Professional Documents

Culture Documents

Viscosity, Viscosity Factors, Kinematic Viscosity, Viscometer, Visccosity Grade (ISO and SAE)

Uploaded by

Hidan Avi0 ratings0% found this document useful (0 votes)

79 views31 pagesDyanimic viscosity (equation - unit)

Kinematic viscosity (equation - unit)

Newtonian and non newtonian fluids

Shearing stress vs velocity gradient

Bingham, dilatant and pseudoplastic fluid

Time independent fluids

viscosity index curves

Original Title

Viscosity, viscosity factors, kinematic viscosity, viscometer, visccosity grade (ISO and SAE)

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentDyanimic viscosity (equation - unit)

Kinematic viscosity (equation - unit)

Newtonian and non newtonian fluids

Shearing stress vs velocity gradient

Bingham, dilatant and pseudoplastic fluid

Time independent fluids

viscosity index curves

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

79 views31 pagesViscosity, Viscosity Factors, Kinematic Viscosity, Viscometer, Visccosity Grade (ISO and SAE)

Uploaded by

Hidan AviDyanimic viscosity (equation - unit)

Kinematic viscosity (equation - unit)

Newtonian and non newtonian fluids

Shearing stress vs velocity gradient

Bingham, dilatant and pseudoplastic fluid

Time independent fluids

viscosity index curves

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 31

2.

Viscosity of Fluids

2.1 Dynamic Viscosity

As a fluid moves, a shear stress is developed

in it, the

magnitude of which depends on the viscosity of

the fluid.

Shear stress, denoted by the Greek letter

(tau), , can

be defined as the force required to slide one unit

area

layer of a substance over another.

Thus, is a force divided by an area and can

be

measured in the units of N/m2 (Pa) or lb/ft2.

2.1 Dynamic Viscosity

The fact that the shear stress in the fluid is

directly

proportional to the velocity gradient can be

stated

mathematically as:

where the constant of proportionality (the

Greek

letter miu) is called the dynamic viscosity of the

fluid.

The term absolute viscosity is sometimes used.

2.1 Dynamic Viscosity

Fig 2.1 shows the velocity gradient in a moving

fluid.

2.1.1 Unit of Dynamic Viscosity

The definition of dynamic viscosity can be

derived

from Eq. (21) by solving for :

The units for can be derived by substituting

the SI

units into Eq. (22) as follows:

Because Pa is another name for N/m2 , we can

also express as

cause 1N = 1 kgm/s2 can be expressed as

Thus Nm/s2, Pas or kg/ms may be used for

in the

SI system.

2.2.1 Unit of Dynamic Viscosity

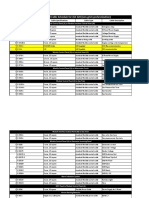

Table 2.1 shows the system conversion

2.2 Kinematic Viscosity

The kinematic viscosity (the Greek letter nu) is

defined as

Because and are both properties of the fluid, is

also a property.

2.2.1 Units of Kinematic Viscosity

We can derive the SI units for kinematic viscosity by

substituting the previously developed units for and

:

Table 2.2 lists the kinematic viscosity units in

the

three most widely used systems.

2.3 Newtonian Fluids and Non-Newtonian

Fluids

The study of the deformation and flow

characteristics

of substances is called rheology, which is the

field from which we learn about the viscosity of

One important distinction is between a

fluids.

Newtonian

fluid and a non-Newtonian fluid.

Any fluid that behaves in accordance with

Eq. (21) is

called a Newtonian fluid.

Conversely, a fluid that does not behave in

accordance with Eq. (21) is called a nonNewtonian fluid.

Fig 2.2 shows the Newtonian and nonNewtonian fluids.

Two major classifications of non-Newtonian

fluids are

time-independent and time-dependent fluids.

As their name implies, time-independent fluids

have a

viscosity at any given shear stress that does not

vary with time.

