Professional Documents

Culture Documents

Materials

Uploaded by

GamalMahranCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Materials

Uploaded by

GamalMahranCopyright:

Available Formats

Marine Services

MATERIALS

CONTENTS

Materials certification

Welding processes

Welder and weld qualification

Weld quality

design

construct

operate

2001 Lloyds Register of Shipping

Marine Services

MATERIALS

MATERIAL CERTIFICATION

2001 Lloyds Register of Shipping

Marine Services

MATERIALS

MATERIAL CERTIFICATION

2001 Lloyds Register of Shipping

Marine Services

MATERIAL CERTIFICATION

MATERIALS

Production Steel processes

Processes for steel

De-oxidation

Supply condition

As rolled

Normalised

Controlled rolling

TMCP

Pipes and tubes

Forgings

Casting

2001 Lloyds Register of Shipping

Marine Services

MATERIAL CERTIFICATION

MATERIALS

Supply condition

Normalized

R

NR

Ar3

As rolled

2001 Lloyds Register of Shipping

Normalized

rolled

Thermomechanical

Marine Services

MATERIALS

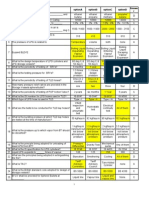

LR ROLLED STEEL PLATES

Strength

Yield

stress

Tensile

strength

Elong.

Charpy V - notch

min. average (J)

N/mm2

N/mm2

50 mm

max.

>50<70

mm

>70 mm

Normal

235

400 - 520

22

27

34

41

32

315

440 - 590

22

31

38

46

36

355

490 - 620

21

34

41

50

Impact test temperatures B & AH = 0 C, D & DH = -20 C,

E & EH = -40 C. Tests on grade A not required unless > 50 mm

2001 Lloyds Register of Shipping

Marine Services

MATERIALS

IACS Recommended Comparable Standards

IACS

grade

ISO 630

ISO 4950

EN 10025

EN 10113

A

B

D

E

AH32

DH32

EH32

AH36

DH36

EH36

Fe 360B

Fe 360C

Fe 360D

Fe 510C

Fe 510D

E 355E

S235JRG2

S235J0

S235J2G3

S275NL/ML

S355N/M

S355N/M

S355ML/ML

ASTM A131 JIS G3106

A

B

D

E

AH32

DH32

EH32

AH36

DH36

EH36

* check impact properties

2001 Lloyds Register of Shipping

SM41B

SM41B

SM41C*

SM50B

SM50C*

SM53B

SM53C*

-

Marine Services

MATERIALS

Minimum requirements to assess equivalency

Items to be

considered

Requirements

Comments

Condition of

supply

Same or better

Supply condition in increasing order;

- as rolled (AR)

- normalised rolled (NR)

- furnace normalised (N)

- thermo-mechanically rolled (TM)

Tolerances

Same or better

Permissible under thickness tolerances;

- plates: 0.3 mm

- sections: according to a recognised

standard.

2001 Lloyds Register of Shipping

Marine Services

MATERIAL CERTIFICATION

MATERIALS

Aluminium Alloys

Grade and alloys

Heat treatment

Transition strips

Copper Alloys

Types

Other materials

Steels

Plastics

2001 Lloyds Register of Shipping

Marine Services

MATERIAL CERTIFICATION

MATERIALS

Works approval

Audit records

Equipment

NDE, Welding and heat treatment

Approval tests

2001 Lloyds Register of Shipping

Marine Services

MATERIAL CERTIFICATION

MATERIALS

Testing

Chemical

Testing Process

Major chemical element

Grain refining elements

Mechanical

Tensile

Toughness (Impact)

