Professional Documents

Culture Documents

Induction Generator

Uploaded by

ARVINDCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Induction Generator

Uploaded by

ARVINDCopyright:

Available Formats

INTRO:

An induction generator or asynchronous generator is a type

of AC electrical generator that uses the principles of

induction motors to produce power.

Induction generators operate by mechanically turning

their rotor in generator mode, giving negative slip

Principle of operation

Induction generators and motors produce electrical power when

their shaft is rotated faster than the synchronous frequency.

For a typical four-pole motor (two pairs of poles on stator)

operating on a 60 Hz electrical grid, synchronous speed is 1800

rotations per minute.

Similar four-pole motor operating on a 50 Hz grid will have

synchronous speed equal to 1500 rpm

MODES:

1. In normal motor operation, stator flux rotation is faster than the rotor rotation. This

is causing stator flux to induce rotor currents, which create rotor flux with magnetic

polarity opposite to stator. In this way, rotor is dragged along behind stator flux, by

value equal to slip.

2. In generator operation, certain prime mover (turbine, engine) is driving the rotor

above the synchronous speed. Stator flux still induces currents in the rotor, but

since the opposing rotor flux is now cutting the stator coils, active current is

produced in stator coils, and motor is now operating as a generator, and sending

power back to the electrical grid.

Excitation

Induction generators are not, in general, self-exciting, meaning they require an

electrical supply, at least initially, to produce the rotating magnetic flux

The electrical supply can be supplied from the electrical grid or, once it starts

producing power, from the generator itself. The rotating magnetic flux from the

stator induces currents in the rotor, which also produces a magnetic field.

If the rotor turns slower than the rate of the rotating flux, the machine acts like

an induction motor. If the rotor is turned faster, it acts like a generator,

producing power at the synchronous frequency.

Active power

Active power delivered to the line is proportional to slip above the synchronous

speed. Full rated power of the generator is reached at very small slip values

(motor dependent, typically 3%). At synchronous speed of 1800 rpm, generator

will produce no power. When the driving speed is increased to 1860 rpm, full

output power is produced. If the prime mover is unable to produce enough

power to fully drive the generator, speed will remain somewhere between 1800

and 1860 rpm range.

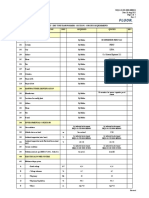

Required capacitance

Capacitor bank must supply reactive power to the motor when

used in stand-alone mode. Reactive power supplied should be

equal or greater than the reactive power that machine normally

draws when operating as a motor. Terminal voltage will

increase with capacitance, but is limited by iron saturation.

Grid and stand-alone connections

n induction generators the magnetizing flux is established by a

capacitor bank connected to the machine in case of stand alone system

and in case of grid connection it draws magnetizing current from the

grid.

For a grid connected system, frequency and voltage at the machine will

be dictated by the electric grid, since it is very small compared to the

whole system.

For stand-alone systems, frequency and voltage are complex function

of machine parameters, capacitance used for excitation, and load value

and type.

Use of induction generators

nduction generators are often used in wind turbines and some

micro hydro installations due to their ability to produce useful power at

varying rotor speeds. Induction generators are mechanically and

electrically simpler than other generator types. They are also more

rugged, requiring no brushes or commutators.

Induction generators are particularly suitable and usually used for wind

generating stations as in this case speed is always a variable factor,

and the generator is easy on the gearbox.

INTRO….

Doubly-fed electric machines are electric motors or

electric generators that have windings on both stationary and

rotating parts, where both windings transfer significant power

between shaft and electrical system. Doubly-fed machines are

useful in applications that require varying speed of the

machine's shaft for a fixed power system frequency.

Classification

Electric machines are either Singly-Fed with one winding set that

actively participates in the energy conversion process or Doubly-

Fed with two active winding sets. The wound-rotor induction machine

and the field-excited synchronous machine are singly-fed machines

because only one winding set actively participates in the energy

conversion process.

