Professional Documents

Culture Documents

Ss Case Study

Uploaded by

Vidit GargCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ss Case Study

Uploaded by

Vidit GargCopyright:

Available Formats

Implementing Six Sigma Quality

at Better Body Manufacturing

D M A I

Define

Measure Analyze

Improve Control

D M A I

Overview

Define

Measure Analyze

Improve Control

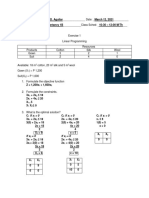

ABC Incorporated (ABC) is not achieving Six Sigma quality levels for all critical

Body-Side Sub-Assembly dimensions as requested by their customers.

200000

DPM

150000

DPM

ASM_9Y

3874

ASM_10Y

776

ASM_6Y

ASM_6Y

50000

19786

ASM_10Y

85824

ASM_3Y

ASM_9Y

ASM_8Y

ASM_3Y

172475

ASM_8Y

100000

ASM_7Y

ASM_7Y

Dimension

Ensure that all critical body-side subassembly dimensions are within Six Sigma

quality levels of < 3.4 DPM. Cp 2.0 and Cpk 1.67.

Determined the correlation between body side and assembly dimensions.

Evaluated the significance of Tonnage > 935 for ASM_7Y & ASM_8Y.

Conducted a DOE for Clamp position for ASM_9Y & ASM_10Y.

Change tonnage to > 935 to correct ASM_7Y and ASM_8Y

Set clamp position to location 2 for ASM_9Y and ASM_10Y

Re-machine A-pillar die to correct A_3Y and ASM_3Y

2

Problem Statement & The Goal

D M A I

Define

Measure Analyze

Improve Control

ABC Incorporateds customer wants ABC to apply Six Sigma problem solving

methodology to insure that the body side subassembly is achieving Six Sigma quality

levels of less than 3.4 defects per million for all critical body side subassembly

dimensions.

ABC needs an improvement strategy that minimizes the rework costs while achieving the

desired quality objective. ABCs goal is to produce module subassemblies that meet the

customer requirements and not necessarily to insure that every individual stamped

component within the assembly meets it original print specifications sub-system

optimizations vs. local optimization.

A -Pillar

Reinforcement

B-Pillar

Reinforcement

Body Side Outer

D M A I

Measure Phase

Define

Measure Analyze

Improve Control

Key Variables:

Assembly process variables:

Weld Pattern (density), Clamp Location, and Clamp Weld Pressure

Stamping process variables (body side):

Press Tonnage, Die Cushion Pressure, Material Thickness

Body Assembly Dimensions ASM_1Y through ASM_10Y

Assembly Dimensions with Highest Defects

200000

172475

DPM

150000

100000

85824

50000

19786

3874

776

0

ASM_7Y

ASM_8Y

ASM_3Y

ASM_9Y

ASM_10Y

ASM_6Y

Analyze Phase

D M A I

Define

Measure Analyze

Improve Control

Resolution alternatives (based upon past experience):

1. Make adjustments to assembly process settings

2. Reduce variation of components through better control of stamping

process input variables

3. Rework stamping dies to shift component mean deviation that is off

target and causing assembly defects

Target Performance Level:

All ten critical assembly dimensions at Six Sigma quality level of 3.4 DPM.

Cp 2.0 and Cpk 1.67

Fish Bone and P-Diagrams:

Understanding potential causes of defects. From this we pick the assembly and

component dimensions that require further analysis

D M A I

Analyze Phase

Define

Measure Analyze

Improve Control

Environment

Quality

Component

Variability

Inspection

Process

Clamp Weld

Pressure

Clamp

Location

Methods

For our analysis we will do a DOE to check

for levels that contribute to better quality

product.

