand per period and replenishment lead time are normally distributed

D:Average demand per period

o

D

:Standard deviation of demand per period (demand uncertainty)

L: Average lead time for replenishment

S

L

:Standard deviation of lead time (supply uncertainty)

Consider continuous review policy, we have:

Demand during the lead time is N(D

L

,o

L

2

)

DL D

L

=

51

Example

550 , 17 7 2500 500 7

500 , 17 7 500 , 2

9 . 0 ) days ( 7 ) days ( 7 500 500 , 2

2 2 2 2 2 2

= + = + =

= = =

= = = = =

L D L

L

L D

S D L

DL D

CSL S L D

o o

o

( ) 491 , 22

1

= =

L s

CSL F ss o

S

L

L

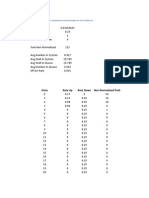

ss(units) ss(days)

6 15,058 7.72

5 12,570 6.44

4 10,087 5.17

3 7,616 3.90

2 5,172 2.65

1 2,828 1.45

0 1,323 0.68

Suppose we have

Required safety inventory,

A reduction in lead time uncertainty can help reduce safety inventory

19,298

16,109

12,927

9,760

6,628

3,625

1,695

52

/

5

CoolCLIPS

(http://dir.coolclips.com/Popular/World_of_Industry/Food/Shopping_cart_full_of_gr

oceries_vc012266.html )2011/12/28465265

6

WIKIPEDIA(http://en.wikipedia.org/wiki/File:Palm-m505.jpg)

2012/2/21

6

Microsoft Office 2007Microsoft

465265

19

19

22

22

53

/

33

WIKIPEDIA(http://en.wikipedia.org/wiki/File:10_DM_Serie4_Vorderseite.jpg)

2012/2/21

43

47

47

54

You might also like

- Supply Chain Management Lecture OutlineDocument39 pagesSupply Chain Management Lecture OutlinekmeshramNo ratings yet

- Lect 12 EOQ SCMDocument38 pagesLect 12 EOQ SCMApporva MalikNo ratings yet

- Lect 12 - Continuous & Periodic Review SystemsDocument38 pagesLect 12 - Continuous & Periodic Review SystemsBharath BalasubramanianNo ratings yet

- SCM - 13-14 - Chapter 12 - UpdatedDocument15 pagesSCM - 13-14 - Chapter 12 - UpdatedUdhav JoshiNo ratings yet

- Managing Uncertainty in A Supply Chain Safety InventoryDocument41 pagesManaging Uncertainty in A Supply Chain Safety InventorySyed Kamran AbbasNo ratings yet

- Managing Uncertainty: Safety Inventory: Peeyush Pandey Assistant Professor IIM RohtakDocument31 pagesManaging Uncertainty: Safety Inventory: Peeyush Pandey Assistant Professor IIM RohtakdurgaNo ratings yet

- Scma 444 - Exam 2 Cheat SheetDocument2 pagesScma 444 - Exam 2 Cheat SheetAshley PoppenNo ratings yet

- Chapter 12Document61 pagesChapter 12Sandeep PanNo ratings yet

- W3 - Inventory Management Part 2 (Pendek 2022 2023)Document47 pagesW3 - Inventory Management Part 2 (Pendek 2022 2023)HENRIKUS HARRY UTOMONo ratings yet

- DAO2703 DSC2006 Lecture 6 On Feb 19Document32 pagesDAO2703 DSC2006 Lecture 6 On Feb 19Victoria Kayla TiaraNo ratings yet

- Managing Uncertainty in The Supply Chain Safety Inventory8&9Document30 pagesManaging Uncertainty in The Supply Chain Safety Inventory8&9niruthir100% (1)

- 10 Lecture - 9 - HandoutDocument10 pages10 Lecture - 9 - HandoutAbhiNo ratings yet

- Lecture 20Document36 pagesLecture 20pavan79No ratings yet

- Reorder Point 2Document38 pagesReorder Point 2Abhilash NoxNo ratings yet

- 2.0 Managing Uncertainty in Demand With Safety StockDocument19 pages2.0 Managing Uncertainty in Demand With Safety Stocksaswat1953419No ratings yet

- P ModelsDocument4 pagesP ModelsBreno FrançaNo ratings yet

- Inventory ControlDocument26 pagesInventory ControlhajarawNo ratings yet

- CT13&14Document49 pagesCT13&14Sushant RanjanNo ratings yet

- Chapter 11-Without AggregationDocument42 pagesChapter 11-Without AggregationMayank PrakashNo ratings yet

- EOQ Model for Inventory ManagementDocument32 pagesEOQ Model for Inventory ManagementFurikuri AziziNo ratings yet

- Chapter 17. Inventory Control: Inventory Is The Stock of Any Item or Resource Used in AnDocument21 pagesChapter 17. Inventory Control: Inventory Is The Stock of Any Item or Resource Used in AnHassan SalamaNo ratings yet

