Professional Documents

Culture Documents

Measurement System Analysis

Uploaded by

Akash KumarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Measurement System Analysis

Uploaded by

Akash KumarCopyright:

Available Formats

Measurement System Analysis

Measurement System Analysis

The overall variation observed in any product or

service consists of process variation and variation

induced by the measurement system.

Therefore, attempts should be made to maintain the

variation in the measurement system as low as

possible, preferably within 10% of the allowed

tolerance.

MSA is a systematic study of the various aspects of

the measurement system and its variation.

Whereas, Gage R & R studies concentrates on

Repeatability and reproducibility, MSA extents to

dealing with other aspects like Bias, Linearity and

Stability. Though, these two are used

interchangeably in most literatures.

Measurement System Analysis:Definitions

BIAS

The difference between the average measured value and a

reference value is referred as bias. The reference value is an agreed

value depending on the specification of the process/ product. Bias

is controlled by calibration.

BIAS

REFERENCE

VALUE

AVERAGE

MEASUREMENT

Measurement System Analysis:Definitions

Repeatability: Variation in measurement obtained with

one measuring instrument by one appraiser while

measuring a characteristic of a product/process

repeatedly.

REPEATABILITY

Measurement System Analysis:Definitions

Reproducibility : It is defined as

the variation in average performance

JANE

of the characteristic in the same

part when measured by more

DICK

than one appraiser using the

same measuring instrument

FRANK

REPRODUCIBILITY

Measurement System Analysis:Definitions

Stability : Stability is the total variation in the

measurements obtained with a measurement system on

the same part when measuring a single characteristic

over an extend period of time. A system is said to be

stable if the variation is of the same order at different

time points.

MONDAY

WEDNESDAY

FRIDAY

STABILITY

Measurement System Analysis: Definitions

Linearity : Linearity is the difference in the bias values

through the expected operating range of the gage.

PART SIZE NEAR

LOW END OF RANGE

(Low Bias)

REFERENCE

VALUE

PART SIZE NEAR

REFERENCE VALUE

MEASUREMENTS

OF A PART CHECKED

REPEATEDLY

PART SIZE NEAR

HIGH END OF

RANGE (High Bias)

Attribute Gage R & R

Attribute studies are used for measuring the overall

effectiveness of observers inspecting attribute

characteristic. When working with attributes, the

measures of repeatability and reproducibility do not

apply as with variables. Some definitions are:

Uniformity is the overall agreement within and among

observers.

Effectiveness is the ability of the observers to detect

both good and bad product.

Miss means accepting a bad part

False Alarm means rejecting a good part

Bias is when observers are biased toward rejection or

acceptance.

Attribute Gage R & R

Primary purpose of attribute studies

Ensure that the acceptance criteria for the

product and its characteristics have been

properly established and communicated.

Identify and correct problems with the

inspection acceptance criteria

Identify observer related problems and train

observers accordingly

Improve overall inspection effectiveness for

product acceptance and/or process control

purposes.

Attribute Gage R & R

P

A

R

T

M

A

S

T

E

R

Observer A Observer B Results

T1 T2 T3 T1 T2 T3 AGood BBad

as

good

as

bad

M

Bad

as

good

Effectiveness (E) = ( A + B ) / Total Inspections

Probability of a false alarm ( Pfa) = F / (A+F)

Probability of a Miss ( Pmiss ) = M / (B + M )

Bias (B)

= Bfa / BMiss

F

Good

as

bad

Attribute Gage R & R

THE FOLLOWING ARE GUIDELINE MEASURES:

Parameter

Effective

P miss

Pfa

accept.

0.9

< 0.02

<0.05

Marginal unacceptable

0.8 0.9

< 0.80

0.02-0.05

> 0.05.

0.05-0.10

>0.10.

Attribute Gage R & R

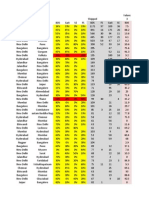

Example : 14 parts are given for

inspection to two observer A and B.

Each person checks the part thrice and

gives his opinion. A master inspector

gives his opinion which is final. The

whole experiment is randomized for

the two observers so that there

opinions are unbiased every time. Data

is given in the next slide.

