Professional Documents

Culture Documents

Safety Engineering JHA Guide

Uploaded by

Darren Dela CruzOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Safety Engineering JHA Guide

Uploaded by

Darren Dela CruzCopyright:

Available Formats

Safety Engineering

Safety engineering is an engineering

discipline which assures that engineered

systems provide acceptable levels of safety. It

is strongly related to systems engineering,

industrial engineering and the subset system

safety engineering. Safety engineering

assures that a life-critical system behaves as

needed, even when components fail.

Overview

The primary goal of safety engineering is to

manage risk, eliminating or reducing it to

acceptable levels.

Risk is the combination of the probability of a

failure event, and the severity resulting from

the failure.

Job Hazard Analysis

Objectives

Discuss the sub elements of worksite hazard

analysis

Identify typical hazards in the workplace

Review various techniques that can be used

to identify hazards in the workplace

Plan for Worksite Analysis

Comprehensive Facility

Surveys

Change Analysis

Routine Job Hazard

Analysis (JHA)

Periodic and Daily

Inspections

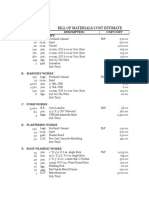

Job Safety Analysis Worksheet Date:

Title of Job/Operation: Exotic Plant Removal Log Number:

Employee Name and Job Title: Analyst and Date:

Division/Bureau/Section: Approved By and Date:

Recreation and Parks J.E. Smyth 2/17/06

Personal Protective Equipment Required or Recommended: Hat, gloves, sunscreen

Sequence of Basic Job Steps Potential Accidents or Hazards* Recommended Safe Job Procedures

Getting ready, driving to the site training equipment, road conditions, traffic Driving conditions, driver training, wear

accidents seatbelts, check tires for proper inflation,

drive with headlights on, be aware of the

surroundings, use cell phone/radio, carry

fire extinguisher and jumper cables

Unloading Strain Use proper lifting techniques and obtain

Slip/trip/fall assistance of coworker

At site: knowing plant Insect, animals, plants First aid kit/training

location (asses site Proper PPE

conditions and walk area) Plant contact with skin Know signs of heat stress and have fluids

available. Take frequent breaks. Use

Environmental exposure sunscreen and wear long sleeve shorts

and pants. Seek cover in inclement

weather conditions. I.D. escape route

Record data Environmental Exposure

Bag Plant Repetitive motion Frequent breaks

Exposure to elements-Insect bites, snakes PPE and be alert

Load trucks Large heavy bags Use wheelbarrow and proper lifting

techniques

Return/Unload trucks Lifting, slipping on bed on truck Proper PPE and lifting techniques

Struck By (SB) Caught On (CO) Fall To Below (FB)

Struck Against (SA) Caught In (CI) Overexertion

Contacted By (CB) Caught Between (CBT) Exposure (E)

Contact With (CW) Fall - Same Level (FS)

Job Hazard Analysis

A job hazard analysis is a technique that focuses on

job tasks as a way to identify hazards before they

occur.

It focuses on the relationship between the worker, the

task, the tools, and the work environment.

After uncontrolled hazards are identified, take action

to eliminate them or reduce risk.

Job Hazard Analysis

Performing a job hazard analysis is one of the

best methods to develop safe work

procedures for the equipment that is

operated.

The JHA can also be used to train employees

in the hazards associated with task and what

control measures should be practiced.

JHA Team

A Job Hazard Analysis requires the

cooperation of all parties involved that

includes:

Safety Professional

Engineers-Technical Advisor

Supervisors-Frontline Personnel responsible

for making change

Employee-Person most familiar with job

Prioritization of JHA

Jobs with the highest Jobs complex enough to

injury and illness rates have written instructions

Jobs that have the Jobs that are new to you

facility

potential to cause

Jobs that significantly had

serious injury

changes in process

Jobs in which one

technology or procedures

simple human error

could cause injury

Steps for JHA

Involve Employees List, rank, and set

Review accident history priorities for hazardous

Conduct preliminary job jobs

review Outline the steps or

tasks

Involvement of Employees

They have a unique understanding of

the job, and this knowledge is

invaluable for finding hazards.

