Professional Documents

Culture Documents

Selection of Type of Bridge

Uploaded by

Abhishek0 ratings0% found this document useful (0 votes)

50 views8 pagesThis document discusses factors to consider when selecting a bridge type, including span length determination, bridge material selection, and structural types. Continuous reinforced concrete bridges have advantages like reduced piers, bearings, and expansion joints, providing better strength and lower lifetime costs compared to simple span bridges. Concrete bridges can be adapted to various loads but are heavier, while steel bridges are lighter and faster to construct but require more maintenance due to corrosion. Selection depends on site conditions, traffic needs, constructability, and lifetime costs.

Original Description:

Selection of Type of Bridge

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document discusses factors to consider when selecting a bridge type, including span length determination, bridge material selection, and structural types. Continuous reinforced concrete bridges have advantages like reduced piers, bearings, and expansion joints, providing better strength and lower lifetime costs compared to simple span bridges. Concrete bridges can be adapted to various loads but are heavier, while steel bridges are lighter and faster to construct but require more maintenance due to corrosion. Selection depends on site conditions, traffic needs, constructability, and lifetime costs.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

50 views8 pagesSelection of Type of Bridge

Uploaded by

AbhishekThis document discusses factors to consider when selecting a bridge type, including span length determination, bridge material selection, and structural types. Continuous reinforced concrete bridges have advantages like reduced piers, bearings, and expansion joints, providing better strength and lower lifetime costs compared to simple span bridges. Concrete bridges can be adapted to various loads but are heavier, while steel bridges are lighter and faster to construct but require more maintenance due to corrosion. Selection depends on site conditions, traffic needs, constructability, and lifetime costs.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 8

Part 2-Bridge Construction

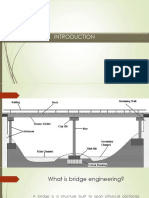

1 1- Introduction & Investigation

1.2. Investigation for Bridge

12

1.2.4. Span Determination

A. EconomicSpan: Min span length where cost of superstructure = Cost of

substructure.

B. Hydraulic Requirement: bridges are designed to accommodate design discharge

at design flood.

C. Location of Piers: Piers should be located to cause minimum obstruction to flow

D. Free Board: water way belowsuperstructure should be designed to pass design

flood & floating debris with back water effect.

50

2.2. Selection of Bridge Types

a. Geometric condition of the site (Road Alignment, Design flood and highest water

mark)

b. Aesthetics,

c. Traffic capacity,

d. Need for future widening,

e. Structural stability,

f. Foundation (sub-surface) conditions, and strength of abutments.

g. Erection procedures,

h. Available Material

i. Knowledge(skill) and Equipment(capacity) of the contractor

j. Clearance requirement above and below the road way

k. General civic requirements with respect to location, financing and community

values.

51

2.2. Selection of Bridge Types

For Curved Bridges continuous box girder and slab bridges are good choices because

They have pleasing appearance

Can readily be built on a curve

Have relatively high torsional resistance

2.2. Selection of Bridge Types

52

Continuous reinforced concrete bridge

Less number of bearings than simply supported bridge since on line of

bearings are used over the piers.

Reduced width of pier, thus less flow obstruction and less amount of material.

Requires less number of expansion joints due to which both the initial

cost and maintenance cost become less.

Better architectural appearance.

Lesser Vibration and deflection.

Additional strength from moment redistribution due to continuity & rigid.

Smaller cross section of bridge components both superstructure & sub structure

Analysis is laborious and time consuming.

2.2. Selection of Bridge Types

53

Simple Span reinforced concrete bridge

Elastic moment capacities are used for design resulting in large cross sections

Analysis and design is simple

High maintenance cost

Many construction joints at the discontinuities

2.2. Selection of Bridge Types

54 Concrete Construction

Advantage

Adaptable to wide variety of structural shapes and loads

Low cost of maintenance (less than 1% of construction cost per year).

Long life and better resistance to temporary overloads and dynamic loads than

steel bridges.

Cast-in-place reinforced concrete structure are continuous and monolithic

Easy construction, low cost and good seismic resistance.

They can also be given the desired aesthetic appearance.

Disadvantage

Large dead weight that require large foundation

Difficulty to widen or rebuild

Longer construction time

Expensive formwork and false work

2.2. Selection of Bridge Types

55 Steel Construction

Advantage

Steel bridges can be built faster than reinforced concrete or pre stressed concrete bridge.

They can be erected with ease and this minimizing construction costs.