Attribute Gage R & R

Master

Observer 1

Observer 2

T1

T2

T3

T1

T2

T3

B

G

G

G

G

B

B

G

G

B

G

G

G

B

B

G

G

G

G

B

B

G

G

B

G

G

G

B

B

G

G

G

G

B

B

G

G

B

G

G

G

B

B

G

G

G

G

B

B

G

G

G

G

G

G

B

B

G

G

G

G

G

B

G

G

B

G

G

G

B

G

G

G

G

G

B

B

G

G

B

G

G

G

B

B

G

G

G

G

B

B

G

B

B

G

G

G

B

0

6

6

6

6

0

0

6

5

0

6

6

6

0

5

0

0

0

0

5

6

0

0

5

0

0

0

6

1

0

0

0

0

1

0

0

0

1

0

0

0

0

0

0

0

0

0

0

0

0

1

0

0

0

0

0

Attribute Gage R & R

Total Inspection = 84

Total (A) = 53

Total (M) = 3

Total (B) = 27

Total (F) = 1

Effectiveness = (A+B)/total inspection

= (53+27)/84 =0.952

Prob. of Miss (Pmiss ) = M(B+M) =3/(27+3) =3/30 = 0.1

Prob. Of False Alarm (Pfa ) = F/(A+F) = 1/(53+1) = 0.02

Bfa = 0.0488 corresponding to Pfa

Bmiss = 0.1758 corresponding to Pmiss

B = Bfa / Bmiss = 0.28

Gage R & R for Variable Inspection

BUG TYPE

PERSON1

1.2,1.3

3.0,3.1

4.2, 4.2

2.9,3.0

5.1,5.3

6.1,6.3

8.1,8.0

3.2,3.2

0.5,0.4

PERSON2 PERSON3

2.0,2.1

2.3,2.1

3.4,3.6

3.9,4.0

4.5,4.6

4.7,4.8

3.1,3.3

3.5,3.1

5.0,5.0

5.5,5.5

6.3,6.5

7.0,7.1

8.4,8.4

8.7,9.0

3.5,3.5

4.0,4.0

0.9,0.8

1.1,1.2

Gage R & R for Variable Inspection

ANALYSIS OF VARIANCE WAS CARRIED OUT

AND THE RESULTS ARE AS FOLLOWS:

SOURCE D.F. S.S

M.S

F(CAL) p VALUE

BUG

8

261.8

32.7

3270.0

0.0000

PERSON 2

4.3

2.14

214.0

0.0000

PER*BUG 16

0.85

0.05

5.0

0.0002

REPEAT. 27

0.25

0.01

TOTAL

53 267.3

Gage R & R for Variable Inspection

Based on Expected Value of MS, we calculate:

Repeatability

= 0.01 0.1

Person

= 0.11 0.33

Person*Bug

= 0.02 0.14

Reproducibility = 0.13 0.36

Overall

=

0.14 0.375

Bug

=

5.37 2.32

The system of estimation is not so good.

Standard guidelines for estimation is necessary.

You might also like

- NEF Advanced SB Answer KeyDocument98 pagesNEF Advanced SB Answer KeyMaria Blasco86% (7)

- McPherson 1967 - Political ObligationDocument95 pagesMcPherson 1967 - Political ObligationCivis Vulgaris0% (1)

- Value EngineeringDocument51 pagesValue Engineeringjagfifa71% (14)

- Measurement Systems Analysis: Total Quality ManagementDocument17 pagesMeasurement Systems Analysis: Total Quality Managementtlatuani1000No ratings yet

- Measurement System AnalysisDocument10 pagesMeasurement System AnalysisRodrigo CandelariaNo ratings yet

- Attribute Gauge R&RDocument5 pagesAttribute Gauge R&Rhel2905No ratings yet

- MSA For Attribute or Categorical DataDocument18 pagesMSA For Attribute or Categorical DatadesurkarbNo ratings yet

- FMEA & Measurement Systems AnalysisDocument23 pagesFMEA & Measurement Systems AnalysisViswanathan SrkNo ratings yet

- GR&R Training DraftDocument53 pagesGR&R Training DraftLOGANATHAN VNo ratings yet

- Residual AnalysisDocument6 pagesResidual AnalysisGagandeep SinghNo ratings yet

- PPT4-Statistical Process Control and Capability AnalysisDocument120 pagesPPT4-Statistical Process Control and Capability AnalysisDini MaharNo ratings yet

- Measurement Systems Analysis: Total Quality ManagementDocument17 pagesMeasurement Systems Analysis: Total Quality ManagementkhamaludinNo ratings yet

- MSA Sample PresentationDocument9 pagesMSA Sample PresentationTom@GGCNo ratings yet

- MSA TrainingDocument30 pagesMSA Trainingshukumar_24No ratings yet

- X-Bar and R ChartsDocument13 pagesX-Bar and R ChartspraveenNo ratings yet

- SPCDocument49 pagesSPCJosephi_abbasNo ratings yet

- Statistical Process ControlDocument79 pagesStatistical Process ControlKrunal PandyaNo ratings yet

- Value Stream MappingDocument35 pagesValue Stream MappingNevets NonnacNo ratings yet

- OEE PresentationDocument15 pagesOEE PresentationIbrahim FaragNo ratings yet

- Kaizen EyeDocument28 pagesKaizen EyeJPNo ratings yet

- 1.5 LSS Quality Files Bus. Risk ManagementDocument81 pages1.5 LSS Quality Files Bus. Risk ManagementMurrell J RizonNo ratings yet

