Professional Documents

Culture Documents

Technolog 21652443265 y

Uploaded by

ralphCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technolog 21652443265 y

Uploaded by

ralphCopyright:

Available Formats

Innovative Logistics Solutions,

Inc.

And

The Pyromex Group

Introducing

a Dramatic new

Waste to Energy Technology

ILS, Inc copyright @ 2003

Rev 1.5

ILS, Inc.

PYR MEX

HISTORY

1989 Development of patented waste

neutralization and solidification system

1992 First demo plant operational in

Switzerland

1993 Start of development of pyrolysis

technology

1995 Development of ultra high

temperature gasification by means of

induction electricity

1996 construction of a demo plant in

Brentwood, England

1999 Development of industrial plant and

delivery of plant to a municipal waste

water treatment plant in Germany

2003 Partner with ILS, Inc. for North

America launch

ILS, Inc.

PYR MEX

PATENTS

AND TECHNOLOGIES

The Pyromex process and

technologies are patented

worldwide

The Group possesses 68

patents, patent applications

and know-how related to

solving waste and

environmental problems

ILS, Inc.

PYR MEX

MISSION

STATEMENT

To safeguard human

health and the

environment by using

the latest technology

to provide efficient

and cost-effective,

environmentally

friendly industrial

and domestic waste

management and

disposal.

Innovative Logistics Solutions,

Inc.

And

The Pyromex Group

SOME

WASTE STATISTICS

ILS, Inc.

PYR MEX

WASTE STATISTICS

ANNUAL WASTE ACCUMULATION

Country

USA

Canada

Netherland

Switzerland

Japan

Great Britain

Germany

Spain

France

1000

900

800

700

600

500

400

300

200

100

0

Italy

kilos in 1989

PER INHABITANT IN KILOS

ILS, Inc.

PYR MEX

WASTE STATISTICS

EVOLUTION OF THE ANNUAL

HOUSEHOLD WASTE ACCUMULATION

PER INHABITANT IN KILOS

1000

900

800

kilos

700

600

500

400

300

200

100

0

USA

France

1975

1980

1985

year

1989

ILS, Inc.

PYR MEX

WASTE STATISTICS

This picture illustrates the quantity of trash

produced by an average American family per

year

(over 3 tons)

Innovative Logistics Solutions,

Inc.

And

The Pyromex Group

THE PYROMEX TECHNOLOGY

THE SOLUTION!

ILS, Inc.

PYR MEX

ULTRAHIGH TEMPERATURE

GASIFICATION

Ultrahigh temperature gasification

is the destructive distillation of an

organic material.

This distillation process involves

the application of intense, indirect

thermal energy in the absence of

oxygen which reduces the material

to combustible gases and a nonhazardous, non-leachable

inorganic.

ILS, Inc.

PYR MEX

WHAT HAPPENS

IN THE REACTOR?

CnHm

> CH4 + H2 + C

CH4 + H2O > CO + 3H2

C + H2O

> CO + H2

C + CO2

> 2 CO

ILS, Inc.

PYR MEX

WHAT

DOES THIS MEAN?

ORGANIC MATERIAL

Converts to a pyrogas with

the following approximate

composition

Gas

Vol.%

H2

33

CH4

11

CO

36

CO2

18

C2H4

INORGANIC MATERIAL

Converts to a nonleachable, sand or basaltlike, environmentally

harmless residue which can

be reused

ILS, Inc.

PYR MEX

WHY GASIFICATION

WITHOUT OXYGEN?

Principle differences

between incineration and

Pyromex thermal degradation

INCINERATION

PYROMEX HIGH TEMEPRATURE

GASIFICATION

Oxidation with O=O

Very slow reacting molecule

Thermal degradation without O=O

Very fast reaction molecule

Low temperature

Slow reaction

No risk of recombination of

dangerous elements

Great danger of recombination

of dangerous elements

(+100 times faster)

PYR MEX

ILS, Inc.