Steel superstructures are usually lighter than concrete superstructures which translate

into reduced substructures costs, which can be significant when soil conditions are poor.

Steel superstructures can be designed with shallower depth than RC, which is an

important consideration when overhead clearance is required.

Steel bridges are easy and faster to repair than RC.

Disadvantage

Corrosion of steel is the major drawback which requires prohibitively high maintenance

cost. Corrosion can reduce cross section of structural members and weaken the

superstructure.

The second disadvantage is that steel fatigues under repeated loading (its strength

decreases under repeated loading at high number of cycles of loading)

You might also like

- Paper - Integral BridgesDocument10 pagesPaper - Integral BridgesviralisursNo ratings yet

- Advantages and Limitations of Prestressed ConcreteDocument4 pagesAdvantages and Limitations of Prestressed ConcreteKanadeTachibanaNo ratings yet

- Digital Assignment 1Document4 pagesDigital Assignment 1Atul RajNo ratings yet

- Gaja Mini ProjectDocument78 pagesGaja Mini ProjectBharath Chakravarthy100% (3)

- Finite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesFrom EverandFinite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesRating: 4.5 out of 5 stars4.5/5 (16)

- Steel Bridges SeminarDocument21 pagesSteel Bridges SeminarAamodh Kuthethur100% (2)

- Bridges Design and ConstructionDocument70 pagesBridges Design and ConstructionChibuokemLeviAwaNo ratings yet

- Bridges - Initial DesignDocument20 pagesBridges - Initial Design2003655300% (1)

- IJCRT2107063Document6 pagesIJCRT2107063shaik saifulla lNo ratings yet

- Design and Analysis of Beam Supported BridgeDocument8 pagesDesign and Analysis of Beam Supported BridgeBhanu Prakash BNo ratings yet

- Ass FinalDocument10 pagesAss FinalTajura TamiraatiNo ratings yet

- 5A-4 - 19014 - LRFD Micropile Design and Testing For Major Urban Bridges - HDR - BattenDocument47 pages5A-4 - 19014 - LRFD Micropile Design and Testing For Major Urban Bridges - HDR - BattenSwarton Del AguilaNo ratings yet

- Bridge Construction: Structure Span Body of Water Valley RoadDocument4 pagesBridge Construction: Structure Span Body of Water Valley Roadst nazirahNo ratings yet

- Group #2 Members: 1. Kenneth Banaez 2. Aljun Bechaida 3. Habel D. MacasiDocument47 pagesGroup #2 Members: 1. Kenneth Banaez 2. Aljun Bechaida 3. Habel D. MacasiPeter Adrian NgoNo ratings yet

- 1.1 General: Chabahil Road in Kathmandu District, BagmatiDocument25 pages1.1 General: Chabahil Road in Kathmandu District, Bagmatienlacer009No ratings yet

- Name:Rasal Nikhil Gautam REG - NO:17BPI0046 Course Code:MEE2036 Project ReviewsDocument20 pagesName:Rasal Nikhil Gautam REG - NO:17BPI0046 Course Code:MEE2036 Project ReviewsNikhil RasalNo ratings yet

- Introduction To Bridges1Document16 pagesIntroduction To Bridges1eugenia omuhindi100% (1)

- UNIT-2 (Lecture-3) Types of BridgesDocument41 pagesUNIT-2 (Lecture-3) Types of BridgesMd Sabbir HossainNo ratings yet

- RoofDocument31 pagesRoofsamNo ratings yet

- 20-0005 Alawneh MA22Document21 pages20-0005 Alawneh MA22Nicholas FeatherstonNo ratings yet

- Prestressed ConcreteDocument18 pagesPrestressed ConcreteLarete PaoloNo ratings yet

- Advances in The Analysis of Simply Supported Concrete Bridge Deck PDFDocument16 pagesAdvances in The Analysis of Simply Supported Concrete Bridge Deck PDFDarshan GowdaNo ratings yet

- Bridge Design NewDocument46 pagesBridge Design NewAdheesha BandaraNo ratings yet

- Finall Structurall Report For PrintDocument66 pagesFinall Structurall Report For Printpoojitha100% (1)

- Composite Construction'Document35 pagesComposite Construction'hungarianNo ratings yet

- Analysis and Design of Box Culvert For 70R LoadingDocument22 pagesAnalysis and Design of Box Culvert For 70R LoadingPratyasha PadalNo ratings yet

- Notes - Bridge Design - Box Girder BridgesDocument20 pagesNotes - Bridge Design - Box Girder BridgesBobby Wong100% (4)

