Professional Documents

Culture Documents

55m Span Shed - Rev 02

Uploaded by

Jagadeesh Sundaram0 ratings0% found this document useful (0 votes)

147 views13 pagessteel truss

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentsteel truss

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

147 views13 pages55m Span Shed - Rev 02

Uploaded by

Jagadeesh Sundaramsteel truss

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You are on page 1of 13

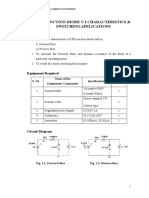

Design of Steel Structures

Design of Steel Roof Truss

- G. S. Deshmukh

INTRODUCTION

Trusses are triangular frame

works in which the members

are subjected to essentially axial

forces due to external load.

External load and the members

lie in the same plane.

In case of space trusses

members are oriented in three

dimensions and also the loads

may act in any direction.

2 Design of Steel Roof Truss

Lattice Girders

lattice girders are the trusses which frequently used to span

long lengths in the place of solid web girders.

3 Design of Steel Roof Truss

Steel members subjected to axial forces are generally more

efficient than members in flexure since the cross section is

nearly uniformly stressed.

Trusses are extensively used, especially to large span

structures.

4 Design of Steel Roof Truss

USES

Trusses are used in

Roofs of single storey industrial buildings

Long span floors and roofs of multistory buildings, to resist

gravity loads [Figs. (a) and (b)].

5 Design of Steel Roof Truss

Walls of multi-storey buildings and horizontal planes of

industrial buildings to resist lateral loads and give lateral

stability [Figs. (c) and (d)].

long span bridges to carry

gravity loads and lateral loads [Fig. (e)].

6 Design of Steel Roof Truss

LOADS ACTING ON TRUSS

Dead load- 1) Dead load of claddings

2) Dead load of purlins

3) Self weight of the trusses

4) weight of bracings

Live load

As per IS:875-1987 (Reaffirmed 1992).

Wind load

Earthquake load

As per IS:1893-1985.

7 Design of Steel Roof Truss

ANALYSIS OF TRUSSES

The loads are assumed to be acting only at the nodes of the

trusses.

They are usually statically determinate.

Can be analysed manually by the method of joints or by the

method of sections.

8 Design of Steel Roof Truss

CONFIGURATION OF TRUSSES

Pitched Roof Truss

Parallel Chord Truss

Trapezoidal Truss

9 Design of Steel Roof Truss

TRUSS MEMBERS

The members of trusses are made of either rolled steel

sections or built-up sections depending upon the span length,

intensity of loading.

10 Design of Steel Roof Truss

DESIGN OF TRUSSES

The design standard (IS: 800) imposes restrictions on the

maximum slenderness ratio, (l/r), as given below:

Member type Max l/r limit

Members under compression under loads other than wind/ earthquake load 180

Tension members undergoing stress reversal due to loads other than wind load 180

or seismic forces

Members normally under tension but may have to resist compression under 250

wind load

Compression flange of a beam against lateral torsional buckling 300

Members designed only for tension even though they may experience 350

stress reversal

Members always under tension (unless pre-tensioned to avoid sag) 400

11 Design of Steel Roof Truss

These limits are imposed to ensure the following:

Too slender a member is avoided which may be damaged during

transportation and erection.

Members do not sag excessively under self-weight during service

causing excessive deflection in truss.

Compression members do not sag greater than 1/1000th of their

length, which is beyond the imperfection limit assumed in the

compressive strength calculation.

It is a common practice to specify a minimum angle size of 50 X

50 X 6 in the case of roof trusses.

12 Design of Steel Roof Truss

13 Design of Steel Roof Truss

You might also like

- Column Design As Per Is 456 PDFDocument2 pagesColumn Design As Per Is 456 PDFAnsNo ratings yet

- Structural Design of Bridges, Robs and UnderpassesDocument4 pagesStructural Design of Bridges, Robs and UnderpassessujupsNo ratings yet

- Reinforced Concrete Design: By: Dr. Haleem K. HussainDocument65 pagesReinforced Concrete Design: By: Dr. Haleem K. HussainNHEM KEAMNo ratings yet

- F1. SCT - SN-Steel Formwork Design - GTG BEAM FORMWORKDocument32 pagesF1. SCT - SN-Steel Formwork Design - GTG BEAM FORMWORKshihabNo ratings yet

