Professional Documents

Culture Documents

Sorrento Fuser Training Update 3-14-07

Uploaded by

Luis Gon RamOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sorrento Fuser Training Update 3-14-07

Uploaded by

Luis Gon RamCopyright:

Available Formats

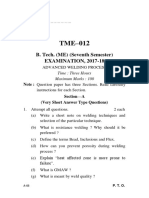

Sorrento Fuser Configuration

Paper Exit

Pressure Roll (PL 10.4)

055K39922

Stripper Finger (PL 10.6)

Four Finger Stripper Baffle Assy:

Fuser Roll (PL 10.7) 19S21202, Stripper Finger (605K16150)

022K53281 55K35871, Four Finger Baffle

Donor Roll (PL 10.9)

022K27670

Pressure Roll

Fuser Roll

Metering Roll (PL 10.8)

022K09163

Fusing Process Conditions / CP's / CS's

Fusing Nip Width:15.5 +/- 0.5mm

Fuser Roll Surface Temperature: 201degC (395 +/-5 degF)

Dwell: 21.0msec (+/- 1ms)

Thermistor (PL 10.4) Bulk Oil Rate: 4.5 +/- 1.5 mg/print

130K56330 Air Knife Pressure: 20 +/- 3psi

RAM Air Knife Gap Setting (Adj. 10.9): 0.86 +0.3 /-0.1mm

Metering Blade (PL 10.8) Pressure Roll Stripper Finger Baffle Gap (Adj. 10.34): 2.2 +0.8 / -0.4m

Fuser Oil 033E01110 Metering Roll Temperature 116 degC (240-250degF)

Paper Entrance Donor Roll to Metering Roll Contact Arc (Adj. 10.5): 3-4mm

8R4077 Fuser Shield Mainline (8R12938 Fuser Blend (90%

(752.86mm/sec)

Mercapto:10% Amino) situational)

Fuser Reservoir (PL 10.1) 093K14130

Containment Tray (PL 10.1) 050K60371

Blocking Flag (PL 10.1) 031K08250 Image

Other

Retrofit kit RAM Components

604K42310 5090 Production Toner: 6R206

Metering Blade (PL 10.8) 033E01110 Highlight Color Toners

Wick 094E00680 and Absorbent Mat 094E02770

Modified 03-07 by Yelena Shapiro Confidential Material

Slide1

Oil Formulation Change Enables Prime Function

Fuser Fluid Fuser Shield Mainline Oil

Reasons for change

Improved fuser roll life demonstrated in internal testing and at several customer sites prior to field release

Part Numbers: 8R4077 (1) or 8R7618 (6)

Bottle: blue with paper label containing the part number

Cut-in occurred in manufacturing in summer 06

Tag 382P, Fuser Shield is packaged in MIK

Machines serial number PYW7744130 (60 Hz), 112627552 (50 Hz), 2480381028 (50 Hz, Dundalk)

Announcement Bulletin (453836) was issued in July

For fluid ordering information contact supplies hot line (1-800-822-2200 in USSG)

Fuser Shield conversion kit, 606K15850, for existing customers is available

Torino configuration shows acceptable performance with Fuser Shield

If customer is running with specialty in-line finishing equipment (e.g. pressure sealing), converting to Fuser

Shield may cause degraded performance. In that situation they can convert back to Fuser Blend and should

remain on that fluid.

Part Numbers: 8R12938 (1) or 8R12939 (6)

Bottle: yellow with paper label containing the part number

Change over can be done with Fuser Blend conversion kit, 606K15860

For metered customers to ensure that they receive correct fuser fluid, CSE should call metered

services (1-800-599-2198 in USSG) and provide machine serial number

Neither fluid is compatible in DocuFamily MICR machine

Modified 03-07 by Yelena Shapiro Confidential Material

Slide2

Pressure Roll Formulation Change Enables Prime Function

Pressure Roll (Silicone Base w/Teflon Sleeve)

Current Part Number: 59K39922

Appearance: orange/red in color with metal end caps

HFSI replacement interval of 1.5M should be ignored

Leads to premature roll replacements

Bulletin 355536 addresses this issue

Rolls should be replaced based on IQ or roll integrity (coating, wear marks, dings) reasons

Silicone crumbling on the ends has been mitigated in the latest design

Grease added between silicone and metal end plate

Have had some instances of insufficient grease that resulted in small amount of debris