The viscosity of timedependent fluids,

however,

changes with time.

Three types of time-independent fluids can

1.

bePseudoplastic

defined:

or Thixotropic The plot of shear

stress versus velocity gradient lies above the

straight, constant sloped line for Newtonian fluids,

as shown in Fig. 2.2. The curve begins steeply,

indicating a high apparent viscosity. Then the slope

decreases

increasing

velocity

gradient.

2. Dilatant with

Fluids

The plot of

shear stress

versus

velocity gradient lies below the straight line for

Newtonian fluids. The curve begins with a low slope,

indicating a low apparent viscosity. Then, the slope

increases with increasing velocity gradient.

3. Bingham Fluids Sometimes called plug-flow fluids,

Bingham fluids require the development of a

significant level of shear stress before flow will begin,

as illustrated in Fig. 2.2. Once flow starts, there is an

essentially linear slope to the curve indicating a

Viscosity of Liquid Polymers 2.3.1

Five additional viscosity factors are typically

:measured or computed for polymers

Relative viscosity. 1

Inherent viscosity. 2

Reduced viscosity. 3

Specific viscosity. 4

Intrinsic viscosity (also called limiting viscosity. 5

number)

2.4 Variation of Viscosity with

Temperature

Table 2.3 shows the viscosity for different

fluids.

2.4.1 Viscosity Index

A fluid with a high viscosity index exhibits a

small change in viscosity with temperature. A

fluid with a low viscosity index exhibits a large

change in viscosity with emperature.

All kinematic viscosity values are in the unit of

mm2/s:

where

U = Kinematic viscosity at of the test oil.

L = Kinematic viscosity 40C at of a standard oil

of 0 VI having the same viscosity at 100C as

the test oil.

H = Kinematic viscosity at 40C of a standard oil

of 100 VI having the same viscosity at 100C as

Fig 2.3 shows the typical viscosity index curves.

2.5 Viscosity Measurement

Devices for characterizing the flow behavior of

liquids are called viscometers or rheometers.

ASTM International generates standards for

viscosity measurement and reporting.

2.5.1 Rotating Drum Viscometer

Fig 2.4 shows the rotating-drum viscometer.

2.5.1 Rotating Drum Viscometer

The apparatus shown in Fig. 2.4(a) measures

viscosity by the definition of dynamic viscosity

given in Eq. (22), which we can write in the form

The dynamic viscosity of the fluid can be

computed from the simple equation

where n2 is the speed of the outer tube and n1 is

the speed of the internal rotor. K is a calibration

constant provided by the instrument

manufacturer.

2.5.2 Capillary Tube Viscometer

Fig 2.5 shows the Capillary-tube viscometer.

2.5.2 Capillary Tube Viscometer

In Eq. (25), D is the inside diameter of the tube,

v is the fluid velocity, and L is the length of the

tube between points 1 and 2 where the pressure

is measured.

As the fluid flows through the tube with a

constant velocity, some energy is lost from the

system, causing a pressure drop that can be

measured by using manometers.

The magnitude of the pressure drop is related

to the

fluid viscosity by the following equation,

2.5.3 Standard Calibrated Glass Capillary

Viscometers

Fig 2.6 shows the CannonFenske routine

viscometer.

Fig 2.7 shows the Ubbelohde viscometer.

2.5.4 Falling-Ball Viscometer

As a body falls in a fluid under the influence of

gravity only, it will accelerate until the

downward force (its weight) is just balanced by

the buoyant force and the viscous drag force

acting

upward.

Its

velocity

at that time is called

the terminal velocity.

Fig 2.8 shows the kinematic

viscosity bath for holding

standard calibrated glass

capillary viscometers.

Fig 2.9 shows the falling-ball

viscometer.

Fig 2.10 shows the free-body

diagram of a ball in a falling-ball

Figure 2.10 shows a

free-body diagram of

the ball, where w is the

weight of the ball, Fb, is

the buoyant force, and

is the viscous drag

force on the ball.

