Professional Documents

Culture Documents

US Bone Gelatin Sourcing and Manufacturing

Uploaded by

Tapan SharmaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

US Bone Gelatin Sourcing and Manufacturing

Uploaded by

Tapan SharmaCopyright:

Available Formats

Bovine Bone Sourcing Practices and Bone Gelatin Manufacturing Processes in the United States

FDA TSE ADVISORY COMMITTEE MEETING

July 17, 2003

J. Michael Dunn, Ph.D

Vice President, Regulatory Affairs, GELITA North America Chairman, Regulatory Committee Gelatin Manufacturers Institute of America (GMIA)

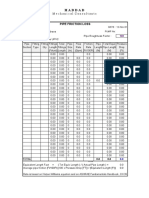

US BONE GELATIN MANUFACTURERS

Eastman Gelatine Corp. Peabody, MA

35%

5%

GELITA USA Inc. Sioux City, IA

60%

Photo

Pharma

Edible

US manufacturers produce primarily limed bone gelatin (Type B) and to some extent acid bone gelatin (Type A)

The sourcing practices and processing conditions discussed today will be representative of both US manufacturers

2

BOVINE BONE SOURCING PRACTICES AND BONE GELATIN MANUFACTURING PROCESSES IN THE US Overall Objectives

Adequately describe the bovine bone sourcing practices and processing conditions for the manufacturing of bone gelatin in the US

Confirm that the bone gelatin processing conditions employed in the US are:

Virtually the same as those used in the EU Meet or exceed all of the minimum processing requirements as specified in the GME TSE Inactivation Study Protocol

BOVINE BONE SOURCING PRACTICES

Sourcing

Degreased gelatin bone is sourced exclusively from USDA inspected beef processing facilities in the US

This raw material is derived solely from healthy cattle that have been deemed fit for human consumption

based upon both ante and postmortem inspections

BOVINE BONE SOURCING PRACTICES

SRMs

All US gelatin bone suppliers have been removing Specified Risk Materials (SRMs) with the exception of

vertebrae since as early as 1998

Limited quantities of vertebrae-free gelatin bone have been available since the Fall of 2002

Currently, there are no FDA or USDA requirements for

the removal of SRMs in the US

GELATIN MANUFACTURING PROCESS OVERVIEW

Daily Bone Gelatin Production

Degreased Gel Bone HCl Acid Water Labor

Gelatin Process

Dicalcium Phosphate

Gelatin

6

Bone /Type B Acidulation Lime Treatment Washing Acidification

Bone/Type A Acidulation NaOH Option Acid Treatment Washing

GELATIN MANUFACTURING PROCESS

Overall Objectives

Extraction Initial Filtration Ion Exchange Initial Concentration

Hydrolyze collagen

Hydrolyze sufficient cross-links and peptide bonds within the collagen matrix to render the hydrolyzed collagen (gelatin) highly soluble in water

Final Filtration

pH Adjustment Final Concentration Sterilization Chilled Extrusion Drying Milling/Screening

Purify the gelatin

Employ appropriate processing steps to ensure its physical, chemical and microbiological purity

Concentrate the finished product

Use additional processes to remove water from the gelatin liquor to produce a dry, stable product

7

Blending

Formulation Final Packaging

Bone /Type B Acidulation Lime Treatment Washing Acidification

Bone/Type A Acidulation NaOH Option Acid Treatment Washing

GELATIN MANUFACTURING PROCESS

Incoming Gel Bone

Extraction Initial Filtration Ion Exchange Initial Concentration Final Filtration

Typical Characteristics

Fat content = 1 to 2.5%

Size range = 1/8 to 5/8

Mineral/protein ratio = 1.9 - 2.1 Moisture content = 6 to 9%

pH Adjustment

Final Concentration Sterilization Chilled Extrusion Drying Milling/Screening Blending Formulation Final Packaging

In contrast, EU gelatin producers have their own degreasing facilities

Bone /Type B Acidulation Lime Treatment Washing Acidification

Bone/Type A Acidulation NaOH Option Acid Treatment Washing

GELATIN MANUFACTURING PROCESS

Acidulation

Objectives / Conditions

Extraction Initial Filtration Ion Exchange

Initial Concentration

Final Filtration pH Adjustment Final Concentration Sterilization Chilled Extrusion

