Professional Documents

Culture Documents

Concrete Cracks

Uploaded by

vinithemmanuel0 ratings0% found this document useful (0 votes)

24 views12 pagesfhid

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentfhid

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

24 views12 pagesConcrete Cracks

Uploaded by

vinithemmanuelfhid

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 12

CRACKS IN CONCRETE

STRUCTURES

WHAT CAUSES CONCRETE TO

CRACK?

A:Unexpected cracking of concrete is a frequent

cause of complaints. Cracking can be the result of one

or a combination of factors, such as drying shrinkage,

thermal contraction, restraint (external or internal)

to shortening,sub-gradesettlement, and applied

loads. Cracking can be significantly reduced when the

causes are taken into account andpreventative steps

are utilized.

Cracking in concrete can be reduced significantly

or eliminated by observing the following

practices:

1. Use proper sub-grade preparation, including

uniform support and proper sub-base material at

adequate moisture content.

2. Minimize the mix water content by maximizing the

size and amount of coarse aggregate and use lowshrinkage aggregate.

3. Use the lowest amount of mix water required for

workability

4. Avoid calcium chloride admixtures.

5. Prevent rapid loss of surface moisture while the

concrete is still plastic

6. Provide contraction joints at reasonable intervals,

30 times the slab thickness.

7. Provide isolation joints to prevent restraint from

adjoining elements of a structure.

8. Prevent extreme changes in temperature.

9.Consider using a shrinkage-reducing admixture

to reduce drying shrinkage, which may reduce

shrinkage cracking.

10. Consider using synthetic fibers to help control

plastic shrinkage cracks.

Crazingis a pattern of fine cracks that do not

penetrate much below the surface and are

usually a cosmetic problem only. They are barely

visible, except when the concrete is drying after

the surface has been wet.

Drying Shrinkage: Because almost all concrete is

mixed with more water than is needed to hydrate the

cement, much of the remaining water evaporates,

causing the concrete to shrink. Restraint to shrinkage,

provided by the subgrade, reinforcement, or another

part of the structure, causes tensile stresses to develop

in the hardened concrete. Restraint to drying shrinkage

is the most common cause of concrete cracking. In many

applications, drying shrinkage cracking is inevitable.

Therefore, contraction (control) joints are placed in

concrete to predetermine the location of drying

shrinkage cracks.

D-crackingis a form of freeze-thaw deterioration that

has been observed in some pavements after three or

more years of service. Due to the natural accumulation

of water in the base and subbase of pavements, the

aggregate may eventually become saturated. Then

with freezing and thawing cycles, cracking of the

concrete starts in the saturated aggregate at the

bottom of the slab and progresses upward until it

reaches the wearing surface. D-cracking usually starts

near pavement joints.

Alkali-aggregate reaction: Alkali-aggregate reactivity

is a type of concrete deterioration that occurs when the

active mineral constituents of some aggregates react

with the alkali hydroxides in the concrete. Alkaliaggregate reactivity occurs in two formsalkali-silica

reaction (ASR) and alkali-carbonate reaction (ACR).

Indications of the presence of alkali-aggregate reactivity

may be a network of cracks, closed or spalling joints, or

displacement of different portions of a structure.

Thermal cracks:Temperature rise (especially

significant in mass concrete) results from the heat of

hydration of cementitious materials. As the interior

concrete increases in temperature and expands, the

surface concrete may be cooling and contracting. This

causes tensile stresses that may result in thermal

cracks at the surface if the temperature differential

between the surface and center is too great. The width

and depth of cracks depends upon the temperature

differential, physical properties of the concrete, and the

reinforcing steel.

Loss of supportbeneath concrete structures, usually

caused by settling or washout of soils and subbase

materials, can cause a variety of problems in concrete

structures, from cracking and performance problems

to structural failure. Loss of support can also occur

during construction due to inadequate formwork

support or premature removal of forms.