- Prof. A. Meher Prasad: Department of Civil Engineering Indian Institute of Technology MadrasDocument101 pagesProf. A. Meher Prasad: Department of Civil Engineering Indian Institute of Technology MadrasEsteban Gabriel Misahuamán CórdovaNo ratings yet

- Time Period Calculation in ETABS As Per IS 1893 Part 1Document2 pagesTime Period Calculation in ETABS As Per IS 1893 Part 1NAYAN RANPURA100% (1)

- Truss DesignDocument16 pagesTruss DesignRabindraUpretiNo ratings yet

- Truss DesignDocument111 pagesTruss DesignSuhas NatuNo ratings yet

- COLUMN EFFECTIVE LENGTH - Yura1971q2Document6 pagesCOLUMN EFFECTIVE LENGTH - Yura1971q2ellisbl100% (1)

- Combined Footing Design With Example and Types of Combined FootingDocument2 pagesCombined Footing Design With Example and Types of Combined FootingNick GeneseNo ratings yet

- Design of FootingDocument15 pagesDesign of FootingRumylo AgustinNo ratings yet

- Column Design - As Per BS CodeDocument16 pagesColumn Design - As Per BS CodeYam BalaoingNo ratings yet

- Project MezzanineDocument2 pagesProject Mezzaninepujan77No ratings yet

- ETABS Example-RDocument39 pagesETABS Example-RAnonymous nwByj9LNo ratings yet

- Civil Engg Basic Knowledge PDFDocument3 pagesCivil Engg Basic Knowledge PDFASHUTOSH GUPTA100% (5)

- Staircase Design 001Document18 pagesStaircase Design 001Er navneet jassiNo ratings yet

- Design of ColumnDocument54 pagesDesign of ColumnMonika AcharyaNo ratings yet

- Engg. Build. DesignDocument67 pagesEngg. Build. DesignAyon SenguptaNo ratings yet

- Truss Design - Faculty Wing - EN1993Document13 pagesTruss Design - Faculty Wing - EN1993JonathanNo ratings yet

- Design of RC Retaining Walls PDFDocument27 pagesDesign of RC Retaining Walls PDFqaiserkhan001No ratings yet

- C. Pressure On Silo Walls Due To Stored Material: Primary Load 109: Seismic Load Along +Z Direction (+ezDocument1 pageC. Pressure On Silo Walls Due To Stored Material: Primary Load 109: Seismic Load Along +Z Direction (+ezdantevariasNo ratings yet

- Steel Truss Roof Structure For Kattumana Porialar 24.4.2014Document6 pagesSteel Truss Roof Structure For Kattumana Porialar 24.4.2014Ahmad AnasNo ratings yet

- DSS Grillage FoundationDocument7 pagesDSS Grillage FoundationSivaSubramanyamNo ratings yet

- Capacity Charts For The Hydraulic Design of Highway CulvertsDocument95 pagesCapacity Charts For The Hydraulic Design of Highway CulvertsphisitlaiNo ratings yet

- Cap PlateDocument18 pagesCap PlateVinoth KumarNo ratings yet

- XyzDocument64 pagesXyzP S HARSHITANo ratings yet

- Vertical Loads On Building Frames: Assumptions For The Analysis of Girders Using Approximate AnalysisDocument10 pagesVertical Loads On Building Frames: Assumptions For The Analysis of Girders Using Approximate AnalysisNeven Ahmed HassanNo ratings yet

- Culverts and Low Level CrossingsDocument3 pagesCulverts and Low Level CrossingsAbdykafy ShibruNo ratings yet

- ACI Design AidsDocument60 pagesACI Design AidsNabeel SheikhNo ratings yet

- ETABS ExampleDocument40 pagesETABS ExampleRaj ShahNo ratings yet

- Summary of Loads-Left Bank Abutment: Sukhaura River Motorable Bridge, Makwanpur Abutment Design IDD, ChitwanDocument26 pagesSummary of Loads-Left Bank Abutment: Sukhaura River Motorable Bridge, Makwanpur Abutment Design IDD, ChitwanPoshan DhunganaNo ratings yet

- Design of TrussDocument29 pagesDesign of Trussfrancis100% (1)

- Strap Footing TheoryDocument4 pagesStrap Footing TheorySwopnilOjhaNo ratings yet