Examples of operational doubly-fed electric machines are

the conventional wound-rotor doubly-fed electric machine with a

multiphase slip-ring assembly, the brushless wound-rotor doubly-fed

electric machine, and the brushless doubly-fed induction electric

machines.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Generator Hydrogen Gas System DiagramDocument1 pageGenerator Hydrogen Gas System DiagramARVINDNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Skin Response CircuitDocument1 pageSkin Response Circuiturbikash081266No ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Solar CellsDocument23 pagesSolar CellsARVINDNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- MattMaupin FreescaleSemiconductorDocument32 pagesMattMaupin FreescaleSemiconductorKiran KumarNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- MicrocontrollerDocument128 pagesMicrocontrollerRavi KiranNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Zigebee: Arvind KumarDocument41 pagesZigebee: Arvind KumarARVINDNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Finger PrintDocument45 pagesFinger PrintARVINDNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- DC To DC ConversionDocument8 pagesDC To DC ConversionMichael-Denis NeculaNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- MicrocontrollerDocument128 pagesMicrocontrollerRavi KiranNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Touch Screen Sensor MatheenDocument24 pagesTouch Screen Sensor MatheenARVINDNo ratings yet

- Type The Document SubtitleDocument83 pagesType The Document SubtitleARVINDNo ratings yet

- ZIGBEEDocument6 pagesZIGBEEARVINDNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- EepromDocument20 pagesEepromARVINDNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Rom, Eprom, and Eeprom TechnologyDocument15 pagesRom, Eprom, and Eeprom TechnologytoloykhanNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Deccan CementDocument4 pagesDeccan CementARVINDNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Reactive Power Compensation Using Capacitor BanksDocument16 pagesReactive Power Compensation Using Capacitor BanksARVIND100% (1)

- Broadband 123Document60 pagesBroadband 123ARVINDNo ratings yet

- Reactive Power Compensation Using Capacitor BanksDocument82 pagesReactive Power Compensation Using Capacitor BanksARVIND100% (1)

- Broadband Over Power LineDocument24 pagesBroadband Over Power LineARVINDNo ratings yet

- Capacitor Bank ProtectionDocument17 pagesCapacitor Bank ProtectionskisakNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Protection of Transmission Lines Using Series Compensation CapacitorsDocument5 pagesProtection of Transmission Lines Using Series Compensation CapacitorskittleboyNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Capacitor Bank ProtectionDocument17 pagesCapacitor Bank ProtectionskisakNo ratings yet

- Capacitor Bank ShuntDocument13 pagesCapacitor Bank Shuntnavinchopra1986No ratings yet

- Reactive Power CompensationDocument12 pagesReactive Power CompensationSyed Muhammad Munavvar Hussain100% (5)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Pro2 11Document1 pagePro2 11ARVINDNo ratings yet

- Fuel Energizer 1Document25 pagesFuel Energizer 1mishramanish044705100% (4)

- Article 3: What Is Reactive Power?Document8 pagesArticle 3: What Is Reactive Power?MAT JIBRUDNo ratings yet

- Power Factor and Reactive Power: 2 FT X 5 LB 10 FT-LB 0.0000038 KWH 0.0033 "Calories"Document25 pagesPower Factor and Reactive Power: 2 FT X 5 LB 10 FT-LB 0.0000038 KWH 0.0033 "Calories"ARVINDNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Guide For LV Compensation CubiclesDocument44 pagesGuide For LV Compensation CubiclesARVINDNo ratings yet

- Earth Tester UT528Document23 pagesEarth Tester UT528dinakaran2020No ratings yet

- SMALL POWER TRANSFORMERS Crompton Greaves Power SystemsDocument2 pagesSMALL POWER TRANSFORMERS Crompton Greaves Power SystemsjosepablohgNo ratings yet

- Litobulb Turbines: Litobulb Unit A Reliable and Cost-Effective Alternative Solution in The Green Energy ProductionDocument2 pagesLitobulb Turbines: Litobulb Unit A Reliable and Cost-Effective Alternative Solution in The Green Energy ProductionnamitaNo ratings yet

- Commutation in DC Machine PDFDocument2 pagesCommutation in DC Machine PDFDanielle0% (1)

- ATP Motor Starting PDFDocument13 pagesATP Motor Starting PDFgilbertomjcNo ratings yet