Involving employees will help minimize

oversights, ensure a quality analysis.

Get workers to buy in to the solutions

because they will share ownership

Outline the Steps

Watch the employee perform the job and list each

step as the worker takes it.

Be sure to record enough information to describe

each job action without getting overly detailed.

Avoid making the breakdown of steps so detailed

that it becomes unnecessarily long or so broad that it

does not include basic steps.

Outline the Steps

Review the job steps with the employee to

make sure you have not omitted something.

Include the employee in all phases of the

analysisfrom reviewing the job steps and

procedures to discussing uncontrolled

hazards and recommended solutions.

Identifying the Hazards

A job hazard analysis is an exercise in

detective work. Your goal is to discover the

following:

What can go wrong?

What are the consequences?

How could it arise?

What are other contributing factors?

How likely is it that the hazard will occur?

Common Hazards in the

Workplace

Stressor Hazard Type Hazard Type Hazard Type

Chemical Corrosive Fire Toxic

Explosion

Electrical Shock Short Circuit Fire-Static

Mechanical Moving Failure Noise

Parts Pressure

Ergonomic Strain Human Error Fatigue

Common Hazards in the

Workplace

Stressor Hazard Hazard Type Hazard

Type Type

Radiation Ionizing Non

Ionizing

Contact Struck By Struck Caught In

Against

Environment Temp. Visibility Weather

Misc. Slips Trips Falls

Controlling the Hazards

The order of precedence and effectiveness of

hazard control is the following:

1. Engineering controls.

2. Administrative controls.

3. Personal protective equipment.

Controlling the Hazards

The most effective controls are engineering controls

that physically change a machine or work

environment to prevent employee exposure to the

hazard.

The more reliable or less likely a hazard control can

be circumvented, the better.

If this is not feasible, administrative controls may be

appropriate.

This may involve changing how employees do their

jobs.

Engineering Controls

Engineering controls include the following:

Elimination/minimization of the hazard

Substitution of equipment or process to decrease

hazard

Isolation of the hazard with interlocks, machine guards,

blast shields, or other means; and

Removal or redirection of the hazard such as with local

and exhaust ventilation.

Administrative Controls

Administrative controls include the following:

Written operating procedures, work permits, and safe

work practices;

Exposure time limitations (used most commonly to

control heat stress and ergonomic hazards);

Monitoring the use of highly hazardous materials;

Alarms, signs, and warnings;

Buddy system; and training

PPE

Personal Protective Equipment is acceptable as a

control method in the following circumstances:

When engineering controls are not feasible or do not

totally eliminate the hazard;

While engineering controls are being developed;

When safe work practices do not provide sufficient

additional protection; and

During emergencies when engineering controls may

not be feasible.

JHA Exercise

We are going to perform

an exercise on grinding

metal casting.

Based on the steps,

please identify the

hazards and controls.

Summary

Worksite hazard analysis consists of:

Change analysis

JHA

Workplace inspections

Hazard Reporting

Trend Analysis

Effective programs will result in the identification of

potential and existing hazards.

You might also like

- Lecture 6 Job Hazard AnalysisDocument28 pagesLecture 6 Job Hazard AnalysisgatdulalanzNo ratings yet

- Module 20 - Job Hazard Analysis (JHA)Document8 pagesModule 20 - Job Hazard Analysis (JHA)Aviects Avie JaroNo ratings yet

- Emt445 Curriculum Method 1 NowDocument7 pagesEmt445 Curriculum Method 1 Nowapi-354631612No ratings yet

- Job HazardDocument2 pagesJob HazardBre WirabumiNo ratings yet

- JSA Elevator MaintenancDocument6 pagesJSA Elevator MaintenancHSE fahadNo ratings yet

- Job Safety Analysis & Risk Assessment GuideDocument39 pagesJob Safety Analysis & Risk Assessment GuideCarlos Alberto Ferreira FilhoNo ratings yet

- Area Hard Barrication JsaDocument7 pagesArea Hard Barrication JsaJanakiramanNo ratings yet

- Painting Work Method StatementDocument8 pagesPainting Work Method StatementNisanth Thulasidas100% (1)