- Example Design of Roof TrussDocument3 pagesExample Design of Roof TrussIk Einstein OjoganNo ratings yet

- GlazingsDocument9 pagesGlazingsVikas Singh ChandelNo ratings yet

- Earthquake Lateral Forces Calculations According To UBC97: InputDocument10 pagesEarthquake Lateral Forces Calculations According To UBC97: InputOnurUmanNo ratings yet

- Deformed Shape: Load Case/ Load Combination / Modal CaseDocument4 pagesDeformed Shape: Load Case/ Load Combination / Modal CasesovannchhoemNo ratings yet

- Raft TheoryDocument37 pagesRaft Theorymuktha mukuNo ratings yet

- 1 A C A+b+c B: Code Shape Type Shape Formula U-Shape (US)Document2 pages1 A C A+b+c B: Code Shape Type Shape Formula U-Shape (US)Saugat PaudelNo ratings yet

- Steel Structure Calculation SheetDocument62 pagesSteel Structure Calculation SheetSeifeldin Ali Marzouk100% (1)

- Wind Load On Cable TraysDocument10 pagesWind Load On Cable TraysAaron EasleyNo ratings yet

- An Analytical and Comparitive Study of Composite and RCC Multi Storey BuildingsDocument15 pagesAn Analytical and Comparitive Study of Composite and RCC Multi Storey BuildingsRakkeshKudullaNo ratings yet

- Sr. No. Important Points For Roof Truss Designs: Pitches of TrussesDocument2 pagesSr. No. Important Points For Roof Truss Designs: Pitches of TrussesELISHA SHINDE0% (1)

- Plinth Beam Design CalculationDocument4 pagesPlinth Beam Design CalculationVinod NairNo ratings yet

- Column LoadsDocument3 pagesColumn LoadsV.m. RajanNo ratings yet

- Calculation Summary of Pile FoundationDocument24 pagesCalculation Summary of Pile FoundationdedydarwisNo ratings yet

- Steel Frame Structure Modeling by Staad-Pro (Example - 2) by Prof. Dr. Nabeel Al-BayatiDocument6 pagesSteel Frame Structure Modeling by Staad-Pro (Example - 2) by Prof. Dr. Nabeel Al-BayatiProfessor Dr. Nabeel Al-Bayati-Consultant Engineer100% (1)

- Rev - Office Proposal - 6.11.2014-ModelDocument1 pageRev - Office Proposal - 6.11.2014-ModelChandra ShekarNo ratings yet

- Elevated Steel Tank FoundationDocument10 pagesElevated Steel Tank Foundationchris100% (1)

- Amendment No. 1 November 2014 TO Is 4326: 2013 Earthquake Resistant Design and Construction of Buildings - Code of PracticeDocument9 pagesAmendment No. 1 November 2014 TO Is 4326: 2013 Earthquake Resistant Design and Construction of Buildings - Code of PracticeAKSNo ratings yet

- All Plug-Ins of Arc BdsDocument48 pagesAll Plug-Ins of Arc BdsAshish LoyaNo ratings yet

- R5 - Design of R C Slabs - 2015!01!28Document41 pagesR5 - Design of R C Slabs - 2015!01!28Udaysingh Patil100% (1)

- Design of RC Building - ExerciseDocument6 pagesDesign of RC Building - Exercisesajeerala100% (1)

- Lecture 4 - House DesignDocument18 pagesLecture 4 - House Designkkhan_451062No ratings yet

- Estimating Deadloads On Timber CanopiesDocument1 pageEstimating Deadloads On Timber CanopiesConrad HarrisonNo ratings yet

- Earthquake Load Calculation (Base Shear Method) : Rigid FrameDocument4 pagesEarthquake Load Calculation (Base Shear Method) : Rigid FrameJohn Rheynor MayoNo ratings yet

- Standing Sawtooth Staircase Analysis Design and DetailingDocument8 pagesStanding Sawtooth Staircase Analysis Design and DetailingMahesh SNo ratings yet

- Design of Steel Roof TrussesDocument13 pagesDesign of Steel Roof Trussesgirish_deshmukh88% (8)

- 2 Design-of-steel-roof-Trusses DR G S KameDocument13 pages2 Design-of-steel-roof-Trusses DR G S KameDrGanesh KameNo ratings yet

