Professional Documents

Culture Documents

Fundamentals of Refrigeration: Understanding the Refrigeration Cycle in <40 Characters

Uploaded by

USHA PAWAR0 ratings0% found this document useful (0 votes)

50 views21 pagesVapor Compression Refrigeration Cycle ppt with sketches. Easy to understand.

Original Title

Vapor Compression Refrigeration Cycle

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentVapor Compression Refrigeration Cycle ppt with sketches. Easy to understand.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

50 views21 pagesFundamentals of Refrigeration: Understanding the Refrigeration Cycle in <40 Characters

Uploaded by

USHA PAWARVapor Compression Refrigeration Cycle ppt with sketches. Easy to understand.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You are on page 1of 21

Fundamentals of Refrigeration

Refrigeration means the process of removing heat

from spaces, objects, or materials and maintaining them

at a temperature below that of the surrounding

atmosphere.

To produce a refrigeration effect, the material to

be cooled needs only to be exposed to a colder object or

environment. The heat will flow on its own in its natural

direction-that is, from the warmer material to the cooler

material.

Refrigeration, then, generally means an artificial

way of lowering the temperature. Mechanical

refrigeration is a mechanical system or apparatus that

transfers heat from one substance to another.

The purpose of refrigeration is to maintain spaces ,

objects, or materials at low temperatures. Remember,

you cannot cool anything by adding coolness to it,

instead you will have to remove heat from it. Therefore,

Heat and Temperature

Heat is a form of energy. Temperature is a measure

of the intensity of heat. The quantity or amount of heat

energy in a substance is measured in calorie. At

atmospheric pressure, 1 calorie is the amount of heat

required to raise the temperature of 1 kg of water through

1C. In the opposite case, when 1 calorie heat is removed

from 1 kg of water at atmospheric pressure, then the

temperature of the water will drop 1C.

Temperature, as we know, is measured in Degree

Celsius. Degree Celsius indicates the intensity of the heat

in a given substance. Temperature does not indicate the

number of calories in the substance.

For example, lets consider a cupful of very hot

water and a bucketful of warm water. Which has the

higher temperature? Which has more heat? The heat in

the cupful of hot water is more intense; therefore, its

temperature is higher. The bucketful of warm water has

more calories (more heat energy), but its heat is less

Concept Development for Vapor Compression

Refrigeration Cycle

All vapor compression refrigeration systems are

designed and built around these basic thermodynamic

principles:

1) Fluids absorb heat while changing from liquid

phase to vapor phase and reject heat while

changing from vapor phase to liquid phase.

2) The temperature at which a change in phase

occurs in constant during the change, but this

temperature will vary with the pressure. At one

fixed pressure vaporization takes place only at

fixed corresponding temperature. However, the

temperatures of vaporization at a particular

pressure are different for different fluids.

3) Heat flows from a body at higher temperature to

a body at lower temperature.

4) In selecting metallic parts of cooling and

condensing units, metals are selected which

have high heat conductivity.

5) Heat energy and other forms of energy are

mutually convertible with directional relationship

imposed by the Second Law of Thermodynamic.

Vaporization of the Fluid

An insulated space can be adequately

refrigerated by only allowing liquid refrigerant to

evaporate in a container vented out to atmosphere.

The liquid refrigerant is under atmospheric pressure of

1kg/cm2 and the saturation temperature

corresponding to this pressure is approximately -

29.8C. Thus the liquid refrigerant evaporates at this

low temperature and the latent heat of vaporization is

absorbed from the surroundings, which is shown in the

figure at 5C.

Since the temperature of the liquid remains

same during vaporizing process, the refrigeration will

continue until all liquid is vaporized. Any such

container as shown in figure, where liquid is vaporized

and heat is absorbed by the container from the space

to be refrigerated, is called Evaporator.

Controlling the Vaporizing Temperature

The temperature at which the liquid vaporizes is

tied up with the pressure. There is a definite

vaporizing temperature for a liquid at a particular

pressure. The pressure in the evaporator is kept at 3

kg/cm2 with the help of control valve which allows the

vapor to escape at such rate that the pressure is

maintained inside the evaporating vessel.

If the control valve is closed the pressure will

increase such that the saturation temperature of the

liquid refrigerant in the vessel corresponds to the

space temperature of 5C. This will stop the further

vaporization of liquid refrigerant.

