Professional Documents

Culture Documents

Ken Black QA ch18

Uploaded by

Rushabh VoraOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ken Black QA ch18

Uploaded by

Rushabh VoraCopyright:

Available Formats

Business Statistics, 5

th

ed.

by Ken Black

Chapter 18

Statistical

Quality Control

Discrete Distributions

PowerPoint presentations prepared by Lloyd Jaisingh,

Morehead State University

Understand the concepts of quality, quality

control, and total quality management.

Understand the importance of statistical

quality control in total quality management.

Learn about process analysis and some

process analysis tools.

Learn how to construct x-bar charts,

R charts, p charts, and c charts.

Understand the theory and application of

acceptance sampling.

Learning Objectives

Quality

Quality is when a product delivers what is

stipulated for in its specifications

Crosby: quality is conformance to

requirements

Feigenbaum: quality is a customer

determination

Garvins Five Dimensions of Quality

Transcendent quality: innate excellence

Product quality: quality is measurable

User quality: quality is determined by the

consumer

Manufacturing quality: quality is measured

by the manufacturer's ability to target the

product specifications with little variability

Value Quality: did the consumer get his or

her moneys worth?

Quality Control

Quality control is the collection of strategies,

techniques, and actions taken by an organization to

assure themselves that they are producing a quality

product.

After-process quality control involves inspecting the

attributes of a finished product to determine whether the

product is acceptable, is in need of rework, or is to be

rejected and scrapped.

reporting of the number of defects per time period

screening defective products from consumers

In-process quality control techniques measure product

attributes at various intervals throughout the

manufacturing process in an effort to pinpoint problem

areas.

Demings Fourteen Points (Total Quality

Management, TQM)

1. Create constancy of purpose for improvement of product

and service.

2. Adopt a new philosophy.

3. Cease dependence on mass inspection.

4. End the practice of awarding business on price tag alone.

5. Improve constantly and forever the system of production

and service.

6. Institute training.

7. Institute leadership.

8 Drive out fear.

9. Break down barriers between staff areas.

10. Eliminate slogans.

11. Eliminate numerical quotas.

12. Remove barriers to pride of workmanship.

13. Institute a vigorous program of education and retraining.

14. Take action to accomplish the transformation.

Important Quality Concepts

Benchmarking

examine and emulate the best practices and techniques used in

the industry

a positive, proactive process to make changes that will effect

superior performance

Just-In-Time Inventory Systems

necessary parts for production arrive just in time

reduced holding costs, personnel, and space needed for inventory

no extra raw materials or inventory of parts for production are

stored

Reengineering

complete redesign of the core business process in a company

Six sigma

Total quality approach that measures the capacity of a process to

perform defect -free work

Team Building:

employee groups take on managerial responsibilities

quality circle

Process Analysis

A process is a series of actions, changes or functions

that bring about a result.

Flowcharts - schematic representation of all the

activities and interactions that occur in a process

Pareto Analysis -quantitative tallying of the number and

types of defects that occur with a product

Pareto Chart - ranked vertical bar chart with most

frequently occurring on the left

Fishbone Diagram - display of potential cause-and-

effect relationships

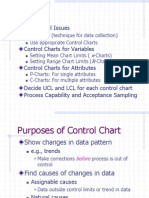

Control Charts - graphical method for evaluating

whether a process is or is not in a state of statistical

control

Flowchart Symbols

Input/Output Symbol

Processing Symbol

Decision Symbol

Start/Stop Symbol

Flow line Symbol

0

10

20

30

40

50

60

70

80

90

100

Poor

Wiring

Short in

Coil

Defective

Plug

Other

F

r

e

q

u

e

n

c

y

0%

10%

20%

30%

40%

50%

60%

70%

80%

90%

100%

Pareto Charts

Cause-and-Effect Diagram

Raw Materials Equipment

Workers Methodology

Poor

Wiring

Wiring Scheme

Pland Layout

Maintenance

Tools

Out-of-Adjustment

Out-of-Date

Vendor

Transportation

Inventory

Training

Attitude

Absenteeism

MINITAB Pareto Chart

C

o

u

n

t

P

e

r

c

e

n

t

Defects

Count

15.4 7.7 3.8

Cum % 42.3 73.1 88.5 96.2 100.0

22 16 8 4 2

Percent 42.3 30.8

O

t

h

e

r

W

r

o

n

g

P

r

e

s

c

r

i

p

t

io

n

W

r

it

t

e

n

M

is

r

e

a

d

H

a

n

d

w

r

it

i

n

g

I

m

p

r

o

p

e

r

l

y

S

t

o

r

e

d

W

r

o

n

g

M

e

d

i

c

in

e

A

d

m

i

n

is

t

e

r

e

d

50

40

30

20

10

0

100

80

60

40

20

0

Pareto Chart of Medication Errors in a Hospital

Types of Control Charts

Control charts for measurements

charts

R charts

Control charts for compliance items

P charts

c charts

X

Control Chart

Monitor process location (center)

