Professional Documents

Culture Documents

Rheology

Uploaded by

omeraijaz599Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rheology

Uploaded by

omeraijaz599Copyright:

Available Formats

CHE315

Velocity Profile (eqn.)for Newtonian

Fluids flowing inside a pipe

Mechanical Energy Balance

CHE315

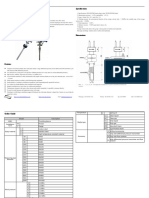

2.9 SHELL MOMENTUM BALANCE INSIDE A PIPE

Ax

Ar

P|

x

P|

x+Ax

R

x

r

Incompressible Newtonian fluid

Let us consider the

following simplifications:

One dimensional flow Laminar flow

Fully developed flow (no entrance effect and velocity is independent from x)

Mechanical Energy Balance

CHE315

2.9 SHELL MOMENTUM BALANCE INSIDE A PIPE

Fully developed flow (no entrance effect and velocity is

independent from x)

Mechanical Energy Balance

CHE315

Net momentum efflux = rate of momentum out - rate of momentum in

The pressure forces = ( ) ( )

x x x x x x

r r p r r p pA pA

A + A +

A A = t t 2 2

( ) ( )

r

rx

r r

rx

x r x r A A =

A +

t t t t 2 2

Ax

Ar

P|

x

P|

x+Ax

R

x

r

Mechanical Energy Balance

CHE315

So:

( ) ( ) ( ) ( )

x x x r

rx

r r

rx

r r p r r p x r x r

A + A +

A A = A A t t t t t t 2 2 2 2

( ) ( ) ( )

x

p p r

r

r r

x x x r

rx

r r

rx

A

=

A

A + A +

t t

( )

r

dx

dp

dr

r d

rx

=

t

Mechanical Energy Balance

( )

r

L

p

dr

r d

rx

A

=

t

CHE315

( )

r

L

p

dr

r d

rx

A

=

t

( ) rdr

L

p

r d

rx

A

= t

C r

L

p

r

rx

+

A

=

2

2

t

r

C

r

L

p

rx

+

A

=

2

t

If the momentum flux cannot be infinite at r =

0, Then C must be zero:

( )

r

L

p p

r

L

p

L

rx

2 2

0

=

A

= t

Mechanical Energy Balance

CHE315

The shear stress profile

Newtonian fluids:

dr

dv

x

rx

t =

Equating the two equations:

( )

r

L

p p

dr

dv

L x

rx

2

0

= = t

Integrating and using

the boundary

condition v

x

(r=R) =

0:

( )

(

(

|

.

|

\

|

=

2

2

0

1

4 R

r

R

L

p p

v

L

x

( )

r

L

p p

r

L

p

L

rx

2 2

0

=

A

= t

Mechanical Energy Balance

CHE315

This result means that the

momentum flux varies linearly

with the radius

( )

r

L

p p

r

L

p

L

rx

2 2

0

=

A

= t

v

x

= 0 v

max

Parabolic

velocity profile

Momentum flux

profile

t

rx

= 0

t

rx max

x

r

This result means that the velocity

distribution is parabolic

( )

(

(

|

.

|

\

|

=

2

2

0

1

4 R

r

R

L

p p

v

L

x

Mechanical Energy Balance

CHE315

Using the definition of the average velocity:

We obtain in this case, the

Hagen-Poiseuille equation:

}}

=

A

av

vdA

A

v

1

( )

( ) ( )

2

0

2

0

32 8

D

L

p p

R

L

p p

v

L L

av

x

=

=

( )

( )

2

0

max

4

R

L

p p

v

L

x

=

( )

( )

2

max

x

av

x

v

v =

Mechanical Energy Balance

CHE315

( )

( )

2

0

8

R

L

p p

v

L

av

x

=

( )

( )

2

0

max

4

R

L

p p

v

L

x

=

( )

( )

2

max

x

av

x

v

v =

Mechanical Energy Balance

( )

(

(

|

.

|

\

|

=

2

2

0

1

4 R

r

R

L

p p

v

L

x

CHE315

3.5 Non-Newtonian fluids

3.5 Non-Newtonian

fluids

S

h

e

a

r

S

t

r

e

s

s

Shear

Rate

Newtonian fluids are

fluids which follow Newtons

law:

t

=

CHE315

S

h

e

a

r

S

t

r

e

s

s

Shear

Rate

Non-Newtonian fluids do not

follow Newtonian law.

Therefore, For non-Newtonian

fluids, the plot of the shear stress

vs. shear rate is not linear through

the origin.

