Professional Documents

Culture Documents

08 Spreader

Uploaded by

Martin Vargas PedroCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

08 Spreader

Uploaded by

Martin Vargas PedroCopyright:

Available Formats

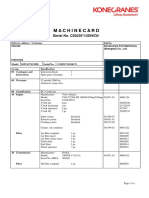

B222 ReachStacker

08 Spreader

B222 ReachStacker

09/06 - Slide1

Slide1

B222 ReachStacker

Course Details

Course name:

B222 Spreader

Content:

This module covers information about the

spreaders on B222 units

General objectives:

Familiarization with the spreader arrangement

Target Group:

Big Truck technicians

Pre-requisites:

The student should have a basic knowledge

about hydraulic and mechanical systems and

should be able to read and interpret hydraulic

schematics.

Learning Objectives: Describe and locate the main components of the

spreader

Perform basic trouble shooting on the spreader

Course Duration:

2 hours

B222 ReachStacker

B222-ELME-EXTENDABLE CONTAINER ATTACHMENT

Elme concept

B222 ReachStacker

B222-ELME-EXTENDABLE CONTAINER ATTACHMENT

813 Dedicated

B222 ReachStacker

B222-ELME-EXTENDABLE CONTAINER ATTACHMENT

815 Fork Mounted

B222 ReachStacker

B222-ELME-EXTENDABLE CONTAINER ATTACHMENT

817- Reach stacker

B222 ReachStacker

B222-ELME-EXTENDABLE CONTAINER ATTACHMENT

Two types:

817

=>

Twist locks

858

=>

Inter-modal

Most common : 817

Rotator

Attachment itself

Important => Always refer to Attachment Serial Number

mentioned on the name plate !

B222 ReachStacker

B222 ELME 817- GENERAL OPERATIONS

1. Twist locks

2. Extension beam

3. Powered pile slope

cylinder

4. Slewing ring

5. Rotator motor

6. Electric box

7. Attachment frame

8. Side shift cylinder

9. Stop cylinder

Dampening cylinders not

shown

(attached to the boom)

B222 ELME 817-ROTATOR

1. Side shift cylinder

2. Wear pads support

3. Wear pads

4. Mechanical stops

5. Lower rotator frame

6. Outer ring

7. Inner ring

8. Upper rotator frame

9. Dampening cylinder mount

10. Hydraulic rotator motor

11. Hydraulic swivel

B222 ReachStacker

B222 ReachStacker

B222 ELME 817 GENERAL FEATURES

Rotation angle => +95 to -185 (mechanical stops)

Hydraulic swivel => Avoid hydraulic hoses twisting

Vertical wear pads => Limit the fore/aft movement

Powered pile slope => lower part of rotor split to allow tilt..

Reinforcements to allow intermediate containers lengths.

B222 ReachStacker

B222 ELME 817 - STRUCTURE

30ft Reinforcement

Top Reinforcement

Different reinforcements

installed to withstand

various applications

40ft Reinforcement

B222 ReachStacker

B222 ELME 817- HYDRAULIC SCHEMATIC

B222 ReachStacker

B222 ELME - PRESSURE VALVE

Noted : Solenoid Y54

Attached to the swivel valve

1. Relief valve

2. Pressure valve

3. Check valve

No function

=> Oil is reapplied

B222 ReachStacker

B222 ELME 817- DAMPING

Forward-Backward Oscillation / Boom

B222 configuration with symmetric

Dampening cylinders.

Dampening Restriction

30 bar (435 psi) minimum to prevent

cavitation.

Quick movement = high flow

=>The restriction limits 30 bar

relief

=> So 80 bar (1160 psi) relief valve

is added

Note:

The Pressure, P, line and Drain,

D, line should be reversed.