- CH 12 Student KrajewskiDocument28 pagesCH 12 Student KrajewskiprasanthmctNo ratings yet

- Safety Inventory: P.Chandiran, LIBADocument42 pagesSafety Inventory: P.Chandiran, LIBAHammad AhmedNo ratings yet

- Pom Ii: Independent Demand InventoryDocument44 pagesPom Ii: Independent Demand InventoryAshokNo ratings yet

- Stochastic Inventory ModelsDocument55 pagesStochastic Inventory ModelsLaura RobayoNo ratings yet

- Inventory Management: Bus Adm 370 - CHP 12 Inventory MGMTDocument7 pagesInventory Management: Bus Adm 370 - CHP 12 Inventory MGMTSidharth GoyalNo ratings yet

- Managing Inventory Throughout The Supply ChainDocument52 pagesManaging Inventory Throughout The Supply ChainJaishree VyasNo ratings yet

- 17 Safety InventoryDocument47 pages17 Safety Inventorymishrakanchan 2396No ratings yet

- Customer Demand Variability and Safety Stock CalculationDocument35 pagesCustomer Demand Variability and Safety Stock CalculationjayakumargjNo ratings yet

- Stochastic Inventory ModelingDocument34 pagesStochastic Inventory ModelinghhhhNo ratings yet

- Safety Inventory - NitinDocument51 pagesSafety Inventory - NitinnitiinNo ratings yet

- Topic 4 Probabilistic Inventory Control ModelDocument36 pagesTopic 4 Probabilistic Inventory Control ModelCarstene RenggaNo ratings yet

- Determining Optimal Level of Product Availability: Uday Venkatadri January 11, 2018Document19 pagesDetermining Optimal Level of Product Availability: Uday Venkatadri January 11, 2018Hasan ShahrierNo ratings yet

- CH 15 Inventory ManagementDocument21 pagesCH 15 Inventory ManagementAshwin MishraNo ratings yet

- Framework & MethodologyDocument4 pagesFramework & MethodologyRahul VermaNo ratings yet

- Chap 015Document43 pagesChap 015Ponkiya AnkitNo ratings yet

- Optimize Inventory with EOQ and ROP ModelsDocument14 pagesOptimize Inventory with EOQ and ROP ModelsHaider Abdul QadirNo ratings yet

- 5.2 Inventory Management (Stochastic Model)Document35 pages5.2 Inventory Management (Stochastic Model)saheb167No ratings yet

- Chapter 05Document75 pagesChapter 05mushtaque61No ratings yet

- Inventory ManagementDocument8 pagesInventory ManagementDiti biswasNo ratings yet

- Cycle InventoryDocument13 pagesCycle InventoryUmang ZehenNo ratings yet

- Inven MNGTDocument32 pagesInven MNGTMahal KitaNo ratings yet

- Slides Sessions 7-10Document58 pagesSlides Sessions 7-10020Abhisek KhadangaNo ratings yet

- Chap015 Inventory ControlDocument43 pagesChap015 Inventory ControlKhushbu ChandnaniNo ratings yet

- Inventory Planning: Nazmun NaharDocument29 pagesInventory Planning: Nazmun NaharKamrulHassanNo ratings yet

- Primavera Delay ActivitiesDocument40 pagesPrimavera Delay ActivitiesPraveenNo ratings yet

- PPIC-5b-01-Independent Demand Ordering Systems-Rabu-4-11 Maret - 2020Document25 pagesPPIC-5b-01-Independent Demand Ordering Systems-Rabu-4-11 Maret - 2020Daffa JNo ratings yet

- Inventory Management Chapter 2 Independent Demand SystemsDocument73 pagesInventory Management Chapter 2 Independent Demand SystemsHungNo ratings yet

- UNIT-3: Inventory ManagementDocument22 pagesUNIT-3: Inventory ManagementJEERU BHAGAVANULUNo ratings yet

- Inventory ManagementDocument7 pagesInventory ManagementTusharNo ratings yet

- ConsolidationsDocument6 pagesConsolidationsEvarist Lema MemberNo ratings yet

- Chapter 9 FormulaDocument4 pagesChapter 9 Formulamay2mstNo ratings yet

- 4 Inventory Management and Risk PoolingDocument54 pages4 Inventory Management and Risk PoolingSpandana AchantaNo ratings yet

- Demand Variability: TV DistributorDocument20 pagesDemand Variability: TV DistributorPawan RajputNo ratings yet

- INVENTORY PLANNINGDocument7 pagesINVENTORY PLANNINGandov9No ratings yet

- Supply Chain Management: Indian Institute of Management LucknowDocument29 pagesSupply Chain Management: Indian Institute of Management LucknowParidhi VarmaNo ratings yet