Produce ossein by removing the mineral content of the bone Initiate the hydrolysis of collagen Remove non-collagen impurities HCL concentration: 4-6% Acidulation time: 5-7 days (counter-current process) Acidulation temperature: 50 to 65 F Washing: Rinse up to 24 hours to remove acid salts, fat and other impurities

9

Drying

Milling/Screening Blending Formulation Final Packaging

Bone /Type B Acidulation Lime Treatment Washing Acidification

Bone/Type A Acidulation NaOH Option Acid Treatment Washing

GELATIN MANUFACTURING PROCESS

Liming / Type B

Objectives / Conditions

Extraction Initial Filtration Ion Exchange

Initial Concentration

Final Filtration pH Adjustment

Continue to hydrolyze collagen Continue to remove noncollagen impurities Convert asparagine and glutamine to their respective acids (pI decreases)

Final Concentration

Sterilization Chilled Extrusion Drying Milling/Screening Blending Formulation Final Packaging

Lime slurry concentration: Over saturated Lime slurry pH: Approximately 12.5 Liming time: 25-70 days Liming temperature: 50-70 F Agitation: Daily Lime slurry changes: Weekly

10

Bone /Type B Acidulation Lime Treatment Washing Acidification

Bone/Type A Acidulation NaOH Option Acid Treatment Washing

GELATIN MANUFACTURING PROCESS

Washing / Acidification

Objectives / Conditions

Extraction Initial Filtration Ion Exchange Initial Concentration Final Filtration pH Adjustment Final Concentration

Remove and neutralize excess lime Remove non-collagen impurities Adjust pH of the ossein slurry

Sterilization

Chilled Extrusion Drying Milling/Screening Blending Formulation Final Packaging

Wash time: 24 to 48 hours Agitation: Vigorous Water temperature: 45 to 70 F Neutralizing acids: Hydrochloric & sulfuric Target pH: 5 to 7

11

Bone /Type B Acidulation Lime Treatment Washing Acidification

Bone/Type A Acidulation NaOH Option Acid Treatment Washing

GELATIN MANUFACTURING PROCESS

Acid Treatment / Type A

Objective / Conditions

Extraction Initial Filtration Ion Exchange Initial Concentration Final Filtration pH Adjustment Final Concentration Sterilization Chilled Extrusion

Condition ossein for extraction at low pH Traditional Treatment: Sulfuric acid at pH = 1.0 - 2.0 Treatment time: = 6 hours > Washing: Rinse up to 24 hours to a pH of 2.8 - 3.2 Alkaline pre-treatment option (under review) pH is maintained at 13 or greater with NaOH for 3 hours (prior to acid treatment)

Drying

Milling/Screening Blending Formulation Final Packaging

12

Bone /Type B Acidulation Lime Treatment Washing Acidification

Bone/Type A Acidulation NaOH Option Acid Treatment Washing

GELATIN MANUFACTURING PROCESS

Gelatin Extraction

Objective / Conditions

Extraction

Initial Filtration

Ion Exchange Initial Concentration Final Filtration pH Adjustment Final Concentration Sterilization Chilled Extrusion

Solubilize hydrolyzed collagen (gelatin) from the ossein Water purity: Demineralized Procedure: Series of extractions with increasing water temperatures Water temperatures: 120 to 200 F Conditioning time: 1 to 6 hours / extraction Number of extractions: 4 to 6

13

Drying

Milling/Screening Blending

Formulation

Final Packaging

Bone /Type B Acidulation Lime Treatment Washing Acidification

Bone/Type A Acidulation NaOH Option Acid Treatment Washing

GELATIN MANUFACTURING PROCESS

Initial Filtration

Objective / Conditions

Extraction Initial Filtration Ion Exchange Initial Concentration Final Filtration pH Adjustment Final Concentration Sterilization Chilled Extrusion Drying Milling/Screening Blending Formulation Final Packaging

14

Clarify dilute gelatin solution Protect ion exchange system Vertical leaf pressure filter Pre-coated with diatomaceous earth and cellulose Gelatin concentration: 4-6%

