Professional Documents

Culture Documents

PTT259 Palm Oil Mill Effluent (POME)

Uploaded by

Nurshaqina Sufian67%(3)67% found this document useful (3 votes)

256 views15 pagesPTT259 Palm Oil Mill Effluent

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentPTT259 Palm Oil Mill Effluent

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

67%(3)67% found this document useful (3 votes)

256 views15 pagesPTT259 Palm Oil Mill Effluent (POME)

Uploaded by

Nurshaqina SufianPTT259 Palm Oil Mill Effluent

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 15

PTT 259

OLEOCHEMICAL PROCESS AND

PRODUCTS

SEMESTER 1 : 2016/2017

Lecture on

Palm Oil Mill Effluent (POME)

By:

ABDUL LATIF BIN ABDUL RANI

29th SEPTEMBER 2016

What is Palm Oil Mill Effluent (POME)?

Palm oil mill effluent (POME) is a wastewater generated from

palm oil milling activities which requires effective treatment

before discharge into watercourses (i.e. river, pond,

groundwater) due to its highly polluting properties.

POME is a colloidal suspension consists of 96% water, 0.7% oil,

and 5% total solids including 2-4% suspended solid.

POME is produced from three major processing operations

sterilisation of FFB (36%), clarification of the extracted CPO

(60%), washing and cleaning of the palm oil and kernel

extraction residue (4%) (Sethupathi et al., 2004)

In Malaysia, palm oil industries have generated almost 53 million

tonnes of POME each year (Lorestani et al., 2006)

Figure 1: POME retention pond at Indonesia

Source: MPOB

Figure 1: POME retention pond at Malaysia

The cheapest way of discharging of POME is by having a

retention pond before releasing it into the river.

However, POME contains high concentrations of :

• organic matter

• suspended solids (SS)

• oil and grease

• plant nutrients

So it can cause significant environmental effects like oxygen

depletion if it is discharged without efficient treatment.

The traditional disposal methods such as open dumping or

land application of POME is become impractical as it is:

Expensive, cause clogging the soil, kills the vegetation on

contact and, limitation on open space.

Views on POME discharges and related retention ponds

Characteristic and composition of Palm Oil Mill

Effluent (POME)

• Fresh POME: is hot, acidic (pH 4 and 5)

• Colour: Brownish colloidal suspension contains high

concentration of organic matter

• High amount of total solids (40 500 mg/L)

• Oil and grease (4000 mg/L)

• COD (chemical oxygen demand) (50 000 mg/L)

• BOD (biochemical oxygen demand) (25 000 mg/L)

Adverse effects of Palm Oil Mill Effluent (POME)

Palm oil mill effluent (POME) can leads to serious

environmental pollution involving:

• Contamination to the water bodies (e.g. river)

• Depletion of oxygen in the water – resulting extinction of

aquatic plants and animals

• Aesthetically unacceptable view

• Production of highly odour problem due to degradation of

the organic compound within POME

Discharge Standards (EQA 1974, 2005)

Current treatment methods for POME

a) Anaerobic digestion system – 2 phase involved, raw POME

converted into volatile fatty acid (1st phase), then Volatile

fatty acid converted into methane and carbon dioxide (2nd

phase)

b) Extended aerobic process – involved continuous aeration

c) Ponding system – pond retention

d) Bioreactor system – microorganism degradation system

e) Compositing system - fertilisers

Palm Oil Mill Effluent (POME) treatment

To remove suspended solid

particles as much as

Primary treatment

possible

(Physical treatment)

Involved:

• Sieving: using screening bar or mechanical sieve

• Sedimentation bed

• Filter

To biodegrade of the remaining

Secondary treatment dissolved organic particles using

(Biological treatment) microorganism

Involved:

• Digestive tank

• Aeration pond or lagoon

• Sedimentation tank

Primary treatment method for Palm Oil Mill Effluent

(POME)

Physical treatment of POME (primary treatment)

Aim of the primary treatment: To remove the suspended solid

particles.

- Primary treatment involved devices: Sieve, Sedimentation bed

and Filter.

- These mechanical techniques were used in sedimentation,

filtration and decolourization of effluent.

-Also been applied: Physico-chemical technique involving

coagulation of finely dispersed suspended solid particles,

adsorption of heavy metals.

Secondary treatment method for Palm Oil Mill Effluent

(POME)

Secondary treatment (known as biological treatment) involving

processes such as:

a) Digestion tank: Acidification phase – whereby the organic

particles been breakdown/converted into volatile fatty acids

(VFA) – this compound is needed as substrate in anaerobic

phase. Degradation process also produce Methane (CH4) and

CO2 gas.

b) Aeration lagoon: To further degrade of the organic substance by

microorganism in the presence of oxygen (by aerators).

c) Decanters: Same as centrifuge. To separate solid and water-

producing solid filter cakes – to be dried and disposed.