- Srividya College of Engineering and Technology Question BankDocument8 pagesSrividya College of Engineering and Technology Question BankAravindNo ratings yet

- Unit 1 PPT AK 7th Sem PDFDocument31 pagesUnit 1 PPT AK 7th Sem PDFNikhil PhulNo ratings yet

- Special Considerations in Marine Pile Design and ConstructionDocument3 pagesSpecial Considerations in Marine Pile Design and ConstructionNitinShepurNo ratings yet

- Basis of Design 25000 ReservoirDocument3 pagesBasis of Design 25000 ReservoirAnonymous D1h2pKNo ratings yet

- Comparative Study of Prestressed Steel - Concrete Composite Bridge of Different Span Length and Girder SpacingDocument6 pagesComparative Study of Prestressed Steel - Concrete Composite Bridge of Different Span Length and Girder SpacingPreeti AgarwalNo ratings yet

- Bridge Asiignment With AnswerDocument7 pagesBridge Asiignment With Answertewelde0% (1)

- Substructure: Abutments and PiersDocument9 pagesSubstructure: Abutments and PiersZeeshan ManzoorNo ratings yet

- Chapter 5Document41 pagesChapter 5tewele brhaneNo ratings yet

- Design Consideration For Bridge Superstructure - (R0-16.08.22-P1)Document117 pagesDesign Consideration For Bridge Superstructure - (R0-16.08.22-P1)ShaileshRastogiNo ratings yet

- Comparative Study of RCC T-Beam Bridge By12Document32 pagesComparative Study of RCC T-Beam Bridge By12Pranay ReddyNo ratings yet

- Steel Bridges Lecture 1Document16 pagesSteel Bridges Lecture 1MohamedNo ratings yet

- Design Criteriafor BridgesDocument95 pagesDesign Criteriafor BridgesRandy BenemeritoNo ratings yet

- Box Girder BridgeDocument14 pagesBox Girder BridgeSatya Chandra SekharNo ratings yet

- Girder Bridges FDocument22 pagesGirder Bridges FajaymrNo ratings yet

- Design and Construction of Pre-Tensioned Sutlej Bridge in PunjabDocument16 pagesDesign and Construction of Pre-Tensioned Sutlej Bridge in PunjabYogesh GhuleNo ratings yet

- Analysis and Design of Prestressed Concrete Box Girder BridgeDocument25 pagesAnalysis and Design of Prestressed Concrete Box Girder BridgeChitharanjan VishnukripalNo ratings yet

- Steel Bridge Design Brief 2024Document6 pagesSteel Bridge Design Brief 2024TelexxNo ratings yet

- A Comparative Design of Reinforced Concrete Solid Slab Bridge For Different SpansDocument6 pagesA Comparative Design of Reinforced Concrete Solid Slab Bridge For Different SpansHabeeb ShaikNo ratings yet

- Design of RC Srtuctural Elements (18CV53)Document71 pagesDesign of RC Srtuctural Elements (18CV53)savinaybharadwaj23122000No ratings yet

- Reinforced Concrete BridgesDocument6 pagesReinforced Concrete BridgesRoshan kumar patelNo ratings yet

- AcknowledgementDocument79 pagesAcknowledgementJaiHanumankiNo ratings yet

- Construction Template 16x9Document23 pagesConstruction Template 16x9HARISH NUTRAGANTINo ratings yet

- A Critical Review of The Reinforced Concrete ColumDocument16 pagesA Critical Review of The Reinforced Concrete ColumcerajibNo ratings yet

- Slab Bridge DesignDocument21 pagesSlab Bridge DesignMars Villaluna100% (2)

- A Review On Concrete Filled Steel Tubes Column: December 2015Document7 pagesA Review On Concrete Filled Steel Tubes Column: December 2015Dony DoanxNo ratings yet

- Slab BridgeDocument10 pagesSlab BridgeGolam Mostofa50% (2)

- Rigid Little: Section DimensionsDocument1 pageRigid Little: Section DimensionsjosNo ratings yet

- Rigid Little: Section DimensionsDocument1 pageRigid Little: Section DimensionsjosNo ratings yet

- A Critical Review of The Reinforced Concrete ColumDocument16 pagesA Critical Review of The Reinforced Concrete ColumMuhamad YusreyNo ratings yet

- Fdocuments - in Integral-BridgesDocument21 pagesFdocuments - in Integral-BridgesYudhir TandonNo ratings yet