Material Thickness

Humidity

Gage R&R

Weld Pattern

(density)

Inputs

Temperature

Operator

Training

Body

Assembly

Yield

Strength

Material

Thickness

Die Cushion

Pressure

Elastic

Limit

Materials

Press

Tonnage

Machine

Control Variables

Clamp Location Press Tonnage

Weld Density

Die Pressure

Clamp Pressure

Body Side Sub-Assembly

Stamping Process

Yield Strength

Outputs

Body Side Sub-Assemblies at

Six Sigma quality levels

Noise Variables

Environment

Inherent Variation

Error

States

Dimensional

defects

6

D M A I

Analyze Phase

Define

Measure Analyze

Improve Control

Analysis of ASM_7Y and ASM_8Y

Run Chart for ASM_7Y

Run Chart for ASM_8Y

1.0

ASM_8Y

ASM_7Y

1.0

0.5

0.5

0.0

0.0

12

4.00000

7.00000

5.00000

0.03464

0.96536

Number of runs up or down:

Expected number of runs:

Longest run up or down:

Approx P-Value for Trends:

Approx P-Value for Oscillation:

12

Subgroup Number

Subgroup Number

Number of runs about median:

Expected number of runs:

Longest run about median:

Approx P-Value for Clustering:

Approx P-Value for Mixtures:

6.00000

7.66667

3.00000

0.10778

0.89222

Number of runs about median:

Expected number of runs:

Longest run about median:

Approx P-Value for Clustering:

Approx P-Value for Mixtures:

4.00000

7.00000

5.00000

0.03464

0.96536

Number of runs up or down:

Expected number of runs:

Longest run up or down:

Approx P-Value for Trends:

Approx P-Value for Oscillation:

8.00000

7.66667

2.00000

0.59781

0.40219

XY Plot of ASM_8Y and ASM_7Y

1.0

ASM_7Y

Conclusion: BS_7Y and ASM_7Y are following a similar trend.

A correlation chart to study this further shows high correlation.

(Pearson correlation, R of 0.701).

0.5

0.0

0.0

0.5

1.0

ASM_8Y

D M A I

Analyze Phase

Define

Capability Analysis of B_7Y

Capability of B_7Y

USL

Target

0.70

*

LSL

Mean

-0.70

0.11

USL

0 DPM

Within

Overall

LSL

Mean

Potential (Within) Capability

Cp

2.96

CPU

2.50

Potential (Within) Capability

Cp

1.56

CPU

-0.44

CPL

Cpk

3.43

2.50

CPL

3.56

Cpk

-0.44

Cpm

Cpm

Overall Capability

-0.4

-0.2

Observed Performance

0.0

0.2

0.4

Exp. "Within" Performance

0.6

0.8

Exp. "Overall" Performance

USL

698416 DPM

Within

-0.700000

0.899444

Sample N

36

StDev (Within) 0.149640

StDev (Overall) 0.383691

-0.6

LSL

Process Data

USL

0.700000

Target

*

Sample N

36

StDev (Within) 0.0788122

StDev (Overall) 0.0791215

-0.8

Improve Control

Capability Analysis of BS_7Y

Capability of BS_7Y

LSL

Process Data

Measure Analyze

Overall Capability

Overall

-1.0

-0.5

0.0

0.5

1.0

1.5

2.0

0.61

-0.17

Observed Performance

PPM < LSL

0.00

PPM > USL

666666.67

Exp. "Within" Performance

PPM < LSL

0.00

PPM > USL

908706.09

Exp. "Overall" Performance

PPM < LSL

15.33

PPM > USL

698400.06

PPL

1.39

PPM Total

PPM Total

PPM Total

Ppk

-0.17

Pp

PPU

2.95

2.49

PPM < LSL

PPM > USL

0.00

0.00

PPM < LSL

PPM > USL

0.00

0.00

PPM < LSL

PPM > USL

0.00

0.00

Pp

PPU

PPL

Ppk

3.41

2.49

PPM Total

0.00

PPM Total

0.00

PPM Total

0.00

666666.67

908706.09

698415.39

XY Plot of ASM_7Y and BS_7Y

1.3

Furthermore, BS_7Y shows strong correlation on

dimension ASM_7Y. (Pearson correlation, R of

0.786).