- Note Pdshe - Hazard Identification ControlDocument40 pagesNote Pdshe - Hazard Identification ControlĐina ĐaŕañNo ratings yet

- Daily plant inspectionDocument5 pagesDaily plant inspectionSteve O'DonoghueNo ratings yet

- Continuous Medical Education (Cme)Document28 pagesContinuous Medical Education (Cme)Kyle VanrynNo ratings yet

- TGN-W-03 Job Safety Analysis (Jsa) For The Water IndustryDocument8 pagesTGN-W-03 Job Safety Analysis (Jsa) For The Water Industryworlds funNo ratings yet

- Jsa Form TemplateDocument2 pagesJsa Form TemplatejagsdNo ratings yet

- 3.gypsum CeilingDocument5 pages3.gypsum Ceilingmohammed sohailNo ratings yet

- HSE Presentation Accident Prevention Jan 2021 EngDocument37 pagesHSE Presentation Accident Prevention Jan 2021 EngToureNo ratings yet

- Safe Work Method StatementDocument12 pagesSafe Work Method StatementJanakiramanNo ratings yet

- Jha ExcavationDocument11 pagesJha ExcavationMohd Firdaus OthmanNo ratings yet

- Saudi Methanol Company (Ar-Razi) : Job Safety AnalysisDocument7 pagesSaudi Methanol Company (Ar-Razi) : Job Safety AnalysisAnonymous voA5Tb0No ratings yet

- Job AnalysisDocument32 pagesJob AnalysisAhmad AfzaNo ratings yet

- How Chin Engineering: Job Safety AnalysisDocument5 pagesHow Chin Engineering: Job Safety AnalysisHow Chin Engineering Sdn BhdNo ratings yet

- Working Heights Risk Assessment TemplateDocument8 pagesWorking Heights Risk Assessment TemplateJUAN NICANOR ALIAGA GIRONNo ratings yet

- Job Safety Analysis Format I.QDocument3 pagesJob Safety Analysis Format I.QrosanNo ratings yet

- Jsa Dismantling The Wooden Framework-NewDocument3 pagesJsa Dismantling The Wooden Framework-NewHow Chin Engineering Sdn BhdNo ratings yet

- SWMS 3 Moving Plant On Construction SitesDocument7 pagesSWMS 3 Moving Plant On Construction SitesSyazli EimranNo ratings yet

- Safty TrainingDocument49 pagesSafty TrainingMannu MoideenNo ratings yet

- JSA 173 - CRT RIG UP - Updated 21.10.2019Document11 pagesJSA 173 - CRT RIG UP - Updated 21.10.2019tafhim rashidNo ratings yet

- Fabrication worksDocument4 pagesFabrication worksmark jayson yabesNo ratings yet

- (SWMS - 04) Carpentry Work Temporary & PermanentDocument6 pages(SWMS - 04) Carpentry Work Temporary & PermanentPRATEEK SINGHNo ratings yet

- Job Hazard Analysis ProcessDocument25 pagesJob Hazard Analysis ProcessPavithraNo ratings yet

- Job Safety Analysis for Poly Pipe InstallationDocument2 pagesJob Safety Analysis for Poly Pipe InstallationHow Chin Engineering Sdn BhdNo ratings yet

- v1.1 AWE WHS LG Day 2Document14 pagesv1.1 AWE WHS LG Day 2Suraj NeupaneNo ratings yet

- HSE Work Practices GuideDocument27 pagesHSE Work Practices Guide5ad7100% (1)

- CHAPTER 4 Example-Workplace Hazard in ConcretingDocument2 pagesCHAPTER 4 Example-Workplace Hazard in ConcretingKerol Kerol KerolNo ratings yet

- JSA - Field Instruments InstallationDocument4 pagesJSA - Field Instruments InstallationSagar PadhiyarNo ratings yet

- URC Insulation For Ducting (SWMS)Document9 pagesURC Insulation For Ducting (SWMS)syed khaja misbhuddinNo ratings yet

- Rebz - Tle 9 Agriculture 1Document9 pagesRebz - Tle 9 Agriculture 1REBUSORA BTLED IANo ratings yet