Bone /Type B Acidulation Lime Treatment Washing Acidification

Bone/Type A Acidulation NaOH Option Acid Treatment Washing

GELATIN MANUFACTURING PROCESS

Ion Exchange

Objective / Conditions

Extraction Initial Filtration Ion Exchange Initial Concentration Final Filtration pH Adjustment Final Concentration Sterilization Chilled Extrusion Drying Milling/Screening Blending Formulation Final Packaging

15

Deionize the thin gelatin liquor Cations removed: Ca+2, Mg+2 and Fe+2 Anions removed: Cl- or S04= Ash (product): 0.1 to 1%

Bone /Type B Acidulation Lime Treatment Washing Acidification

Bone/Type A Acidulation NaOH Option Acid Treatment Washing

GELATIN MANUFACTURING PROCESS

Initial Concentration

Objective / Conditions

Extraction Initial Filtration Ion Exchange Initial Concentration Final Filtration pH Adjustment Final Concentration Sterilization Chilled Extrusion

Concentrate the thin gelatin liquor

Evaporator type: Multiple effect rising film or plate and frame Concentration target: 15-25% Output temperature: 115 F to 150 F

Drying

Milling/Screening Blending Formulation Final Packaging

16

Bone /Type B Acidulation Lime Treatment Washing Acidification

Bone/Type A Acidulation NaOH Option Acid Treatment Washing

GELATIN MANUFACTURING PROCESS

Final Filtration

Objectives / Conditions

Extraction Initial Filtration Ion Exchange Initial Concentration Final Filtration pH Adjustment Final Concentration Sterilization Chilled Extrusion Drying Milling/Screening Blending Formulation Final Packaging

17

Clarify concentrated gelatin solution Remove additional coagulated protein and particulate Plate and flame pressure filters Cellulose / diatomaceous earth filter pads

Bone /Type B Acidulation Lime Treatment Washing Acidification

Bone/Type A Acidulation NaOH Option Acid Treatment Washing

GELATIN MANUFACTURING PROCESS

pH Adjustment

Objective / Conditions

Extraction Initial Filtration Ion Exchange Initial Concentration Final Filtration pH Adjustment Final Concentration Sterilization Chilled Extrusion Drying Milling/Screening Blending

Fine adjustment of the finished product pH

Final pH targets: 5-7 Caustic adjustment: NaOH

Formulation

Final Packaging

18

Bone /Type B Acidulation Lime Treatment Washing Acidification

Bone/Type A Acidulation NaOH Option Acid Treatment Washing

GELATIN MANUFACTURING PROCESS

Final Concentration

Objective / Conditions

Extraction Initial Filtration Ion Exchange Initial Concentration Final Filtration pH Adjustment Final Concentration Sterilization Chilled Extrusion Drying Milling/Screening Blending Formulation Final Packaging

Concentrate the thick gelatin liquor

Evaporator type: Thin film / wiped surface or plate and frame multiple effect Output temperature: 115 to 125 F Concentration target: 25 to 50% (viscosity dependent)

19

Bone /Type B Acidulation Lime Treatment Washing Acidification

Bone/Type A Acidulation NaOH Option Acid Treatment Washing

GELATIN MANUFACTURING PROCESS

Sterilization

Objective / Conditions

Extraction Initial Filtration Ion Exchange Initial Concentration Final Filtration pH Adjustment Final Concentration Sterilization Chilled Extrusion Drying Milling/Screening Blending

Ensure microbiological purity / product hygiene Equipment: Direct steam injection / HTST Temperature: 138 to 149 C Time: 8 to 16 seconds

Formulation

Final Packaging

20

Bone /Type B Acidulation Lime Treatment Washing Acidification

Bone/Type A Acidulation NaOH Option Acid Treatment Washing

GELATIN MANUFACTURING PROCESS

Chilled Extrusion

Objective / Conditions

Extraction Initial Filtration Ion Exchange Initial Concentration Final Filtration pH Adjustment Final Concentration Sterilization Chilled Extrusion Drying Milling/Screening Blending