Therefore, we have

If s is the specific weight of the sphere, f is the

specific weight of the fluid, V is the volume of

the sphere, and D is the diameter of the sphere,

we have

For very viscous fluids and a

small velocity, the drag force

on the sphere is

Equation (26) then becomes

2.7 ISO Viscosity Grade

(Table 2.4) SAE Velocity grade for engine oils

2.6 SAE Viscosity Grade

(Table 2.5) viscosity grades for automotive gear

lubricants

2.7 ISO Viscosity Grades

The standard designation includes the prefix ISO

VG followed by a number representing the

nominal kinematic viscosity in cSt for a

temperature of 40C.

Table 2.6 gives the data.

2.8 Hydraulic Fluid for Fluid Power System

Fluid power systems use fluids under pressure

to actuate linear or rotary devices used in

construction equipment, industrial automation

systems, agricultural equipment, aircraft

hydraulic systems, automotive braking

manytypes

others.

systems,

There areand

several

of hydraulic fluids in

common use, including:

1. Petroleum oils .

2. Waterglycol fluids .

3. High water-based fluids (HWBF) .

4. Silicone fluids .

5. Synthetic oils .

The primary characteristics of such fluids for

operation in fluid power systems are:

1. Adequate viscosity for the purpose .

2. High lubricating capability, sometimes called

lubricity.

3. Cleanliness .

4. Chemical stability at operating temperatures .

5. Noncorrosiveness with the materials used in

fluid power systems.

6. Inability to support bacteria growth .

7. Ecologically acceptable .

8. High bulk modulus (low compressibility) .

You might also like

- PPT 02Document52 pagesPPT 02Dickson LeongNo ratings yet

- Viscosity of FluidDocument26 pagesViscosity of FluidAahjssb HznsmsbNo ratings yet

- Applied Fluid Mechanics - 02 Viscosity of FluidsDocument19 pagesApplied Fluid Mechanics - 02 Viscosity of Fluidssourz18100% (1)

- Technical College of Engineering Department Viscosity ExperimentDocument6 pagesTechnical College of Engineering Department Viscosity Experimentsoran najebNo ratings yet

- Drilling Hydraulic FundamentalsDocument179 pagesDrilling Hydraulic FundamentalsAnisah Zahrah AyuputriNo ratings yet

- Viscosity LabDocument15 pagesViscosity LabM. Fatih Doğan50% (2)

- Viscosity MeasurementDocument8 pagesViscosity MeasurementRian SteveNo ratings yet

- ME 2204 Fluid Mechanics and Machinery TEST (I Unit) KeyDocument12 pagesME 2204 Fluid Mechanics and Machinery TEST (I Unit) KeyVignesh Vicky80% (5)

- Viscosity in Fluids: By: Rahim HassanzadehDocument15 pagesViscosity in Fluids: By: Rahim Hassanzadehsharif_94No ratings yet

- Topic 3 - Fluid LubricantsDocument8 pagesTopic 3 - Fluid LubricantsAmin PatelNo ratings yet

- Viscosity and Rheology of Lubricants: Flow of A Viscous Fluid Between Parallel PlatesDocument22 pagesViscosity and Rheology of Lubricants: Flow of A Viscous Fluid Between Parallel Platesjuan daniel becerrilNo ratings yet

- Fluids For Hydraulic SystemsDocument16 pagesFluids For Hydraulic SystemsAimee SpearsNo ratings yet

- Measure Liquid ViscosityDocument5 pagesMeasure Liquid ViscosityHassaanAhmedNo ratings yet

- Measuring Kinematic & Dynamic Viscosity (40Document7 pagesMeasuring Kinematic & Dynamic Viscosity (40Hevin HassanNo ratings yet

- Table of Contents: Viscosity and ViscometersDocument10 pagesTable of Contents: Viscosity and ViscometersAdanNo ratings yet