- Module: Motors and Generators Chapter 9: Electric Motors (Questions, Page 167)Document2 pagesModule: Motors and Generators Chapter 9: Electric Motors (Questions, Page 167)bananananananaaaNo ratings yet

- IEEE Standard ListDocument4 pagesIEEE Standard ListanuragpugaliaNo ratings yet

- Chapter HDocument34 pagesChapter HSurangaGNo ratings yet

- Distribution CodeDocument58 pagesDistribution CodePartha HazarikaNo ratings yet

- TR TJO 6Document4 pagesTR TJO 6Mahyar MashayekhiNo ratings yet

- USFULL Solar Pump Inverter 2021 01Document4 pagesUSFULL Solar Pump Inverter 2021 01hector ayalaNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- HDW-580-T5 - (DOOSAN-DP180LAF) - (H1) - (STAMFORD) - (Data-Sheet) - EN 1Document1 pageHDW-580-T5 - (DOOSAN-DP180LAF) - (H1) - (STAMFORD) - (Data-Sheet) - EN 1Nomi DostNo ratings yet

- 1) Negative Sequence Test: Test Report For Differential Protection Relay 7um62 PTD/7UM62Document8 pages1) Negative Sequence Test: Test Report For Differential Protection Relay 7um62 PTD/7UM62subhasish03ee6301No ratings yet

- Viper01 PDFDocument1 pageViper01 PDFarturoNo ratings yet

- Bluesun Microinverter Catalogue - 20190219Document4 pagesBluesun Microinverter Catalogue - 20190219Léonce AgamemnonNo ratings yet

- AERMIDocument2 pagesAERMIkylegazeNo ratings yet

- Sivaramakrishnan Part 1Document23 pagesSivaramakrishnan Part 1ShadifNo ratings yet

- Lecture Note - Dr. KB Mohanty - Vector Control of Induction Generators in Wind Energy Conversion Systems PDFDocument61 pagesLecture Note - Dr. KB Mohanty - Vector Control of Induction Generators in Wind Energy Conversion Systems PDFMurli ManoharNo ratings yet

- Prof. Nilesh Chotani Sir - ADIT VV NAGAR, ANAND - EE NGC - RESUMEDocument7 pagesProf. Nilesh Chotani Sir - ADIT VV NAGAR, ANAND - EE NGC - RESUMERavi RajNo ratings yet

- Datta Sheet - TransformadoresDocument5 pagesDatta Sheet - TransformadoresLuis Breña DiazNo ratings yet

- Calculations, Boilers, CapacitiesDocument1 pageCalculations, Boilers, CapacitieswvwintersNo ratings yet

- Maximum power supply from Piller UNIBLOCK UBTD Diesel Rotary UPSDocument12 pagesMaximum power supply from Piller UNIBLOCK UBTD Diesel Rotary UPSShajahan KandothNo ratings yet

- Power Triangle - Engineering Books PDFDocument1 pagePower Triangle - Engineering Books PDFEswar ChNo ratings yet

- INTCV385 Course on HV/MV switchgear O&MDocument3 pagesINTCV385 Course on HV/MV switchgear O&MPMG Bhuswal ProjectNo ratings yet

- 3271005648XX314F3001 As On 110619Document29 pages3271005648XX314F3001 As On 110619kaasroNo ratings yet

- Isolation and Protection of The Motor-Generator Pair System For Fault Ride-Through of Renewable Energy Generation SystemsDocument20 pagesIsolation and Protection of The Motor-Generator Pair System For Fault Ride-Through of Renewable Energy Generation SystemsUmesh GowdaNo ratings yet

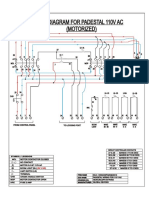

- Padestal MTR 110vacDocument1 pagePadestal MTR 110vacMukesh GuptaNo ratings yet

- Electrical Machines-Transformer Lecture by Prof MD Tawfeeq LazimDocument38 pagesElectrical Machines-Transformer Lecture by Prof MD Tawfeeq LazimTafhim Bin NasirNo ratings yet

- Module 1Document21 pagesModule 1Prema ElizabethNo ratings yet

- Axpert VM III - DS PDFDocument2 pagesAxpert VM III - DS PDFansar shraifNo ratings yet