Professional Documents

Culture Documents

Hot Mix Plant

Uploaded by

Adusumalli Surendra BabuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hot Mix Plant

Uploaded by

Adusumalli Surendra BabuCopyright:

Available Formats

Department

of Mechanical

GMR Institute

ofEngineering

Technology,

Rajam

Humility

Entrepreneurship

Teamwork

STUDY ON HOT MIX PLANT

BY

A.SURENDRA BABU

14341D2201

Department of Civil Engineering

G M R Institute of Technology

(An Autonomous Institute Affiliated to JNTU Kakinada, Kakinada, A.P)

(Accredited by NBA, NACC with A Grade & ISO 9001:2008 Certified

institution)

Approved by AICTE, New Delhi

GMR NAGAR, RAJAM-532127, A.P

March-2016

Deliver The Promise

Learning

Social Responsibility

Respect for Individual

Humility

Entrepreneurship

Teamwork

Department

of Mechanical

GMR Institute

ofEngineering

Technology,

Rajam

CONTENTS

1. ABSTRACT

2. PROJECT FEATURES

3. INTRODUCTION

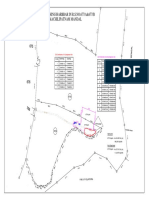

4. PROJECT DGPS MAP

5. JOB MIX DESIGN

6. COCLUSION

Deliver The Promise

Learning

Social Responsibility

Respect for Individual

Humility

Entrepreneurship

Teamwork

Department

of Mechanical

GMR Institute

ofEngineering

Technology,

Rajam

ABSTRACT

The Government of India has launched major initiatives to upgrade and

strengthen

National Highways through various phases of National

Highways Development project (NHDP).

In this project a study on hot mix plant is been explained here with the

field experience at the project site for the road construction, widening,

rehabilitation and reconstruction of the NH-565

Hot mix plant working, operation and production of the Dense Bitumen

Macadam(DBM) and Bitumen Concrete(BC)

Deliver The Promise

Learning

Social Responsibility

Respect for Individual

Humility

Entrepreneurship

Teamwork

Department

of Mechanical

GMR Institute

ofEngineering

Technology,

Rajam

PROJECT FEATURES

The project stretch is one of the newly assigned national highway number NH

565 from NAKREKAL in Telangana to ERPEDU in Andhra Pradesh.

This project is an important connectivity between NH-65 and NH-71

Rehabilitation and Up gradation of Nakrekal to Nagarjuna sagar section of NH565 from Km. 1+000 to Km. 86+057 in the state of Telangana to two lane with

paved shoulders under NHDP-IV through Engineering Procurement &

Construction (EPC) Basis Contract

This project connects Nakrekal, Pangal, Nalgonda, Haliya and Nagarjuna sagar

covering a distance of 85.057 kms originates from Nakrekal and terminates at

Nagarjuna sagar.

The project is to be executed by contractor GVR Infra PROJECTS ltd. as EPC

(ENGINEERING-PROCUREMENT-CONSTRUCTION) project

Deliver The Promise

Learning

Social Responsibility

Respect for Individual

Entrepreneurship

Teamwork

Department

of Mechanical

GMR Institute

ofEngineering

Technology,

Rajam

Humility

Deliver The Promise

Learning

Social Responsibility

Respect for Individual

Humility

Entrepreneurship

Teamwork

Department

of Mechanical

GMR Institute

ofEngineering

Technology,

Rajam

INTRODUCTION

Rapid industrialization has created a demand for improved road

surfaces. For the production of high quality hot asphaltic mixtures

conforming to the desired specifications, suitable mixing plants are

required and the formulation of a standard specification for mixing

plants has become necessary.