1.2

1.1

1.0

BS_7Y

Conclusion: B_7Y has 0 ppm compared to ~700K

DPM in BS_7Y.

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.5

1.0

1.5

ASM_7Y

D M A I

Analyze Phase

Define

Measure Analyze

Improve Control

XY Plot of Tonnage vs. BS_7Y

XY Plot of Tonnage vs. BS_7Y

BS_7Y

1.5

1.0

0.5

905

915

925

935

945

Tonnage

Conclusion: Tonnage values above 935 greatly improves BS_7Y and brings it closer

to the mean. Lets see what impact this has on ASM dimensions 7Y, 8Y, 9Y, and

10Y by creating a subset of the data looking only at Tonnage > 935.

9

D M A I

Analyze Phase

Define

Measure Analyze

Improve Control

Impact this has on ASM dimensions 7Y, 8Y, 9Y & 10Y on Tonnage

Capability Analysis of ASM_8Y at Tonnage > 935

Capability Analysis of ASM_7Y at Tonnage > 935

LSL

Process Data

USL

USL

1.00

Target

LSL

*

-1.00

Mean

0.09

Sample N

Within

Overall

Process Data

1.00000

USL

Target

LSL

*

-1.00000

Mean

-0.12833

Sample N

12

0.163174

StDev (Within)

0.101825

StDev (Overall)

0.147855

StDev (Overall)

0.089161

Potential (Within) Capability

Potential (Within) Capability

Cp

2.04

Cp

3.27

CPU

1.86

CPU

3.69

CPL

2.23

CPL

2.85

Cpk

1.86

Cpk

2.85

-1.0

Overall Capability

-0.5

0.0

Observed Performance

0.5

Exp. "Within" Performance

1.0

Cpm

Within

Overall

-1.0

-0.5

Overall Capability

Exp. "Overall" Performance

USL

12

StDev (Within)

Cpm

LSL

0.0

Observed Performance

0.5

Exp. "Within" Performance

1.0

Exp. "Overall" Performance

Pp

2.25

PPM < LSL

0.00

PPM < LSL

0.00

PPM < LSL

0.00

Pp

3.74

PPM < LSL

0.00

PPM < LSL

0.00

PPM < LSL

0.00

PPU

PPL

2.05

2.46

PPM > USL

PPM Total

0.00

0.00

PPM > USL

PPM Total

0.01

0.01

PPM > USL

PPM Total

0.00

0.00

PPU

PPL

4.22

3.26

PPM > USL

PPM Total

0.00

0.00

PPM > USL

PPM Total

0.00

0.00

PPM > USL

PPM Total

0.00

0.00

Ppk

3.26

Ppk

2.05

Capability Analysis of ASM_9Y at Tonnage > 935

Process Data

1.00000

USL

Target

LSL

*

-1.00000

Mean

0.52083

Sample N

LSL

Capability Analysis of ASM_10Y at Tonnage > 935

USL

LSL

Process Data

Within

Overall

12

USL

*

-1.00

Mean

0.39

Sample N

0.206010

StDev (Within)

0.215541

StDev (Overall)

0.177098

StDev (Overall)

0.187663

Potential (Within) Capability

Potential (Within) Capability

Cp

1.62

Cp

1.55

CPU

0.78

CPU

0.94

CPL

2.46

CPL

2.15

Cpk

0.78

Cpk

0.94

Cpm

*

Overall Capability

-0.5

0.0

Observed Performance

0.5

Exp. "Within" Performance

1.0

Cpm

Exp. "Overall" Performance

Pp

1.88

PPM < LSL

0.00

PPM < LSL

0.00

PPM < LSL

0.00

PPU

PPL

0.90

2.86

PPM > USL

PPM Total

0.00

0.00

PPM > USL

PPM Total

10010.77

10010.77

PPM > USL

PPM Total

3408.51

3408.51

Ppk

0.90

Within

Overall

12

StDev (Within)