1. Decide on the quality to be measured.

2. Determine a sample size.

3. Gather 20 to 30 samples.

4. Compute the sample average for each sample.

5. Compute the sample range for each sample.

6. Determine the average sample mean for all samples.

7. Determine the average sample range (or sample

standard deviation) for all samples.

8 Using the size of the samples, determine the value of A

2

or A

3

.

9. Compute the UCL and the LCL

X

Control Chart: Formulas

X and Charts

X

X

k

UCL X R

LCL X R

R

R

k

LCL R

UCL R

A

A

D

D

R

=

= +

=

=

=

=

2

2

3

4

X and S Charts

X

X

k

UCL X R

LCL X R

S

S

k

UCL R

LCL R

A

A

B

B

=

= +

=

=

=

=

3

3

4

3

X

Data for Demonstration Problem

18.1: Samples 1 - 10

1 2 3 4 5 6 7 8 9 10

5.13 4.96 5.21 5.02 5.12 4.98 4.99 4.96 4.96 5.03

4.92 4.98 4.87 5.09 5.08 5.02 5.00 5.01 5.00 4.99

5.01 4.95 5.02 4.99 5.09 4.97 5.00 5.02 4.91 4.96

4.88 4.96 5.08 5.02 5.13 4.99 5.02 5.05 4.87 5.14

5.05 5.01 5.12 5.03 5.06 4.98 5.01 5.04 4.96 5.11

4.97 4.89 5.04 5.01 5.13 4.99 5.01 5.02 5.01 5.04

4.9933 4.9583 5.0567 5.0267 5.1017 4.9883 5.0050 5.0167 4.9517 5.0450

0.25 0.12 0.34 0.10 0.07 0.05 0.03 0.09 0.14 0.18

X

R

Data for Demonstration Problem

18.1: Samples 11 - 20

11 12 13 14 15 16 17 18 19 20

4.91 4.97 5.09 4.96 4.99 5.01 5.05 4.96 4.90 5.04

4.93 4.91 4.96 4.99 4.97 5.04 4.97 4.93 4.85 5.03

5.04 5.02 5.05 4.82 5.01 5.09 5.04 4.97 5.02 4.97

5.00 4.93 5.12 5.03 4.98 5.07 5.03 5.01 5.01 4.99

4.90 4.95 5.06 5.00 4.96 5.12 5.09 4.98 4.88 5.05

4.82 4.96 5.01 4.96 5.02 5.13 5.01 4.92 4.86 5.06

4.9333 4.9567 5.0483 4.9600 4.9883 5.0767 5.0317 4.9617 4.9200 5.0233

0.22 0.11 0.16 0.21 0.06 0.12 0.12 0.09 0.17 0.09

X

R

Demonstration Problem 18.1:

Control Chart Computations

( )( )

( )( )

( )( )

( )( )

X and Charts

X

X

k

UCL X R

LCL X R

R

R

k

LCL R

UCL R

A

A

D

D

R

= =

+ + + +

=

= + = + =

= = =

= =

+ + + +

=

= = =

= = =

4 9933 4 9583 50566 50233

20

500215

500215 0 483 0136 506784

500215 0 483 0136 4 93646

0 25 012 0 34 0 09

20

0136

0 0136 0

2 004 0136 0 2725

2

2

3

4

. . . .

.

. . . .

. . . .

. . . .

.

.

. . .

Sigma level: 3

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

Bearing Diameter

UCL = 5.0679

Average = 5.0022

LCL = 4.9364

Control Chart: Bearing Diameter

Mean

5.10963

5.05590

5.00217

4.94844

4.89471

Demonstration Problem 18.1:

Control Chart

X

R Chart

Monitor process variation

1. Decide on the quality to be measured.

2. Determine a sample size.

3. Gather 20 to 30 samples.

4. Compute the sample range for each sample.

5. Determine the average sample mean for all

samples.