The main purpose of this project is to know about the hot mix plant

working and production of the Dense Bitumen Macadam (DBM) and

Bitumen Concrete(BC)

The major part of the road construction contains the bitumen which acts

as a surface coarse or protection coarse from the road users and

environmental effects

Deliver The Promise

Learning

Social Responsibility

Respect for Individual

Humility

Entrepreneurship

Teamwork

Department

of Mechanical

GMR Institute

ofEngineering

Technology,

Rajam

DGPS MAP

Deliver The Promise

Learning

Social Responsibility

Respect for Individual

Humility

Entrepreneurship

Teamwork

Department

of Mechanical

GMR Institute

ofEngineering

Technology,

Rajam

Hot Mix Plant At the Project Site

Deliver The Promise

Learning

Social Responsibility

Respect for Individual

Humility

Entrepreneurship

Teamwork

Department

of Mechanical

GMR Institute

ofEngineering

Technology,

Rajam

MATERIALS SOURCE

AGGREGATES: The aggregates are extracted from the locally

available mines at the nalgonda using the mobile and fixed

crushers. The aggregates are crushed to required shapes

based upon the requirement of the plant

BITUMEN: It is imported from Chennai IOCL company of

bitumen VG30 through tankers

Deliver The Promise

Learning

Social Responsibility

Respect for Individual

Humility

Entrepreneurship

Teamwork

Department

of Mechanical

GMR Institute

ofEngineering

Technology,

Rajam

MACHINERIES

Crushers: mobile & fixed crushers

Hawlers: For transporting the DBM & BC from

plant to on site of 30 tones capacity

JCB: For filling the aggregates & filler material in

cold bins of the hot mix plant

Deliver The Promise

Learning

Social Responsibility

Respect for Individual

Humility

Entrepreneurship

Teamwork

Department

of Mechanical

GMR Institute

ofEngineering

Technology,

Rajam

HOT MIX PLANT

An asphalt mixture plant is an assembly of mechanical and

electronic equipment where aggregates, recycled materials or

other additives are blended, heated, dried and mixed with binder

to produce asphalt mixture meeting specified requirements.

Types Of Hot Mix Plant

Deliver The Promise

1. BATCH MIX PLANT

2. DRUM MIX PLANT

Learning

Social Responsibility

Respect for Individual

Humility

Entrepreneurship

Teamwork

Department

of Mechanical

GMR Institute

ofEngineering

Technology,

Rajam

BATCH PLANT OPERATIONS

The operations include:

1) Aggregate storage and cold feeding

2) Aggregate drying and heating

3) Screening and storage of hot aggregates

4) Storage and heating of binder

5) Measuring and mixing of binder and aggregate and recycled materials

(when used)