B222 ReachStacker

B222 ELME 817 - POWER DAMPENING OPTION

60 bars relief pressure

(870 psi)

Actuated by two

solenoid valves

1. Y51 & Y52

2. 60 bars relief valve

3. To rotator/brake

valve

4. To damping

cylinder

5. To swivel valve

B222 ReachStacker

B222 ELME 817- ROTATOR TRANSMISSION

Oil

Dynamic

Suppliers

Bonfiglioli

Bonfiglioli

Standard

B222 ReachStacker

B222 ELME 817- ROTATOR

Rotation only if no other

function activated.

2 motors

No rotation

=> Y15 (brake) not

activated

=> Brake spring force

=> Y16 & Y17

(direction) not activated

B222 ReachStacker

B222 ELME 817- ROTATOR

Rotation

=> Brake released (Y15)

=> Motor pressurised

(Y16-Y17)

=> After 0.5 to 4 seconds, high

speed (Y18)

Rotation 1st limit = 12

2nd limit (+95/-185)

Pressure limit = 80 bars (1160 psi)

B222 ReachStacker

B222 ELME 817- SWIVEL VALVE

Shaft

P

Oil supply to rotating

equipment

Seals

Housing

Bearing

O-ring

Washer

Cover

B222 ReachStacker

B222 ELME 817- ROTATOR TRANSMISSION

Includes

Brake section

Reduction gear section

End housing with pinion

axle

Generally replaced and not

repaired. Except seal kit.

Note the number of transmission

mount bolts (12 or 10) for parts

identification

B222 ReachStacker

B222 ELME 817- ROTATOR TRANSMISSION

Pinion with housing

and bearings

B222 ReachStacker

B222 ELME 817- ROTATOR TRANSMISSION

Planetary gear

reduction

B222 ReachStacker

B222 ELME 817- ROTATOR TRANSMISSION

Brake assembly.

B222 ReachStacker

B222 ELME 817- ROTATOR TRANSMISSION

Bonfiglioli Brake

Nom. 5.5 6.0

mm

Max. 7.5 mm

More than 7.5 mm

(0.3 in), discs

must be replaced.

B222 ReachStacker

B222 ELME 817- ROTATOR TRANSMISSION

Springs

Breather

Discs

Shaft

Cover

Brake housing

Brake connection

Planetary housing

B222 ReachStacker

B222 ELME 817- ROTATOR TRANSMISSION

Brake

Piston

Springs

B222 ReachStacker

B222 ELME 817- ROTATOR TRANSMISSION

Set of discs

8 outer

(separators)

Max 27.7 mm (1.09 in)

7 inner (discs)

Min 25.7 mm (1.01 in)

B222 ReachStacker

B222 ELME 817- OPTIONAL POWERED PILE SLOPE

Assembly

Pile slope cylinders

B222 ReachStacker

B222 ELME 817- OPTIONAL POWERED PILE SLOPE

Side tilt in case of sloping ground or

uneven truck frames (i.e., a 20 ft

container on a 5th wheel).

Y47 & Y48 for LH or RH side tilt

Relief pressure valves for off center

loads.

Y50 & Y49 for optional Tilt Float.

(Self adjustment to container side tilt)

B222 ReachStacker

B222 ELME 817- OPTIONAL POWERED PILE SLOPE

1. Electro-valve

2. Counterbalance

3. R.H. front cylinder ports

4. R.H. front cylinder ports

5. L.H. front cylinder ports

6. L.H. front cylinder ports

7. Tank ports

8. Pressure port

9. Counterbalance

10. R.H. rear cylinder ports

11. R.H. rear cylinder ports

12. L.H. rear cylinder ports

13. L.H. rear cylinder ports

B222 ReachStacker

B222 ELME 817- EXTEND & RETRACT

Extension valve located at

shell end of the extension

cylinder

1. Check Valve

Left hand side shown only

Optional Position

Stops

2. Relief valve, 80 bar

Stop

Extend/Retract

Twist locks

TWL

(1160 psi)

3. To rod side of extension

cylinder

4. To TWL cylinder

5. To stop cylinder

6. Valve on extension cyl.

Stop kit

Extend

=> Position holes & frame reinforcements

=> Position maintained by permanent

pressure.