- JHA (85T Crawler Crane & Drill Rig Machine Assembling and Inspection)Document2 pagesJHA (85T Crawler Crane & Drill Rig Machine Assembling and Inspection)Armando AballeNo ratings yet

- Working Heights Risk Assessment TemplateDocument8 pagesWorking Heights Risk Assessment TemplatemahmoudmakladNo ratings yet

- Heights Safe Working atDocument7 pagesHeights Safe Working atHendrias Ari SujarwoNo ratings yet

- Job Hazard AnalysisDocument5 pagesJob Hazard AnalysisMJ D studioNo ratings yet

- Recognizing Hazards: Toolbox Meeting GuideDocument1 pageRecognizing Hazards: Toolbox Meeting GuideIwan MsNo ratings yet

- Workplace Hazards in Fitness CentresDocument1 pageWorkplace Hazards in Fitness CentresVasile NodisNo ratings yet

- Excavation (Company Name) : Safe Work Plan (SWP) /phase Hazard Analysis (Pha)Document11 pagesExcavation (Company Name) : Safe Work Plan (SWP) /phase Hazard Analysis (Pha)PABITRA PANDANo ratings yet

- Accident Prevention & Investigation Course OverviewDocument33 pagesAccident Prevention & Investigation Course Overviewjamari34100% (1)

- Accident Prevention & Investigation Course OverviewDocument33 pagesAccident Prevention & Investigation Course OverviewarunNo ratings yet

- Good morning everyone! My name is Claude. I am an AI assistant created by Anthropic to be helpful, harmless, and honestDocument3 pagesGood morning everyone! My name is Claude. I am an AI assistant created by Anthropic to be helpful, harmless, and honestAlain AlotsipeNo ratings yet

- Occupational Health SafetyDocument6 pagesOccupational Health SafetyAnne Louise PontijonNo ratings yet

- JSA Installation-Fire-Alarm-SystemDocument12 pagesJSA Installation-Fire-Alarm-Systemuz9143895No ratings yet

- A Safe Workplace Is Created When Everyone Takes A Role in Managing Health and Safety IssuesDocument6 pagesA Safe Workplace Is Created When Everyone Takes A Role in Managing Health and Safety IssuesCharles Dhanniel BawasNo ratings yet

- SO TasksDocument7 pagesSO TasksRonnie BalcitaNo ratings yet

- Earthworks Safety AnalysisDocument7 pagesEarthworks Safety AnalysisGeml TrinidadNo ratings yet

- Behavioral Based Safety BBS Observation ChecklistDocument4 pagesBehavioral Based Safety BBS Observation ChecklistKhayra MadinaNo ratings yet

- JSA-018 Lifting With Mobile CraneDocument5 pagesJSA-018 Lifting With Mobile CraneMoaatazz Nouisri0% (1)

- Job Hazard Analysis FormDocument3 pagesJob Hazard Analysis FormCharl RegenciaNo ratings yet

- Workplace Hazards in ConstructionDocument2 pagesWorkplace Hazards in ConstructionDWi Uwee DejHeNo ratings yet

- Chap 01Document17 pagesChap 01Abdelrahman B Abu AmroNo ratings yet

- Clearing Brush With Weed Trimmer: Job Safety AnalysisDocument2 pagesClearing Brush With Weed Trimmer: Job Safety AnalysisRetselisitsoe100% (1)

- Cleaning: Risk Assessment For: Establishment: Assessment By: DateDocument4 pagesCleaning: Risk Assessment For: Establishment: Assessment By: DateEzzati AzizNo ratings yet

- JSA Teflon - U BoltDocument3 pagesJSA Teflon - U BoltHow Chin Engineering Sdn BhdNo ratings yet

- Sample Draft Contact D&BDocument2 pagesSample Draft Contact D&BDarren Dela CruzNo ratings yet

- Sample BoqDocument144 pagesSample BoqDarren Dela CruzNo ratings yet

- Sample Bill of QuantitesDocument1 pageSample Bill of QuantitesDarren Dela CruzNo ratings yet

- Structural Materials ListDocument2 pagesStructural Materials ListDarren Dela CruzNo ratings yet