- Transport PhenomenaDocument9 pagesTransport PhenomenaMUHAMMAD AKRAMNo ratings yet

- Standard Test Method For Kinematic Viscosity of Transparent and Opaque Liquids (The Calculation of Dynamic Viscosity) D445Document6 pagesStandard Test Method For Kinematic Viscosity of Transparent and Opaque Liquids (The Calculation of Dynamic Viscosity) D445Yomel Ramzi100% (1)

- Unit 6 and 7 - Introduction To Viscosity and Flow Field MeasurementDocument37 pagesUnit 6 and 7 - Introduction To Viscosity and Flow Field Measurementxie garbageNo ratings yet

- Notes Civil-Iii-Fluid Mechanics - 10CV35 PDFDocument251 pagesNotes Civil-Iii-Fluid Mechanics - 10CV35 PDFShruthi IyengarNo ratings yet

- LabbbbbbDocument12 pagesLabbbbbbMuyambo SàmsøñNo ratings yet

- On The Viscosity of Energol 320Document12 pagesOn The Viscosity of Energol 320Charlie HanniganNo ratings yet

- 02 Basics Mixing Technology PDFDocument7 pages02 Basics Mixing Technology PDFjokishNo ratings yet

- Technical College Viscosity ExperimentDocument8 pagesTechnical College Viscosity Experimentsoran najebNo ratings yet

- Viscosity MeasurementDocument20 pagesViscosity MeasurementMohit Awasthi100% (1)

- FOOD2003 Food Engineering Rheology: ViscosityDocument14 pagesFOOD2003 Food Engineering Rheology: ViscosityMaria Fernanda Bustamante LayedraNo ratings yet

- Review of Fluid Review of Fluid MechanicsDocument40 pagesReview of Fluid Review of Fluid MechanicsNebiyou KorraNo ratings yet

- Fluids Lab Manual 1Document6 pagesFluids Lab Manual 1اسامة نعمة جبارNo ratings yet

- Bsen 3310 Lab ReportDocument5 pagesBsen 3310 Lab Reportapi-271759053No ratings yet

- Fluid Mechanics NotesDocument12 pagesFluid Mechanics Notessubha_aeroNo ratings yet

- Edexcel Higher Fluid Mechanics H1 Unit 8 NQF Level 4 Outcome 2 Viscosity Tutorial 2 - The Viscous Nature of FluidsDocument10 pagesEdexcel Higher Fluid Mechanics H1 Unit 8 NQF Level 4 Outcome 2 Viscosity Tutorial 2 - The Viscous Nature of FluidsTejas PatelNo ratings yet

- FLDP Chp.2 LectureDocument39 pagesFLDP Chp.2 LectureAbel SamuelNo ratings yet

- Hydraulic Calculations Oil Pipeline LectureDocument35 pagesHydraulic Calculations Oil Pipeline LecturebahhooNo ratings yet

- Fluid Mechanics & Hydraulic Machinery: Subject Code: PC 301 ME Aicte V SemesterDocument62 pagesFluid Mechanics & Hydraulic Machinery: Subject Code: PC 301 ME Aicte V Semestermmr315No ratings yet

- Fluid Mechanics & Hydraulics BookDocument131 pagesFluid Mechanics & Hydraulics BookJoshua YosuaNo ratings yet

- Viscosity Analysis of Lubricating OilsDocument6 pagesViscosity Analysis of Lubricating OilsNicole AguilarNo ratings yet

- Question Bank - FMDocument14 pagesQuestion Bank - FMsrajapratyNo ratings yet

- NPTEL Fluid Dynamics MeasurementsDocument56 pagesNPTEL Fluid Dynamics MeasurementsMohamed ShareefNo ratings yet

- 1system of Units Amp Fluids Properties 1 2Document41 pages1system of Units Amp Fluids Properties 1 2whosamiruladliNo ratings yet