B222 ReachStacker

B222 ELME 817- SIDE SHIFT

Located on the top of the RH side spreader frame.

1. From swivel valve

2. Adapter pump line

3. Adapter tank line

4. To rear side shift cyl.

5. To left hand ext. valve

6. Relief valve

7. To front side shift cyl.

8. To right hand extension cylinder

80 bar (1160 psi) relief pressure

B222 ReachStacker

B222 ELME 817- TWIST LOCKS

Both sides shown

on this schematic

B222 ReachStacker

B222 ELME 817- TWL ANGLE ADJUSTMENT PROCEDURE

5a

2a

2b

5b

1

B222 ReachStacker

B222 ELME 817- PENDULAR TWL ASSEMBLY

1. Pin

2. Bolt

3. Crank

4. Collet

5. Upper Bearing

6. Lower bearings

7. Bushing

8. Sleeve

9. Springs

10. Key

11. Spring pin

12. TWL

13. Arm

13. Bearing housing

15. Indicator

Note the mechanical locking tabs

B222 ReachStacker

B222 ELME 817- SEATED SIGNAL

1.

2.

3.

4.

5.

6.

7.

8.

Return rod

Proximity switch

Seated pin return spring

Seated pin

Nut

Plate push spring

Indicator plate

Cam

Pin 4 moves up and pushes spring 3 which

pushes up plate 7 toward the proximity

switch 2

B222 ReachStacker

B222 ELME 817- CONTAINER POSITION SENSING

Spreader not seated

7 to 8mm

When the pin is

pushed to the

dimension below, the

proximity switch

should be energized

and lit up.

8-10 mm

Distance from

landing surface

to underside of

seated pin

At this pin position, the

mechanical interlock is

locked.

Locking tab

B222 ReachStacker

B222 ELME 817- CONTAINER POSITION SENSING

Spreader fully seated

When the seated pin is fully

seated, there is ample

clearance of mechanical lock.

Locking tab

B222 ReachStacker

B222 ELME 817- PENDULAR TWL ASSEMBLY

Moving up the seated

pin mechanically

unlocks the TWL

Twistlock

Locking

system

B222 ReachStacker

B222 ELME 817- ELECTRICAL SCHEMATIC

Rotator box circuits

Dampening

Power Dampening

Rotation

Powered Pile Slope.

Spreader box circuits

Side shift

Extension

Twist Locks

Lights

B222 ReachStacker

B222 ELME 817- ELECTRICAL SCHEMATIC

Spreader mechanical and electrical conditions for lock and unlock

functions

Input signals before sending the lock signal to the TWL cylinder :

Lock command (either manual or automatic).

Seated position signals from the four seating pins.

Unlocked position signals from the twist lock position sensors

(LH and RH).

Extension function not activated.

Input signals before sending the unlock signal to the TWL cylinder,

Unlock command (manual only).

Seated position signals from the four seating pins.

Locked position signals from the twist lock position sensors (LH and

RH).

Extension function not activated.

B222 ReachStacker

B222 ELME 817- ELECTRICAL SCHEMATIC

Fault finding:

Each connection on the PCB is provided with an LED

ON when activated

=> verify if required input signal is received

=> verify if required function(s) is activated.

LED color codes

Green indicate battery voltage.

Red indicates activated Output signals.

Yellow indicates activated Input signals.

B222 ReachStacker

B222 ELME 817- ELECTRICAL TROUBLE SHOOTING

Step by step procedure:

1. Determine which functions are failing (TWL activation, seated

indication, etc.).

2. Open the electric box and check the LEDs (visible on the PCB).

3. If the LED signal is ON, but function does not work, => PCB is

probably faulty.

