Professional Documents

Culture Documents

Industrial Internship Programme

Uploaded by

sadeqCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Industrial Internship Programme

Uploaded by

sadeqCopyright:

Available Formats

Name: SADEQ ALI QASEM MOHAMMED Matrix No: DE080205 Industrial Supervisor: Dr.

Nafarizal Nayan Faculty Supervisor: Dr. Khairun Nidzam Bin Ramli

HISTORY

Microelectronics& Nanotechnology - Shamsuddin Research Centre or MiNT-SRC is one of the Center of Excellence at University Tun Hussein Onn Malaysia (UTHM). It was established in November 27th, 2006. Formerly it was known as Microelectronic and Nanotechnology Centre (MiNTEC). In November 25th, 2007, the name of Microelectronic & Nanotechnology - Shamsuddin Research Center was effective as an acknowledgment to our university's former chairman Y. Bhg. Tan Sri Dato' Seri Ir Shamsuddin bin Abdul Kadir for his contribution to the university (2007-2009). He is currently appointed as first Pro-Chancellor of UTHM

Electrical and Electronic Engineering dean prof. HJ. AYOB BIN HJ. JOHARI

Deputy Dean Of Faculty Electrical and Electronic Engineering

Microelectronic Laboratory (En. Ahmad Nasrull Mohamed)

Digital System Design Laboratory (En. Hasnah Rahmad)

Thin Film Technology (Dr. nafarizal Nayan)

Biomedical Engineering (En. Ahmed Alabqari Ma'Radzi)

Nanolithography Technology (Dr. Mohd Arif Agam)

VLSI Design& Microelectronic (En. Mohd Suhaimi Sulong)

To

relate the theory learnt in university to the practical training in the program. To provide the student an opportunity to get an early exposure in the industry. To improve the communication skills of the student. To boost up the confident level of the student.

magnetron sputtering this machine uses DC and RF sputtering to coat the glass in order to make a thin film the Method of depositing thin films by sputtering that is ejecting material from a "target" that is source, then deposits onto a "substrate," such as a silicon wafer. Re-sputtering is reemission of the deposited material during the deposition process by ion or atom bombardment.

The RF diode sputtering system requires an impedance-matching network between the power supply and the discharge chamber. In the RF discharge system the operating pressure is lowered to as low as 1mTorr, since the RF electric field in the discharge chamber increases the collision probability between secondary electrons and gas molecules

RIE system consists of a cylindrical vacuum chamber, with a wafer platter situated in the bottom portion of the chamber. The wafer platter is electrically isolated from the rest of the chamber, which is usually grounded. Gas enters through small inlets in the top of the chamber, and exits to the vacuum pump system through the bottom. The types and amount of gas used vary depending upon the etch process.

Evaporation is a common method of thin film deposition. The source material is evaporated in a vacuum. The vacuum allows vapor particles to travel directly to the target object (substrate), where they condense back to a solid state. Evaporation is used in microfabrication, and to make macro-scale products such as metallized plastic film.

It measure thin-film thickness by analyzing how light is reflected by the film. By analyzing wavelengths beyond those visible to the human eye it can measure nearly all non-metallic films greater than 100 atoms thick. And because there are no moving parts, results are available in seconds: film thickness, refractive index, even roughness.

Atomic force microscopy (AFM) or scanning force microscopy (SFM) is a very high-resolution type of scanning probe microscopy, with demonstrated resolution on the order of fractions of a nanometer, more than 1000 times better than the optical diffraction limit. This device have many image mode as 3D image mode, gain image mode and some more.

Surface Profiler is a measuring instrument used to measure surface's profile, in order to quantify its roughness. A diamond stylus is moved vertically in contact with a sample and then moved laterally across the sample for a specified distance and specified contact force. A Surface Profiler can measure small surface variations in vertical stylus displacement as a function of position. A typical Surface Profiler can measure small vertical features ranging in height from 10 nanometers to 1 millimeter.

A field-emission cathode in the electron gun of a scanning electron microscope provides narrower probing beams at low as well as high electron energy, resulting in both improved spatial resolution and minimized sample charging and damage. For applications which demand the highest magnification possible.

Plasma is partially ionized gases consisting of ions, electrons, free radicals and neutral species. This ionized gas mixture is conductive and highly reactive, which provides the basis for the plasma process.

In circuit board applications the panels are suspended between electrodes. process gas is introduced and the electrodes are energized with RF energy. This initiates the plasma.

The Atmospheric pressure plasma (APP) will be generated by using dielectric-barrier discharge which is the easiest way to generate the APP, got many planner design of dielectric-barrier discharge.

at least one dielectric barrier these discharges require alternating voltages for their operation. The dielectric, being an insulator, cannot pass a dc current. Its dielectric constant and thickness, in combination with the time derivative of the applied voltage, dU/dt, determine the amount of displacement current that can be passed through the dielectric( s). To transport current (other than capacitive) in the discharge gap the electric field has to be high enough to cause breakdown in the gas.

A clean room is a specially constructed enclosed area environmentally controlled with respect to airborne particulate, air temperature, humidity, air pressure, airflow pattern, air motion electromagnetic signals and lighting. Its typically use in manufacturing or scientific research that has a low level of environmental pollutants such as dust, airborne microbes, aerosol particles and chemical vapors. More accurately, a clean room has a controlled level of contamination that is specified by the number of particles per cubic meter and by maximum particle size.