Vaporizing at Sub-atmospheric Pressure

Vapor pump is sucking vapor from the

vaporizing chamber, then compressing and

discharging it to the atmosphere. The evaporator

pressure can thus be maintained at any pressure

below atmosphere provided the rate of formation of

vapor is matching with the capacity of the pump to

compress and discharge the vapor. Depending on the

evaporator pressure the corresponding temperature

can be maintained in evaporator.

The pressure maintained is shown to be 0.6426

kg/cm2 with saturation temperature of -40C .

Maintaining the Constant Mass in Evaporator

It may be noted that in all the previous cases,

the refrigerant vaporizes and escapes, but is not

replenished continuously as it vaporizes. Figure shows

one of the methods of keeping the liquid level

constant by a float and needle valve assembly. Thus

the rate of flow of liquid refrigerant in the chamber is

same as the rate of liquid vaporized and pumped out.

The liquid storage tank is kept at high pressure and its

pressure falls to the evaporator pressure as it passes

through the needle valve.

The evaporator which has been shown in figure-

A as a chamber can be replaced by coil as shown in

figure-B. The vaporization of the liquid takes place in

the coil and at the end of the coil, it is possible that

the vapors may even get slightly superheated.

A temperature sensing device called thermostat

could be placed in the system. The refrigerant control

could be operated by this temperature sensing device.

Recovering the Refrigerants

So far, the refrigerant after vaporizing is

pumped out to the atmosphere. It is uneconomical to

let the refrigerant to atmosphere. Thus it is necessary

that this refrigerant should be recovered and reused.

Thus the vapor discharged from the pump is sent to

an apparatus called condenser, where it is condensed

and then sent the evaporator through the refrigerant

control valve.

Before compression, the refrigerant vapor is at

the vaporizing temperature and pressure of

evaporator. This pressure and temperature is low.

During compression the pressure of the vapor is

increased to a point such that the corresponding

saturation temperature is above the temperature of

the condensing medium used. At the same time,

mechanical work is done on the vapor in compressing

and the enthalpy of the vapor is increased with

corresponding increase in temperature of the vapor.

After compression, the high temperature, high

pressure vapor is discharged into the condenser where

heat is rejected to the condensing medium which is

normally air or water. Thus vapor cools & then

condenses at the saturation temperature

corresponding to the pressure in the condenser. The

condensed liquid passes on to the liquid storage

vessel from where it flows to the evaporator.

Thus it may be noted that the refrigerant which

is the working fluid carries the heat from the space to

be cooled to the outside. The working fluid absorbs

heat from the refrigerated space in the evaporator,

carries it out of the space and rejects it to the

condensing medium in condenser. Thus condenser has

to be located outside the refrigerated space.

Simple Saturated Cycle

Vapor compression refrigeration plant is shown

diagrammatically in figure-A. The working substance is

such that readily evaporates and condenses. The cycle

is thermodynamically assumed such that the

refrigerant vapor leaves the evaporator and enters the

compressor as dry saturated vapor. This point is

denoted as point 1 both on flow diagram shown in

figure and T-s shown figure-B for 1 kg of the working

substance.

Let us take the case when the vapor is dry

saturated at the suction to the compressor shown by

point 1 in the figures. It is at pressure P1 and

temperature T1.The vapor is drawn into the

compressor cylinder during its suction stroke and

during the compression stroke the vapor is

This point is represented by 2 which shows the

vapor in superheated state. The vapor at point 2

passes on to condenser in which cooling water is

supplied to remove the sensible heat from the vapor.

Thus vapor is first cooled to the saturated

temperature at pressure P2 and further removal of

heat, condenses it to liquid removing its latent heat till

point 3 is reached. Thus, in order to carry out this

operation, the saturation temperature corresponding

to pressure P2 should be sufficiently higher than the

temperature of cooling water for efficient heat

transfer.

It may be then possible to even sub-cool the

liquid vapor to temperature below that at point 3. The

high pressure liquid is then expanded through a

throttle valve, and the liquid at point 3 throttles to

lower pressure P1 and the condition obtained after the

After throttling we get the liquid partly

evaporated at lower temperature T4 and lower

pressure P1 Thus, after the throttle valve, we get wet

vapor at a low temperature.