-1.0

USL

1.00

Target

LSL

*

Overall Capability

-1.0

-0.5

0.0

Observed Performance

0.5

Exp. "Within" Performance

1.0

Exp. "Overall" Performance

Pp

1.78

PPM < LSL

0.00

PPM < LSL

0.00

PPM < LSL

0.00

PPU

PPL

1.08

2.47

PPM > USL

PPM Total

0.00

0.00

PPM > USL

PPM Total

2326.72

2326.72

PPM > USL

PPM Total

576.00

576.00

Ppk

1.08

Conclusion: Setting Tonnage to greater than 935 resulted in ASM_7Y and ASM_8Y

meeting the goal of <3.4 DPM. ASM_9Y and ASM_10Y require further analysis.

10

D M A I

Analyze Phase

Define

Measure Analyze

Improve Control

DOE for Response Variable ASM_9Y

DOE factorial analysis shows Clamp Position is the only significant factor in

determining ASM_9Y dimension

Input Variable

Proposed ASM_9Y Setting

Proposed ASM_10Y Setting

DOE Response Optimization for ASM_9Y

Clamp Location

Location 2

Location 2

Weld Density (welds per X inches)

1.33

1.33

Set Clamp Position to Location 2Clamp

(level

Pressure1)

2100 psi

2100 psi

Optimizer recommends setting Weld Density to 1.33 weld per inch (level 1),

but this appears to be a robust parameter, which could be changed for the benefit

of process without reducing quality if processing time or cost shows a benefit.

Optimizer recommends setting Clamp Pressure to 2100 psi (level 1), but this

appears to be a robust parameter, which could be changed for the benefit of process

without reducing quality if processing time or cost shows a benefit.

Run additional tests at recommended settings to confirm results

Weld Density and Clamp Pressure are robust parameters and can be set to optimize

the process capability to maximum level and lowest cost.

11

Analyze Phase

D M A I

Define

Measure Analyze

Improve Control

DOE for Response Variable ASM_10Y

DOE factorial analysis shows Clamp Position is also the only significant

factor in determining ASM_10Y dimension

DOE Response Optimization for ASM_10Y

Setting clamp to location 2 also improves ASM_10Y

Recommend same settings used to improve ASM_9Y to improve process

capability which also allows for no changes to machine setup and helps reduce

possible process concerns

Run additional tests at recommended settings to confirm results

Weld Density and Clamp Pressure are robust parameters and can be set to optimize

the process capability to maximum level and lowest cost.

12

Analyze Phase

D M A I

Define

Measure Analyze

Improve Control

DOE for Response Variable ASM_3Y

DOE factorial analysis shows that no factors are significant

Response Optimization shows no solution for response optimizer

Observe Process Capability of A_3Y and BS_3Y

ASM_3Y and A_3Y have a similar mean shift in the -Y direction

Correlation of Output Variables

No dimensional correlations appear to exist between ASM_3Y and

A_3Y or BS_3Y

Stepwise Regression Analysis of BS_3Y

Tonnage and Die Pressure appear to be significant in determining

dimension BS_3Y

Tonnage values < 920 may improve BS_3Y

Die Pressure appears to have no clear correlation to BS_3Y

13

D M A I

Analyze Phase

Define

Measure Analyze

Improve Control

Process Capability of BS_ 3Y and ASM_3Y at Tonnage < 920

Created subset of body data looking only at dimensions with Tonnage < 935

Tonnage < 920 appears to improve the mean of BS_3Y slightly, but has no

impact on improving the mean of ASM_3Y.