Hardness

2001 Lloyds Register of Shipping

Marine Services

MATERIAL CERTIFICATION

MATERIALS

Marking

Class society

Heat No

Recording

Mill sheets

Composition

Mechanical properties

Supply condition

Certification

Stock holders

2001 Lloyds Register of Shipping

Marine Services

MATERIAL CERTIFICATION

MATERIALS

Plate defects

Hydrogen cracking

Segregation

Inclusions

De-lamination

2001 Lloyds Register of Shipping

Marine Services

MATERIAL CERTIFICATION

MATERIALS

Casting defects

Mis runs

Cold laps

Cold shuts

Scabs

Rat tails

Blow holes, pin holes, air locks

Piping

Hot tears

Cold cracking/clinking

Sagging

Collapse

Segregation

2001 Lloyds Register of Shipping

Marine Services

MATERIAL CERTIFICATION

MATERIALS

Forging defects

Clinks

Inclusions

Seams

Tool marks

Bursts

Segregation

Porosity

Hydrogen cracks

Unsoundness

Laps

Cracks

2001 Lloyds Register of Shipping

Marine Services

WELDING PROCESSES

Materials dept CD

MATERIALS

2001 Lloyds Register of Shipping

Marine Services

WELDING PROCESSES

MMA

MATERIALS

2001 Lloyds Register of Shipping

Marine Services

WELDING PROCESSES

Submerged Arc

MATERIALS

2001 Lloyds Register of Shipping

Marine Services

WELDING PROCESSES

GSMA

MATERIALS

2001 Lloyds Register of Shipping

Marine Services

WELDING PROCESSES

Tungsten inert gas

MATERIALS

2001 Lloyds Register of Shipping

Marine Services

WELDING PROCESSES

Electro slag

MATERIALS

2001 Lloyds Register of Shipping

Marine Services

WELDING PROCESSES

Elecro gas

MATERIALS

2001 Lloyds Register of Shipping

Marine Services

WELDING PROCESSES

Laser

MATERIALS

2001 Lloyds Register of Shipping

Marine Services

WELDER AND WELD QUALIFICATION

MATERIALS

Why Qualify

TECHNICAL REQUIREMENTS

QUALITY ASSURRED

Correct arc length

All depends on SKILL of

welder

Control position of arc

Maintain travel speed

Must assess skill of welder for

each type of welding process,

joint type, material, etc.

(to prevent contamination of the weld

by atmosphere)

(to obtain good fusion)

(to produce welds with good

appearance)

2001 Lloyds Register of Shipping

Marine Services

MATERIALS

WELDER AND WELD QUALIFICATION

Weld qualification tests

Inspection

Visual

Crack Dye penetrant

Ultra Sonic Radiographic

Destructive testing

Macro section

Hardness

Tensile; Transverse, Weld metal,

Bend test; Face, Root

Charpy tests; HAZ, Fusion line, Weld metal

2001 Lloyds Register of Shipping

Marine Services

WELDER AND WELD QUALIFICATION

Qualification tests

MATERIALS

2001 Lloyds Register of Shipping

Marine Services

WELDER AND WELD QUALIFICATION

MATERIALS

Responsibilities

MANUFACTURER RESPONSIBLE

FOR:-

EXAMINER/TEST BODY

RESPONSIBLE FOR:-

Providing the WPS to be used for

testing

Organising qualification testing

Witnessing testing

Ensuring welders are qualified for

Verifying welders possess the

Maintaining and updating

Approval of extension to validity

the work to be undertaken

certificates

2001 Lloyds Register of Shipping

required skills, and that all

qualifications are in compliance

with Codes and Standards

dates

Marine Services

WELDER AND WELD QUALIFICATION

MATERIALS

Why Welding procdures?

PROBLEM

REQUIREMENTS

Construction

Approved Consumables

Such consumables have been shown to

achieve typical tensile strengths and

impact properties.

Welder Qualification

Show that welder is capable of

performing a weld with a specified

technique.