3.5 Non-Newtonian fluids

CHE315

Linear BUT does not go through the

origin.

A finite shear stress (yield stress)

is needed to initiate flow.

Examples :tooth paste, soap and

chocolate mixtures.

|

.

|

\

|

+ =

dr

dv

x

rx

t t

0

3.5 Non-Newtonian fluids

CHE315

( ) 1 <

|

.

|

\

|

= n

dr

dv

K

n

t

K: consistency index And

n: flow behavior index

3.5 Non-Newtonian fluids

CHE315

3. Dilatant fluids.

Less common than pseudoplastic

fluids. Examples are starch in water.

Their apparent viscosities increase

with increasing shear rate.

( ) 1 >

|

.

|

\

|

= n

dr

dv

K

n

t

3.5 Non-Newtonian fluids

CHE31

5

Task:

Study with your group

the following:

Bingham Fluids

Pseudoplastic Fluids

Dilatant Fluids

Hint Questions:

1. Which mathematical model can

represent each type of fluids

2. What is the relation between

shear rate and viscosity for each

type? Compare with Newtonian

fluids.

3. Can you write one general model

for all types of fluids ? Try!!

4. What is the value of n for each

type of fluids?

Group Study

3.5 Non-Newtonian

fluids

CHE315

1

= =

=

n

n

K

K

Viscosity of Non-Newtonian

Q.: What is shear thinning and

shear thickening?

CHE315

2 2 2

Re,

1

1

8

3 1

8

4

n n n n n n

gen

n n

n

D V D V D V

N

K

n

K

n

' ' ' '

'

= = =

'

+

| |

|

\ .

the generalized Reynolds number is defined

as:

=

Quiz: What if n = 1?

CHE315

LAMINAR FLOW OF POWER LAW FLUID

n

n

z

r

KL

p

dr

dv

1

1

2

1

|

.

|

\

|

A

=

rz

r

L

p t 2 = A

n

z

rz

dr

dv

K

|

.

|

\

|

= t

Power Law Model:

Hagen Poiseuille Eq.:

Combined

dr

dv

z

rz

t =

Newtons Law:

r

L

p

dr

dv

z

|

|

.

|

\

| A

=

2

1

CHE315

(

|

.

|

\

|

+

|

.

|

\

|

A

=

+ +

n

n

n

n

n

z

r R

n

n

KL

p

v

1 1

1

1 2

1

( )

( ) n n

n

L

av

x

R

KL

p p

n

n

v

/ 1

0

/ 1

0

2 1 3

+

|

.

|

\

|

|

.

|

\

|

+

=

CHE315

( ) n n

n

L

x

R

KL

p p

n

n

v

/ 1

0

/ 1

0

max

2 1

+

|

.

|

\

|

+

=

( )

(

(

|

.

|

\

|

=

+ n n

x x

R

r

v v

/ 1

max

1

Quiz: What if n = 1?

Models for Generalized Newtonian Fluids

The Carreau-Yasuda model

The power-law model

n < 1, shear-thinning (pesudoplastic) fluids

n = 1 and m = , Newtonian fluids

n > 1, shear-thickening (dilatant) fluids

( ) | |

( )

parameter ess dimensionl : exponent, law - power : time, relaxation :

rate shear : osity, shear visc - infinite : osity, shear visc - zero : , viscosity :

1

0

/ 1

0

a n

a n

a

q q q

q q

q q

+ =

1

=

n

m q

V.1 Models for Generalized Newtonian Fluids

The Eyring model

The Bingham model

Other empirical q functions in the generalized Newtonian fluid

model (see Table 4.5-1, p 228 in the textbook)

( ) theory. molecular a by obtained expression first the as equation w Eyring The

arcsinh

0

q

t q

|

|

.

|

\

|

=

( )

( )

( ) 2 / : , stress yield :

/

0

0 0 0

0

=

> + =

s =

t t

t t t q

t t q

Retrieval of Fundamental Material Constants

Newtonian Power law

Zero-shear

viscosity, q

0

critical

/ 1 time, Relaxation =

Fig 3.3-1 (p 105) in the textbook

( )

o

q q

=

0

Polymer Rheology CHEE 490

22.25

Pseudoplastic Fluids: Flow Curve

shear , meaning that they exhibit pseudoplastic Polymer melts and solutions are

thinning behavior

Polymer Rheology CHEE 490

Pseudoplastic Fluids

This is a plot of the viscosity of various polystyrene samples at

183

o

C as a function of steady shear rate. Make note of the

Newtonian plateau at low shear rates, the clear evidence of shear

thinning behaviour, and the effect of molecular weight

a. M

n

= 242,000

b. M

n

= 217,000

c. M

n

= 179,000

d. M

n

= 48,500

Elastic and Viscoelastic Effects

Weissenberg Effect (Rod Climbing Effect)

does not flow outward when stirred at high speeds

27

Dr. Aldo Acevedo - ERC SOPS

Elastic and Viscoelastic Effects

Fluid Memory

Conserve their shape over time periods or seconds or

minutes

Elastic like rubber

Can bounce or partially retract

Example: clay (plasticina)