SHORT TERM SOLUTION: In order to prevent silicone dust migrating to other

components, it should be checked and cleaned periodically

LONG TERM SOLUTION: working to cut-in 59K39923 pressure roll part number in 1Q07

that would increase amount of grease added between silicone and metal plate

Rolling cut-in

In process of qualifying vendor capabilities

Modified 03-07 by Yelena Shapiro Confidential Material

Slide3

Oil Tank and Tray Re-design - Reliability Enhancement

Oil Tank and Tray (and Other Components)

Reason for change

Provide better protection from oil spills into highlight color developer housing

This configuration requires complete fuser pull out in order to add fuser fluid

Tag 361P Cut in manufacturing in November 05 J Bracket

Machine Serial Numbers: PYW773936 and VKY627530

Relevant Parts

Oil Tank 093K14130 Fuser

Containment Tray 050K60370(1) Door Striker

Striker Plate

Blocking Flag 031K08250 Plate

Fuser Cover 068K47330

Fuser Striker Plate 815E33500 (1)

Fuser Cover

Situational Retrofit Kit -604K42310 J Bracket

Blocking Flag

Oil Tank

Containment Tray

Modified 03-07 by Yelena Shapiro Confidential Material

Slide4

Fuser Wick Configuration Change - Reliability Enhancement

Wick Configuration Change (Absorbent Mat Addition)

Reason for change

Prevent oil sloshing

Prevent oil contamination of HLC Housing

Part Numbers Wick

Wick 94E00680

Absorbent Mat 094E02770

Fuser Wick and Absorbent Mat Kit 605K15460

Absorbent

Appearance Mat

Fuser wick is the longer part

Needs to be placed under metering roll

Absorbent Mat is shorter with notch cut-out

Modified 03-07 by Yelena Shapiro Confidential Material

Slide5

Stripper Finger Baffle Design Change - Reliability Enhancement

Stripper Baffle (Four Fingers)

Reason for Change

Improve stripping reliability by addition of 4 th finger

Alleviate dog-earing

Improve media latitude

Eliminate pressure roll gouging

Part Numbers

Baffle only 55K35850

New Configuration: 4 Finger Baffle with DocuFamily Finger Design

Finger part number - 19S21202

Common to DocuFamily

Scooped shape, leaf spring design

In addition for each finger guard plate is needed 055E13920

Finished baffle assembly 55K35871

Tag 368P Cut in manufacturing on 12/19/05

Machine Serial Numbers: PYW773975 and VKY627535

Mandatory retrofit kit 605K16150

Kit contains four fingers and four guard plates

Modified 03-07 by Yelena Shapiro Confidential Material

Slide6

Donor Roll Service Cost Savings

Donor Roll

There is no change to the actual part number

Donor Roll Cleaning in HFSI table (P10-801)

With colored toners in Sorrento higher contamination rate has been observed

Contamination can be cleaned, instead replacing the part

HFSI interval of 1M

Check for toner buildup on the surface of the Donor Roll. Clean the cool Donor

Roll by wiping the surface with a clean dry cloth

Modified 03-07 by Yelena Shapiro Confidential Material

Slide7

You might also like

- HTFF350AW Service ManualDocument24 pagesHTFF350AW Service ManualUEENo ratings yet

- 03Document10 pages03defiunikasungtiNo ratings yet

- Service PartsDocument6 pagesService Partsslam9No ratings yet

- HAF350A Service ManualDocument17 pagesHAF350A Service ManualUEENo ratings yet

- Deutz Fahr Agrotron K110 Profiline Tractor Parts Catalogue ManualDocument19 pagesDeutz Fahr Agrotron K110 Profiline Tractor Parts Catalogue ManuallaopaodunNo ratings yet

- Product Information Packet: 20HP, 1765RPM, 3PH, 60HZ, 256T, 0952M, TEFC, F1Document10 pagesProduct Information Packet: 20HP, 1765RPM, 3PH, 60HZ, 256T, 0952M, TEFC, F1pavanreguNo ratings yet

- Service PartsDocument6 pagesService PartsESRANo ratings yet

- Service Parts & Drilling ToolsDocument7 pagesService Parts & Drilling ToolsEduardo AgueroNo ratings yet

- AF210 Service ManualDocument17 pagesAF210 Service ManualUEENo ratings yet

- Product Information Packet: 7.5HP, 1125RPM, 3PH, 60HZ, 254T, 0932M, OPENDocument11 pagesProduct Information Packet: 7.5HP, 1125RPM, 3PH, 60HZ, 254T, 0932M, OPENFirulay FirulayNo ratings yet