Welding Procedures

Essential that builder can demonstrate

that they can achieve the required

properties using welding techniques,

material and practices prevalent in

works. This is achieved by performing a

simulation of proposed joint and testing

it destructively

Need to know that construction welds

have acceptable mechanical properties

2001 Lloyds Register of Shipping

Marine Services

WELDER AND WELD QUALIFICATION

Weld procedure

MATERIALS

2001 Lloyds Register of Shipping

Marine Services

WELD INSPECTION

Materials dept CD

MATERIALS

2001 Lloyds Register of Shipping

Marine Services

WELD INSPECTION

Visual

MATERIALS

2001 Lloyds Register of Shipping

Marine Services

WELD INSPECTION

Dye penetrant

MATERIALS

2001 Lloyds Register of Shipping

Marine Services

WELD INSPECTION

Magnetic particle

MATERIALS

2001 Lloyds Register of Shipping

Marine Services

WELD INSPECTION

Eddy current

MATERIALS

2001 Lloyds Register of Shipping

Marine Services

WELD INSPECTION

Ultrasonic

MATERIALS

2001 Lloyds Register of Shipping

Marine Services

WELD INSPECTION

Radio graph

MATERIALS

2001 Lloyds Register of Shipping

You might also like

- Welding in Pipelines - PV - StructureDocument6 pagesWelding in Pipelines - PV - StructureanshumanNo ratings yet

- LR - Material and Qualification Procedures For ShipsDocument17 pagesLR - Material and Qualification Procedures For ShipsprasetyoNo ratings yet

- Lloyd S Register Sec. III 2015 Edition OverviewDocument23 pagesLloyd S Register Sec. III 2015 Edition OverviewYoshua PortugalNo ratings yet

- ML041000284 PDFDocument19 pagesML041000284 PDFAnuj DeoNo ratings yet

- List of Irs SpecificationsDocument4 pagesList of Irs SpecificationsSambhav PoddarNo ratings yet

- Laser Dismantling of PHWR Spent Fuel Bundles and De-Cladding of Fuel Pins in The Highly Radioactive Hot CellsDocument6 pagesLaser Dismantling of PHWR Spent Fuel Bundles and De-Cladding of Fuel Pins in The Highly Radioactive Hot CellsK. JayarajanNo ratings yet

- Development of An Advanced Servo Manipulator For Remote Handling in Nuclear InstallationsDocument8 pagesDevelopment of An Advanced Servo Manipulator For Remote Handling in Nuclear InstallationsK. JayarajanNo ratings yet

- Incident Learning BalcoDocument1 pageIncident Learning BalcothehinduNo ratings yet

- Heat Treatment of SteelsDocument6 pagesHeat Treatment of SteelsSrinivas LaishettyNo ratings yet

- Hydraulic MachineryDocument60 pagesHydraulic MachinerySushil Kumar Singh100% (1)

- Weld GaugesDocument15 pagesWeld GaugessojeckNo ratings yet

- Day-1 Lecture 1 Welding TechnologyDocument141 pagesDay-1 Lecture 1 Welding TechnologyRavi ShankarNo ratings yet

- Fabrication of Components at Dillinger Huette Heavy FabricationDocument82 pagesFabrication of Components at Dillinger Huette Heavy Fabrication66apenlullenNo ratings yet

- Welding of Stainless Steel - Sndo KouDocument17 pagesWelding of Stainless Steel - Sndo KouGovind RajNo ratings yet

- Tri Sector Rotary Air APHDocument2 pagesTri Sector Rotary Air APHthehinduNo ratings yet

- PHYS430: Advanced Lab Laith Marzouka ID: Dr. Khaled Eid: Topic: Vacuum SystemDocument6 pagesPHYS430: Advanced Lab Laith Marzouka ID: Dr. Khaled Eid: Topic: Vacuum SystemLaith MarzoukaNo ratings yet

- Advanced Servo Manipulator: A Milestone in Remote Handling TechnologyDocument12 pagesAdvanced Servo Manipulator: A Milestone in Remote Handling TechnologyK. Jayarajan0% (2)

- Friction Loss To Stock Flow in PipesDocument1 pageFriction Loss To Stock Flow in PipesChristian VargasNo ratings yet