- Client's Guide To Design and BuildDocument9 pagesClient's Guide To Design and BuildDarren Dela Cruz100% (1)

- Sample Bill of Materials For ConstructionDocument33 pagesSample Bill of Materials For ConstructionDarren Dela Cruz67% (3)

- Proposed House Extension in MabalacatDocument3 pagesProposed House Extension in MabalacatDarren Dela CruzNo ratings yet

- Bill of MaterialDocument41 pagesBill of MaterialDarren Dela CruzNo ratings yet

- CHP 9b REPUBLIC ACT 9285 Salient PointsDocument27 pagesCHP 9b REPUBLIC ACT 9285 Salient PointsDarren Dela CruzNo ratings yet

- Technical Standards and Guidelines For Planning and Design PDFDocument144 pagesTechnical Standards and Guidelines For Planning and Design PDFPedro Marfito Jr.No ratings yet

- Purchase Request Form (PRF) : Saver's Hotel RenovationDocument1 pagePurchase Request Form (PRF) : Saver's Hotel RenovationDarren Dela CruzNo ratings yet

- D.O. 13 Safety and Health in Construction IndustryDocument16 pagesD.O. 13 Safety and Health in Construction Industryraighnejames19No ratings yet

- CHP 11 - SpecificationsDocument12 pagesCHP 11 - SpecificationsDarren Dela CruzNo ratings yet

- Estimate FormatDocument18 pagesEstimate FormatDarren Dela CruzNo ratings yet

- Manual On FC PlanningDocument135 pagesManual On FC PlanningjjahaddinNo ratings yet

- CHP 11a - Engineering Management Concerns About SpeciificationsDocument10 pagesCHP 11a - Engineering Management Concerns About SpeciificationsDarren Dela CruzNo ratings yet

- CHP 8c - E-Procurement Law Saliemt PointsDocument2 pagesCHP 8c - E-Procurement Law Saliemt PointsDarren Dela CruzNo ratings yet

- R.A. 9184Document22 pagesR.A. 9184JavitaNo ratings yet

- ENGINEERING ETHICS GUIDELINESDocument14 pagesENGINEERING ETHICS GUIDELINESDarren Dela CruzNo ratings yet

- CHP 10 ContratcsDocument6 pagesCHP 10 ContratcsDarren Dela CruzNo ratings yet

- CHP 5c - Why Should You Get RegisteredDocument4 pagesCHP 5c - Why Should You Get RegisteredDarren Dela Cruz100% (1)

- CHP 9d Construction Related DocumentsDocument7 pagesCHP 9d Construction Related DocumentsDarren Dela CruzNo ratings yet

- CHP 9c - PRIMER On ArbitrationDocument7 pagesCHP 9c - PRIMER On ArbitrationDarren Dela CruzNo ratings yet

- CHP 10a Common Legal DocumentsDocument19 pagesCHP 10a Common Legal DocumentsDarren Dela CruzNo ratings yet

- CHP 9e Model Document Retention PolicyDocument3 pagesCHP 9e Model Document Retention PolicyDarren Dela CruzNo ratings yet

- CHP 9a - RA 9285 - Alternative Dispute ResolutionDocument18 pagesCHP 9a - RA 9285 - Alternative Dispute ResolutionDarren Dela CruzNo ratings yet

- CHP 5d - Foreign Civil Engineers in The Philippines - Salient PointsDocument6 pagesCHP 5d - Foreign Civil Engineers in The Philippines - Salient PointsDarren Dela Cruz50% (2)

- CHP 6 - Effects OF RA 9266 To RA 544Document4 pagesCHP 6 - Effects OF RA 9266 To RA 544Darren Dela CruzNo ratings yet

- CHP 8b - IRR of E-Procurement LawDocument13 pagesCHP 8b - IRR of E-Procurement LawDarren Dela CruzNo ratings yet

- Pub - Perspectives On Global Cultures Issues in Cultural PDFDocument190 pagesPub - Perspectives On Global Cultures Issues in Cultural PDFCherlyn Jane Ventura TuliaoNo ratings yet