- Daily PrayersDocument11 pagesDaily Prayerssaurabh0015No ratings yet

- Yajur VedamDocument312 pagesYajur VedamJagadeesh SundaramNo ratings yet

- Nse Options Strategies Explanation With ExamplesDocument60 pagesNse Options Strategies Explanation With ExamplesVatsal ShahNo ratings yet

- ரிக்வேதம்@digitalelibrary PDFDocument929 pagesரிக்வேதம்@digitalelibrary PDFSiva Kumar100% (6)

- Microsoft Word - Bhajan PDFDocument132 pagesMicrosoft Word - Bhajan PDFAnnapoorani RajappanNo ratings yet

- May 2018 SlokasDocument2 pagesMay 2018 SlokasJagadeesh SundaramNo ratings yet

- Manual CheckDocument1 pageManual CheckAhmmed MuhseeNo ratings yet

- பஜ கோவிந்தம் PDFDocument67 pagesபஜ கோவிந்தம் PDFJagadeesh SundaramNo ratings yet

- Loa Execution PDFDocument135 pagesLoa Execution PDFOmar Gimenez PalmaNo ratings yet

- Reaffirmed 1997Document14 pagesReaffirmed 1997Jagadeesh SundaramNo ratings yet

- Standard Method of Measurement Indian StandardDocument8 pagesStandard Method of Measurement Indian StandardmohdidrisjmNo ratings yet

- Is 516 Method of Test For Strength of ConcreteDocument25 pagesIs 516 Method of Test For Strength of Concreteselva_65195078% (9)

- Sama VedamDocument162 pagesSama VedamJagadeesh SundaramNo ratings yet

- DeviDocument32 pagesDeviJagadeesh SundaramNo ratings yet

- Yoga SutramDocument335 pagesYoga SutramJagadeesh SundaramNo ratings yet

- Message 01 PDFDocument3 pagesMessage 01 PDFNaren MukherjeeNo ratings yet

- Kriya YogaDocument1 pageKriya YogaJagadeesh SundaramNo ratings yet

- Intraday Trading SystemDocument6 pagesIntraday Trading SystemJagadeesh SundaramNo ratings yet

- Numerology PDFDocument31 pagesNumerology PDFJagadeesh SundaramNo ratings yet

- Opportunities in Civil EngineeringDocument34 pagesOpportunities in Civil EngineeringJagadeesh SundaramNo ratings yet

- Purlins, Rails & Eaves Beams: Design GuideDocument44 pagesPurlins, Rails & Eaves Beams: Design GuideJagadeesh SundaramNo ratings yet

- Application For Membership Technologist (MTIE) : DdmmyyyyDocument6 pagesApplication For Membership Technologist (MTIE) : DdmmyyyyJagadeesh SundaramNo ratings yet

- Creators Projects: Er. T.K.Arun Kumar Chief ExecutiveDocument73 pagesCreators Projects: Er. T.K.Arun Kumar Chief ExecutiveJagadeesh SundaramNo ratings yet

- Pile FoundationDocument9 pagesPile FoundationJagadeesh SundaramNo ratings yet

- Degree Form1Document2 pagesDegree Form1ramvenkat0077No ratings yet

- Properties of Alkali-Activated Fly Ash Concrete Blended With SlagDocument8 pagesProperties of Alkali-Activated Fly Ash Concrete Blended With SlagJagadeesh SundaramNo ratings yet

- Detailed SyllabusDocument81 pagesDetailed Syllabuspankajchandre30No ratings yet

- Properties of Alkali-Activated Fly Ash Concrete Blended With SlagDocument8 pagesProperties of Alkali-Activated Fly Ash Concrete Blended With SlagJagadeesh SundaramNo ratings yet

- M02 PDFDocument9 pagesM02 PDFJagadeesh SundaramNo ratings yet

- Purlins, Rails & Eaves Beams: Design GuideDocument44 pagesPurlins, Rails & Eaves Beams: Design GuideMinhphuc DaoNo ratings yet

- Tutorial On SchedulingDocument14 pagesTutorial On Schedulingrktiwary256034No ratings yet

- Book - Lattice Boltzmann Methods For Shallow Water FlowsDocument117 pagesBook - Lattice Boltzmann Methods For Shallow Water FlowsMauricio Fabian Duque DazaNo ratings yet

- Diagnostic Trouble Codes For Sinotruk HOWO Engines PDFDocument4 pagesDiagnostic Trouble Codes For Sinotruk HOWO Engines PDFhektor AtkinsonNo ratings yet