6. Using the size of the samples, determine the

values of D

3

and D

4

.

7. Compute the UCL and the LCL

R Chart Formulas

R Charts

R

R

k

LCL R

UCL R

D

D

=

=

=

3

4

Demonstration Problem 18.2:

R Control Chart

Control Chart: Bearing Diameter

Sigma level: 3

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

Range

.4

.3

.2

.1

0.0

Bearing Diameter

UCL = .2725

Average = .1360

LCL = .0000

P Charts

Monitor proportion in noncompliance

1. Decide on the quality to be measured.

2. Determine a sample size.

3. Gather 20 to 30 samples.

4. Compute the sample proportion for each

sample.

5. Determine the average sample proportion for

all samples.

6. Compute the UCL and the LCL

P Chart Formulas

:

p

n

the number of noncomplying items in the sample

the number of items in the sample

=

the sample proportion

the number of samples

UCL = P +3

P Q

n

LCL P 3

P Q

n

non

non

n

n

=

=

=

=

=

where

n

P

p

k

where p

k

where Q P 1

Demonstration Problem 18.3:

Twenty Samples of Bond Paper

Sample n

Number Out

of

Compliance Sample n

Number Out

of

Compliance

1 50 4 11 50 2

2 50 3 12 50 6

3 50 1 13 50 0

4 50 0 14 50 2

5 50 5 15 50 1

6 50 2 16 50 6

7 50 3 17 50 2

8 50 1 18 50 3

9 50 4 19 50 1

10 50 2 20 50 5

Demonstration Problem 18.3:

Preliminary Calculations

Sample n n

non

Sample n n

non

1 50 4 0.08 11 50 2 0.04

2 50 3 0.06 12 50 6 0.12

3 50 1 0.02 13 50 0 0.00

4 50 0 0.00 14 50 2 0.04

5 50 5 0.10 15 50 1 0.02

6 50 2 0.04 16 50 6 0.12

7 50 3 0.06 17 50 2 0.04

8 50 1 0.02 18 50 3 0.06

9 50 4 0.08 19 50 1 0.02

10 50 2 0.04 20 50 5 0.10

p p

Demonstration Problem 18.3:

Centerline, UCL, and LCL Computations

( )( )

( )( )

P

p

k

UCL P

P Q

n

LCL P

P Q

n

LCL

= =

+ + + +

=

= +

= + =

=

= =

=

. . . .

.

.

. .

.

.

. .

.

08 06 02 10

20

053

3 053 3

053 947

50

148

3 053 3

053 947

50

042

0

Demonstration Problem 18.3:

P Control Chart

0.00

0.02

0.04

0.06

0.08

0.10

0.12

0.14

0.16

0 5 10 15 20

Sample Number

P = .053

UCL = .148

LCL = 0

p

Demonstration Problem 18.3:

MINITAB P Control Chart

Sample

P

r

o

p

o

r

t

i

o

n

20 18 16 14 12 10 8 6 4 2

0.16

0.14

0.12

0.10

0.08

0.06

0.04

0.02

0.00

_

P=0.053

UCL=0.1480

LCL=0

P Chart of Out of Compliance

c Charts

Monitor number of nonconformances per item

1. Decide on nonconformances to be evaluated.

2. Determine the number of items to be studied (at

least 25).

3. Gather items.

4. Determine the value of c for each item by

summing the number of nonconformances in the

item.

5. Determine the average number of

nonconformances per item.

6. Determine the UCL and the LCL

c Chart Formulas

c c LCL

c c UCL

where

i

c

c c c c

i

3 -

3 + =

item per ities nonconform of number

items of number = i :

c

i

3 2 1

=

=

+ + + +

=

Demonstration Problem 18.4:

Number of Nonconformities in Oil Gauges

Item

Number

Number of

Nonconformities

Item

Number

Number of

Nonconformities

1 2 14 2

2 0 15 1

3 3 16 4

4 1 17 0

5 2 18 2

6 5 19 3

7 3 20 2

8 2 21 1

9 0 22 3

10 0 23 2

11 4 24 0

12 3 25 3

13 2

Demonstration Problem 18.4:

c Chart Calculations

c

i

UCL c c

LCL c c

LCL

c c c c

i

=

+ + + +

=

+ + + +

=

= + =

= = =

=

1 2 3

2 0 3 3

25

2 0

3 2 0 3 2 0 62

3 2 0 3 2 0 2 2

0

.