- GVAR210 Service ManualDocument17 pagesGVAR210 Service ManualUEENo ratings yet

- Service Parts & Drilling ToolsDocument7 pagesService Parts & Drilling ToolsOzan SahinNo ratings yet

- EM7054T-I: Product Information PacketDocument11 pagesEM7054T-I: Product Information PacketCikalong YardNo ratings yet

- DAC1 79 01 Rev 0Document10 pagesDAC1 79 01 Rev 0vanNo ratings yet

- BHA#2 Trip TPN - DZ 20.6 (TPN-223)Document1 pageBHA#2 Trip TPN - DZ 20.6 (TPN-223)Setya AminNo ratings yet

- Rec. Spare Parts - EWWQ970B-XS - Promar 09 - List Price - R-01Document1 pageRec. Spare Parts - EWWQ970B-XS - Promar 09 - List Price - R-01olinda.controlNo ratings yet

- TL-80SN (AA80E) : 8 Speed RWD (Electronic Control) LS460/470, GS460/470, IS F (Lexus), Crown Majesta (Toyota)Document4 pagesTL-80SN (AA80E) : 8 Speed RWD (Electronic Control) LS460/470, GS460/470, IS F (Lexus), Crown Majesta (Toyota)Mothana HusbanNo ratings yet

- Parts Book of ZE230E Hydraulic Crawler Excavator2Document200 pagesParts Book of ZE230E Hydraulic Crawler Excavator2Bruno Rodrigues100% (1)

- Piese Motor KD2V86Document2 pagesPiese Motor KD2V86Popescu RoxanaNo ratings yet

- LP Bypass Spray Control Valve Seal KitDocument6 pagesLP Bypass Spray Control Valve Seal KitsoorajssNo ratings yet

- ZE230E - Parts+manual.20120228Document232 pagesZE230E - Parts+manual.20120228Bruno Rodrigues100% (1)

- LG30GLTDocument66 pagesLG30GLTNINA.HZSKYNo ratings yet

- $RTONPXJDocument6 pages$RTONPXJddgtNo ratings yet

- 773 Ka3450p1Document1 page773 Ka3450p1anna mannaNo ratings yet

- Renewal Parts YK (Stype F)Document56 pagesRenewal Parts YK (Stype F)Thang TV100% (2)

- Sandvik dd320Document6 pagesSandvik dd320Ozan SahinNo ratings yet

- Service PartsDocument6 pagesService Partsbundajoseph148No ratings yet

- KTA50G3 Parts Manual FinalDocument8 pagesKTA50G3 Parts Manual FinalLuisPupiales100% (1)

- Service PartsDocument8 pagesService PartsYankonde ChisenseNo ratings yet

- Spare Parts Catalogue: Edition 09/1996 ENDocument20 pagesSpare Parts Catalogue: Edition 09/1996 ENAlfred HitchcockNo ratings yet

- GVAF100 Service ManualDocument12 pagesGVAF100 Service ManualUEENo ratings yet

- Service PartsDocument6 pagesService Partsdavid mendozaNo ratings yet

- Series 9000 Precleaner Adaptation Kit: For Donaldson SSG & SRG Filter HousingsDocument2 pagesSeries 9000 Precleaner Adaptation Kit: For Donaldson SSG & SRG Filter HousingsHector RodriguezNo ratings yet

- Portals Raybestos Files PM 1340 TCCcatalogDocument32 pagesPortals Raybestos Files PM 1340 TCCcatalogrobertoperez525No ratings yet

- Honda Goldwing GL1100 1980 To 1982 Honda Parts Manual-B760BDocument195 pagesHonda Goldwing GL1100 1980 To 1982 Honda Parts Manual-B760BstormaNo ratings yet

- Pulsar 180 Ug3 PDFDocument30 pagesPulsar 180 Ug3 PDFCristian BarbozaNo ratings yet

- Sr220 Skid Steer Loader - Tier 3 Manual de PartesDocument906 pagesSr220 Skid Steer Loader - Tier 3 Manual de PartessimonNo ratings yet

- SUZUKI-DT40S Motor Fuera de BordaDocument199 pagesSUZUKI-DT40S Motor Fuera de BordaDiego martinez castellanosNo ratings yet