- InventoryDocument65 pagesInventoryRavindra GoyalNo ratings yet

- CISA EXAM-Testing Concept-Recovery Time Objective (RTO) & Recovery Point Objective (RPO)From EverandCISA EXAM-Testing Concept-Recovery Time Objective (RTO) & Recovery Point Objective (RPO)Rating: 1 out of 5 stars1/5 (2)

- LP Dual Primal EquivalenceDocument27 pagesLP Dual Primal EquivalenceRohan ViswanathNo ratings yet

- Sai Sameer Tammana, Rohan ViswanathDocument1 pageSai Sameer Tammana, Rohan ViswanathRohan ViswanathNo ratings yet

- Sai Sameer Tammana, Rohan ViswanathDocument1 pageSai Sameer Tammana, Rohan ViswanathRohan ViswanathNo ratings yet

- Alpha Delay Overtime Objective 0.999 20 240 20.22 0.001 140 60 60.08 0.5 100 100 100Document1 pageAlpha Delay Overtime Objective 0.999 20 240 20.22 0.001 140 60 60.08 0.5 100 100 100Rohan ViswanathNo ratings yet

- Answers Are Due Before Start of Class On Thursday, March 27, 2014Document2 pagesAnswers Are Due Before Start of Class On Thursday, March 27, 2014Rohan ViswanathNo ratings yet

- 第六單元:Inventory Management: Safety Inventory (I)Document54 pages第六單元:Inventory Management: Safety Inventory (I)Rohan ViswanathNo ratings yet

- SK II Japan Marketing Plan - Group 1-LibreDocument23 pagesSK II Japan Marketing Plan - Group 1-LibreRohan ViswanathNo ratings yet

- Case SCMDocument9 pagesCase SCMbarkha_agarwal_4No ratings yet

- Ioe 419 ExamDocument6 pagesIoe 419 ExamRohan ViswanathNo ratings yet

- Ioe 419 Exam Problme 1Document50 pagesIoe 419 Exam Problme 1Rohan ViswanathNo ratings yet

- EWC Case Studies: The Merloni GroupDocument10 pagesEWC Case Studies: The Merloni GroupRohan ViswanathNo ratings yet

- PDCA CyclesDocument9 pagesPDCA CyclesRohan ViswanathNo ratings yet

- Chi Square&F: StatsDocument21 pagesChi Square&F: StatsLauren McNamaraNo ratings yet

- Scheduling Incoming and Outgoing Semi Trailers for Cross-Docking EfficiencyDocument6 pagesScheduling Incoming and Outgoing Semi Trailers for Cross-Docking EfficiencyRohan ViswanathNo ratings yet

- 591 DiagramDocument1 page591 DiagramRohan ViswanathNo ratings yet

- 7 1Document4 pages7 1Rohan ViswanathNo ratings yet

- 007 0660Document34 pages007 0660Rohan ViswanathNo ratings yet

- Chi Square&F: StatsDocument21 pagesChi Square&F: StatsLauren McNamaraNo ratings yet

- Case Study - 440Document4 pagesCase Study - 440Rohan ViswanathNo ratings yet

- Standard Uniform Standard TriangularDocument1 pageStandard Uniform Standard TriangularRohan ViswanathNo ratings yet

- Whats AppDocument4 pagesWhats AppPetruNo ratings yet

- Tesla China Chief Unveils Aggressive Growth Plan For China - ReutersDocument4 pagesTesla China Chief Unveils Aggressive Growth Plan For China - ReutersRohan ViswanathNo ratings yet

- Carmaking - A Drive To Lego Land - FTDocument4 pagesCarmaking - A Drive To Lego Land - FTRohan ViswanathNo ratings yet

- Assignment 6Document1 pageAssignment 6Rohan ViswanathNo ratings yet

- IOE 591 - Crossdocks (XD) : Shape IOE 591 - Crossdocks (XD) : ShapeDocument17 pagesIOE 591 - Crossdocks (XD) : Shape IOE 591 - Crossdocks (XD) : ShapeRohan ViswanathNo ratings yet

- An Example of Dantzig-Wolfe DecompositionDocument7 pagesAn Example of Dantzig-Wolfe DecompositionRohan ViswanathNo ratings yet

- IOE 510 FinalsDocument1 pageIOE 510 FinalsRohan ViswanathNo ratings yet

- Copyright Notice for Private StudyDocument87 pagesCopyright Notice for Private StudyRohan ViswanathNo ratings yet

- Stutent's Solution Manual To Introduction To Statistical Quality Control 5E - MontgomeryDocument472 pagesStutent's Solution Manual To Introduction To Statistical Quality Control 5E - MontgomeryDoem69% (13)

- Mathematical Programming - PART 2 - LINEAR PROGRAMMING - 20.6. Exercises - PGDocument2 pagesMathematical Programming - PART 2 - LINEAR PROGRAMMING - 20.6. Exercises - PGRohan ViswanathNo ratings yet