6) Loading of finished asphalt mixture

Deliver The Promise

Learning

Social Responsibility

Respect for Individual

Humility

Entrepreneurship

Teamwork

Department

of Mechanical

GMR Institute

ofEngineering

Technology,

Rajam

Major Batch Plant Components

Deliver The Promise

Learning

Social Responsibility

Respect for Individual

Humility

Entrepreneurship

Teamwork

Department

of Mechanical

GMR Institute

ofEngineering

Technology,

Rajam

BATCH PLANT OPERATION

The cold bins are filled with the materials of different aggregate

sizes and the filler dust

These aggregates in the cold bins are transported by the

excavator which is situated at the bottom of the hopper to dryer

Deliver The Promise

Learning

Social Responsibility

Respect for Individual

Humility

Entrepreneurship

Teamwork

Rajam

AGGREGATE DRYING & HEATING

Department

of Mechanical

GMR Institute

ofEngineering

Technology,

From the cold bins, aggregates are delivered to the dryer. The dryer

removes moisture from the aggregates and raises the aggregate

temperature to the desired level

Deliver The Promise

Learning

Social Responsibility

Respect for Individual

Humility

Entrepreneurship

Teamwork

Department

of Mechanical

GMR Institute

ofEngineering

Technology,

Rajam

SCREENING OF HOT AGGREGATE

After the aggregates have been heated and dried, the aggregate is

carried by a hot elevator (an enclosed bucket conveyor) to the

gradation unit

In the gradation unit, the hot aggregate passes over a series of

screens that separate the aggregate into various-sized fractions

and deposit those fractions in "hot" bins

Deliver The Promise

Learning

Social Responsibility

Respect for Individual

Humility

Entrepreneurship

Teamwork

Department

of Mechanical

GMR Institute

ofEngineering

Technology,

Rajam

Cross-section View Showing Details of

Flow Material Through Screens and Bins

Deliver The Promise

Learning

Social Responsibility

Respect for Individual

Humility

Entrepreneurship

Teamwork

From the weigh hopper, the aggregates are deposited into the

plant pug mill(mixing chamber) to be blended

Department

of Mechanical

GMR Institute

ofEngineering

Technology,

Rajam

INTRODUCING THE BINDER

Deliver The Promise

Learning

Social Responsibility

Respect for Individual

Humility

Entrepreneurship

Teamwork

Department

of Mechanical

GMR Institute

ofEngineering

Technology,

Rajam

PUGMILL MIXING OPERATIONS

Deliver The Promise

Learning

Social Responsibility

Respect for Individual

Humility

Entrepreneurship

Teamwork

Department

of Mechanical

GMR Institute

ofEngineering

Technology,

Rajam

TEMPERATURES

The temperatures at which the aggregates are dried in a typical

dryer is 160C 170C

The temperatures of the Bitumen is to be maintained is 150C 160C

The mixing temperatures for the Bitumen and aggregates in the

pugmill is to be maintained is 140C 150C

The laying temperatures of Dense Bitumen Macadam

(DBM)and Bituminous Concrete(BC) should be 120C

Deliver The Promise

Learning

Social Responsibility

Respect for Individual

Humility

Entrepreneurship

Teamwork

Department

of Mechanical

GMR Institute

ofEngineering

Technology,

Rajam

CONTROL STATION

Deliver The Promise

Learning

Social Responsibility

Respect for Individual

Humility

Entrepreneurship

Teamwork

Department

of Mechanical

GMR Institute

ofEngineering

Technology,

Rajam

CONTROLS AT THE CONTROL ROOM

Deliver The Promise

Learning

Social Responsibility

Respect for Individual

Humility

Entrepreneurship

Teamwork

Department

of Mechanical

GMR Institute

ofEngineering

Technology,

Rajam

JOB MIX DESIGN FOR DBM

AGG MIX

PROPORTION

1000

KG

1200

KG

1400

KG

1600 KG 1800 KG

2000 KG

36 mm 23.97 % 239.675 287.610 355.545 383.480

431.415

479.350

22 mm 18.22 % 182.153 218.584 255.014 291.445

327.875

364.306

10 mm 19.17 % 191.740 230.088 268.436 306.784

345.132

383.480

4 mm

621.238

690.264

34.51 % 345.132 414.158 483.185 552.211

Bitum 4.13 %

en %

41.300

49.560

57.820

66.080

74.340

82.600

TOTAL 100

1000

1200

1400

1600

1800

2000

Deliver The Promise

Learning

Social Responsibility

Respect for Individual

Humility

Entrepreneurship

Teamwork

Department

of Mechanical

GMR Institute

ofEngineering

Technology,

Rajam

JOB MIX DESIGN FOR BC