4. If the LED signal is OFF, then check all LEDs for the relevant circuit.

5. Check the LEDs on the proximity switch, solenoid.

6. Check wire connection from PCB to solenoid or proximity switch.

7. Check if the proximity switch functions properly.

8. The proximity switch should have switched ON 4 mm (0.157 in.)

before it would touch the steel. Replace if faulty.

B222 ReachStacker

B222 ELME 817- TWL AUTOMATIC LOCKING

The automatic locking feature is controlled by PCB3.

It automatically locks the twist locks 1 seconds after all required

input signals have been received.

Plug K1 switches the automatic locking system ON/OFF, and

Potentiometer P3 adjusts the time delay of the locking signal.

Do not calibrate to less than 1.0 seconds.

B222 ELME 817- ELECTRICAL WIRING DIAGRAM

Spreader

B222 ReachStacker

B222 ELME 817- ELECTRICAL WIRING DIAGRAM

Rotator

B222 ReachStacker

B222 ReachStacker

B222 ELME 817- ELECTRICAL SCHEMATIC

Spreader

B222 ReachStacker

B222-ELME- MAINTENANCE WEAR PADS

Wear pads =>

A minimum=18mm (0.71 in)

B222 ReachStacker

B222-ELME- MAINTENANCE TWL WEAR

TWL maximum allowable wear.

=> Replacement required at 25mm (1.00 in)

The crosshatching

shows areas of wear

B222 ReachStacker

B222-ELME- MAINTENANCE SIDE SHIFT WEAR PADS

Maintain 4 to 6 mm play

(0.157 to 0.236 in.)

between spreader frame

and vertical wear pads at

the lower rotator frame.

Add shims behind the

vertical wear pads when

play exceeds 6 mm

1.

Horizontal wear pad

(0.236 in.).

2.

Vertical wear pad

B222 ReachStacker

B222-ELME- MAINTENANCE GENERAL

B222-ELME- MAINTENANCE GENERAL

B222 ReachStacker

B222 ReachStacker

B222-ELME- MAINTENANCE GENERAL

B222 ReachStacker

B222-ELME- MAINTENANCE GENERAL

B222 ReachStacker

B222-ELME- INTERMODAL

Spreader fitted with legs

which allow an alternative

load clamping.

1. Rotator assembly

2. Folding leg assembly

3. TWL assembly

4. Foot and folding leg.

B222 ReachStacker

B222-ELME- INTERMODAL

This schematic is similar to

the 817 Elme TWL only

spreader

B222 ReachStacker

B222-ELME- INTERMODAL

Intermodal features.

Two pairs of legs fold into

spreader overall dimensions

Fold front & rear legs

Block-stack front & rear

sides.

Load clamp

Clamp front & rear sides

B222 ReachStacker

QUESTIONS?

B222 ReachStacker

09/06 - Slide58

Slide58

You might also like

- B222 Drive Axle ModuleDocument36 pagesB222 Drive Axle ModuleMartin Vargas PedroNo ratings yet

- KC Technical Customer enDocument48 pagesKC Technical Customer enAri YandokoNo ratings yet

- STS45 May-2016 LR Compressed EN PDFDocument24 pagesSTS45 May-2016 LR Compressed EN PDFAmel Abbas Abbas Abbaker100% (1)

- PS - Serivces - Course Catalogue 0308 PDFDocument20 pagesPS - Serivces - Course Catalogue 0308 PDFIvan Dario100% (1)

- SpreadersDocument13 pagesSpreadersEdgardo Alfonso Ilabaca Saez100% (1)

- Training Manual ProvisionalDocument524 pagesTraining Manual ProvisionalArriola Sergio50% (2)

- BGS ManualDocument144 pagesBGS ManualSubhaanNo ratings yet

- 2632-1266-9900 StinisDocument302 pages2632-1266-9900 StinisJugaro OscarNo ratings yet

- H16 22 00 12EC PDF 4Document24 pagesH16 22 00 12EC PDF 4Ing FermínNo ratings yet

- DRD420Document15 pagesDRD420neper14100% (2)