. . .

. . .

= +

-

Demonstration Problem 18.4: c Chart

0

1

2

3

4

5

6

7

0 5 10 15 20 25

Item Number

c

UCL = 6.2

LCL = 0

c = 2.0

Demonstration Problem 18.4:

MINITAB c Chart

Sample

S

a

m

p

l

e

C

o

u

n

t

24 22 20 18 16 14 12 10 8 6 4 2

7

6

5

4

3

2

1

0

_

C=2

UCL=6.243

LCL=0

C Chart of Number of Nonconformances

Interpreting Control Charts

Points are above UCL and/or below LCL

Eight or more consecutive points fall above or

below the centerline. Ten out of 11 points fall

above or below the centerline. Twelve out of 14

points fall above or below the centerline.

A trend of 6 or more consecutive points

(increasing or decreasing) is present

Two out of 3 consecutive values are in the outer

one-third.

Four out 5 consecutive values are in the outer

two-thirds.

The centerline shifts from chart to chart.

Interpreting Control Charts:

Points above UCL and/or below LCL

UCL

LCL

Centerline

Interpreting Control Charts: 8 Consecutive

Points on One Side of the Centerline

UCL

LCL

Centerline

Interpreting Control Charts:

7 Consecutive Increasing Points

UCL

LCL

Centerline

Interpreting Control Charts:

2 out of 3 Consecutive Points in Outer 1/3

UCL

LCL

Centerline

Interpreting Control Charts:

4 out of 5 Consecutive Points in Outer 2/3

UCL

LCL

Centerline

Acceptance Sampling

Acceptance sampling is the inspection of a

sample from a lot of goods to determine if

the lot will be accepted or rejected.

N = the lot size

n = the sample size

Single Sample Plan

Double-Sample Plan

Multiple-Sample Plan

Rules for Sampling Plans

Accept lot if

Reject lot if

x c

x c

s

>

First sample:

Accept if

Reject if

Take second sample if

Second sample:

Accept if

Reject if

1

1

1

1

1

x

x

c

x

x

s

>

< <

+ s

+ >

1

1

1 1

2 2

2 2

c

r

x r

x c

x c

Single Sample

Plan

Double Sample

Plan

Producers and Consumers Risk

State of Nature

Null True Null False

Actions

Fail to

Reject Null

Type II error Correct

Decision --

Consumers

Risk

Reject Null Type I

error --

Producers

Risk

Correct

Decision

H

0

: the lot is of acceptable quality

Bicycle Manufacturer Example

N = 3,000 (Braces arrive at the manufacturers plant in lots of 3,000.)

n = 15 (The bicycle manufacturer randomly selects a sample of 15 braces

to inspect.)

X is the number of nonconforming braces in the

sample of 15.

A 2% nonconformance rate is acceptable to the

consumer (the bicycle manufacturer).

If the lot contains 60 nonconforming braces, what is

the probability that the consumer will reject the lot

(producers risk)?

If the lot contains 360 nonconforming braces, what is

the probability that the consumer will not reject the

lot (consumers risk)?

Bicycle Manufacturer Example:

Sampling Plan

n

c

x

x

=

s

>

15

1

1

1

=

Accept lot if

Reject lot if

Bicycle Manufacturer Example:

Analysis for 2% Nonconforming Braces

( ) ( )

( ) ( ) ( ) ( )

0

0 15 1 14

02

0 1

15

0

15

1

1 9647 0353

02 98 02 98

p

P x P x

=

= + = =

|

\

|

.

|

+

|

\

|

.

|

=

=

.

.

. .

. . . .

Probability of accepting

Probability of rejecting

9647

Producers Risk

Bicycle Manufacturer Example:

Analysis for 12% Nonconforming

Braces

( ) ( )

( ) ( ) ( ) ( )

1

0 15 1 14

12

0 1

15

0

15

1

4476

1 4476 5524

12 88 12 88

p

P x P x

=

= + = =

|

\

|

.

|

+

|

\

|

.

|

=

=

.

.

. .

. . . .