- Experiment 6: Fluid Friction Apparatus This Is A Sample Report, It Is The Perfect FormatDocument15 pagesExperiment 6: Fluid Friction Apparatus This Is A Sample Report, It Is The Perfect FormatBryan Pashian ManaluNo ratings yet

- 4 Special Information For Designing Centrifugal Pump InstallationsDocument11 pages4 Special Information For Designing Centrifugal Pump InstallationsSandi AslanNo ratings yet

- Viscosity Determination of Lubricating OilsDocument14 pagesViscosity Determination of Lubricating OilsAnurag JaiswalNo ratings yet

- Hid Chapter 2 Lec. EDocument42 pagesHid Chapter 2 Lec. Eahmed jemalNo ratings yet

- FM and TMDocument445 pagesFM and TMKrishna Singh100% (1)

- Sp250-78 Nist Calibration Services For HydrometersDocument36 pagesSp250-78 Nist Calibration Services For HydrometersJeyson Ocampo100% (1)

- Chapter 2 Physical Properties of Hydraulic FluidDocument26 pagesChapter 2 Physical Properties of Hydraulic FluidSiraj BusseNo ratings yet

- Chapter 2 Fundamental Hydraulic Fluid MechanicsDocument19 pagesChapter 2 Fundamental Hydraulic Fluid MechanicsYabu MakNo ratings yet

- Factors Affecting Fluid ViscosityDocument12 pagesFactors Affecting Fluid ViscosityBF3nobelNo ratings yet

- Hydraulic Fluid - PropertiesDocument7 pagesHydraulic Fluid - Propertiesprajapati1436No ratings yet

- Properties of Fluids ExplainedDocument70 pagesProperties of Fluids ExplainedAmin Zaquan0% (1)

- LAB MANUAL. EXPERIMENT 1. Viscosity of Fluids (Ball Drop Method)Document6 pagesLAB MANUAL. EXPERIMENT 1. Viscosity of Fluids (Ball Drop Method)james Principe0% (2)

- Chap. 1 Fluid PropertiesDocument45 pagesChap. 1 Fluid PropertiesctkhadeejaNo ratings yet

- Week 2 Lec1Document18 pagesWeek 2 Lec1Muhammad Bin ZubairNo ratings yet

- Redwood Viscometer ExperimentDocument4 pagesRedwood Viscometer ExperimentSudarshan Ghotekar100% (1)

- Name: Onkar Pardeshi Branch: Chemical Dept. Division: B Roll No.:12 PRN No.: 12011027 Subject: Fluid Flow OperationsDocument5 pagesName: Onkar Pardeshi Branch: Chemical Dept. Division: B Roll No.:12 PRN No.: 12011027 Subject: Fluid Flow OperationsOnkar BhosleNo ratings yet

- 1.1. General:: Design and Fabrication of Hydraulic Machine With Pulling and Bending OperationsDocument48 pages1.1. General:: Design and Fabrication of Hydraulic Machine With Pulling and Bending OperationssudheerNo ratings yet

- Brookfield Viscometer ExplainedDocument13 pagesBrookfield Viscometer ExplainedKunal Arora100% (3)

- Laporan PraktikumDocument19 pagesLaporan PraktikumMuhamad Choirul AzizNo ratings yet

- Working Guide to Reservoir Rock Properties and Fluid FlowFrom EverandWorking Guide to Reservoir Rock Properties and Fluid FlowRating: 3 out of 5 stars3/5 (1)

- TM 1-1500-204-23-1, Change 5Document448 pagesTM 1-1500-204-23-1, Change 5"Rufus"No ratings yet

- Reciprocating Compressor Testing GuideDocument10 pagesReciprocating Compressor Testing GuideS DasNo ratings yet

- Liquid Biofuel - A Viable Choice For Power Generation PDFDocument2 pagesLiquid Biofuel - A Viable Choice For Power Generation PDFRussell CarterNo ratings yet