These vapors now pass through, the evaporator

coils immersed in brine or the chamber to be

refrigerated. These vapors absorb latent heat from

brine in further evaporating itself. The vapors may

reach point 1, i.e., dry saturated at pressure P1. This

completes the cycle. This cycle is also called Simple

Saturated Cycle..

You might also like

- Refrigeration Cycle DiagramDocument7 pagesRefrigeration Cycle DiagramsrybsantosNo ratings yet

- Unit VDocument12 pagesUnit VYuvaperiyasamy MayilsamyNo ratings yet

- Air Conditioning Theory (Automotive)Document21 pagesAir Conditioning Theory (Automotive)ingenierosunidosNo ratings yet

- Hvac Lab Report: Name: Ali Raza Roll No: 18-MCE-18 Submitted To: Sir Murawat Abbas Semester 6Document11 pagesHvac Lab Report: Name: Ali Raza Roll No: 18-MCE-18 Submitted To: Sir Murawat Abbas Semester 6AliNo ratings yet

- 01 Principles of Refrigeration & Reversed Carnot CycleDocument13 pages01 Principles of Refrigeration & Reversed Carnot CycleVinNo ratings yet

- Refrigeration CycleDocument5 pagesRefrigeration CycleLiezel Quijada LicupNo ratings yet

- BME-Module 2Document23 pagesBME-Module 2Ajith KumarNo ratings yet

- Everything You Need to Know About Air ConditioningDocument163 pagesEverything You Need to Know About Air ConditioningAshok AmnarNo ratings yet

- Refregeration UnitDocument24 pagesRefregeration UnitEZWANNo ratings yet

- Study of RefrigiratorDocument14 pagesStudy of RefrigiratorRobo RajaNo ratings yet

- Refrigeration Cycle, HVAC System Basics and Refrigerant Charging PDFDocument13 pagesRefrigeration Cycle, HVAC System Basics and Refrigerant Charging PDFMurillo MendesNo ratings yet

- Comfort Air ConditioningDocument85 pagesComfort Air Conditioningshrikant100% (6)

- Study Flow Boiling's PhasesDocument9 pagesStudy Flow Boiling's PhasesSamsung Note 9No ratings yet

- Group 5 Melab3Document14 pagesGroup 5 Melab3Gigi SalesNo ratings yet

- Condenser: Lesson 3 Lesson Title: Learning Outcomes: at The End of The Lesson, Students of BTLE Will Be Able ToDocument37 pagesCondenser: Lesson 3 Lesson Title: Learning Outcomes: at The End of The Lesson, Students of BTLE Will Be Able ToAliceNo ratings yet

- Performance and Efficiency Test of Refrigeration PlantDocument52 pagesPerformance and Efficiency Test of Refrigeration PlantIvy Joy UbinaNo ratings yet

- Building ServicesDocument154 pagesBuilding ServicesjeevaNo ratings yet

- Group 5 Refrigeration Plant CycleDocument4 pagesGroup 5 Refrigeration Plant CycleGigi SalesNo ratings yet

- FridgeDocument6 pagesFridgeshashlearnNo ratings yet

- Refrigeration CycleDocument5 pagesRefrigeration CycleMa Zaira ObilloNo ratings yet

- Heat Pump and RefrigertorDocument10 pagesHeat Pump and RefrigertordohlalaNo ratings yet

- What Is The Basic Principle of Refrigeration and What Do You Understand by Refrigeration Cycle?Document3 pagesWhat Is The Basic Principle of Refrigeration and What Do You Understand by Refrigeration Cycle?a4104165No ratings yet

- RefrigerationDocument65 pagesRefrigerationyassinNo ratings yet

- Mechanical-Compression Refrigeration SystemsDocument4 pagesMechanical-Compression Refrigeration Systemsaruna MoonNo ratings yet

- Lecture 1A Refrigeration & Air ConditioningDocument25 pagesLecture 1A Refrigeration & Air ConditioningHamida HamidaNo ratings yet

- General Vehicle AC TheoryDocument8 pagesGeneral Vehicle AC TheoryMarco Martinez DuranNo ratings yet

- Unit-V: Refrigeration & Air-ConditioningDocument25 pagesUnit-V: Refrigeration & Air-ConditioningNalliah PrabakaranNo ratings yet

- Basics of Refrigeration PDFDocument35 pagesBasics of Refrigeration PDFPradeep Kumar YadavNo ratings yet