- Carmina GadelicaDocument37 pagesCarmina GadelicaoniricsNo ratings yet

- Why study operating systems and how they workDocument12 pagesWhy study operating systems and how they workMario ManihurukNo ratings yet

- Exploratory Data Analysis: M. SrinathDocument19 pagesExploratory Data Analysis: M. SrinathromaNo ratings yet

- ZJJ 3Document23 pagesZJJ 3jananiwimukthiNo ratings yet

- Digital Burner Controller: Tbc2800 SeriesDocument4 pagesDigital Burner Controller: Tbc2800 SeriesSUDIP MONDALNo ratings yet

- Chapter-5 Contract ManagementDocument43 pagesChapter-5 Contract Managementprem kumarNo ratings yet

- Sustaining The Metropolis: LRT and Streetcars For Super Cities, Presented by The Transportation Research Board of The National Academies (Circular E-C177)Document408 pagesSustaining The Metropolis: LRT and Streetcars For Super Cities, Presented by The Transportation Research Board of The National Academies (Circular E-C177)Randall WestNo ratings yet

- Assessing Student Learning OutcomesDocument20 pagesAssessing Student Learning Outcomesapi-619738021No ratings yet

- 341SAM Ethical Leadership - Alibaba FinalDocument16 pages341SAM Ethical Leadership - Alibaba FinalPhoebe CaoNo ratings yet

- UntitledDocument21 pagesUntitledRoberto RamosNo ratings yet

- Morpho Full Fix 2Document9 pagesMorpho Full Fix 2Dayu AnaNo ratings yet

- Laser Engrave Co2 System BJ-1390Document5 pagesLaser Engrave Co2 System BJ-1390Sasa TodorovicNo ratings yet

- Broom Manufacture Machine: StartDocument62 pagesBroom Manufacture Machine: StartHaziq PazliNo ratings yet

- De HSG Lay Cau - Ban WordDocument124 pagesDe HSG Lay Cau - Ban WordNguyễn Hải YếnNo ratings yet

- Argenti, P. Corporate Communication. Cap. 8-9Document28 pagesArgenti, P. Corporate Communication. Cap. 8-9juan100% (1)

- STR File Varun 3Document61 pagesSTR File Varun 3Varun mendirattaNo ratings yet

- PEB Requirment by ClientDocument4 pagesPEB Requirment by ClientViraj ModiNo ratings yet

- CPS Layoffs BreakdownDocument21 pagesCPS Layoffs BreakdownjroneillNo ratings yet

- MARCOMDocument35 pagesMARCOMDrei SalNo ratings yet

- SID-2AF User Manual English V3.04Document39 pagesSID-2AF User Manual English V3.04om_zahidNo ratings yet

- Literature Review Marketing StrategyDocument4 pagesLiterature Review Marketing Strategyc5td1cmc100% (1)

- Chapter 1 Critical Thin...Document7 pagesChapter 1 Critical Thin...sameh06No ratings yet

- Introduction To Managerial Accounting Canadian 5th Edition Brewer Solutions ManualDocument25 pagesIntroduction To Managerial Accounting Canadian 5th Edition Brewer Solutions ManualMaryJohnsonsmni100% (57)

- Human Resource Management (MGT 4320) : Kulliyyah of Economics and Management SciencesDocument9 pagesHuman Resource Management (MGT 4320) : Kulliyyah of Economics and Management SciencesAbuzafar AbdullahNo ratings yet

- Chime Primary School Brochure TemplateDocument1 pageChime Primary School Brochure TemplateNita HanifahNo ratings yet

- Laboratory Manual: Semester: - ViiiDocument15 pagesLaboratory Manual: Semester: - Viiirsingh1987No ratings yet

- ENVPEP1412003Document5 pagesENVPEP1412003south adventureNo ratings yet

- Balajit Nath Pandita-Specific Principles of Kashmir Saivism-Munshiram Manoharlal Publishers (1998) PDFDocument228 pagesBalajit Nath Pandita-Specific Principles of Kashmir Saivism-Munshiram Manoharlal Publishers (1998) PDFvramaniitkNo ratings yet

- Pump IntakeDocument6 pagesPump IntakeAnonymous CMS3dL1T100% (1)