- 00022443the Application of A Continuous Leak Detection System To Pipelines and Associated EquipmentDocument4 pages00022443the Application of A Continuous Leak Detection System To Pipelines and Associated EquipmentFaizal AbdullahNo ratings yet

- Rotary EnginesDocument27 pagesRotary EnginesMuhammad AsifNo ratings yet

- 78EKG-1 Sr. No. 4 Examination of Marine Engineer Officer Engineering KnowledgeDocument2 pages78EKG-1 Sr. No. 4 Examination of Marine Engineer Officer Engineering KnowledgeThiet PhamNo ratings yet

- Rotary Lift: Trouble Shooting Guide IndexDocument20 pagesRotary Lift: Trouble Shooting Guide IndexFarhsa Dhom Eemihahs DhomNo ratings yet

- Trouble Shooting Water Carry Over in BoilersDocument6 pagesTrouble Shooting Water Carry Over in BoilersAnonymous OkaG2VNo ratings yet

- Bornemann - Twin Screw Pumps - Series W, V, U and TDocument16 pagesBornemann - Twin Screw Pumps - Series W, V, U and Tfwkl100% (1)

- Brake Accumulator Test and ChargeDocument8 pagesBrake Accumulator Test and ChargeBarzola Soto Omar100% (1)

- Flash Point and Fire Point - FinalDocument33 pagesFlash Point and Fire Point - FinalAnonymous QM0NLqZONo ratings yet

- Reference Cable Schedule - JGS 320 - Non-Grid SynchronizationDocument2 pagesReference Cable Schedule - JGS 320 - Non-Grid SynchronizationfaisalnadimNo ratings yet

- I C EngineDocument154 pagesI C EngineoperationmanagerNo ratings yet

- Hydraulic Circuits Design and AnalysisDocument19 pagesHydraulic Circuits Design and AnalysisklashincoviskyNo ratings yet

- 13 Chapter 3Document43 pages13 Chapter 3anaamikaaNo ratings yet

- Accumulator, air hoists, API definedDocument6 pagesAccumulator, air hoists, API definedrcabrera90No ratings yet

- Trickle Bed ReactorDocument23 pagesTrickle Bed ReactorgautamahujaNo ratings yet

- Gas DocumentationDocument45 pagesGas DocumentationYUKOOCKNo ratings yet

- Case Study No.1Document2 pagesCase Study No.1Marinale LabroNo ratings yet

- 412-MD-04-S02 Handling and ServicingDocument18 pages412-MD-04-S02 Handling and ServicingJhoann Miguel Galvan SarabiaNo ratings yet

- Grit Industries CWT Indirect Heater SolutionDocument31 pagesGrit Industries CWT Indirect Heater SolutionPankajDhobleNo ratings yet

- Assigement 1 Pete OlmecaDocument2 pagesAssigement 1 Pete OlmecaleeNo ratings yet

- Instruction Manual Guide D'Utilisation Manual de InstruccionesDocument64 pagesInstruction Manual Guide D'Utilisation Manual de InstruccionesNealca CanonNo ratings yet

- 38 Alemite Product Catalog PDFDocument277 pages38 Alemite Product Catalog PDFthailan100% (1)

- Punto de Congelación Catálogo EngDocument1 pagePunto de Congelación Catálogo EngJorge EpbNo ratings yet

- Hino DPRDocument2 pagesHino DPRhamm6780% (1)

- Microprocessors & Interfacing Techniques Assignment No. 2Document2 pagesMicroprocessors & Interfacing Techniques Assignment No. 2Abdullah Nasir100% (4)

- Wap 740wDocument18 pagesWap 740wDontraVoltaNo ratings yet

- 3030 Car Reader Instructions EnglishDocument32 pages3030 Car Reader Instructions EnglishDonald Newberry WoodsNo ratings yet

- List of Companies For Email DatabaseDocument2 pagesList of Companies For Email DatabaseKishore Kumar50% (2)