- Building Services - ThermodynamicsDocument108 pagesBuilding Services - ThermodynamicsDevansh MehtaNo ratings yet

- Refregent and CryogenicsDocument7 pagesRefregent and CryogenicsViren ParwaniNo ratings yet

- 5 200 PDFDocument12 pages5 200 PDFPrince RajaNo ratings yet

- Heat Pump TrainerDocument6 pagesHeat Pump TrainerAfzaal FiazNo ratings yet

- The Pressure - Enthalpy ChartDocument12 pagesThe Pressure - Enthalpy ChartJohnMerrNo ratings yet

- Performance and Efficiency Test of A Refrigeration PlantDocument17 pagesPerformance and Efficiency Test of A Refrigeration Plantjun75% (4)

- Reerigeation System Basics, Week 2 Part 1Document17 pagesReerigeation System Basics, Week 2 Part 1Musfirah AdeelNo ratings yet

- Parts of A Refrigeration SystemDocument8 pagesParts of A Refrigeration SystemRay RavelNo ratings yet

- REFRIGERATIONDocument24 pagesREFRIGERATIONDark ShadyNo ratings yet

- Refrigeration 1Document13 pagesRefrigeration 1Vishwanathan RishanthNo ratings yet

- Refrigeration Unit Lab ReportDocument28 pagesRefrigeration Unit Lab ReportShinigdho Synthia79% (14)

- Aircon NotesDocument5 pagesAircon Notesprado01No ratings yet

- Cooling Tower Lab ReportDocument20 pagesCooling Tower Lab Reportgodfrey100% (1)

- Performance and Efficiency Test of A Refrigeration PlantDocument17 pagesPerformance and Efficiency Test of A Refrigeration PlantAllen Espeleta0% (1)

- 409 - 5 Refrigeration & Air ConditioningDocument104 pages409 - 5 Refrigeration & Air Conditioningisrat jahanNo ratings yet

- Heat Ventilation Heat Pump Cooling Cycle Hvac Home Temperature ControlDocument3 pagesHeat Ventilation Heat Pump Cooling Cycle Hvac Home Temperature ControlGio LagadiaNo ratings yet

- Refrigeration and Air Conditioning With Take Home TestDocument14 pagesRefrigeration and Air Conditioning With Take Home Testhim100% (1)

- Refrigeration With Hot and Cooled BoxDocument69 pagesRefrigeration With Hot and Cooled Boxkris_soneNo ratings yet

- Building Services-III: Unit-1Document25 pagesBuilding Services-III: Unit-1surekaNo ratings yet

- Wet Bulb TemperatureDocument4 pagesWet Bulb Temperaturearvindmit2013No ratings yet

- Lecture 1. Basic Concepts in RefrigerationDocument27 pagesLecture 1. Basic Concepts in Refrigerationaddisudagne33% (3)

- Vapor Compression CycleDocument10 pagesVapor Compression Cyclevinit joryNo ratings yet

- Performance and Efficiency Test of A Refrigeration Plant (Lecture)Document56 pagesPerformance and Efficiency Test of A Refrigeration Plant (Lecture)Anonymous xjV1llZS75% (4)

- Refrigeration Unit-5Document16 pagesRefrigeration Unit-5Mr. P. Ramkumar MECHNo ratings yet

- Flow Boiling UnitDocument9 pagesFlow Boiling UnitMuhammad Bin RiazNo ratings yet

- RAC Experiment 01Document24 pagesRAC Experiment 01Sudhir AdsulNo ratings yet

- RAC Lab AssignmentDocument6 pagesRAC Lab AssignmentAhmed AliNo ratings yet

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesFrom EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo ratings yet

- Refrigerator Revelations: A User's Guide to Operation and MaintenanceFrom EverandRefrigerator Revelations: A User's Guide to Operation and MaintenanceNo ratings yet

- Nama Struktur Sifat FisikokimiaDocument12 pagesNama Struktur Sifat FisikokimiaFarisi RazakNo ratings yet

- Chapter-6 ThermodynamicsDocument11 pagesChapter-6 ThermodynamicsDaksh ChothaniNo ratings yet

- Gibbs free energy sample problemsDocument3 pagesGibbs free energy sample problemsLeticia CarandangNo ratings yet

- DUPLEX 500 - 11000 Multi EN - 2018 - 03Document8 pagesDUPLEX 500 - 11000 Multi EN - 2018 - 03Constantin CilibiuNo ratings yet