Probability of accepting

Probability of rejecting

Consumers

Risk

Bicycle Manufacturer Example:

OC Curve for n = 15 and c = 1

0.00

0.20

0.40

0.60

0.80

1.00

0% 10% 20% 30% 40%

Percent nonconforming

Probability

of

acceptance

2%

.9647

} .0353 Producers Risk

.4476 Consumers Risk

12%

.4476

Bicycle Manufacturer Example:

OC Curve for n = 15 and c = 0

0.00

0.20

0.40

0.60

0.80

1.00

0% 10% 20% 30% 40%

Percent nonconforming

Probability

of

acceptance

2%

.74

12%

.21

Demonstration Problem 18.5

Demonstration Problem 18.5

Demonstration

Problem 18.5

n = 20

c = 2

p P(Accept)

0.00001 =BINOMDIST(B$2,B$1,A5,TRUE)

0.01 =BINOMDIST(B$2,B$1,A6,TRUE)

0.02 =BINOMDIST(B$2,B$1,A7,TRUE)

0.03 =BINOMDIST(B$2,B$1,A8,TRUE)

0.04 =BINOMDIST(B$2,B$1,A9,TRUE)

0.05 =BINOMDIST(B$2,B$1,A10,TRUE)

0.06 =BINOMDIST(B$2,B$1,A11,TRUE)

0.07 =BINOMDIST(B$2,B$1,A12,TRUE)

0.08 =BINOMDIST(B$2,B$1,A13,TRUE)

0.09 =BINOMDIST(B$2,B$1,A14,TRUE)

0.1 =BINOMDIST(B$2,B$1,A15,TRUE)

0.11 =BINOMDIST(B$2,B$1,A16,TRUE)

0.12 =BINOMDIST(B$2,B$1,A17,TRUE)

0.13 =BINOMDIST(B$2,B$1,A18,TRUE)

0.14 =BINOMDIST(B$2,B$1,A19,TRUE)

0.15 =BINOMDIST(B$2,B$1,A20,TRUE)

0.16 =BINOMDIST(B$2,B$1,A21,TRUE)

0.17 =BINOMDIST(B$2,B$1,A22,TRUE)

0.18 =BINOMDIST(B$2,B$1,A23,TRUE)

0.19 =BINOMDIST(B$2,B$1,A24,TRUE)

0.2 =BINOMDIST(B$2,B$1,A25,TRUE)

Copyright 2008 John Wiley & Sons, Inc.

All rights reserved. Reproduction or translation

of this work beyond that permitted in section 117

of the 1976 United States Copyright Act without

express permission of the copyright owner is

unlawful. Request for further information should

be addressed to the Permissions Department, John

Wiley & Sons, Inc. The purchaser may make

back-up copies for his/her own use only and not

for distribution or resale. The Publisher assumes

no responsibility for errors, omissions, or damages

caused by the use of these programs or from the

use of the information herein.

You might also like

- SPCDocument59 pagesSPCadibhai06100% (2)

- Chap 4 SPCDocument47 pagesChap 4 SPCماياأمال100% (1)

- Economic and Financial Modelling with EViews: A Guide for Students and ProfessionalsFrom EverandEconomic and Financial Modelling with EViews: A Guide for Students and ProfessionalsNo ratings yet

- Assign # 1-SPCDocument9 pagesAssign # 1-SPCNour LyNo ratings yet

- Six Sigma Green Belt, Round 2: Making Your Next Project Better than the Last OneFrom EverandSix Sigma Green Belt, Round 2: Making Your Next Project Better than the Last OneNo ratings yet

- Week-8-TQM Concept and ToolsDocument43 pagesWeek-8-TQM Concept and ToolsM A HasanNo ratings yet

- Process Capability and SPC : Operations ManagementDocument43 pagesProcess Capability and SPC : Operations ManagementRahul KhannaNo ratings yet

- Technical Note 8: Process Capability and Statistical Quality ControlDocument46 pagesTechnical Note 8: Process Capability and Statistical Quality ControlVipin NairNo ratings yet

- Quality ControlDocument20 pagesQuality ControlDeepak Kumar Arya50% (2)

- Total Quality Management, Statistical Process ControlDocument11 pagesTotal Quality Management, Statistical Process ControlElmer GatchalianNo ratings yet

- Operations Management: Statistical Process Control Supplement 6Document34 pagesOperations Management: Statistical Process Control Supplement 6Hafiz UmmarNo ratings yet

- Operation ManagementDocument66 pagesOperation ManagementsemerederibeNo ratings yet