AGG MIX

PROPORTION

1000

KG

1200

KG

1400

KG

1600

KG

1800

KG

2000

KG

28 mm

17.37 % 173.700 208.440 243.180 277.920 312.660 347.400

16 mm

42.46 % 424.600 509.520 594.440 679.360 764.280 849.200

10 mm

21.23 % 212.300 254.760 297.220 339.680 382.140 424.600

4 mm

15.44 % 154.400 185.280 216.160 247.040 277.920 308.800

Bitume

n%

3.5 %

35.0

42.0

49.0

56.0

63.0

70.0

TOTAL

100

1000

1200

1400

1600

1800

2000

Deliver The Promise

Learning

Social Responsibility

Respect for Individual

Humility

Entrepreneurship

Teamwork

Department

of Mechanical

GMR Institute

ofEngineering

Technology,

Rajam

MOVEMENT OF THE TRUCKS

The movement of the truck traffic should be free and accessible

for filling the DBM and BC

There should be no collisions between one truck to another

truck

The path of trucks should come around the plant i.e. circular

motion to come for filling

After filling the material into the truck it should be taken to the

weigh bridge and weigh slip is generated to the truck

Deliver The Promise

Learning

Social Responsibility

Respect for Individual

Humility

Entrepreneurship

Teamwork

Department

of Mechanical

GMR Institute

ofEngineering

Technology,

Rajam

CONCLUSION

The WBM and the BC are produced upon the prescribed or

required job mix design

These are free and more productionable for major projects

These are freely operatable

These are more economical for completing the projects in time

The main disadvantage is these are not operated during the heavy

rain because the mixing temperatures will be reduced or changed

Every night of the working day the maintenance work has to be

done

Deliver The Promise

Learning

Social Responsibility

Respect for Individual

Humility

Entrepreneurship

Teamwork

Department

of Mechanical

GMR Institute

ofEngineering

Technology,

Rajam

Internship Project Certificate

Deliver The Promise

Learning

Social Responsibility

Respect for Individual

Entrepreneurship

Teamwork

Department

of Mechanical

GMR Institute

ofEngineering

Technology,

Rajam

Humility

Deliver The Promise

THANK YOU

Learning

Social Responsibility

Respect for Individual

You might also like

- Hot Mix Plant PDFDocument12 pagesHot Mix Plant PDFGautam Rai100% (2)

- Industrial Training Presentation on Spare Parts of Hot Mix PlantDocument19 pagesIndustrial Training Presentation on Spare Parts of Hot Mix PlantRiya Tripathi100% (1)

- Training Hot-Mix Plant OperatorDocument9 pagesTraining Hot-Mix Plant OperatorAnonymous ciKyr0t100% (2)

- Amp LintecDocument24 pagesAmp Lintecdk_moehammed100% (2)

- Part Manual Drum Mix 120Document69 pagesPart Manual Drum Mix 120Justice Machiwana100% (2)

- Kaushik Cesan Asphalt Batch Mix Catalog PDFDocument9 pagesKaushik Cesan Asphalt Batch Mix Catalog PDFDebasish MurmuNo ratings yet

- ISO9001 Company Parts Manual for Asphalt Batch Mix PlantDocument165 pagesISO9001 Company Parts Manual for Asphalt Batch Mix PlantNiten Gupta88% (16)

- WMM Plant MaconsDocument2 pagesWMM Plant Maconsharikrishna007No ratings yet

- HOT MIX ASPHALT PLANT OPERATIONS GUIDEDocument81 pagesHOT MIX ASPHALT PLANT OPERATIONS GUIDEMehaboob Basha100% (1)

- Asphalt Plant OperationDocument4 pagesAsphalt Plant OperationJack MorrisNo ratings yet

- TSAP-3000FFW Asphalt Mixing PlantDocument24 pagesTSAP-3000FFW Asphalt Mixing PlantElumalai SrinivasanNo ratings yet

- Project Report For Fly Ash Brick Making MachinesDocument7 pagesProject Report For Fly Ash Brick Making Machinesg26agarwalNo ratings yet

- Hot Mix Plant ReportDocument19 pagesHot Mix Plant ReportRiya TripathiNo ratings yet

- M1 Batching PlantDocument4 pagesM1 Batching PlantDibyalochan ParidaNo ratings yet

- Project Profile - Mat Products ManufactuingDocument6 pagesProject Profile - Mat Products Manufactuingmadhusudhans100% (1)

- Ajax FioriDocument9 pagesAjax Fioriguthale50% (2)

- Batching Plant LBPD22142035 A00Document1 pageBatching Plant LBPD22142035 A00mechajay2002No ratings yet

- Hot Mix Plant Calibration, Laying & TestingDocument55 pagesHot Mix Plant Calibration, Laying & Testingjaffna88% (17)

- Vizag Grinding Unit, Gobburupalem Village, Visakhapatnam Andhra Pradesh (0.95 MTPA) Plant DetailsDocument35 pagesVizag Grinding Unit, Gobburupalem Village, Visakhapatnam Andhra Pradesh (0.95 MTPA) Plant Detailsvijay kumar100% (1)