- Swedish Spreader Service ManualDocument57 pagesSwedish Spreader Service ManualleNo ratings yet

- PSA Crane Spreader Cable Reel Data ProjeDocument72 pagesPSA Crane Spreader Cable Reel Data ProjeCristel Rodríguez BarríaNo ratings yet

- Drf450-60s5m Volvotwd1240ve EngDocument3 pagesDrf450-60s5m Volvotwd1240ve EngMohamedSalahNo ratings yet

- Cargotec Lashing Systems Items FALDocument41 pagesCargotec Lashing Systems Items FALstopless_dalian685No ratings yet

- Historia de KalmarDocument49 pagesHistoria de KalmarJuanMiguel Carranza Cruzado100% (1)

- Technical Manual: Safety and EnvironmentDocument30 pagesTechnical Manual: Safety and EnvironmentRachid SmailiNo ratings yet

- 1-2586 817-18685 MaintenanceDocument34 pages1-2586 817-18685 MaintenanceRachid SmailiNo ratings yet

- BR1700850a ApprovalDocument30 pagesBR1700850a ApprovalMIGUEL PEÑA100% (1)

- Yard CraneDocument16 pagesYard CraneMuhammad Zahiir Elric100% (2)

- Spreader Training - EH5U & EH170UDocument43 pagesSpreader Training - EH5U & EH170UDavid Adeola Ogunyemi100% (3)

- Kalmar DRF 400 450 PDFDocument12 pagesKalmar DRF 400 450 PDFcoelhoclaudios100% (1)

- PSC Reachstackers & Heavy Lift TrucksDocument8 pagesPSC Reachstackers & Heavy Lift TrucksPinki SahayNo ratings yet

- 2 DRF - Brake SystemDocument21 pages2 DRF - Brake SystemDinh SangNo ratings yet

- MM - 9E Planetary Axle Wheel EndsDocument41 pagesMM - 9E Planetary Axle Wheel EndsPablo Rodriguez100% (1)

- Kalmar Official Presentation - 060719 2Document29 pagesKalmar Official Presentation - 060719 2jean claude BledouNo ratings yet

- Kalmar DRF 450 Drive AxleDocument8 pagesKalmar DRF 450 Drive Axletuấn anh nguyễnNo ratings yet

- Hub assembly documentsDocument5 pagesHub assembly documentsHumberto Augusto de Borba100% (1)

- D3549 2Document14 pagesD3549 2Minh Canh100% (1)

- Kalmar PDFDocument8 pagesKalmar PDFSimion PetruNo ratings yet

- C20235-13554CN SMV67 Ecb90Document4 pagesC20235-13554CN SMV67 Ecb90Abas AbasariNo ratings yet

- MDL-display Reachstacker - Eng PDFDocument25 pagesMDL-display Reachstacker - Eng PDFmarioNo ratings yet

- Service-Products TPS PDFDocument39 pagesService-Products TPS PDFJack CorreiaNo ratings yet

- Emm 41360-41373 GB PDFDocument356 pagesEmm 41360-41373 GB PDFEdward Erney Salas ValenzuelaNo ratings yet

- STR40 STR45 STS45Document1 pageSTR40 STR45 STS45g665013100% (1)

- QC Technical Specification - Schedule 5 BCT 14 Jan 13 PoprDocument160 pagesQC Technical Specification - Schedule 5 BCT 14 Jan 13 PoprCarlos Luis Esquerdo MarcanoNo ratings yet

- Ervice AND Arts AnualDocument74 pagesErvice AND Arts AnualMelanie GerdesNo ratings yet

- Kalmar OPERATOR TRAININGDocument40 pagesKalmar OPERATOR TRAININGWhite Tiger100% (7)

- Service Training Hydraulic: Reachstacker Forklift ECBDocument27 pagesService Training Hydraulic: Reachstacker Forklift ECBmario100% (1)

- RS 2003 ADD Training MatDocument220 pagesRS 2003 ADD Training Matmliugong90% (10)