- Assembly and Parts Drawing: Wuxi Kipor Power Co., LTDDocument2 pagesAssembly and Parts Drawing: Wuxi Kipor Power Co., LTDDuvan Garridt MillanNo ratings yet

- Df40a 50a 60a PDFDocument496 pagesDf40a 50a 60a PDFpm.....100% (1)

- Pressure Reducing, Pilot Operated Spool Type: Common Cavity, Size 10Document2 pagesPressure Reducing, Pilot Operated Spool Type: Common Cavity, Size 10tecnicomanelNo ratings yet

- Facility ( ) Location (+) Item Designa Tion (-) Component Name Comp. Manufacturer Comp. Description Cross-Ref Circ-Diag VismanrDocument6 pagesFacility ( ) Location (+) Item Designa Tion (-) Component Name Comp. Manufacturer Comp. Description Cross-Ref Circ-Diag VismanrhamzehNo ratings yet

- SLC 1 Spec SheetDocument2 pagesSLC 1 Spec SheetArstNo ratings yet

- Sistema de Lubricacion Pump HorizontalesDocument16 pagesSistema de Lubricacion Pump HorizontalesRodríguez EdwardNo ratings yet

- 3 BKM SP MKT Get Ex1900Document2 pages3 BKM SP MKT Get Ex1900Max Sashikhin100% (2)

- Yunchai YC6B125-T20Document72 pagesYunchai YC6B125-T20Vüsal 1100% (3)

- DF250A 300A SuzukiDocument128 pagesDF250A 300A SuzukiWidhana FajarNo ratings yet

- Product Information Packet: 250HP, 3570RPM, 3PH, 60HZ, 449TS, 18104M, TEFCDocument9 pagesProduct Information Packet: 250HP, 3570RPM, 3PH, 60HZ, 449TS, 18104M, TEFCJosé Isaac Chávez HuamánNo ratings yet

- Tecumseh TC300-3136 Parts Manual 9109901 (1999) WWDocument10 pagesTecumseh TC300-3136 Parts Manual 9109901 (1999) WWfairfaxcyclesNo ratings yet

- Optional EquipmentDocument36 pagesOptional EquipmentatertemizNo ratings yet

- 3R1040 Spare Parts PDFDocument90 pages3R1040 Spare Parts PDFSergio Ramos Rivera100% (1)

- Big End Bearing BoreDocument1 pageBig End Bearing BorePoma100% (2)

- Generator Bearing ServiceDocument10 pagesGenerator Bearing ServiceMustafa A.W100% (1)

- Chapter 1-8: Industrial Gas Generator Illustrated Parts CatalogueDocument18 pagesChapter 1-8: Industrial Gas Generator Illustrated Parts CataloguejuanaNo ratings yet

- Spare Parts KirkDocument10 pagesSpare Parts KirkGianluca PireddaNo ratings yet

- RE0F09A (JF010E) : FWD CVT (Electronic Control)Document4 pagesRE0F09A (JF010E) : FWD CVT (Electronic Control)Diego GarciaNo ratings yet

- Parts Catalogue: ST EditionDocument30 pagesParts Catalogue: ST EditionBecker DidierNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- T8601-02 Boletín de ServicioDocument4 pagesT8601-02 Boletín de ServicioLuis Gon RamNo ratings yet

- Brother HL-2600cn Service Manual PDFDocument385 pagesBrother HL-2600cn Service Manual PDFLuis Gon RamNo ratings yet

- UnderstandingColor PDFDocument107 pagesUnderstandingColor PDFLuis Gon RamNo ratings yet

- 5335 GP 14 Special Boot ModesDocument3 pages5335 GP 14 Special Boot ModesLuis Gon RamNo ratings yet

- 5335 Device Firmware ReloadDocument2 pages5335 Device Firmware ReloadLuis Gon RamNo ratings yet

- Toshiba E-Studio 3511-4511 Service ManualDocument342 pagesToshiba E-Studio 3511-4511 Service Manualjvelez4309No ratings yet

- Detailed Study On The Role of Nature and Distribution of Pinholes and Oxide Layer On The Performance of Tunnel Oxide Passivated Contact TOPCon Solar CellDocument6 pagesDetailed Study On The Role of Nature and Distribution of Pinholes and Oxide Layer On The Performance of Tunnel Oxide Passivated Contact TOPCon Solar Cellgxf980518No ratings yet