Capability Analysis of ASM_3Y

Die remachined to move mean +0.80

Capability of A_3Y and ASM_3Y with +0.80

mm mean offset

LSL

Process Data

USL

Target

LSL

*

-1

Mean

Sample N

USL

Within

Overall

0

36

StDev (Within) 0.0851436

Manipulate data for A_3Y and ASM_3Y

by +0.80 mm to simulate re-machining

StDev (Overall) 0.0971725

Potential (Within) Capability

Cp

3.91

CPU

3.91

CPL

3.91

Cpk

3.91

Cpm

Process capability shows 0 defects for

A_3Y and ASM_3Y with this mean offset

*

Overall Capability

-1.0

-0.5

0.0

Observed Performance

0.5

Exp. "Within" Performance

1.0

Exp. "Overall" Performance

Pp

3.43

PPM < LSL

0.00

PPM < LSL

0.00

PPM < LSL

0.00

PPU

PPL

3.43

3.43

PPM > USL

PPM Total

0.00

0.00

PPM > USL

PPM Total

0.00

0.00

PPM > USL

PPM Total

0.00

0.00

Ppk

3.43

14

Analyze Phase

D M A I

Define

Measure Analyze

Improve Control

Conclusions

From the analysis of ASM_7Y and ASM_8Y we can conclude that:

Setting tonnage > 935 results in ASM_7Y and ASM_8Y meeting the goal

Analyzing ASM_9Y and ASM_10Y helps determine that:

Setting clamp position to location 2, weld density to 1 weld every 1.33

and clamp pressure to 2000 psi helps with dimensions ASM_9Y and

ASM_10Y

Analyzing ASM_3Y helps us conclude that:

Re-machine A-Pillar die to move A_3Y to nominal which could cause

BS_3Y to shift towards nominal effectively shifting ASM_3Y to nominal

15

D M A I

Analyze Phase

Define

Measure Analyze

Improve Control

With the recommended changes the process performance will improve significantly

Dimension Mean

StDev

Overall

DPM_Obsv DPM_Within DPM_Exp

Pp

Ppk

Cp

Cpk

ASM_1Y

-0.035

0.165

2.01

1.94

2.47

2.39

ASM_2Y

0.259

0.152

2.20

1.63

2.31

1.71

ASM_3Y

0.000

0.097

ASM_4Y

0.009

0.115

2.90

2.87

3.53

3.50

ASM_5Y

-0.330

0.145

2.30

1.54

3.72

2.50

ASM_6Y

-0.284

0.160

2.08

1.49

2.24

1.60

ASM_7Y

0.090

0.148

2.25

2.05

2.04

1.86

ASM_8Y

-0.128

0.089

3.74

3.26

3.27

2.85

ASM_9Y

0.521

0.180

ASM_10Y

0.395

0.191

16

Improve Phase

D M A I

Define

Measure Analyze

Improve Control

Recommendations for improving the process:

Set Tonnage to above 935 to improve ASM_7Y & ASM_8Y

Set Clamp to Location 2 to improve ASM_9Y & ASM_10Y

Re-machine the A-Pillar die to move the mean of A_3Y to nominal which in turn

will move ASM_3Y to nominal

Implement the above recommendations and run additional samples to verify results.

17

Control Phase

D M A I

Define

Measure Analyze

Improve Control

Recommended controls :

Implement a gauge on the body side component press to monitor tonnage

Implement an alarm and shut-off feature on the body side press if tonnage

falls below 935 tons

Implement poke-yoke clamping fixture that ensures clamp is always in

Position 2

Establish an affordable control plan for ongoing monitoring of the 10

critical assembly dimensions.

18

Summary

D M A I

Define

Measure Analyze

Improve Control

ABC Incorporated is not achieving Six Sigma quality levels for all critical BodySide Sub-Assembly dimensions as requested by their customers. BBM needs to

apply Six Sigma problem solving methodology to establish an improvement strategy

that minimizes rework costs, yet achieves the desired quality objective.

Bring the key process output variables within Six Sigma quality level of < 3.4 DPM.

Cp 2.0 and Cpk 1.67

Set Tonnage to above 935 to improve ASM_7Y & ASM_8Y

Set Clamp to Location 2 to improve ASM_9Y & ASM_10Y

Re-machine the A-Pillar die to move the mean of A_3Y to nominal

Implement a gauge on the body side component press to monitor tonnage

Implement an alarm & shut-off feature on body side press if tonnage falls below 935

Implement poke-yoke clamping fixture that ensures clamp is always in Position 2

Establish control plan for ongoing monitoring of the 10 critical assembly dimensions.