- Ash and Slag Handling SystemsDocument3 pagesAsh and Slag Handling Systemsrmm99rmm99No ratings yet

- Lecture 10 Hot Mix Asphalt Plant PDFDocument59 pagesLecture 10 Hot Mix Asphalt Plant PDFramNo ratings yet

- Asphalt Batch Type Portable PlantDocument8 pagesAsphalt Batch Type Portable Plantfisco4rilNo ratings yet

- Sand SeparatorDocument10 pagesSand SeparatorganeshNo ratings yet

- Modern Ginning and Pressing UnitDocument8 pagesModern Ginning and Pressing UnitHiteshGondalia100% (3)

- Hot Mix PlantDocument53 pagesHot Mix PlantRinkesh Rathi33% (3)

- Internship Report VedantDocument59 pagesInternship Report Vedantvgsuryawanshib20No ratings yet

- BHS Prospekt DKX en 112014 WebDocument20 pagesBHS Prospekt DKX en 112014 Websudhir5441No ratings yet

- 1 Comparison of SANY and SINO HOWO 10m3 Transit MixerDocument1 page1 Comparison of SANY and SINO HOWO 10m3 Transit MixerAdeelNo ratings yet

- Project Report On R M CDocument41 pagesProject Report On R M Csunny84% (77)

- Guidelines for pollution control in stone crushing industryDocument20 pagesGuidelines for pollution control in stone crushing industrypratapagenciesNo ratings yet

- Rajiv RMC ProjectDocument75 pagesRajiv RMC Projectbhosalerajiv63% (8)

- Twin Shaft Mixer Instruction ManualDocument87 pagesTwin Shaft Mixer Instruction ManualSotiris Andronis100% (2)

- Air Compressor Using Crank and Slotted Link MechanismDocument22 pagesAir Compressor Using Crank and Slotted Link MechanismSaravanan Viswakarma75% (4)

- Slip Form and Fixed Form PaversDocument63 pagesSlip Form and Fixed Form PaversShubham Pawar100% (1)

- Questionnaire On RMCDocument5 pagesQuestionnaire On RMCProsenjit Roy100% (1)

- Apollo ATM 6 Transit Mixer SpecsDocument2 pagesApollo ATM 6 Transit Mixer SpecsbhargavipulivarthiNo ratings yet

- Kyb Conmat PVT LTDDocument9 pagesKyb Conmat PVT LTDMd Jibon HossenNo ratings yet

- Fly Ash Brick Manufacturing PlantDocument5 pagesFly Ash Brick Manufacturing Plantkarthikraja21No ratings yet

- Manually Operated Groundnut Shelling MachineDocument6 pagesManually Operated Groundnut Shelling MachineIshanShikarkhane100% (2)

- Road Construction With AsphaltDocument6 pagesRoad Construction With AsphaltbabeNo ratings yet

- Final Project ReportDocument15 pagesFinal Project ReportRishi Mehta100% (1)

- Project Report On Fly Ash Bricks PlantDocument11 pagesProject Report On Fly Ash Bricks PlantVineet Singhal80% (5)

- Sieving Machine Design and FabricationDocument14 pagesSieving Machine Design and Fabrication18E3457 MukundiniNo ratings yet

- 1.6004 Block Machine Price List Item Specifications QTY Picture Batching System 3 Bin Batching Machine 950000Document11 pages1.6004 Block Machine Price List Item Specifications QTY Picture Batching System 3 Bin Batching Machine 950000Sai SrimanthNo ratings yet

- Concrete Pipe Making MachineDocument134 pagesConcrete Pipe Making MachineYeabsraNo ratings yet

- Exhaust Impeller For Hot Mix PlantDocument3 pagesExhaust Impeller For Hot Mix PlantAarti Varma100% (1)

- 1) Compact Batching Plant CP30Document12 pages1) Compact Batching Plant CP30mohan kamkarNo ratings yet