28

Dr. Aldo Acevedo - ERC SOPS

Elastic and Viscoelastic Effects

Viscoelastic fluids subjected to a stress deform

when the stress is removed, it does not instantly vanish

internal structure of material can sustain stress for some

time

this time is known as the relaxation time, varies with

materials

due to the internal stress, the fluid will deform on its own,

even when external stresses are removed

important for processing of polymer melts, casting, etc..

29

Dr. Aldo Acevedo - ERC SOPS

Elastic and Viscoelastic Effects Die

Swell

as a polymer exits a die, the diameter of liquid stream increases by

up to an order of magnitude

caused by relaxation of extended polymer coils, as stress is

reduced from high flow producing stresses present within the die to

low stresses, associated with the extruded stream moving through

ambient air

30

Dr. Aldo Acevedo - ERC SOPS

You might also like

- Solar Thermal DesalinationDocument5 pagesSolar Thermal Desalinationomeraijaz599No ratings yet

- Batch Reverse Osmosis Desalination Modeling Under A Time-Dependent Pressure ProfileDocument20 pagesBatch Reverse Osmosis Desalination Modeling Under A Time-Dependent Pressure Profileomeraijaz599No ratings yet

- Nickel Removal From Electrospun MembranesDocument17 pagesNickel Removal From Electrospun Membranesomeraijaz599No ratings yet

- Microcapsule Brochure V2Document24 pagesMicrocapsule Brochure V2omeraijaz599No ratings yet

- Applied SciencesDocument16 pagesApplied Sciencesomeraijaz599No ratings yet

- Paper 3 USA ConfDocument6 pagesPaper 3 USA Confomeraijaz599No ratings yet

- Batch Reverse Osmosis Desalination Modeling Under A Time-Dependent Pressure ProfileDocument20 pagesBatch Reverse Osmosis Desalination Modeling Under A Time-Dependent Pressure Profileomeraijaz599No ratings yet

- Paper 4-Desalination and Water TreatmentDocument15 pagesPaper 4-Desalination and Water Treatmentomeraijaz599No ratings yet

- Speed Velocity N Acc PDFDocument10 pagesSpeed Velocity N Acc PDFomeraijaz599No ratings yet

- 9 MPR Septemeber 2016Document4 pages9 MPR Septemeber 2016omeraijaz599No ratings yet

- Fabrication and Morphology Study of Electrospun Cellulose Acetate/polyethylenimine NanofiberDocument18 pagesFabrication and Morphology Study of Electrospun Cellulose Acetate/polyethylenimine Nanofiberomeraijaz599No ratings yet

- Recycling of PVC and Mixed Plastic WasteDocument203 pagesRecycling of PVC and Mixed Plastic Wasteomeraijaz599No ratings yet

- English Revision Guide Answers PDFDocument13 pagesEnglish Revision Guide Answers PDFomeraijaz599100% (1)

- Ielts7 PDFDocument165 pagesIelts7 PDFzshanhanif1No ratings yet

- Highly Aligned Narrow Diameter Chitosan Electrospun Nanofibersn Electrospun NanofibersDocument11 pagesHighly Aligned Narrow Diameter Chitosan Electrospun Nanofibersn Electrospun Nanofibersomeraijaz599No ratings yet

- Optical and Transport Properties of Poly (3-Hexylthiophene) - Single-Walled-Carbon-Nanotube CompositesDocument5 pagesOptical and Transport Properties of Poly (3-Hexylthiophene) - Single-Walled-Carbon-Nanotube Compositesomeraijaz599No ratings yet

- Contact AngleDocument12 pagesContact Angleomeraijaz599No ratings yet

- General Brochure DataPhysicsDocument20 pagesGeneral Brochure DataPhysicsomeraijaz599No ratings yet

- Tga MSDocument36 pagesTga MSpatilamardip007No ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Gravity SettlingDocument10 pagesGravity SettlingNithinKallayil100% (1)