- Assignment TemperatureDocument4 pagesAssignment TemperatureBank RoadsNo ratings yet

- Closed Loop Control System of Geysers: Name: B.Harish. ROLL NO: 16EEE1002Document6 pagesClosed Loop Control System of Geysers: Name: B.Harish. ROLL NO: 16EEE1002baswa vamsi krishnaNo ratings yet

- Cold Storage For Vegetables: Design and Cost EstimationDocument10 pagesCold Storage For Vegetables: Design and Cost EstimationManoj PaudelNo ratings yet

- HVAC Testing-Adjusting-Balancing For Small SystemsDocument17 pagesHVAC Testing-Adjusting-Balancing For Small SystemsgabrielNo ratings yet

- 0625 Thermal Properties and Temperature - P4 - QP2Document20 pages0625 Thermal Properties and Temperature - P4 - QP2apdrenlNo ratings yet

- Measuring Heat and TemperatureDocument4 pagesMeasuring Heat and Temperaturexyz 999No ratings yet

- Contoh Soal Heat ExchangerDocument5 pagesContoh Soal Heat Exchangerridho fharozi0% (1)

- PTAP El Portico Proyecto III HVAC Load Analysis: Prepared byDocument8 pagesPTAP El Portico Proyecto III HVAC Load Analysis: Prepared bykatherine palominoNo ratings yet

- Energy Saving Potential of Thermoelectric Radiant Cooling Panels With A Dedicated Outdoor AirDocument41 pagesEnergy Saving Potential of Thermoelectric Radiant Cooling Panels With A Dedicated Outdoor AirFernando Manuel Gómez CastroNo ratings yet

- HAP ReportDocument7 pagesHAP ReportaliNo ratings yet

- CallenDocument5 pagesCallenDiericon SousaNo ratings yet

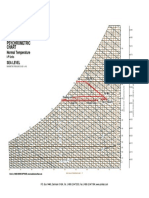

- Air Conditioning Notes (Psychrometric)Document3 pagesAir Conditioning Notes (Psychrometric)Yohan ManaligodNo ratings yet

- RAC Lab Experiment No 1Document3 pagesRAC Lab Experiment No 1HallucinatoryNo ratings yet

- Psychrometric chart analysisDocument1 pagePsychrometric chart analysisIzaaz AhamedNo ratings yet

- Steam Trap Sizing CalculationsDocument4 pagesSteam Trap Sizing CalculationsbecpavanNo ratings yet

- Thermodynamics: By: Engr. Ejay P. MarasiganDocument49 pagesThermodynamics: By: Engr. Ejay P. MarasiganGodwill Escabel100% (1)

- Unilab Shark Components List: Plate Heat ExchangersDocument9 pagesUnilab Shark Components List: Plate Heat ExchangersUnilabNo ratings yet

- Refrigeration: U U W Q Du W QDocument20 pagesRefrigeration: U U W Q Du W QVandyck Mensah EmmanuelNo ratings yet

- Thermodynamics-1 MindmapDocument1 pageThermodynamics-1 Mindmapsarthakyedlawar04No ratings yet

- Two Phase Flow and Heat Transfer - Assignment 3Document11 pagesTwo Phase Flow and Heat Transfer - Assignment 3Joel Jr Rudinas (Remodulator)No ratings yet

- ErP Information for AR12HSSFAWKN / AR12HSSFAWKX Air ConditionerDocument1 pageErP Information for AR12HSSFAWKN / AR12HSSFAWKX Air ConditionerpfsfosnecaNo ratings yet

- Constants, Data, Definitions Diffusion and Heat Conduction Physics 213 Formula SheetDocument1 pageConstants, Data, Definitions Diffusion and Heat Conduction Physics 213 Formula SheetBenjamin ChiangNo ratings yet

- FAC (Heating and Cooling)Document6 pagesFAC (Heating and Cooling)Nemanja SailovicNo ratings yet

- Atlantis Solar Tech SpecsDocument1 pageAtlantis Solar Tech SpecsAditya GognaNo ratings yet

- Aspen-Physical Property System Physical Property ModelsDocument286 pagesAspen-Physical Property System Physical Property ModelsSurya Budi Widagdo100% (1)

- Iso-7730-1984Document11 pagesIso-7730-1984Hasrul RosliNo ratings yet