- ProcessBuildingVentilationSystemDesignDescription - CM A ME 001 R6 PDFDocument37 pagesProcessBuildingVentilationSystemDesignDescription - CM A ME 001 R6 PDFShaimaa SaadNo ratings yet

- Vacuum Furnace ControlDocument2 pagesVacuum Furnace Controlmsaadullah0% (1)

- Report On NTPC Industrial Training at Barh (Patna)Document24 pagesReport On NTPC Industrial Training at Barh (Patna)Gautam KumarNo ratings yet

- Quality Control in Welding Repair of Pelton RunnerDocument8 pagesQuality Control in Welding Repair of Pelton RunnerDheeraj ThakurNo ratings yet

- SA253MA DetailDocument16 pagesSA253MA Detailksquare2001100% (1)

- Create 1 - 2 Hex Bolt - SolidWorks TutorialsDocument9 pagesCreate 1 - 2 Hex Bolt - SolidWorks Tutorialsandres_palacios_1433No ratings yet

- Development of Hot Cells and Their Embedded PartsDocument3 pagesDevelopment of Hot Cells and Their Embedded PartsK. JayarajanNo ratings yet

- Chap22 WELDING REPRESENTATIONDocument33 pagesChap22 WELDING REPRESENTATION7abib77No ratings yet

- Types of ElectrodesDocument8 pagesTypes of ElectrodesTIBEBUNo ratings yet

- 750-180 OM Boiler Feed Systems 10-08Document23 pages750-180 OM Boiler Feed Systems 10-08Sumit ChaurasiaNo ratings yet

- PMP CH 5-2Document76 pagesPMP CH 5-2عصمت ضيف اللهNo ratings yet

- Frustum Calculator:: Given: d1, d2, & Phi 0.25 3 Calculation: (D 2R) HDocument3 pagesFrustum Calculator:: Given: d1, d2, & Phi 0.25 3 Calculation: (D 2R) HAnonymous AyDvqg100% (1)

- Importance of Thermal Hydraulics Different Reactor TypesDocument19 pagesImportance of Thermal Hydraulics Different Reactor TypesDilip YadavNo ratings yet

- Balance of PlantDocument5 pagesBalance of PlantshringimaheshNo ratings yet

- Application Notes Welding (English)Document8 pagesApplication Notes Welding (English)metallurgist100% (6)

- Spiral Wound Gaskets PDFDocument4 pagesSpiral Wound Gaskets PDFSumit ChaurasiaNo ratings yet

- 1.4462 PropertiesDocument1 page1.4462 PropertiesutreshwarmiskinNo ratings yet

- ThesisDocument48 pagesThesismuhammad amir100% (1)

- ABB 2014 Main Catalog - Motor Protection and ControlDocument792 pagesABB 2014 Main Catalog - Motor Protection and Controlcj7man80No ratings yet

- GTAW Welding of CP Titanium and Ti6Al4VDocument1 pageGTAW Welding of CP Titanium and Ti6Al4VDeepak KumarNo ratings yet

- Introduction To Heat Exchangers (HXS) : DR Rashid AliDocument36 pagesIntroduction To Heat Exchangers (HXS) : DR Rashid AliUsama IbrahimNo ratings yet

- Iodine FilterDocument5 pagesIodine FilterRajeev Kumar GuptaNo ratings yet

- Final Welding of Ti Alloys and MG AlloysDocument32 pagesFinal Welding of Ti Alloys and MG AlloysArjyajyoti GoswamiNo ratings yet

- Cone LayoutDocument4 pagesCone Layoutagrocel_bhv5591No ratings yet

- I150 I350 Installation Operation Manual enDocument9 pagesI150 I350 Installation Operation Manual enIvan ZuritaNo ratings yet

- GMAWDocument12 pagesGMAWsushant47No ratings yet

- Plate Rolling Machine WikiDocument1 pagePlate Rolling Machine WikiShawn SimNo ratings yet