- Annubar Flow MeterDocument2 pagesAnnubar Flow MeterEran MeiriNo ratings yet

- Board of Aeronautical Engineering SB 1Document3 pagesBoard of Aeronautical Engineering SB 1Cruz PlusNo ratings yet

- Examples of Written Test 1 ProblemsDocument15 pagesExamples of Written Test 1 ProblemsAndrew PantaleonNo ratings yet

- Fma3602 Fi Concession Examination 2020Document3 pagesFma3602 Fi Concession Examination 2020Shadreck Ndlovu100% (1)

- BM Unit Ii NotesDocument98 pagesBM Unit Ii NotesCPL MohanNo ratings yet

- CFD LectureDocument51 pagesCFD LectureBilal AhmadNo ratings yet

- Parts of Hydraulic and Pneumatic SystemsDocument13 pagesParts of Hydraulic and Pneumatic Systemsnidhidarklord100% (1)

- Wind Turbine PosterDocument1 pageWind Turbine PosterDhanu T ANo ratings yet

- Ravindra Pethiyagoda ThesisDocument164 pagesRavindra Pethiyagoda ThesisHua Hidari YangNo ratings yet

- Multi Phase PR - DropDocument43 pagesMulti Phase PR - Dropmts1234No ratings yet

- Unsteady Laminar Flow Around A CylinderDocument25 pagesUnsteady Laminar Flow Around A CylinderCantalicioNo ratings yet

- Mee2016 Rapid Manufacturing Technologies Dr. Fathima Patham K, A2 SlotDocument10 pagesMee2016 Rapid Manufacturing Technologies Dr. Fathima Patham K, A2 SlotRishitej rao KulakarniNo ratings yet

- 14.2 Properties of Fluids (Press Read Only To Open)Document72 pages14.2 Properties of Fluids (Press Read Only To Open)Abdullah Alqahtani100% (1)

- Condensation and Boiling Heat TransferDocument11 pagesCondensation and Boiling Heat TransferChemical EngineeringNo ratings yet

- Modeling and Simulation of Hemihydrate Phosphoric Acid PlantDocument10 pagesModeling and Simulation of Hemihydrate Phosphoric Acid PlantIngrid ContrerasNo ratings yet

- H408 Handout 2013 Spring Updated 07 Apr 2015wDocument11 pagesH408 Handout 2013 Spring Updated 07 Apr 2015wAbid AnuarNo ratings yet

- Single-Phase Heat Transfer and Fluid Flow Phenomena of Microchannel Heat ExchangersDocument41 pagesSingle-Phase Heat Transfer and Fluid Flow Phenomena of Microchannel Heat ExchangersJeff Anderson CollinsNo ratings yet

- 2015 Seven Ocean-CatalogDocument142 pages2015 Seven Ocean-CatalogCristobal0% (1)

- Ee 6501 - Power System Analysis Unit-5 Stability Analysis Part ADocument2 pagesEe 6501 - Power System Analysis Unit-5 Stability Analysis Part AVbalaji Vaithiyanathan100% (1)

- White Paper Powder FlowDocument6 pagesWhite Paper Powder FlowCamii RomeroNo ratings yet

- Compressible Flow Through Convergent and Laval NozzlesDocument10 pagesCompressible Flow Through Convergent and Laval NozzlesIshwar SinghNo ratings yet

- Theory: Interaction in Two-Variable Control Systems Distillation Columns - IiDocument24 pagesTheory: Interaction in Two-Variable Control Systems Distillation Columns - IiVardhan KaushikNo ratings yet

- Che CHM QuestionsDocument82 pagesChe CHM QuestionsErik WeeksNo ratings yet

- Eregiron Control SystemDocument32 pagesEregiron Control SystemJose Hurtado OjedaNo ratings yet

- Effect of SEN Immersion Depth On Mold Flow Profile and Slag Entrapment During Continuous Casting of SteelDocument17 pagesEffect of SEN Immersion Depth On Mold Flow Profile and Slag Entrapment During Continuous Casting of SteelMallikarjunrao PanabakaNo ratings yet

- Intermediate Lab 4 Manual V2Document19 pagesIntermediate Lab 4 Manual V2Mohammed KhalidNo ratings yet

- Lect - 12 Natural Convection, Empirical Equations For Free and Forced ConvectionDocument18 pagesLect - 12 Natural Convection, Empirical Equations For Free and Forced ConvectionVivaan SharmaNo ratings yet

- Hydraulic NoiseDocument4 pagesHydraulic NoiseShyam KumarNo ratings yet