- Government Technical Institute (MAGWAY) : Department of Civil EngineeringDocument12 pagesGovernment Technical Institute (MAGWAY) : Department of Civil EngineeringBanyar Thiha ZawNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- A Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsFrom EverandA Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsNo ratings yet

- Final FAQs Phase 4 Wef 01072022Document7 pagesFinal FAQs Phase 4 Wef 01072022AbhishekNo ratings yet

- LinkedPIDsWithMobile No Dues Certificate ManageDocument1 pageLinkedPIDsWithMobile No Dues Certificate ManageAbhishekNo ratings yet

- Satish (Calibration Certificate)Document1 pageSatish (Calibration Certificate)AbhishekNo ratings yet

- Sika® Rustop: Product Data SheetDocument2 pagesSika® Rustop: Product Data SheetAbhishekNo ratings yet

- Performance of High Strength Recycled Aggregate Concrete Using MetakaolinDocument64 pagesPerformance of High Strength Recycled Aggregate Concrete Using MetakaolinAbhishekNo ratings yet

- LB Sample Paper PH 4 Wef 01072022Document16 pagesLB Sample Paper PH 4 Wef 01072022AbhishekNo ratings yet

- Hitesh PaperDocument7 pagesHitesh PaperAbhishekNo ratings yet

- Lab QuizDocument3 pagesLab QuizAbhishek44% (9)

- Bridge Bearings - Types of Bearings For Bridge Structures and DetailsDocument4 pagesBridge Bearings - Types of Bearings For Bridge Structures and DetailsAravindanNo ratings yet

- Hitesh PaperDocument7 pagesHitesh PaperAbhishekNo ratings yet

- Miscellaneous Bridge Components - ClassDocument86 pagesMiscellaneous Bridge Components - ClassAbhishekNo ratings yet

- Elastomeric Bearing 1Document9 pagesElastomeric Bearing 1Anonymous jLLjBdrNo ratings yet

- Bridge Hydrology ClassDocument16 pagesBridge Hydrology ClassAbhishek100% (1)

- Objectives HiteshDocument5 pagesObjectives HiteshAbhishekNo ratings yet

- Lab QuizDocument3 pagesLab QuizAbhishekNo ratings yet

- Intoduction To BridgesDocument52 pagesIntoduction To BridgesAbhishekNo ratings yet

- Types of Loads Considered For Design of Bridge StructuresDocument57 pagesTypes of Loads Considered For Design of Bridge StructuresAbhishek100% (1)

- Types of Loads Considered For Design of BridgeDocument45 pagesTypes of Loads Considered For Design of BridgeAbhishek100% (1)

- Week 1 Lecture MaterialDocument161 pagesWeek 1 Lecture MaterialAnonymousNo ratings yet

- Pdeng Application Form: Personal DataDocument2 pagesPdeng Application Form: Personal DataAbhishekNo ratings yet

- Types of Loads Considered For Design of BridgeDocument45 pagesTypes of Loads Considered For Design of BridgeAbhishek100% (1)

- Bearing of BridgesDocument39 pagesBearing of BridgesAbhishek100% (1)

- Introduction To Bridge EngineeringDocument16 pagesIntroduction To Bridge EngineeringAbhishekNo ratings yet

- 17 RFP Vol III Feasibility Report Part III PDFDocument97 pages17 RFP Vol III Feasibility Report Part III PDFSrinivas PNo ratings yet

- Presentation Case StudyDocument37 pagesPresentation Case StudyAbhishekNo ratings yet

- Lab QuizDocument3 pagesLab QuizAbhishek44% (9)

- Rehabilitation of Buildings Research PaperDocument25 pagesRehabilitation of Buildings Research PaperAbhishekNo ratings yet

- Case Study of Sangrur PunjabDocument10 pagesCase Study of Sangrur PunjabAbhishekNo ratings yet

- Lec 1Document28 pagesLec 1SivaRajNo ratings yet

- STEEL BRIDGE DESIGN (ASSHTO) RedundancyDocument25 pagesSTEEL BRIDGE DESIGN (ASSHTO) RedundancyHowo4Die0% (1)

- NistructeDocument6 pagesNistructeA KNo ratings yet

- Structural Design of RCC BridgeDocument101 pagesStructural Design of RCC BridgeShambhu Sah92% (48)

- Comparison of BD 37 01 and AASHTO LRFD 2Document59 pagesComparison of BD 37 01 and AASHTO LRFD 2Jan Gerona ApostaderoNo ratings yet