- OptionA Ethane/ Butane 10500 1.8% - 4%Document62 pagesOptionA Ethane/ Butane 10500 1.8% - 4%garavindNo ratings yet

- Welcome To: Training Program On GUIDED TOUR OF Asme CodesDocument120 pagesWelcome To: Training Program On GUIDED TOUR OF Asme CodesDiego HenriqueNo ratings yet

- Lloyds Register IMO MEPC 75 Summary Report 2020 - 11Document17 pagesLloyds Register IMO MEPC 75 Summary Report 2020 - 11StefanVisNo ratings yet

- INS P 035, Circularity Check - Cyl.sectionsDocument10 pagesINS P 035, Circularity Check - Cyl.sectionsDeepakNo ratings yet

- Strip Weld OverlayDocument24 pagesStrip Weld OverlaymayataNo ratings yet

- Friction Stir WeldingDocument23 pagesFriction Stir WeldingNallappan Rajj ANo ratings yet

- Inspection Pressure Vessels Heads PDFDocument4 pagesInspection Pressure Vessels Heads PDFKarthikeyan GanesanNo ratings yet

- Pipe Schedule ChartDocument16 pagesPipe Schedule ChartSamir ChaudharyNo ratings yet

- Hardness Testing of Metallic MaterialsDocument4 pagesHardness Testing of Metallic MaterialsAshan Marambe100% (1)

- 4 - PRESSURE VESSEL (Inspection and Testing)Document69 pages4 - PRESSURE VESSEL (Inspection and Testing)Wahyu Lailil FaisNo ratings yet

- Welding Procedure QualificationDocument23 pagesWelding Procedure QualificationHosam AhmedNo ratings yet

- Implications of NORSOK M-650 Standard in The OffshoreDocument27 pagesImplications of NORSOK M-650 Standard in The OffshoreJoherNo ratings yet

- Inspector Course OutlineDocument23 pagesInspector Course Outlinebhingmeh yotalNo ratings yet

- Document Governing Amp Welding InspectionDocument56 pagesDocument Governing Amp Welding Inspectionshahaljawaie87No ratings yet

- Hot Work Risk AssessementDocument4 pagesHot Work Risk AssessementGamalMahranNo ratings yet

- Mitsui-Man B&W Me-B Engines InstructionDocument520 pagesMitsui-Man B&W Me-B Engines InstructionGamalMahran100% (4)

- C-10 2017 Secondary Venting ArrangementDocument3 pagesC-10 2017 Secondary Venting ArrangementGamalMahranNo ratings yet

- Saf 16a - Critical Operations - Master ListDocument1 pageSaf 16a - Critical Operations - Master ListGamalMahranNo ratings yet

- Risk Assessment ManualDocument45 pagesRisk Assessment ManualGamalMahran100% (1)

- Container Vessel ProceduresDocument23 pagesContainer Vessel ProceduresGamalMahran100% (1)

- VGPDocument506 pagesVGPGamalMahran100% (2)

- Lifting ProcedureDocument48 pagesLifting ProcedureGamalMahran100% (3)

- Recovery of Persons From The WaterDocument60 pagesRecovery of Persons From The WaterGamalMahranNo ratings yet

- Spillages Through Pumproom Sea ValvesDocument12 pagesSpillages Through Pumproom Sea ValvesGamalMahran50% (2)

- Port State Control - 2014Document69 pagesPort State Control - 2014GamalMahran100% (1)

- QMS-M01 Operation ManualDocument35 pagesQMS-M01 Operation ManualGamalMahranNo ratings yet

- Chomsky's Universal GrammarDocument4 pagesChomsky's Universal GrammarFina Felisa L. AlcudiaNo ratings yet

- Waste Foundry Sand and Its Leachate CharDocument10 pagesWaste Foundry Sand and Its Leachate CharJanak RaazzNo ratings yet

- Use The Analysis ToolPak To Perform Complex Data Analysis - Excel - OfficeDocument5 pagesUse The Analysis ToolPak To Perform Complex Data Analysis - Excel - OfficedakingNo ratings yet