- Bone Specific Alkaline PhophataseDocument6 pagesBone Specific Alkaline PhophataseMohan DesaiNo ratings yet

- Holiday Homework Class 12 MathematicsDocument2 pagesHoliday Homework Class 12 MathematicsKartik SharmaNo ratings yet

- Ondemand: Key SpecificationsDocument2 pagesOndemand: Key SpecificationsNUBIA DIAZNo ratings yet

- Periodicity in 3D Lab Report FormDocument2 pagesPeriodicity in 3D Lab Report FormZIX326100% (1)

- FTKM 0419 B L (Leaflet)Document2 pagesFTKM 0419 B L (Leaflet)Wan SyahlanNo ratings yet

- Airplane Wing Geometry and ConfigurationsDocument7 pagesAirplane Wing Geometry and Configurationsh_mahdiNo ratings yet

- On The Theories of Plates and Shells at The Nanoscale: Holm Altenbach and Victor A. EremeyevDocument34 pagesOn The Theories of Plates and Shells at The Nanoscale: Holm Altenbach and Victor A. EremeyevAbr. MengistuNo ratings yet

- Predicting Residual Stresses Due To Solidification in Cast Plastic Plates VladoTropsaPhDDocument225 pagesPredicting Residual Stresses Due To Solidification in Cast Plastic Plates VladoTropsaPhDAghajaniNo ratings yet

- Semiconductor Devices and Circuits LaboratoryDocument53 pagesSemiconductor Devices and Circuits LaboratoryKaryampudi RushendrababuNo ratings yet

- In The Next Three Chapters, We Will Examine Different Aspects of Capital Market Theory, IncludingDocument62 pagesIn The Next Three Chapters, We Will Examine Different Aspects of Capital Market Theory, IncludingRahmat M JayaatmadjaNo ratings yet

- 2 Parameter Circular (61-80)Document6 pages2 Parameter Circular (61-80)Papan SarkarNo ratings yet

- Human Face Recognition Attendance SystemDocument17 pagesHuman Face Recognition Attendance SystemAnish ArunaNo ratings yet

- Ranjit Kumar-Research Methodology A Step-by-Step G-15-16Document2 pagesRanjit Kumar-Research Methodology A Step-by-Step G-15-16Trendy NewsNo ratings yet

- EEE2205 Introduction To MeasurementsDocument4 pagesEEE2205 Introduction To MeasurementsKibelennyNo ratings yet

- Series: 973 - 1327 KWM (Gross) at 1500 RPMDocument18 pagesSeries: 973 - 1327 KWM (Gross) at 1500 RPMlahcen boudaoudNo ratings yet

- CapacitanceDocument71 pagesCapacitanceTharaj ThajNo ratings yet

- Statistical Characteristics of Extreme Rainfall Events in EgyptDocument9 pagesStatistical Characteristics of Extreme Rainfall Events in EgyptAhmed El-AdawyNo ratings yet

- Aphing Systemsof Linear Inequalities PR5Document3 pagesAphing Systemsof Linear Inequalities PR5Panagiotis SotiropoulosNo ratings yet

- Rough Surfaces in ANSYSDocument17 pagesRough Surfaces in ANSYSIgor BlanariNo ratings yet

- DSA Lab1Document22 pagesDSA Lab1dukeyasser107967No ratings yet

- XS4P08PC410TF: Product Data SheetDocument5 pagesXS4P08PC410TF: Product Data SheetGonzalo GarciaNo ratings yet

- The Effect of Backrest Roller On Warp Tension in Modern LoomDocument11 pagesThe Effect of Backrest Roller On Warp Tension in Modern LoomRavi KumarNo ratings yet

- CNS TechnicianDocument2 pagesCNS TechnicianSohailNo ratings yet

- IP 7-1-1 Fired HeatersDocument9 pagesIP 7-1-1 Fired HeatersArnold Jose Batista RodriguezNo ratings yet

- Manual de Programacao r6 N 1.3Document160 pagesManual de Programacao r6 N 1.3Ian MechuraNo ratings yet

- CH 13Document27 pagesCH 13Shaivy TyagiNo ratings yet

- Minerals Down The Microscope PDFDocument8 pagesMinerals Down The Microscope PDFArijit LaikNo ratings yet