19

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Optimal Space Flight NavigationDocument277 pagesOptimal Space Flight Navigationmoafr100% (1)

- Application of 6-Sigma For Service Improvement-AT International Management Institute CanteenDocument31 pagesApplication of 6-Sigma For Service Improvement-AT International Management Institute CanteenModak Priy Singh100% (2)

- DemandDrivenMRP S4HANADocument19 pagesDemandDrivenMRP S4HANABhasaar65100% (3)

- 3G RF Planning OptimizationDocument1 page3G RF Planning OptimizationShalua YonahNo ratings yet

- PIMS - Refinery EngineersDocument63 pagesPIMS - Refinery EngineersUrcan Georgiana75% (4)

- Market SegmentationDocument4 pagesMarket SegmentationVidit GargNo ratings yet

- Green BeltDocument24 pagesGreen BeltVidit GargNo ratings yet

- Group 11 Negotiating With The ChineseDocument9 pagesGroup 11 Negotiating With The ChineseVidit Garg100% (1)

- IMCproject Group 7Document25 pagesIMCproject Group 7Vidit GargNo ratings yet

- Project GuidelinesDocument2 pagesProject GuidelinesVidit GargNo ratings yet

- The Growing Competitionn Over Maritime RightsDocument4 pagesThe Growing Competitionn Over Maritime RightsVidit GargNo ratings yet

- Key Takeaways:: 1. When Anger and Power Collide It Yields Greater Value in A NegotiationDocument2 pagesKey Takeaways:: 1. When Anger and Power Collide It Yields Greater Value in A NegotiationVidit GargNo ratings yet

- Imc End Term Project Part 1Document21 pagesImc End Term Project Part 1Vidit GargNo ratings yet

- Nego Q2Document2 pagesNego Q2Vidit GargNo ratings yet

- SituationDocument1 pageSituationVidit GargNo ratings yet

- Hindustan Lever LTDDocument4 pagesHindustan Lever LTDVidit GargNo ratings yet

- Nego Q2Document2 pagesNego Q2Vidit GargNo ratings yet

- Woman On Board Adds To DiversityDocument13 pagesWoman On Board Adds To DiversityVidit GargNo ratings yet

- Continental India Limited - IntroductionDocument8 pagesContinental India Limited - IntroductionVidit GargNo ratings yet

- Marketing Question 1Document3 pagesMarketing Question 1Vidit GargNo ratings yet

- Question 3) Evaluate The Process of Conversion of Strategy To The Big Idea Through Word Association and Suggest Possibilities of AlternativesDocument4 pagesQuestion 3) Evaluate The Process of Conversion of Strategy To The Big Idea Through Word Association and Suggest Possibilities of AlternativesVidit GargNo ratings yet

- Delhi Metro Rail Corporation LTDDocument3 pagesDelhi Metro Rail Corporation LTDVidit GargNo ratings yet

- Casestudy Kaya 130831073641 Phpapp01Document22 pagesCasestudy Kaya 130831073641 Phpapp01Vidit GargNo ratings yet

- Bap - PNGDocument21 pagesBap - PNGVidit GargNo ratings yet

- Six Sigma 10 Improve Phase-2Document50 pagesSix Sigma 10 Improve Phase-2Vidit GargNo ratings yet

- S 5 The Communication ProcessDocument35 pagesS 5 The Communication ProcessVidit GargNo ratings yet

- 6 Sigma Projects PresentationDocument31 pages6 Sigma Projects PresentationVidit GargNo ratings yet

- SM Project FinalDocument24 pagesSM Project FinalVidit GargNo ratings yet

- FCB GridDocument4 pagesFCB GridVidit GargNo ratings yet

- Six Sigma 9 Analyze-2Document46 pagesSix Sigma 9 Analyze-2Vidit GargNo ratings yet

- 6 Sigma Projects PresentationDocument31 pages6 Sigma Projects PresentationVidit GargNo ratings yet