- Quality Construction Equipment Drum Mix PlantDocument4 pagesQuality Construction Equipment Drum Mix PlantTheodore Teddy KahiNo ratings yet

- AD Star Bags QualityDocument18 pagesAD Star Bags QualityKhizzar IshaqueNo ratings yet

- Efficient Sand Sieving Machine DesignDocument19 pagesEfficient Sand Sieving Machine Design18E3457 MukundiniNo ratings yet

- Benefits of Cold Mix Technology Over Hot Mix Technology in Sustainable Road NetworkDocument7 pagesBenefits of Cold Mix Technology Over Hot Mix Technology in Sustainable Road NetworkAdvanced Research PublicationsNo ratings yet

- Mixer TheoryDocument8 pagesMixer TheorySheikh Nouman Mohsin RamziNo ratings yet

- Hasnain Marble FactoryDocument18 pagesHasnain Marble FactoryADIL ALI SHAH100% (1)

- Hot Mix Asphalt Plant OperationsDocument81 pagesHot Mix Asphalt Plant OperationsJaikishan Kumaraswamy100% (3)

- Roadnews: Top Feature: Vögele Inline Pave Lays The Basis For The FutureDocument52 pagesRoadnews: Top Feature: Vögele Inline Pave Lays The Basis For The Futuredamian00005No ratings yet

- Fds Series: Fiber Dosing-Feeding SystemDocument15 pagesFds Series: Fiber Dosing-Feeding SystemPaul Ticla PuenteNo ratings yet

- Planning & Cost Analysis For Setting Up of A New RMC Plant - MangaloreDocument18 pagesPlanning & Cost Analysis For Setting Up of A New RMC Plant - MangaloreRaj ConsultancyNo ratings yet

- 128170592002Document114 pages128170592002Krupali100% (1)

- JK Laxmi Cement LTD: A Internship Report ONDocument13 pagesJK Laxmi Cement LTD: A Internship Report ONKunal Khatri100% (1)

- Iundustry FileDocument34 pagesIundustry FileHarsh ChauhanNo ratings yet

- Fishing Harbbar 677 PDFDocument1 pageFishing Harbbar 677 PDFAdusumalli Surendra BabuNo ratings yet

- Environmental Management Plan: Revision RecordDocument31 pagesEnvironmental Management Plan: Revision RecordAdusumalli Surendra BabuNo ratings yet

- Hot Mix PlantDocument34 pagesHot Mix PlantAdusumalli Surendra BabuNo ratings yet

- Project Sand Repacement and Cement Replacement With Crusher DustDocument47 pagesProject Sand Repacement and Cement Replacement With Crusher DustAdusumalli Surendra BabuNo ratings yet

- Project 1st ReviewDocument7 pagesProject 1st ReviewAdusumalli Surendra BabuNo ratings yet

- Excel Sheet For Sieve Analysis of Aggregate and To Calculate Fineness ModulusDocument6 pagesExcel Sheet For Sieve Analysis of Aggregate and To Calculate Fineness ModulusAdusumalli Surendra BabuNo ratings yet

- Biofuel & Developement From Plant Based Sources & Environmentally Benign Adaptation and ImplementationDocument23 pagesBiofuel & Developement From Plant Based Sources & Environmentally Benign Adaptation and ImplementationAdusumalli Surendra BabuNo ratings yet

- New Microsoft PowerPoint PresentationDocument18 pagesNew Microsoft PowerPoint PresentationAdusumalli Surendra BabuNo ratings yet

- New Microsoft PowerPoint PresentationDocument18 pagesNew Microsoft PowerPoint PresentationAdusumalli Surendra BabuNo ratings yet

- 3000 CalorieDocument10 pages3000 CalorieNIKHILNo ratings yet

- Concept PaperDocument6 pagesConcept Paperapple amanteNo ratings yet

- DNV Rules For Electrical Instal at IonsDocument80 pagesDNV Rules For Electrical Instal at Ionsnzjohn100% (3)

- Myofascial Release for Piriformis MyalgiaDocument14 pagesMyofascial Release for Piriformis MyalgiaApoorvNo ratings yet