Clean room consist of one partition or room which surrounded by a return air chamber. RAC (Return Air Chamber) is needed to allow the air flow below the raised floor return to FFU (Fan Filter Unit). The sizes of return air chamber is very important, because the rate of fresh air volume needed to supply back to the clean room must be less than the volume of the RAC. In other words, the RAC must be able to supply the volume of air needed back to the clean room. Air flow in the RAC is at different direction as inside the clean room which is facing up; this is due to the suction of the FFU at the top of the clean room. The schematic of clean room at Media of M1 and M2 plants are shown

Communication Skills Time Management

Teamwork Reporting

Safety Training & Awareness

Problem Solving Skill

For

MiNT-SRC ~ Training should be well planned

For

University ~ Organize an industrial talk

All

objectives were successfully achieved. Various lessons learned and experience gained. Learn the work culture A success Industrial internship program

THANK YOU

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Interference of ManDocument3 pagesInterference of ManChristian Paul RamosNo ratings yet

- CSI 50 DivDocument2 pagesCSI 50 DivRavinder SinghNo ratings yet

- Basics UFH Manual 2002Document69 pagesBasics UFH Manual 2002Djordje GazdicNo ratings yet

- 4 Thermodynamics Nov2004 NR 21030Document8 pages4 Thermodynamics Nov2004 NR 21030Nizam Institute of Engineering and Technology LibraryNo ratings yet

- Module 2 Week 3 4Document9 pagesModule 2 Week 3 4LeiRne Jo KBahingawan TanGuidNo ratings yet

- Physical Chemistry With Formulas and Examples: 1 ThermodynamicDocument5 pagesPhysical Chemistry With Formulas and Examples: 1 Thermodynamicjkc collegeNo ratings yet

- Geothermal Power Plant Problem SetDocument8 pagesGeothermal Power Plant Problem SetAriel GamboaNo ratings yet

- Balance Chemical Equation - Online BalancerDocument2 pagesBalance Chemical Equation - Online BalancershoyebNo ratings yet

- The Correlation Between The CBR and Shear Strength in Unsaturated Soil ConditionsDocument13 pagesThe Correlation Between The CBR and Shear Strength in Unsaturated Soil ConditionsVetriselvan ArumugamNo ratings yet

- Dizertace SmidaDocument139 pagesDizertace SmidaJuan EspinosaNo ratings yet

- Simple Distillation-1Document6 pagesSimple Distillation-1Shweta ChaudhariNo ratings yet

- Impulse Lines For Differential-Pressure Flow Meters.Document20 pagesImpulse Lines For Differential-Pressure Flow Meters.Shijumon KpNo ratings yet

- Gamma Rays LogDocument7 pagesGamma Rays LogBalqis yasinNo ratings yet

- Theoretical CyclesDocument56 pagesTheoretical CyclesADOBONo ratings yet

- Activity 1 (Topic: Newton's Law of Universal Gravitation)Document1 pageActivity 1 (Topic: Newton's Law of Universal Gravitation)John JohnnyNo ratings yet

- Bioplastic Made With Jicama StarchDocument2 pagesBioplastic Made With Jicama StarchTHE MONSTAAGAMERNo ratings yet

- UK Brick PlantDocument47 pagesUK Brick PlantSenthilkumar PragasamNo ratings yet

- De Thi Thu THPT Quoc Gia Mon Anh Truong THPT Chuyen Luong The VinDocument7 pagesDe Thi Thu THPT Quoc Gia Mon Anh Truong THPT Chuyen Luong The VinPhan Văn VũNo ratings yet

- Introduction: The Formation of Deep EcologyDocument48 pagesIntroduction: The Formation of Deep EcologySRIKANTA MONDALNo ratings yet

- CCTP AdstractDocument10 pagesCCTP Adstractmkarthikeyan023No ratings yet

- G4 Geology AssignmentDocument5 pagesG4 Geology AssignmentAmanuel AlemayehuNo ratings yet

- (Tamas I. Gombosi) Physics of The Space EnvironmenDocument357 pages(Tamas I. Gombosi) Physics of The Space Environmenbrky100% (1)

- Code-A: Fortnightly Test - 03Document16 pagesCode-A: Fortnightly Test - 03hh58m8mdx2No ratings yet

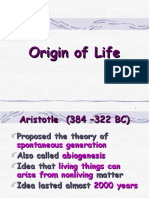

- 4 - Origin of Life (1.6MB)Document53 pages4 - Origin of Life (1.6MB)Wahyuni Eka SariNo ratings yet

- Azerbaijan Renewable EnergyDocument20 pagesAzerbaijan Renewable EnergyAhmed Imtiaz RaoNo ratings yet

- Project - Second Follow Up - Maria Camila Salleg - Alexander MercadoDocument2 pagesProject - Second Follow Up - Maria Camila Salleg - Alexander MercadoEduardo EmilioNo ratings yet

- Final Class 8 Science 20230828084415550Document5 pagesFinal Class 8 Science 20230828084415550aryantomar5112No ratings yet

- History of Atom Elements and Compounds Mastery 1Document13 pagesHistory of Atom Elements and Compounds Mastery 1feyrelysNo ratings yet

- 1st Law of ThermodynamicsDocument95 pages1st Law of ThermodynamicsMARUMO_LEVYNo ratings yet

- Mechanical Work FormulaDocument4 pagesMechanical Work FormulavikassNo ratings yet