You might also like

- Zero Discharge Treatment of POMEDocument9 pagesZero Discharge Treatment of POMEAnonymous DJrec2No ratings yet

- The Biodiesel HandbookFrom EverandThe Biodiesel HandbookGerhard KnotheRating: 5 out of 5 stars5/5 (2)

- Palm Oil Mill EffluentDocument3 pagesPalm Oil Mill EffluentChrisna Saputra Archlord100% (2)

- Rapeseed and Canola Oil: Production, Processing, Properties and UsesFrom EverandRapeseed and Canola Oil: Production, Processing, Properties and UsesNo ratings yet

- Effluent Treatment Plant System at Palm Oil MillDocument15 pagesEffluent Treatment Plant System at Palm Oil MillSyukri MiazawaNo ratings yet

- Pretreatment of Biomass: Processes and TechnologiesFrom EverandPretreatment of Biomass: Processes and TechnologiesRating: 5 out of 5 stars5/5 (1)

- Palm Oil Mill Design Procedure Ch1Document2 pagesPalm Oil Mill Design Procedure Ch1Amin Buhari Md Zain100% (3)

- Energy BalanceDocument6 pagesEnergy BalanceAnissa MuniraNo ratings yet

- Report LiDocument68 pagesReport Lipitt8780% (5)

- Refining of Palm Kernel OilDocument75 pagesRefining of Palm Kernel Oilhagung100% (3)

- Palm Oil and Palm Kernel OilDocument26 pagesPalm Oil and Palm Kernel OilRachel Yessica WinartiNo ratings yet

- Palm Oil Mills Targets Zero EmissionDocument5 pagesPalm Oil Mills Targets Zero EmissionscreenscreamerNo ratings yet

- Palm Oil Mill - Clarification StationDocument1 pagePalm Oil Mill - Clarification StationkiraikNo ratings yet

- Refining and Degumming For OilDocument7 pagesRefining and Degumming For Oiljaymie_llanera100% (1)

- Palm Oil Mill EffluentDocument3 pagesPalm Oil Mill EffluentAmir AimanNo ratings yet

- Palm Oil MillDocument52 pagesPalm Oil MillengrsurifNo ratings yet

- Introduction Palm Oil Processing - 2Document32 pagesIntroduction Palm Oil Processing - 2hantudonatNo ratings yet

- PALM OIL MILL SAFETY AND MAINTENANCE - pptx1Document18 pagesPALM OIL MILL SAFETY AND MAINTENANCE - pptx1Nadia Asyiqin75% (4)

- Palm Oil Manufacturing and Effluent TreatmentDocument13 pagesPalm Oil Manufacturing and Effluent Treatmentnp27031990100% (1)

- Chemical Properties Palm OilDocument21 pagesChemical Properties Palm OilAmirah Mohd ZuberNo ratings yet

- Calcul Conveioare SurubDocument2 pagesCalcul Conveioare SurubgvisanNo ratings yet

- Palm Oil Milling ProcessDocument4 pagesPalm Oil Milling Processtoon chanNo ratings yet

- A General Review of Palm Oil Mill EffluentDocument3 pagesA General Review of Palm Oil Mill EffluentMykel-Deitrick Boafo DuoduNo ratings yet

- Palm Oil Mill ProcessDocument20 pagesPalm Oil Mill Processmuhdjusri50% (2)

- Feasibility Study On Palm Oil Processing Wastes TowardsDocument6 pagesFeasibility Study On Palm Oil Processing Wastes TowardsighowilfredNo ratings yet

- TOC Oil Palm HB Immature - 2Document6 pagesTOC Oil Palm HB Immature - 2Jackson Jerome50% (6)

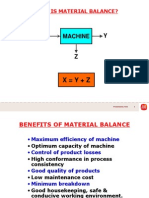

- Material Balance Palm Oil MillDocument9 pagesMaterial Balance Palm Oil Millmalikldu100% (2)

- MISGuidelines PalmOilIndustryDocument91 pagesMISGuidelines PalmOilIndustryGary Clark100% (2)

- 2.0 SDPA - Palm Oil Mill ProjectDocument19 pages2.0 SDPA - Palm Oil Mill ProjectAmeen Zenn100% (1)

- LMC Oleochemical Report 2019Document19 pagesLMC Oleochemical Report 2019KUKU100% (4)

- Industrial Process and The Environment - Crude Palm Oil IndustryDocument102 pagesIndustrial Process and The Environment - Crude Palm Oil IndustryWahyu SutrisnoNo ratings yet

- Exp 1 Physical Refining of Crude Palm OilDocument13 pagesExp 1 Physical Refining of Crude Palm Oilaffeena100% (1)