- National Pension System (NPS) - Subscriber Registration FormDocument3 pagesNational Pension System (NPS) - Subscriber Registration FormPratikJagtapNo ratings yet

- Problems: C D y XDocument7 pagesProblems: C D y XBanana QNo ratings yet

- Unit 1 - Plant & Eqpt. Safety Apprisal & Control Techq.Document147 pagesUnit 1 - Plant & Eqpt. Safety Apprisal & Control Techq.Madhan MNo ratings yet

- CHASE SSE-EHD 1900-RLS LockedDocument2 pagesCHASE SSE-EHD 1900-RLS LockedMarcos RochaNo ratings yet

- 8051 Programs Using Kit: Exp No: Date: Arithmetic Operations Using 8051Document16 pages8051 Programs Using Kit: Exp No: Date: Arithmetic Operations Using 8051Gajalakshmi AshokNo ratings yet

- Harriet Tubman Lesson PlanDocument7 pagesHarriet Tubman Lesson PlanuarkgradstudentNo ratings yet

- Empowerment Series Social Work With Groups Comprehensive Practice and Self Care 10Th Edition Charles Zastrow Full ChapterDocument67 pagesEmpowerment Series Social Work With Groups Comprehensive Practice and Self Care 10Th Edition Charles Zastrow Full Chapterruby.levi441100% (5)

- Modular Heavy Duty Truck TransmissionDocument6 pagesModular Heavy Duty Truck Transmissionphucdc095041No ratings yet

- Make Yeast StarterDocument2 pagesMake Yeast StarterAlexandraNo ratings yet

- Powering Laser Diode SystemsDocument134 pagesPowering Laser Diode SystemsNick100% (1)

- Void Engineers (Convention: Mage The Ascension)Document6 pagesVoid Engineers (Convention: Mage The Ascension)Beth0% (1)

- ERP Solution in Hospital: Yangyang Shao TTU 2013Document25 pagesERP Solution in Hospital: Yangyang Shao TTU 2013Vishakh SubbayyanNo ratings yet

- Stress: Problem SetDocument2 pagesStress: Problem SetDanielle FloridaNo ratings yet

- ALTS150-12P Datasheet1Document2 pagesALTS150-12P Datasheet1mamloveNo ratings yet

- En 1993 09Document160 pagesEn 1993 09Vio ChiNo ratings yet

- WicDocument6 pagesWicGonzalo Humberto RojasNo ratings yet

- International Supply Chain ManagementDocument2 pagesInternational Supply Chain ManagementPRASANT KUMAR SAMALNo ratings yet

- IU IIDC Time Management and Organizational SkillsDocument40 pagesIU IIDC Time Management and Organizational SkillsAsger HamzaNo ratings yet

- Romano Uts Paragraph Writing (Sorry For The Late)Document7 pagesRomano Uts Paragraph Writing (Sorry For The Late)ទី ទីNo ratings yet

- DLL Drafting 7Document4 pagesDLL Drafting 7Ram Dacz100% (3)

- 2011 Burris CatalogDocument56 pages2011 Burris CatalogMario Lopez100% (1)

- Code of Federal RegulationsDocument14 pagesCode of Federal RegulationsdiwolfieNo ratings yet

- GP 09-04-01Document31 pagesGP 09-04-01Anbarasan Perumal100% (1)

- Design of Footing R1Document8 pagesDesign of Footing R1URVESHKUMAR PATELNo ratings yet

- Mining Discriminative Patterns To Predict Health Status For Cardiopulmonary PatientsDocument56 pagesMining Discriminative Patterns To Predict Health Status For Cardiopulmonary Patientsaniltatti25No ratings yet

- Angle ModulationDocument26 pagesAngle ModulationAtish RanjanNo ratings yet

- Drsent PT Practice Sba OspfDocument10 pagesDrsent PT Practice Sba OspfEnergyfellowNo ratings yet