- Materi 4Document24 pagesMateri 4AuliamNo ratings yet

- MeasurementSystemsAnalysis PDFDocument37 pagesMeasurementSystemsAnalysis PDFJorge MartinezNo ratings yet

- Basic Statistical Process ControlDocument30 pagesBasic Statistical Process ControlStephen DeasNo ratings yet

- Value Stream MappingDocument40 pagesValue Stream Mappingjinyue7302No ratings yet

- MSA Case StudiesDocument10 pagesMSA Case StudiesMuthuswamyNo ratings yet

- Statistical Process ControlDocument66 pagesStatistical Process Controlanshuldce50% (2)

- CP, CPK, CM, CMK, Control LimitsDocument5 pagesCP, CPK, CM, CMK, Control LimitsBruno MauroNo ratings yet

- 2.3.4 Variable and Attribute MSA PDFDocument0 pages2.3.4 Variable and Attribute MSA PDFAlpha SamadNo ratings yet

- Msa-R&R Training Program: DateDocument25 pagesMsa-R&R Training Program: DateHarshad KulkarniNo ratings yet

- 4.1 Introduction To SPCDocument57 pages4.1 Introduction To SPCVinith MoorthyNo ratings yet

- 1 CP-CPK and PP PPK FormulasDocument4 pages1 CP-CPK and PP PPK FormulasJulion2009No ratings yet

- Minitab CheatDocument9 pagesMinitab Cheatwaqas104No ratings yet

- Fmea Chart 70kb PDFDocument1 pageFmea Chart 70kb PDFmike gamerNo ratings yet

- Kaizen: The Continuous Improvement Process ProgramDocument62 pagesKaizen: The Continuous Improvement Process ProgramFouzan SoniwalaNo ratings yet

- 8D Report Training MIDDocument23 pages8D Report Training MIDanon_86320488No ratings yet

- Martin Gibson QIS 3 June 2014Document13 pagesMartin Gibson QIS 3 June 2014nadeemkarimiNo ratings yet

- Maintenances Engineering: Fault Tree AnalysisDocument8 pagesMaintenances Engineering: Fault Tree AnalysisSurbhi SarawagiNo ratings yet

- Problem Solving - PdcaDocument61 pagesProblem Solving - PdcaNurul HidayahNo ratings yet

- Statistical Process ControlDocument57 pagesStatistical Process ControlSandeep PasumarthiNo ratings yet

- Basic 7 Tools of QualityDocument31 pagesBasic 7 Tools of Qualityapi-3835934100% (2)

- Quality Control and Acceptance SamplingDocument15 pagesQuality Control and Acceptance SamplingMark Ortiz Luis OllerNo ratings yet

- 3G and 7 QC Tools - PomDocument26 pages3G and 7 QC Tools - Pombinga35No ratings yet

- Problem Solving & 7qc Tools (Compatibility Mode)Document42 pagesProblem Solving & 7qc Tools (Compatibility Mode)Krunal PandyaNo ratings yet

- 7 QC ToolsDocument8 pages7 QC ToolspremNo ratings yet

- Ch03 SPC and Process CapabilityDocument55 pagesCh03 SPC and Process CapabilityRaj Kumar100% (1)

- How To Conduct A Measurement Systems AnalysisDocument5 pagesHow To Conduct A Measurement Systems AnalysisNavnath TamhaneNo ratings yet

- Tests For One Poisson MeanDocument9 pagesTests For One Poisson MeanJulyAntoNo ratings yet

- 15 Mistake ProofingDocument4 pages15 Mistake ProofingSteven Bonacorsi100% (2)

- The Application of Gage R&R Analysis in S Six Sigma Case of ImproDocument83 pagesThe Application of Gage R&R Analysis in S Six Sigma Case of ImproDLNo ratings yet

- Poka YokeDocument33 pagesPoka YokejanisahebNo ratings yet

- Gage R&RDocument24 pagesGage R&RLuis ConstanteNo ratings yet

- Poka-Yoke Team 4Document14 pagesPoka-Yoke Team 4Ratandeep PandeyNo ratings yet

- 06control Chart 1Document37 pages06control Chart 1abishank09100% (1)

- Quality Management System Process A Complete Guide - 2020 EditionFrom EverandQuality Management System Process A Complete Guide - 2020 EditionNo ratings yet

- Reliability Analysis and Plans for Successive Testing: Start-up Demonstration Tests and ApplicationsFrom EverandReliability Analysis and Plans for Successive Testing: Start-up Demonstration Tests and ApplicationsNo ratings yet

- ANOVA Gauge R&RDocument3 pagesANOVA Gauge R&Rtehky63No ratings yet

- ASQ MSA An Alternative Method For Estimating Percentage Tolerance 20120418Document78 pagesASQ MSA An Alternative Method For Estimating Percentage Tolerance 20120418solmaz MOVAFAGHINo ratings yet