- 2011 PipocDocument42 pages2011 PipocBung HarunNo ratings yet

- Palm Oil ProcessingDocument101 pagesPalm Oil ProcessingAshly Alexander100% (2)

- Palm Oil Effluent Treatment SchemeDocument11 pagesPalm Oil Effluent Treatment SchemebathalapalliNo ratings yet

- Refinery of Palm OilDocument36 pagesRefinery of Palm Oildoshi_ritesh100% (6)

- Palm Oil Mill EffluentDocument6 pagesPalm Oil Mill Effluentankitsaxena123100% (2)

- Westfalia in Palm Oil MillDocument24 pagesWestfalia in Palm Oil MillSupatmono NAINo ratings yet

- Crude Palm Oil Refining Process by Gibon 2007Document21 pagesCrude Palm Oil Refining Process by Gibon 2007AlexNo ratings yet

- Summary Value Map of Palm OilDocument5 pagesSummary Value Map of Palm OilAlia100% (3)

- Margarine 12Document74 pagesMargarine 12the_gunners2004No ratings yet

- Canola Oil Physical Chemical Properties 1Document6 pagesCanola Oil Physical Chemical Properties 1elpancaseroNo ratings yet

- Oil Palm Fertilization - Sharing Some PerspectivesDocument7 pagesOil Palm Fertilization - Sharing Some PerspectivesLucy LimNo ratings yet

- Palm Acid Oil (PAO) Palm Fatty Acid Distillate (PFAD) RBD PalmDocument34 pagesPalm Acid Oil (PAO) Palm Fatty Acid Distillate (PFAD) RBD PalmBaek Ho Kim100% (1)

- A Palm Oil Mill in Oyo StateDocument10 pagesA Palm Oil Mill in Oyo StateindiamillersNo ratings yet

- Palm OilDocument55 pagesPalm Oilhemanggor100% (1)

- Sterilizer TiltingDocument23 pagesSterilizer Tiltingofchis50% (2)

- Oleochem Chap 1Document47 pagesOleochem Chap 1lolahonez100% (4)

- Fatty AcidDocument44 pagesFatty AcidaryannoNo ratings yet

- MPOB Sterilizer Process ControlDocument9 pagesMPOB Sterilizer Process ControlgerrykhangNo ratings yet

- Flottweg Centrifuges: For Biodiesel ProductionDocument8 pagesFlottweg Centrifuges: For Biodiesel Productionpachis3No ratings yet

- Risk Assessment Palm OilDocument22 pagesRisk Assessment Palm Oilanniq141100% (1)

- Lecture 28Document11 pagesLecture 28Tejas MhaiskarNo ratings yet

- Lab No 07Document5 pagesLab No 07Usama Subhan AliNo ratings yet

- S Announcement 15750Document4 pagesS Announcement 15750Sarah SanchezNo ratings yet

- CH4 Wastewater Treat PRIMARY SECONDARY TERTIARY 39Document60 pagesCH4 Wastewater Treat PRIMARY SECONDARY TERTIARY 39Dr Mohamed OmerNo ratings yet

- Sludge TreatmentDocument4 pagesSludge TreatmentRicaMyrivilleArellagaNo ratings yet

- Effluent Treatment PlantDocument20 pagesEffluent Treatment PlantSajib IglesiasNo ratings yet

- Topic 4.0 WW PorcessingDocument26 pagesTopic 4.0 WW PorcessingikhwanstorageNo ratings yet

- Oil & Fat AnalysisDocument59 pagesOil & Fat AnalysisNurshaqina SufianNo ratings yet

- Chapter 4 Psychomentry, Humidification and DehumidificationDocument14 pagesChapter 4 Psychomentry, Humidification and DehumidificationNurshaqina SufianNo ratings yet

- Chapter 12 - Thermodynamic Property RelationsDocument27 pagesChapter 12 - Thermodynamic Property RelationsNurshaqina SufianNo ratings yet

- Chapter 11-Refrigeration CyclesDocument24 pagesChapter 11-Refrigeration CyclesAbas S. AcmadNo ratings yet

- Chapter 1 - Concept of Thermodynamics PDFDocument28 pagesChapter 1 - Concept of Thermodynamics PDFNurshaqina SufianNo ratings yet

- Chapter 1 - Concept of ThermodynamicsDocument28 pagesChapter 1 - Concept of ThermodynamicsNurshaqina SufianNo ratings yet

- Chapter 6 - Second Law of ThermodynamicsDocument29 pagesChapter 6 - Second Law of ThermodynamicsNurshaqina Sufian100% (1)

- Chapter 2 - Properties Pure SubtancesDocument38 pagesChapter 2 - Properties Pure SubtancesNurshaqina SufianNo ratings yet