Corrosion: Corrosion of reinforcing steel and other

embedded metals is one of the leading causes of

deterioration of concrete. When steel corrodes, the

resulting rust occupies a greater volume than steel.

The expansion creates tensile stresses in the concrete,

which can eventually cause cracking and spalling.

You might also like

- ThermDocument46 pagesThermvinithemmanuelNo ratings yet

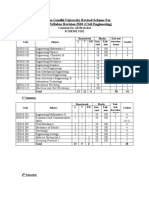

- Mahatma Gandhi University Revised Scheme For B Tech Syllabus Revision 2010 (Civil Engineering)Document4 pagesMahatma Gandhi University Revised Scheme For B Tech Syllabus Revision 2010 (Civil Engineering)vinithemmanuelNo ratings yet

- Model QN Paper BCEDocument2 pagesModel QN Paper BCEvinithemmanuelNo ratings yet

- UntitledDocument11 pagesUntitledapi-256504985No ratings yet

- Process Economics Report 216 Acid Gas Treatment and Sulfur Recovery (October 1997)Document11 pagesProcess Economics Report 216 Acid Gas Treatment and Sulfur Recovery (October 1997)vinithemmanuelNo ratings yet

- 3.5 Karman's Momentum Integral Approach: 3.5.1 General IdeasDocument8 pages3.5 Karman's Momentum Integral Approach: 3.5.1 General IdeasRatovoarisoaNo ratings yet

- Opti Model QPDocument3 pagesOpti Model QPvinithemmanuelNo ratings yet

- Chapter 10 Worksheet 3 ANSWER KEY 2013Document2 pagesChapter 10 Worksheet 3 ANSWER KEY 2013vinithemmanuelNo ratings yet

- Spread Spectrum: Fhss DsssDocument26 pagesSpread Spectrum: Fhss DsssvinithemmanuelNo ratings yet

- MAP ExtractionDocument20 pagesMAP ExtractionvinithemmanuelNo ratings yet

- Opti Model QPDocument3 pagesOpti Model QPvinithemmanuelNo ratings yet

- Module - 1: Part ADocument3 pagesModule - 1: Part AvinithemmanuelNo ratings yet

- Fluoride DW 4 MaaaDocument11 pagesFluoride DW 4 MaaavinithemmanuelNo ratings yet

- Fluoride w3 ChitosinDocument32 pagesFluoride w3 ChitosinvinithemmanuelNo ratings yet

- Ritewater EdfDocument18 pagesRitewater EdfvinithemmanuelNo ratings yet

- ELF Ealing Oncret EDocument19 pagesELF Ealing Oncret EvinithemmanuelNo ratings yet

- Spread Spectrum: Fhss DsssDocument26 pagesSpread Spectrum: Fhss DsssvinithemmanuelNo ratings yet

- MM Qstns ModuleWiseDocument3 pagesMM Qstns ModuleWisevinithemmanuelNo ratings yet

- Seeee AshwinDocument9 pagesSeeee AshwinvinithemmanuelNo ratings yet

- Wireless Wans: Cellular Telephone and Satellite NetworksDocument61 pagesWireless Wans: Cellular Telephone and Satellite Networksvinithemmanuel100% (1)

- ELF Ealing Oncret EDocument19 pagesELF Ealing Oncret EvinithemmanuelNo ratings yet

- Seeee AshwinDocument9 pagesSeeee AshwinvinithemmanuelNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Plans SEW-EuroDriveDocument690 pagesPlans SEW-EuroDriveAntuan KourosNo ratings yet

- Failures AmalgamDocument14 pagesFailures AmalgamPriyaancaHaarsh100% (4)

- Design Guideline - Tank Roof Access Hatch and Work PlatformDocument10 pagesDesign Guideline - Tank Roof Access Hatch and Work PlatformDmacNo ratings yet

- Rustlick™ B: Rust PreventativeDocument2 pagesRustlick™ B: Rust PreventativeJesús PalomaresNo ratings yet