- hệ thống thủy lực DRF 450Document51 pageshệ thống thủy lực DRF 450Đại Anh HùngNo ratings yet

- Technical Deviation List - Cable Reel RTG CargotecDocument6 pagesTechnical Deviation List - Cable Reel RTG CargotectuanvupnNo ratings yet

- Weight Reduction of Reach Stacker (Konecrane)Document111 pagesWeight Reduction of Reach Stacker (Konecrane)Bruno SantosNo ratings yet

- Kalmar DRF 450 BrakeDocument42 pagesKalmar DRF 450 Braketuấn anh nguyễnNo ratings yet

- Sc4127-4535ta-Ca GB 6053.111Document95 pagesSc4127-4535ta-Ca GB 6053.111Rachid Smaili100% (1)

- RS HysterDocument8 pagesRS Hysterezz1985243450% (1)

- Elme Spreader ManualDocument73 pagesElme Spreader Manualpurushmicro100% (5)

- Linde c4026-4535 en SiDocument8 pagesLinde c4026-4535 en Sigus100% (1)

- Machine Card for Peinemann Kalmar Forklift T33104.0117Document5 pagesMachine Card for Peinemann Kalmar Forklift T33104.0117ANH LÊNo ratings yet

- Kalmar Services Course Catalogue 0405Document20 pagesKalmar Services Course Catalogue 0405Muhammad rizki100% (1)

- Manual Kalmar DRF420Document8 pagesManual Kalmar DRF420Mark BarriosNo ratings yet

- Deslizantes Spreader DRF450Document4 pagesDeslizantes Spreader DRF450JorgeAlvesNo ratings yet

- Contmaster 45 Tons Technical Information Container Handler PDFDocument12 pagesContmaster 45 Tons Technical Information Container Handler PDFAhmad Salimin100% (1)

- DRT 450 Training Material 150423Document206 pagesDRT 450 Training Material 150423Sione100% (3)

- ELME Spreader ManualDocument53 pagesELME Spreader ManualSimon100% (1)

- Powering The Port of The Future With Eco-Efficient SolutionsDocument28 pagesPowering The Port of The Future With Eco-Efficient Solutionsbobbyhardian100% (1)

- Reachstacker Technical Guide: Flexible Container Handling & Low Operating CostsDocument12 pagesReachstacker Technical Guide: Flexible Container Handling & Low Operating CostsPavlovstefan618750% (4)

- DRF450 Workshop Manual VDRF03 - 02GB PDFDocument128 pagesDRF450 Workshop Manual VDRF03 - 02GB PDFANH LÊ100% (1)

- KC SC Spreader en 01Document7 pagesKC SC Spreader en 01Mohammed Muzzammil100% (1)

- Manual: Original InstructionsDocument71 pagesManual: Original InstructionsMelanie GerdesNo ratings yet

- Butterfly ValvesDocument6 pagesButterfly ValvesMustapha_Kamel_6389No ratings yet

- dd210 Specification Sheet EnglishDocument4 pagesdd210 Specification Sheet EnglishCesar Chu AcevedoNo ratings yet

- Allis Chalmers Motor Grader Model 65b 68c 62s 75a Parts Manual-1Document356 pagesAllis Chalmers Motor Grader Model 65b 68c 62s 75a Parts Manual-1Florin DobasNo ratings yet

- W. Ctt/Vrartaft. No. Swr/Hq/P.607/Mech/Gr."B" Selection/70%/2017Document12 pagesW. Ctt/Vrartaft. No. Swr/Hq/P.607/Mech/Gr."B" Selection/70%/2017Sujit BarmanNo ratings yet

- DC Mini FCCCDocument22 pagesDC Mini FCCCJoy BittuNo ratings yet

- Three Axis Hydraulic Modern TrailerDocument124 pagesThree Axis Hydraulic Modern Trailerganesh83% (6)