Increase the surface area of the gel mass Glycol - cooled heat exchanger / extruder Temperature: Approx. 70 F Noodle dimensions: 1 to 2 long / 1/8 thick

Formulation

Final Packaging

21

Bone /Type B Acidulation Lime Treatment Washing Acidification

Bone/Type A Acidulation NaOH Option Acid Treatment Washing

GELATIN MANUFACTURING PROCESS

Drying

Objective / Conditions

Extraction Initial Filtration Ion Exchange Initial Concentration Final Filtration pH Adjustment Final Concentration Sterilization Chilled Extrusion Drying Milling/Screening Blending Formulation Final Packaging

Produce a dry, stable product Air quality: Heated, dehumidified and filtered Number of zones: 10 to 12 Temperature gradient: 80 to 160 F Time: 1 - 3 hours Moisture content (gelatin): 10 to 12%

22

Bone /Type B Acidulation Lime Treatment Washing Acidification

Bone/Type A Acidulation NaOH Option Acid Treatment Washing

GELATIN MANUFACTURING PROCESS

Milling and Screening

Objective / Conditions

Grind gelatin to a uniform size Equipment: Cage mill Particle size: 8 to 30 mesh

Extraction Initial Filtration Ion Exchange

Initial Concentration

Final Filtration pH Adjustment Final Concentration Sterilization Chilled Extrusion Drying Milling/Screening Blending Formulation Final Packaging

23

Bone /Type B Acidulation Lime Treatment Washing Acidification

Bone/Type A Acidulation NaOH Option Acid Treatment Washing

GELATIN MANUFACTURING PROCESS

Blending

Blender Drumming and weighing

Extraction Initial Filtration Ion Exchange Initial Concentration Final Filtration pH Adjustment Final Concentration

Sterilization

Chilled Extrusion Drying Milling/Screening Blending Formulation Final Packaging

24

QC/QA Analysis

Bone /Type B Acidulation Lime Treatment Washing Acidification

Bone/Type A Acidulation NaOH Option Acid Treatment Washing

GELATIN MANUFACTURING PROCESS

Formulation

Component Selection

High Capacity Blender

Extraction Initial Filtration Ion Exchange

Initial Concentration

Final Filtration pH Adjustment

Final Concentration

Sterilization

Chilled Extrusion

Drying Milling/Screening Blending Formulation Final Packaging

25

QC/QA Analysis

Bone /Type B Acidulation Lime Treatment Washing Acidification

Bone/Type A Acidulation NaOH Option Acid Treatment Washing

GELATIN MANUFACTURING PROCESS

Final Packaging

Drums

FIBCs

Extraction Initial Filtration Ion Exchange Initial Concentration Final Filtration pH Adjustment Final Concentration

Sterilization

Chilled Extrusion Drying Milling/Screening Blending Formulation Final Packaging

26

Small Bags

You might also like

- ch20 Organic Chemistry SolomonsDocument103 pagesch20 Organic Chemistry Solomonsbrownhazel78% (9)

- Internship Report On Dashen BreweryDocument27 pagesInternship Report On Dashen Brewerydesalegn abera70% (10)

- Using honey and water to prevent enzymatic browningDocument14 pagesUsing honey and water to prevent enzymatic browningBeemzNo ratings yet

- Review: Gelatin, Source, Extraction and Industrial ApplicationsDocument14 pagesReview: Gelatin, Source, Extraction and Industrial ApplicationsJade NguyenNo ratings yet

- Thermal Properties of Matter: Internal Energy, Heat Capacity, Phase ChangesDocument79 pagesThermal Properties of Matter: Internal Energy, Heat Capacity, Phase ChangesHafiza JaweriaNo ratings yet

- CSB DetailsDocument52 pagesCSB DetailsVelmurugan ElumalaiNo ratings yet

- Yaws - Chemical Properties Handbook Physical, Thermodynamics, Engironmental Transport, Safety & Health Related Properties For Organic & Inorganic ChemicalDocument2 pagesYaws - Chemical Properties Handbook Physical, Thermodynamics, Engironmental Transport, Safety & Health Related Properties For Organic & Inorganic ChemicalRanny NovellaNo ratings yet