- Construction Impact On in Situ Preservation of Archaeological Sites and ArtefactDocument4 pagesConstruction Impact On in Situ Preservation of Archaeological Sites and ArtefactSebastian SantanaNo ratings yet

- B-268 Phosphate Hideout PDFDocument4 pagesB-268 Phosphate Hideout PDFJayanath Nuwan SameeraNo ratings yet

- Distek EPA ArticleDocument5 pagesDistek EPA ArticleNagendra KumarNo ratings yet

- API 570 - Course NotesDocument173 pagesAPI 570 - Course Notessheikbba97% (31)

- Non-Shrink Cementitious Grout SHRINKKOMP: An ISO 9001-2015 Accredited CompanyDocument6 pagesNon-Shrink Cementitious Grout SHRINKKOMP: An ISO 9001-2015 Accredited Companyvahid khanNo ratings yet

- Ugiweb 762845Document5 pagesUgiweb 762845Humza SulheriNo ratings yet

- Barrier ZEP: Technical Data Sheet Application GuideDocument7 pagesBarrier ZEP: Technical Data Sheet Application GuideNurmalinda SihombingNo ratings yet

- IJOGST - Volume 3 - Issue 4 - Pages 67-77Document11 pagesIJOGST - Volume 3 - Issue 4 - Pages 67-77Hka IsmailNo ratings yet

- Kens Metal Brochure PDFDocument40 pagesKens Metal Brochure PDFMike0% (1)

- Sae J75-2018Document3 pagesSae J75-2018Marcos RosenbergNo ratings yet

- Introduction To Corrosion ScienceDocument11 pagesIntroduction To Corrosion ScienceFrancois BornmanNo ratings yet

- Solenoid Valve S06Document28 pagesSolenoid Valve S06korpaapNo ratings yet

- H-19330 - Gloss (Du Pont)Document30 pagesH-19330 - Gloss (Du Pont)Josh LuNo ratings yet

- Ailures in Ammonia Plant Vertical Waste Heat BoilersDocument14 pagesAilures in Ammonia Plant Vertical Waste Heat BoilersMir AsifNo ratings yet

- Prospectus EnglishDocument20 pagesProspectus EnglishMilan GašićNo ratings yet

- Lim - Erosion Corrosion Damages of Water Pump ImpellerDocument7 pagesLim - Erosion Corrosion Damages of Water Pump ImpellerYudha PradhanaNo ratings yet

- Liposuction Instruments CatalogueDocument14 pagesLiposuction Instruments Catalogueahmed atefNo ratings yet

- DSS ShelvingDocument12 pagesDSS ShelvingCoya ValentinaNo ratings yet

- Chloride Attack On Stainless SteelDocument9 pagesChloride Attack On Stainless SteelAnand GuptaNo ratings yet

- Boiler Water Treatment FAQ PDFDocument76 pagesBoiler Water Treatment FAQ PDFRisqi Putri Nur PriatmaNo ratings yet

- Sunpower Module Degradation Rate: A Conventional Module Is Defined As 240W, 15% Efficient, Approximately 1.6 MDocument61 pagesSunpower Module Degradation Rate: A Conventional Module Is Defined As 240W, 15% Efficient, Approximately 1.6 MDimitris GikasNo ratings yet

- Petroleum MCQDocument35 pagesPetroleum MCQpriya dharshiniNo ratings yet

- Protect Buried Pipes with Eco-Friendly ECOTAPE SystemDocument2 pagesProtect Buried Pipes with Eco-Friendly ECOTAPE SystemTeguh SilaNo ratings yet

- Pitting Corrosion: MechanismDocument4 pagesPitting Corrosion: MechanismCarlos BustamanteNo ratings yet

- Evk2rv 110-390 Manual enDocument13 pagesEvk2rv 110-390 Manual enKjsNo ratings yet

- Electrochemical CorrosionDocument76 pagesElectrochemical CorrosionMeshack NyitiNo ratings yet