- 1.5 Measurement (Gage R&R)Document19 pages1.5 Measurement (Gage R&R)rollickingdeol100% (1)

- Excel - DashboardingDocument54 pagesExcel - DashboardingAkash KumarNo ratings yet

- Mintab-Practice Data001Document22 pagesMintab-Practice Data001Akash KumarNo ratings yet

- English Book For Competitive ExamsDocument698 pagesEnglish Book For Competitive ExamsAkash KumarNo ratings yet

- Algo PPT of Bits WilpDocument62 pagesAlgo PPT of Bits WilpAkash KumarNo ratings yet

- Courier SharingDocument15 pagesCourier SharingAkash KumarNo ratings yet

- Appliances - Packaging GuidelinesDocument5 pagesAppliances - Packaging GuidelinesAkash KumarNo ratings yet

- Computer FundamentalsDocument17 pagesComputer Fundamentalsdarmahnoor0% (1)

- Counter-Strike: Game Version: GeneralDocument5 pagesCounter-Strike: Game Version: GeneralAkash KumarNo ratings yet

- Advantages and Disadvantages of Virtual TeamsDocument3 pagesAdvantages and Disadvantages of Virtual TeamsAnand KVNo ratings yet

- Front Fin All Print LDocument10 pagesFront Fin All Print LRichelle TanNo ratings yet

- Effective Early EducationDocument356 pagesEffective Early Educationekamaya28No ratings yet

- Annotated BibliographyDocument4 pagesAnnotated Bibliographyapi-317336978No ratings yet

- Managing Individual Differences and BehaviorDocument40 pagesManaging Individual Differences and BehaviorDyg Norjuliani100% (1)

- 23 Traits of Good LeadersDocument1 page23 Traits of Good LeadersNaeem AkhtarNo ratings yet

- Retrograde PlanetsDocument2 pagesRetrograde PlanetsthavaNo ratings yet

- Seanewdim Philology VII 60 Issue 204Document118 pagesSeanewdim Philology VII 60 Issue 204seanewdimNo ratings yet

- Interview Questions HRDocument6 pagesInterview Questions HRNaveen KumarNo ratings yet

- Contemporary Practices - A Holistic Approach To Teacher EmpowermentDocument4 pagesContemporary Practices - A Holistic Approach To Teacher EmpowermentJeevaNo ratings yet

- Type Conditions and StyleDocument18 pagesType Conditions and StyleAmir ChohanNo ratings yet

- Kinesiology Info 1Document3 pagesKinesiology Info 1hwardell_oooNo ratings yet

- My Philosophy of Teaching and English TeachingDocument2 pagesMy Philosophy of Teaching and English TeachingAmber Austin0% (1)

- DepEd-NCR Self-Paced Learners ProgramDocument10 pagesDepEd-NCR Self-Paced Learners ProgramCherilyn SaagundoNo ratings yet

- Assignment HMEF5123 Models of Teaching and Learning September 2020 SemesterDocument7 pagesAssignment HMEF5123 Models of Teaching and Learning September 2020 SemesterNurul IzzatyNo ratings yet

- 7es Lesson Plan ISODocument4 pages7es Lesson Plan ISOMidrel Jasangas71% (7)

- Perception of SpaceDocument56 pagesPerception of Spacelalala100% (6)

- Vac STS L100Document20 pagesVac STS L100Safura AliNo ratings yet

- Industrial Security ManagementDocument8 pagesIndustrial Security ManagementKenn-jei PeregrinoNo ratings yet

- Speech & Language Therapy in Practice, Spring 2009Document32 pagesSpeech & Language Therapy in Practice, Spring 2009Speech & Language Therapy in PracticeNo ratings yet

- Biology Project Class 8Document6 pagesBiology Project Class 8jazzNo ratings yet

- De THI CHINH THUC - Ma 401 Co Loi Giai Chi TietDocument11 pagesDe THI CHINH THUC - Ma 401 Co Loi Giai Chi TietTrịnh NamNo ratings yet

- Holiday Homework - Class VIII PDFDocument7 pagesHoliday Homework - Class VIII PDFDua FatimaNo ratings yet

- 12th House SecreteDocument3 pages12th House SecreteRahulshah1984No ratings yet

- Class 12 ENGLISH PROJECTDocument5 pagesClass 12 ENGLISH PROJECTCricket ClutchNo ratings yet

- Therapeutic Communication TechniquesDocument8 pagesTherapeutic Communication TechniquesPhilip Jay BragaNo ratings yet

- Review Visi Dan Misi - Arief Wahyu SDocument3 pagesReview Visi Dan Misi - Arief Wahyu SErni Yessyca SimamoraNo ratings yet