- Green Building ProjectDocument15 pagesGreen Building ProjectVidit GargNo ratings yet

- Lenovo SBM 3Document6 pagesLenovo SBM 3Vidit GargNo ratings yet

- Distributed Query Processing Layers and OptimizationDocument48 pagesDistributed Query Processing Layers and OptimizationNIKS BHARDWAJNo ratings yet

- Graphical Method Vs Simplex MethodDocument2 pagesGraphical Method Vs Simplex MethodYurih Khei Jham Aluminum100% (1)

- Accelerated Synthesis of Novel MaterialsDocument12 pagesAccelerated Synthesis of Novel MaterialsHaibin SuNo ratings yet

- The Significance of Reducing Setup Times - Setup CostsDocument7 pagesThe Significance of Reducing Setup Times - Setup CostsAdrienn PánovicsNo ratings yet

- Iterative Reweighted Least Squares (IRLS) algorithmDocument14 pagesIterative Reweighted Least Squares (IRLS) algorithmVanidevi ManiNo ratings yet

- Data MineDocument4 pagesData MineMilan LLanque CondeNo ratings yet

- Logistics Management: Dirk Mattfeld Thomas Spengler Jan Brinkmann Martin Grunewald EditorsDocument278 pagesLogistics Management: Dirk Mattfeld Thomas Spengler Jan Brinkmann Martin Grunewald EditorsBernard TerrayoNo ratings yet

- Transparency and Algorithmic Governance PDFDocument57 pagesTransparency and Algorithmic Governance PDFannas fahlevieNo ratings yet

- 73 220 Lecture03Document34 pages73 220 Lecture03api-26315128100% (1)

- Aspen DMC3®: Study Guide For CertificationDocument6 pagesAspen DMC3®: Study Guide For CertificationBassem BalghouthiNo ratings yet

- Topic 3aDocument41 pagesTopic 3aSyafiq HassanNo ratings yet

- Final ProjectDocument107 pagesFinal ProjectBert AguilarNo ratings yet

- RMT - 2 MarksDocument17 pagesRMT - 2 MarksSatheesh kumarNo ratings yet

- Selecting Tenants in A Shopping MallDocument10 pagesSelecting Tenants in A Shopping MallErick Guerrero CamachoNo ratings yet

- Design OptimizationDocument12 pagesDesign OptimizationNam VoNo ratings yet

- AEC4 - Aguilar, Hayna Marie - BSA1B - Exercise1Document3 pagesAEC4 - Aguilar, Hayna Marie - BSA1B - Exercise1Hayna Marie AguilarNo ratings yet

- Course 06Document33 pagesCourse 06Ruchi SharmaNo ratings yet

- 07 Network Flow IDocument96 pages07 Network Flow IDrhsn AlsadNo ratings yet

- The New Palgrave Dictionary of Economics OnlineDocument5 pagesThe New Palgrave Dictionary of Economics OnlineMarcos BandeiraNo ratings yet

- Integer Programming Examples OR1 WK 1 Lecture NotesDocument34 pagesInteger Programming Examples OR1 WK 1 Lecture NotesAdrian d'AuvergneNo ratings yet

- A Multi Clustering Method Based On Evolutionary Multi - 2020 - Swarm and EvolutiDocument12 pagesA Multi Clustering Method Based On Evolutionary Multi - 2020 - Swarm and Evolutimohamed albasunyNo ratings yet

- MOSEKModeling CookbookDocument127 pagesMOSEKModeling CookbookBukaNo ratings yet

- Opt ModelDocument524 pagesOpt ModelerichwilgenbusNo ratings yet

- MAS Assignment (Quantitative Techniques)Document3 pagesMAS Assignment (Quantitative Techniques)Angelica AllanicNo ratings yet

- ORDocument716 pagesORSelva Raj100% (1)

- Module 1 Branch Bound TSPDocument25 pagesModule 1 Branch Bound TSPBadriNo ratings yet