- Solid Bulk DensityDocument21 pagesSolid Bulk DensityMauricio RodriguezNo ratings yet

- Apendice 2Document12 pagesApendice 2JA UMAN1No ratings yet

- Basic Data EntryDocument12 pagesBasic Data EntryVimal Anbalagan0% (1)

- Piping PDSDocument2 pagesPiping PDSsunii19847908No ratings yet

- Yaws Chapter 1Document1 pageYaws Chapter 1basana siamremareNo ratings yet

- Milk ProductsDocument16 pagesMilk ProductsTeodora AncaNo ratings yet

- Library WebDocument128 pagesLibrary WebVikash AgarwalNo ratings yet

- Conversion Factors: A Comprehensive Guide to Measurement UnitsDocument11 pagesConversion Factors: A Comprehensive Guide to Measurement Unitsmicro kidNo ratings yet

- Water - Dynamic and Kinematic ViscosityDocument3 pagesWater - Dynamic and Kinematic ViscosityManik KandanNo ratings yet

- How To Estimate The Heat Penetration Factor FH of Packaged Foods PDFDocument71 pagesHow To Estimate The Heat Penetration Factor FH of Packaged Foods PDFAlex Samuel SilvaNo ratings yet

- Unit Conversion All in OneDocument32,767 pagesUnit Conversion All in OneAnonymous dRl45itNo ratings yet

- Determining Specific Heat Capacity Using a Heating CoilDocument32 pagesDetermining Specific Heat Capacity Using a Heating CoilMartinNo ratings yet

- How To Use The Excel "Linest" Function For Linear Regression Models With Multiple Input Variables XDocument8 pagesHow To Use The Excel "Linest" Function For Linear Regression Models With Multiple Input Variables XANIL PALNo ratings yet

- Lecture 1-2 Vacuum SystemDocument113 pagesLecture 1-2 Vacuum SystemMehreen AkmalNo ratings yet

- Enthalpy / Entropy DiagramDocument34 pagesEnthalpy / Entropy DiagramMara TrofinNo ratings yet

- Appendix D-2 Viscosity of Pure Water 0-100° PDFDocument1 pageAppendix D-2 Viscosity of Pure Water 0-100° PDFLuis Argüelles SaenzNo ratings yet

- Density Viscosity and Surface Tension of Five Vegetable Oils at Elevated Temperatures Measurement and Modeling PDFDocument18 pagesDensity Viscosity and Surface Tension of Five Vegetable Oils at Elevated Temperatures Measurement and Modeling PDFSnigdha SarmahNo ratings yet

- Piping Specialty Worksheets IndexDocument110 pagesPiping Specialty Worksheets IndexmanhngoducNo ratings yet

- Viscosity (SI)Document6 pagesViscosity (SI)Liem Handi Wijaya SusantoNo ratings yet

- Data Bank Reid SherwoodDocument88 pagesData Bank Reid SherwoodAlejandro Sandoval GuillénNo ratings yet

- Excel PolynomialDocument5 pagesExcel Polynomial______.________No ratings yet

- Calculate Gas Compressibility Excel FunctionDocument2 pagesCalculate Gas Compressibility Excel FunctionCHANADASNo ratings yet

- Dimensions (Based On ASME/ANSI B16.9) and Example Weights For Equal TeesDocument1 pageDimensions (Based On ASME/ANSI B16.9) and Example Weights For Equal TeesHassan SleemNo ratings yet

- Psychrometrics 2017030200Document3 pagesPsychrometrics 2017030200Jawoto Nur RafifNo ratings yet

- Tank Schematic: Horizontal Cylinder: Dimensions of The TankDocument4 pagesTank Schematic: Horizontal Cylinder: Dimensions of The Tankabhay_joshi2002No ratings yet

- Freeze Protection: Heat TracingDocument4 pagesFreeze Protection: Heat TracingNaser JahangiriNo ratings yet

- AHU SizingDocument8 pagesAHU Sizingmohammad hamdanNo ratings yet

- Gelatin Manufacturing Process ChartDocument5 pagesGelatin Manufacturing Process Chartkavilankutty100% (1)