- 8 Forms of CorrosionDocument3 pages8 Forms of CorrosionSuhaib AshrafNo ratings yet

- Sedimentation Tank DesignDocument7 pagesSedimentation Tank DesignMichael Asmith Unique67% (3)

- Advanced Welding Process PDFDocument3 pagesAdvanced Welding Process PDFbusiness singhNo ratings yet

- Atlantic Research Hybrid Propulsion Tech ProgramDocument314 pagesAtlantic Research Hybrid Propulsion Tech Programspacelaunch0% (1)

- H-E Parts Data Sheet PT-80 Chromium CarbideDocument1 pageH-E Parts Data Sheet PT-80 Chromium CarbideJorge VillalobosNo ratings yet

- W. Herman de Groot (Auth.) - Sulphonation Technology in The Detergent Industry (1991, Springer Netherlands)Document299 pagesW. Herman de Groot (Auth.) - Sulphonation Technology in The Detergent Industry (1991, Springer Netherlands)Plant Design100% (3)

- Responses of Lactic Acid Bacteria To OxygenDocument12 pagesResponses of Lactic Acid Bacteria To OxygenKerstin BernNo ratings yet

- 11 Fibre Ropes PDFDocument12 pages11 Fibre Ropes PDFThomas KamongNo ratings yet

- CladdingDocument11 pagesCladdingManohar SeetharamNo ratings yet

- Elastic Vitrimers BeyondDocument32 pagesElastic Vitrimers BeyondMostafa AhmadiNo ratings yet

- AE1402 Composite Materials and StructuresDocument23 pagesAE1402 Composite Materials and StructuresGeorlinNo ratings yet

- Ari 560-2000Document25 pagesAri 560-2000rajat vermaNo ratings yet

- 8.fe - Fe3C Phase DiagramDocument27 pages8.fe - Fe3C Phase DiagramMhackSahuNo ratings yet

- Luban 1102MBF-MSDSDocument6 pagesLuban 1102MBF-MSDSAK ZaiNo ratings yet

- Guidelines For Coheseive Parameters Ebook 3Document11 pagesGuidelines For Coheseive Parameters Ebook 3arkan1976No ratings yet

- Steam BookDocument66 pagesSteam Bookdekate_manoj100% (1)

- 3 JEE Chemistry Solutions Methods of Expressing Concentration of SolutionDocument6 pages3 JEE Chemistry Solutions Methods of Expressing Concentration of Solutionmalboys555No ratings yet

- One-Dimensional, Steady-State Heat Conduction: 5.1 Planar GeometriesDocument5 pagesOne-Dimensional, Steady-State Heat Conduction: 5.1 Planar GeometriesThulasi RamNo ratings yet

- Lab Report 4: Afsana Islam (AFI2) Department of Environmental Science and Management North South UniversityDocument3 pagesLab Report 4: Afsana Islam (AFI2) Department of Environmental Science and Management North South UniversityMr WatsonNo ratings yet

- DS4B - (1988) Physical Constants of Hydrocarbon and Non-Hydrocarbon CompoundsDocument216 pagesDS4B - (1988) Physical Constants of Hydrocarbon and Non-Hydrocarbon CompoundsJacques Strappe0% (1)

- Rosin Based Chemicals and PolymersDocument44 pagesRosin Based Chemicals and PolymersHimanshu PanchalNo ratings yet

- DSE ElectrodeDocument1 pageDSE Electrodeastaria22No ratings yet

- Kla DeterminationDocument23 pagesKla DeterminationJokanoe LertNo ratings yet

- Experience With Lined and Clad PipelinesDocument17 pagesExperience With Lined and Clad Pipelinesjoni Mart Sitio100% (1)

- 300L Liuid Soap Making MachineDocument3 pages300L Liuid Soap Making MachineFoe AungNo ratings yet

- One-Dimensional Compressible Flow in Variable AreaDocument6 pagesOne-Dimensional Compressible Flow in Variable AreaswatiNo ratings yet

- Oxygen Scavengers For Food Packaging ApplicationsDocument9 pagesOxygen Scavengers For Food Packaging ApplicationsbiswasblrNo ratings yet

- Penetration of Microwaves Into AluminumDocument5 pagesPenetration of Microwaves Into AluminumJohn Michael WilliamsNo ratings yet

- Air Pollution Persuasive WritingDocument7 pagesAir Pollution Persuasive WritingPamela LeeNo ratings yet