EXAMPLE

INCINERATION

PYROMEX

HIGH TEMPERATURE GASIFICATION

CH3CL+7/4O2-CO2+3/2 H2O+1/2 CL2

CH3CL-C+H2 +HCL

Very difficult to handle

Very easy to dissolve in water

Innovative Logistics Solutions,

Inc.

And

The Pyromex Group

EXAMPLE OF

A PYROMEX PLANT

(OPERATING IN GERMANY)

ILS, Inc.

PYR MEX

FEEDING SYSTEM

ILS, Inc.

PYR MEX

HIGH TEMPERATURE

REACTOR

PYR MEX

ILS, Inc.

INDUCTION

SYSTEM

ILS, Inc.

PYR MEX

CERAMIC

REACTOR PIPE

ILS, Inc.

PYR MEX

RESIDUE OUTFEED

ILS, Inc.

PYR MEX

GENERAL

PLANT VIEW

ILS, Inc.

PYR MEX

SCHEMATIC

PYR MEX

ILS, Inc.

TYPICAL

MATERIAL FLOW

Fum es

D e h u m id ific a tio n

S to ra g e

T ra n s p o rt

G A S IF IC A T IO N

A fte rb u rn e r

In e r t M a t e r i a l

S te a m

M a rk e t

S te a m T u rb in e

E le c tr ic ity /H e a tin g

O w n Use

M a rk et

Innovative Logistics Solutions,

Inc.

And

The Pyromex Group

ECONOMIC

CONSIDERATIONS

ILS, Inc.

PYR MEX

REVENUE SOURCES

Tipping fees

Recycled material

Services rendered

BEFORE

Pyromex Technology

AFTER

Energy Production

Steam

Heating

Any manufacturing

process requiring energy

ILS, Inc.

PYR MEX

ENERGY BALANCE

If a gas engine is used to

recover the energy from the

pyrogas, the following energy

balance can be assumed:

Electricity production with a gas engine

Required energy for the Pyromex reactor

Available for sale

Furthermore, off-heat can be used with

an additional value of

1,400 kWh

600-800 kWh

600 kWh

1,800 kWh

ILS, Inc.

PYR MEX

ENERGY RECOVERY

Pyromex offers the following

energy recovery technologies:

Utilization of the pyrogas for

heating purposes or industrial

applications, replacing oil and

gas

Operation of a high temperature

afterburner with successive

steam production, steam turbine

and generator

Operation of a gas engine

combined with a generator

Conversion of the pyrogas to

hydrogen and production of

electricity via fuel cells

PYR MEX

ILS, Inc.

PYROGAS TO HYDROGEN

CO + H2O

CO2 + H2

CH4 + 2H2O

CO2 + 4H2

At 750C

=

Conversion of

pyrogas to hydrogen

ILS, Inc.

PYR MEX

FINANCIAL PROJECTIONS

for ........................ tons / day

INCOME

From Tipping Fees

a)

b)

c)

From Recycling

a)

b)

c)

From Energy Production

a)

b)

c)

TOTAL INCOME

OPERATING COST

Capital Costs

Electricity

Gas

Administration

Maintenance

Labor

Reagents

Rent

Miscellaneous

TOTAL COSTS

PROFIT / LOSS

PER TON

PER DAY

PER YEAR

ILS, Inc.

PYR MEX

THE PYROMEX TECHNOLOGY

A COMPLETE LINE

AND UPGRADING

SYSTEM TO TREAT

WASTE WITHOUT

WASTE RESIDUES

Rational

Economical

Environmentally

compatible

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Open Cholecystectomy ReportDocument7 pagesOpen Cholecystectomy ReportjosephcloudNo ratings yet

- Post Traumatic Stress DisorderDocument2 pagesPost Traumatic Stress Disorderapi-188978784100% (1)

- Recommendation On The Acquisation of VitasoyDocument8 pagesRecommendation On The Acquisation of Vitasoyapi-237162505No ratings yet

- Course Syllabus Manufacturing Processes (1) Metal CuttingDocument4 pagesCourse Syllabus Manufacturing Processes (1) Metal CuttingG. Dancer GhNo ratings yet