- Motor Starting Voltage ImpactDocument8 pagesMotor Starting Voltage ImpactVíctor RojasNo ratings yet

- Sucrose - Properties and ApplicationsDocument307 pagesSucrose - Properties and ApplicationsSharini_Mu_oz_137100% (1)

- Physics Thermal Properties of Matter Worksheet ThgeoryDocument12 pagesPhysics Thermal Properties of Matter Worksheet ThgeoryrajiaNo ratings yet

- Thermal Properties of FoodsDocument12 pagesThermal Properties of FoodspedroloxxxNo ratings yet

- Physical properties data tables and referencesDocument32 pagesPhysical properties data tables and referencesmidooooo198767% (3)

- SolutionsDocument125 pagesSolutionsCamille WuNo ratings yet

- FD Fan Sizing CalculationDocument3 pagesFD Fan Sizing CalculationkumarananyarupeshNo ratings yet

- Use of The Langelier Index To Balance Pool Water: GeneralDocument3 pagesUse of The Langelier Index To Balance Pool Water: GeneralLee860531100% (1)

- GelatinDocument3 pagesGelatinMutiara ParisaNo ratings yet

- Gelatin Property - Sigma AldrichDocument3 pagesGelatin Property - Sigma AldrichRitesh RanganiNo ratings yet

- Chapter 11: Refrigeration Rules of Thumb For Chemical Engineers, 5th Edition by Stephen HallDocument4 pagesChapter 11: Refrigeration Rules of Thumb For Chemical Engineers, 5th Edition by Stephen HallReza SaeeNo ratings yet

- LASTlifting Pump PDSDocument3 pagesLASTlifting Pump PDSsunii19847908No ratings yet

- HyCAP Beverage ClosuresDocument4 pagesHyCAP Beverage ClosureskhalidNo ratings yet

- Saturation IndexDocument5 pagesSaturation IndexMetin ÇelenkNo ratings yet

- 1974 Murray Filtering Quallity of RAw Sugar - Mechanism of Starch Influence in CarbonatationDocument11 pages1974 Murray Filtering Quallity of RAw Sugar - Mechanism of Starch Influence in CarbonatationnghiNo ratings yet

- Resin Guidelines 111102132909 Phpapp01Document33 pagesResin Guidelines 111102132909 Phpapp01Agoenk KertawijayaNo ratings yet

- GMIA Gelatin Manual 2012Document26 pagesGMIA Gelatin Manual 2012Phan QuanhNo ratings yet

- Introduction To BioseparationsDocument5 pagesIntroduction To BioseparationsbaanniiNo ratings yet

- Gmia Gelatin Manual 2019 PDFDocument27 pagesGmia Gelatin Manual 2019 PDFBruna Moura BastosNo ratings yet

- Flavor-Forward Fruit - Boiron-Baldor 31 January 2012Document12 pagesFlavor-Forward Fruit - Boiron-Baldor 31 January 2012mlaiskonis50% (2)

- Jam and PreservesDocument6 pagesJam and Preserveskolita kamalNo ratings yet

- Treatment of Wastewater From Arabica Coffee ProcessingDocument13 pagesTreatment of Wastewater From Arabica Coffee ProcessingAV TeoNo ratings yet

- Cerveceria TreatmenteDocument40 pagesCerveceria TreatmenteJulio TovarNo ratings yet

- Bio-Ethanol Production in DetailDocument46 pagesBio-Ethanol Production in DetailSCIENCE EDUCATION BY PIYUSH HANSNo ratings yet

- Bioethanol from Banana Peel WasteDocument50 pagesBioethanol from Banana Peel WasteRichard Carizon0% (1)

- All About HydrocolloidsDocument28 pagesAll About HydrocolloidsBambang NurhadiNo ratings yet

- Organic Acids by MicroorganismsDocument38 pagesOrganic Acids by MicroorganismsMuhammad Adeel JavedNo ratings yet

- Shell Environmentally Acceptable Lubes WTC2005Document2 pagesShell Environmentally Acceptable Lubes WTC2005Steve JenkinsNo ratings yet

- Properties of PolyacrylamidesDocument2 pagesProperties of PolyacrylamidesArifa NuriyaniNo ratings yet