- Advanced Organic Chemistry-Part BDocument3 pagesAdvanced Organic Chemistry-Part BMisge Chekole100% (1)

- Operation and Maintenance Manual: Pipelayer Attachment For D5H LGP, D6M LGP, and D6N LGPDocument40 pagesOperation and Maintenance Manual: Pipelayer Attachment For D5H LGP, D6M LGP, and D6N LGPLuis Fernando Giraldo Ospina100% (1)

- Hino 145 Specification SheetDocument2 pagesHino 145 Specification Sheetsmani170100% (1)

- TM 9-2320-420-10 M983a2let Part 4Document43 pagesTM 9-2320-420-10 M983a2let Part 4AdvocateNo ratings yet

- Hyster P2.5-3.0Document3 pagesHyster P2.5-3.0alkskgNo ratings yet

- Vibratory Soil Compactor CS533EDocument16 pagesVibratory Soil Compactor CS533Efirman manalu100% (3)

- Hyster LPG ForkliftDocument7 pagesHyster LPG Forkliftncthanhck100% (1)

- Regenerative Braking Seminar on Energy RecoveryDocument27 pagesRegenerative Braking Seminar on Energy RecoveryPallav SharmaNo ratings yet

- Jan-Feb ReportDocument106 pagesJan-Feb ReportMartin Slick IbeNo ratings yet

- SIF1007 DL-A Wheel Loaders - 12 - TransmissionDocument25 pagesSIF1007 DL-A Wheel Loaders - 12 - Transmissionbasem elhosanyNo ratings yet

- Radial Piston Motor MCRDocument56 pagesRadial Piston Motor MCRjuanchis650100% (1)

- Ha12i Australie 0400Document59 pagesHa12i Australie 0400vatasaNo ratings yet

- W650 Service ManualDocument433 pagesW650 Service ManualCol Chisel100% (3)

- Manitou Brochure MRT 2145 115Document6 pagesManitou Brochure MRT 2145 115yonggilNo ratings yet

- Litronic Performance Liebherr Wheel Excavators Have Been DesignedDocument20 pagesLitronic Performance Liebherr Wheel Excavators Have Been DesignedLiebherr100% (1)

- Supplier Guide PDFDocument52 pagesSupplier Guide PDFGara Pedraza100% (1)

- Design and Analysis of Drum Brakes: DVSRBM Subramanyam L.SravaniDocument13 pagesDesign and Analysis of Drum Brakes: DVSRBM Subramanyam L.SravaniShubham MahajanNo ratings yet

- CC1200 Parts SERIAL 10000332xxa012669Document332 pagesCC1200 Parts SERIAL 10000332xxa012669Adrian Mora100% (1)

- 1.an Introduction To Regenerative Braking of Electric Vehicles AsDocument5 pages1.an Introduction To Regenerative Braking of Electric Vehicles AsEssa SiddiquiNo ratings yet

- Honda xr150-l - Service Manual PDFDocument40 pagesHonda xr150-l - Service Manual PDFsanchezrolando27yahoo.es80% (15)

- X351 - Service & Repair Manual 2010 To 2012 PDFDocument3,448 pagesX351 - Service & Repair Manual 2010 To 2012 PDFDawid GNo ratings yet

- Manuale Officina Rsv4 Factory 2010Document477 pagesManuale Officina Rsv4 Factory 2010Emiliano VighiNo ratings yet

- Wheel Loaders L 550 - L 580: New GenerationDocument28 pagesWheel Loaders L 550 - L 580: New Generationhaiccdk6No ratings yet

- MTC WorkshopDocument19 pagesMTC WorkshopSmart GopiNo ratings yet

- Electric Traction Multiple Choice Questions and Answers Preparation For Competition Exams PDF - Preparation For Engineering PDFDocument11 pagesElectric Traction Multiple Choice Questions and Answers Preparation For Competition Exams PDF - Preparation For Engineering PDFER Mukesh ThakurNo ratings yet