- Wago PCB Terminal Blocks and Connectors Catalog 7Document105 pagesWago PCB Terminal Blocks and Connectors Catalog 7alinupNo ratings yet

- ICSE Class 10 HRJUDSK/Question Paper 2020: (Two Hours)Document9 pagesICSE Class 10 HRJUDSK/Question Paper 2020: (Two Hours)Harshu KNo ratings yet

- Deloitte Uk Mining and Metals DecarbonizationDocument10 pagesDeloitte Uk Mining and Metals DecarbonizationfpreuscheNo ratings yet

- Extraordinary GazetteDocument10 pagesExtraordinary GazetteAdaderana OnlineNo ratings yet

- Hydrogen Production From The Air: Nature CommunicationsDocument9 pagesHydrogen Production From The Air: Nature CommunicationsdfdffNo ratings yet

- Multilevel Full Mock Test 5: Telegramdagi KanalDocument20 pagesMultilevel Full Mock Test 5: Telegramdagi KanalShaxzod AxmadjonovNo ratings yet

- Api 579-2 - 4.4Document22 pagesApi 579-2 - 4.4Robiansah Tri AchbarNo ratings yet

- Cough PDFDocument3 pagesCough PDFKASIA SyNo ratings yet

- UK FreshTECH Jammer RecipeBook 0Document24 pagesUK FreshTECH Jammer RecipeBook 0Temet NoscheNo ratings yet

- Macroscopic Physics Chemistry HW #1Document11 pagesMacroscopic Physics Chemistry HW #1Akash ModyNo ratings yet

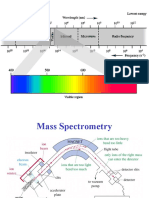

- Mass SpectrometryDocument49 pagesMass SpectrometryUbaid ShabirNo ratings yet

- TDS Shell Spirax s6 Gxme 75w-80Document2 pagesTDS Shell Spirax s6 Gxme 75w-80rstec pyNo ratings yet

- 13 Alvarez II vs. Sun Life of CanadaDocument1 page13 Alvarez II vs. Sun Life of CanadaPaolo AlarillaNo ratings yet

- Final Manuscript GROUP2Document102 pagesFinal Manuscript GROUP222102279No ratings yet

- Capacity Requirement PlanningDocument17 pagesCapacity Requirement PlanningvamsibuNo ratings yet

- Studovaný Okruh: Physical Therapist Sample Test Questions (G5+)Document8 pagesStudovaný Okruh: Physical Therapist Sample Test Questions (G5+)AndreeaNo ratings yet

- CL Analyzer: Coagulometric, Chromogenic and Immunological AssaysDocument2 pagesCL Analyzer: Coagulometric, Chromogenic and Immunological AssaysEdwinNo ratings yet

- Data Performance 2Document148 pagesData Performance 2Ibnu Abdillah MuhammadNo ratings yet

- Presentation of DR Rai On Sahasrara Day Medical SessionDocument31 pagesPresentation of DR Rai On Sahasrara Day Medical SessionRahul TikkuNo ratings yet

- SUPERHERO Suspension Training ManualDocument11 pagesSUPERHERO Suspension Training ManualCaleb Leadingham100% (5)

- NCP On DiabetesDocument2 pagesNCP On DiabetesShumaila AlviNo ratings yet

- Creamy and Thick Mushroom Soup: IngredientsDocument8 pagesCreamy and Thick Mushroom Soup: IngredientsSheila Mae AramanNo ratings yet

- Generic 5S ChecklistDocument2 pagesGeneric 5S Checklistswamireddy100% (1)

- WT Chapter 5Document34 pagesWT Chapter 5Wariyo GalgaloNo ratings yet

- Full Bridge Phase Shift ConverterDocument21 pagesFull Bridge Phase Shift ConverterMukul ChoudhuryNo ratings yet

- Mental Status ExaminationDocument34 pagesMental Status Examinationkimbomd100% (2)