- Oil and Fat AnalysisDocument64 pagesOil and Fat AnalysisNurshaqina SufianNo ratings yet

- Oil and Fat Analysis2 PDFDocument7 pagesOil and Fat Analysis2 PDFNurshaqina SufianNo ratings yet

- Algae M FisherDocument23 pagesAlgae M FisherAndreea-Gabriela IonicaNo ratings yet

- Coal Mining in India: 2013Document4 pagesCoal Mining in India: 2013Anil RastogiNo ratings yet

- Constructed Wetlands CompleteDocument219 pagesConstructed Wetlands CompleteNguyen Cong ThanhNo ratings yet

- Book Geology in Engineering by S Tabon Draft Excerpt 2022 PDFDocument16 pagesBook Geology in Engineering by S Tabon Draft Excerpt 2022 PDFMoira Elizabeth SyNo ratings yet

- Cagayan de Oro River Basin Master PlanDocument6 pagesCagayan de Oro River Basin Master PlanIvan Colastica CayabyabNo ratings yet

- Lesson 6.1 Running WaterDocument29 pagesLesson 6.1 Running Waterazzamomar2018No ratings yet

- Achieving Industrial Energy Efficiency 2006Document47 pagesAchieving Industrial Energy Efficiency 2006Muhammad AnwarNo ratings yet

- Konsep InfiltrasiDocument5 pagesKonsep InfiltrasimuhardionoNo ratings yet

- CompReg 13NOVEMBER2019Document1,551 pagesCompReg 13NOVEMBER2019Arvind KumarNo ratings yet

- Varaha River YieldtestreportDocument13 pagesVaraha River Yieldtestreportrama krishnaNo ratings yet

- Ensure Access To Affordable, Reliable, Sustainable and Modern Energy For AllDocument3 pagesEnsure Access To Affordable, Reliable, Sustainable and Modern Energy For Allpratham singhviNo ratings yet

- Part VI The Central Plains GEOG 321Document26 pagesPart VI The Central Plains GEOG 321jack stauberNo ratings yet

- Organic FarmingDocument18 pagesOrganic FarmingSOHEL BANGINo ratings yet

- University of Bradford: Environmental Water Engineering GroupDocument3 pagesUniversity of Bradford: Environmental Water Engineering GroupmrtweetsNo ratings yet

- Kimberlitic Tubes Underquarry ReservesDocument4 pagesKimberlitic Tubes Underquarry ReservesManuel AragonNo ratings yet

- Manual On Small Dams in Jharkhand - 1-1Document23 pagesManual On Small Dams in Jharkhand - 1-1Ibrahim DanishNo ratings yet

- Quartz FamilyDocument4 pagesQuartz FamilySORIANO, JEZEREEL JOYCE A.No ratings yet

- Milan 2020 RainforestationDocument204 pagesMilan 2020 RainforestationFran DelNo ratings yet

- Tinker Creek Fish Kill - Questions and AnswersDocument3 pagesTinker Creek Fish Kill - Questions and AnswersWSET100% (1)

- Pond Building:: A Guide To Planning, Constructing, and Maintaining Recreational PondsDocument16 pagesPond Building:: A Guide To Planning, Constructing, and Maintaining Recreational PondssobodanpatronuNo ratings yet

- Sustainable Agricultural Mechanization For SmallholdersDocument21 pagesSustainable Agricultural Mechanization For SmallholdersJeisson Steven HERNANDEZ BEDOYANo ratings yet

- 3228-Article Text-13128-1-10-20190801Document9 pages3228-Article Text-13128-1-10-20190801cvetan1983No ratings yet

- Band 7 IELTS Advantages Disadvantages EssayDocument7 pagesBand 7 IELTS Advantages Disadvantages EssayRania Chokor0% (1)

- GGASS Investor Presentation 3-09Document14 pagesGGASS Investor Presentation 3-09api-1158549167% (3)

- Water Action PlanDocument31 pagesWater Action PlanAakanksha VijayNo ratings yet

- Groundnut@ShaliniDocument15 pagesGroundnut@Shalinishalini shuklaNo ratings yet

- S&T For Development in TZ: DS 102 Module 2 STI by H. MakundiDocument7 pagesS&T For Development in TZ: DS 102 Module 2 STI by H. MakundiJackson LoceryanNo ratings yet

- Writing Task 1 - Integrated Question (Test #12) : Your Guide For TOEFL Writing 24+Document3 pagesWriting Task 1 - Integrated Question (Test #12) : Your Guide For TOEFL Writing 24+AstridBarraNo ratings yet

- Reliance Power Limited - List of Installed & Planned Power ProjectsDocument1 pageReliance Power Limited - List of Installed & Planned Power ProjectsZahoor AhmedNo ratings yet

- ETPDocument3 pagesETPSanaNo ratings yet