- Effect of Fruit Storage Conditions On Olive Oil QualityDocument4 pagesEffect of Fruit Storage Conditions On Olive Oil Qualitycsrajmohan2924No ratings yet

- Biosurfactants Defined as Microbe-Produced Surface-Active BiomoleculesDocument2 pagesBiosurfactants Defined as Microbe-Produced Surface-Active BiomoleculesSania ShehzadiNo ratings yet

- Resonance - : Resonance Structures Things To RememberDocument29 pagesResonance - : Resonance Structures Things To RememberDan Sebastian TilaoNo ratings yet

- Vermeiren2009 PDFDocument31 pagesVermeiren2009 PDFRizky Fahmi 27No ratings yet

- Enzymes PDFDocument50 pagesEnzymes PDFMuhammad Luqman NisaNo ratings yet

- Experiment 4Document6 pagesExperiment 4Jio SantosNo ratings yet

- Oil and Fats ProcessingDocument10 pagesOil and Fats ProcessingRomel Giannor AgcaoiliNo ratings yet

- Ammonium Nickel Sulphate Mediated Nitration of Aromatic Compounds With Nitric Acid PDFDocument8 pagesAmmonium Nickel Sulphate Mediated Nitration of Aromatic Compounds With Nitric Acid PDFrabiaNo ratings yet

- Usp 1663Document12 pagesUsp 1663anilsamuel0077418100% (1)

- LEE KONG CHIAN FACULTY ENGINEERING AND SCIENCE RESEARCHDocument21 pagesLEE KONG CHIAN FACULTY ENGINEERING AND SCIENCE RESEARCHYu HuiNo ratings yet

- Group 17 - General Properties of Halogens - Chemistry LibreTextsDocument6 pagesGroup 17 - General Properties of Halogens - Chemistry LibreTextsKanhai LeishangthemNo ratings yet

- Extraction of Total Lipids From Chicken Egg Yolk, Column Chromatography and Qualitative Tests For LipidsDocument10 pagesExtraction of Total Lipids From Chicken Egg Yolk, Column Chromatography and Qualitative Tests For Lipidsmarilujane75% (8)

- Chemical Carcinogenesis I and Ii: Michael Lea 2016Document31 pagesChemical Carcinogenesis I and Ii: Michael Lea 2016aasiyaNo ratings yet

- G10 Lesson1 DLPDocument15 pagesG10 Lesson1 DLPAngeles, Mark Allen CNo ratings yet

- Zinc Stearate Production by Precipitatio PDFDocument7 pagesZinc Stearate Production by Precipitatio PDFLeslie Gotica Tarapa SinticalaNo ratings yet

- Cleaning and Corrosion ControlDocument241 pagesCleaning and Corrosion ControlOz TamayoNo ratings yet

- Vitamins and MineralsDocument4 pagesVitamins and MineralsNoreen Orro BernalNo ratings yet

- CSA-Li 2018Document9 pagesCSA-Li 2018Subramanian MoorthyNo ratings yet

- Homogeneous Precipitation of Nickel RevistedDocument2 pagesHomogeneous Precipitation of Nickel RevistedcarlosapemNo ratings yet

- Bio CNG From City WasteDocument12 pagesBio CNG From City WastenehareshailNo ratings yet

- 8447 1384066805 Lectures.1-4.polyDocument50 pages8447 1384066805 Lectures.1-4.polyPragatiNo ratings yet

- Calvin Cycle On CAM PlantsDocument33 pagesCalvin Cycle On CAM PlantseraasyahirahNo ratings yet

- Polyethylene Plastic Production ProcessDocument11 pagesPolyethylene Plastic Production ProcessVauzan RivaldieNo ratings yet

- Chelate and Macrocyclic EffectsDocument24 pagesChelate and Macrocyclic EffectsRahul Kumar Gautam100% (2)

- Acs Energyfuels 7b03733Document12 pagesAcs Energyfuels 7b03733Dinesh JoshiNo ratings yet

- DNA Structure & Sequence Model-Remote Learning VersionDocument2 pagesDNA Structure & Sequence Model-Remote Learning VersionstellaNo ratings yet