- Grade 9 P.EDocument16 pagesGrade 9 P.EBrige SimeonNo ratings yet

- Chemistry CHM 1311C 2012 Test 1 BlankDocument6 pagesChemistry CHM 1311C 2012 Test 1 BlankSimon HagosNo ratings yet

- Coal Workers' Pneumoconiosis (Black Lung Disease) Treatment & Management - Approach Considerations, Medical Care, Surgical CareDocument2 pagesCoal Workers' Pneumoconiosis (Black Lung Disease) Treatment & Management - Approach Considerations, Medical Care, Surgical CareامينNo ratings yet

- D Formation Damage StimCADE FDADocument30 pagesD Formation Damage StimCADE FDAEmmanuel EkwohNo ratings yet

- Ups Installation Method StatementDocument197 pagesUps Installation Method StatementehteshamNo ratings yet

- Therminol 55Document5 pagesTherminol 55Dinesh KumarNo ratings yet

- Presente Continuo Present ContinuosDocument4 pagesPresente Continuo Present ContinuosClaudio AntonioNo ratings yet

- Sugar Reseach in AustraliaDocument16 pagesSugar Reseach in AustraliaJhonattanIsaacNo ratings yet

- Duty Roster Class IV JulyDocument2 pagesDuty Roster Class IV JulyTayyab HassanNo ratings yet

- DOC023.97.80076 - 3ed Sensores ORPDocument148 pagesDOC023.97.80076 - 3ed Sensores ORPAlejandroNo ratings yet

- Final Profile Draft - Zach HelfantDocument5 pagesFinal Profile Draft - Zach Helfantapi-547420544No ratings yet

- Chin Cup Therapy An Effective Tool For The Correction of Class III Malocclusion in Mixed and Late Deciduous DentitionsDocument6 pagesChin Cup Therapy An Effective Tool For The Correction of Class III Malocclusion in Mixed and Late Deciduous Dentitionschic organizerNo ratings yet

- Undas Deployment PadsDocument15 pagesUndas Deployment PadsVic NairaNo ratings yet

- Fiitjee JEE Adv p1 Phase II SolDocument10 pagesFiitjee JEE Adv p1 Phase II SolPadamNo ratings yet

- Human Resources Management Article Review On "The 3 Essential Jobs That Most Retention Programs Ignore"Document14 pagesHuman Resources Management Article Review On "The 3 Essential Jobs That Most Retention Programs Ignore"Pang Kok ShengNo ratings yet

- Compensation and BenefitsDocument8 pagesCompensation and BenefitsOthman FaroussiNo ratings yet

- Reflective Essay Assignment #8 - Managing Emotions and Coping With StressDocument2 pagesReflective Essay Assignment #8 - Managing Emotions and Coping With StressRej GarbosaNo ratings yet

- Lecture 1 Biochem 232 CellsDocument13 pagesLecture 1 Biochem 232 CellsaelmowafyNo ratings yet

- 632 MA Lichauco vs. ApostolDocument2 pages632 MA Lichauco vs. ApostolCarissa CruzNo ratings yet

- Cswip Visual Welding Inspector 3.0 BrochureDocument1 pageCswip Visual Welding Inspector 3.0 BrochureNasfauzan100% (2)

- Radiol 2020201473Document37 pagesRadiol 2020201473M Victoria SalazarNo ratings yet

- Ethnobotany Manual 14th September 2016Document54 pagesEthnobotany Manual 14th September 2016Rahul0% (1)

- Catálogo SEDIVERDocument32 pagesCatálogo SEDIVEREnver Rojas DiazNo ratings yet

- Secondary AssessmentsDocument12 pagesSecondary Assessmentsapi-338389967No ratings yet

- Easy and Successful Plumbing Methods You Can Now Applyhslhj PDFDocument2 pagesEasy and Successful Plumbing Methods You Can Now Applyhslhj PDFbeartea84No ratings yet

- Chapter 2 Electronic StructureDocument62 pagesChapter 2 Electronic StructureLivan TuahNo ratings yet