- Bridge RepairDocument6 pagesBridge Repairharnishtanna212No ratings yet

- Missouri Department of Transportation Bridge Division: Click Here For IndexDocument26 pagesMissouri Department of Transportation Bridge Division: Click Here For Indexvalerio losiNo ratings yet

- Design and Proof Checking of Foundation, Substructure and Superstructure of Rail Cum Road Bridge at Munger, Bihar, IndiaDocument7 pagesDesign and Proof Checking of Foundation, Substructure and Superstructure of Rail Cum Road Bridge at Munger, Bihar, IndiaGregory Cámara SánchezNo ratings yet

- 3.4.4.1 Magnitude and Configuration: 8 Kips 32 Kips 32 Kips 14'-0" 30'-0"Document50 pages3.4.4.1 Magnitude and Configuration: 8 Kips 32 Kips 32 Kips 14'-0" 30'-0"Ian SNo ratings yet

- Aci SP-151 - 1994Document294 pagesAci SP-151 - 1994ananthNo ratings yet

- Conceptual Design of Lightweight StructuresDocument10 pagesConceptual Design of Lightweight StructuresAnkur MehtaNo ratings yet

- Item Unit Rate No U Shs DescriptionDocument23 pagesItem Unit Rate No U Shs DescriptionsolebNo ratings yet

- Asme B302 Interpretations: Replies To Technical Inquiries December 1995 March 1997Document12 pagesAsme B302 Interpretations: Replies To Technical Inquiries December 1995 March 1997Jhon Fabio ParraNo ratings yet

- Probabilistic Seismic Performance Analysis of RC BridgesDocument26 pagesProbabilistic Seismic Performance Analysis of RC BridgesTanjil MominNo ratings yet

- Sen Resume Latest - April 28Document46 pagesSen Resume Latest - April 28straulleNo ratings yet

- BRIDGE DESIGN AID 2004 Sep PDFDocument20 pagesBRIDGE DESIGN AID 2004 Sep PDFAnonymous hbAzrkJ100% (1)

- Sensitivity Analysis-Rail-Structure Interaction Force Effects For Direct-Fixation BridgesDocument31 pagesSensitivity Analysis-Rail-Structure Interaction Force Effects For Direct-Fixation BridgesOlesea NesterencoNo ratings yet

- Study On Cable Stayed Bridge and Its AppDocument3 pagesStudy On Cable Stayed Bridge and Its AppDouglas OngomNo ratings yet

- Bridge PPT Modified PDFDocument86 pagesBridge PPT Modified PDFephrem100% (1)

- Cable Bridge PDFDocument9 pagesCable Bridge PDFJam PelNo ratings yet

- Flexural Strength of Externally Prestressed Concrete BridgesDocument11 pagesFlexural Strength of Externally Prestressed Concrete BridgespicottNo ratings yet

- BRIDGE ENGINEERING DefinitionDocument3 pagesBRIDGE ENGINEERING DefinitionFor TwitterNo ratings yet

- Gradient Temp On Long Span BridgesDocument1 pageGradient Temp On Long Span BridgessachindhikaniaNo ratings yet

- PB97142129 PDFDocument192 pagesPB97142129 PDFMike2322No ratings yet

- Bridge Design Manual - July09Document250 pagesBridge Design Manual - July09Jose Roberto Papa Jr.No ratings yet

- Engineering Assessment of Steel Railway BridgesDocument15 pagesEngineering Assessment of Steel Railway BridgesAndy AcousticNo ratings yet

- Analytical Study On Safety Level of Stay Cables of Cable Stayed BridgeDocument8 pagesAnalytical Study On Safety Level of Stay Cables of Cable Stayed Bridgesushil deshmukhNo ratings yet

- Seismic Design of BridgesDocument14 pagesSeismic Design of BridgesFei XiongNo ratings yet

- China Highway Railway Concrete Beam Erection Launching Crane Bridge Girder Launcher - China Beam Launcher, Beam Launching CraneDocument12 pagesChina Highway Railway Concrete Beam Erection Launching Crane Bridge Girder Launcher - China Beam Launcher, Beam Launching CraneTAMILNo ratings yet

- SSR 2022-23Document619 pagesSSR 2022-23BASADNo ratings yet

- Accelerated Bridge Construction With Folded Steel Plate Girders-Bridge & STructural Engineer-Mar 2017Document9 pagesAccelerated Bridge Construction With Folded Steel Plate Girders-Bridge & STructural Engineer-Mar 2017Subramanian NarayananNo ratings yet