- Operation ManagementDocument35 pagesOperation ManagementVishwanath SNNo ratings yet

- 7 Quality Control Tool / QCDocument86 pages7 Quality Control Tool / QCshuklahouseNo ratings yet

- Statistical Process ControlDocument43 pagesStatistical Process ControlninaswayNo ratings yet

- Chap 04Document9 pagesChap 04gttomcatNo ratings yet

- SPC: Statistical Process ControlDocument53 pagesSPC: Statistical Process ControlSaoloan NaiborhuNo ratings yet

- Statistical Quality Control (SQC) FinalDocument47 pagesStatistical Quality Control (SQC) FinalSagar DhageNo ratings yet

- Lean 6 Sigma - 7 QC ToolsDocument18 pagesLean 6 Sigma - 7 QC ToolsLeankannanNo ratings yet

- Introduction To Six SigmaDocument65 pagesIntroduction To Six SigmaAdi Hans PoerbaNo ratings yet

- Basic Business Statistics: Statistical Applications in Quality and Productivity ManagementDocument67 pagesBasic Business Statistics: Statistical Applications in Quality and Productivity ManagementToufiq Khan MajlisNo ratings yet

- Chapter 10 NotesDocument21 pagesChapter 10 NotesfrtisNo ratings yet

- Statistical Process Control: Operations Management - 5 EditionDocument49 pagesStatistical Process Control: Operations Management - 5 EditionGunasekaran ChinnusamyNo ratings yet

- Statistical Quality ControlDocument23 pagesStatistical Quality ControlJanine ArtigoNo ratings yet

- 16 Chapter 10Document16 pages16 Chapter 10Harshi AggarwalNo ratings yet

- Additional Homework ProblemsDocument5 pagesAdditional Homework ProblemsSivaMarojuNo ratings yet

- Statistic ProcessDocument39 pagesStatistic ProcessxredjokerxNo ratings yet

- Statistical Quality Control (S.Q.C.) Presented By-: Nikhil Garg ROLL NO-0129626Document38 pagesStatistical Quality Control (S.Q.C.) Presented By-: Nikhil Garg ROLL NO-0129626jolaakNo ratings yet

- Question of Business StatisticsDocument4 pagesQuestion of Business Statisticsآفاق بن یوسفNo ratings yet

- Ch.4 - Control Charts For AttributesDocument34 pagesCh.4 - Control Charts For AttributesAbdullah Hazeem100% (3)

- Quality Control Tools For Improving Processes: Supplement 6Document55 pagesQuality Control Tools For Improving Processes: Supplement 6janssen.villian3621No ratings yet

- Statistical Quality ControlDocument13 pagesStatistical Quality ControlsekelanilunguNo ratings yet

- 7 QC ToolsDocument44 pages7 QC ToolsNEHANo ratings yet

- Control Chart TheoryDocument6 pagesControl Chart TheoryJorge BurgueteNo ratings yet

- Session 17,18, Quality ManagementDocument57 pagesSession 17,18, Quality ManagementpearlsapphireNo ratings yet

- Iso ManualDocument9 pagesIso ManualSanjay MalhotraNo ratings yet

- UNIT - IV (Simulation)Document18 pagesUNIT - IV (Simulation)ram84322100% (1)

- Quality and PerformanceDocument96 pagesQuality and PerformanceHoNestLiArNo ratings yet

- BTDocument13 pagesBTNhân VănNo ratings yet

- Multiple RegressionDocument29 pagesMultiple Regressionpriy14100% (1)

- Quality ControlDocument56 pagesQuality ControlMuslima MohammedNo ratings yet

- (DONE) OPIM - Practice Questions Week 6Document5 pages(DONE) OPIM - Practice Questions Week 6Dexter KhooNo ratings yet

- Quality ProblemsDocument7 pagesQuality Problemsnikaro1989No ratings yet

- Unit V QualityDocument51 pagesUnit V QualityMabood Ahmad AnsariNo ratings yet

- OM Assignment Roll No 88Document14 pagesOM Assignment Roll No 88ankurmakhija50% (4)

- Statistical Process Control: Douglas M. Stewart, Ph.D. The Anderson Schools of Management The University of New MexicoDocument68 pagesStatistical Process Control: Douglas M. Stewart, Ph.D. The Anderson Schools of Management The University of New Mexicoenzo atsituabNo ratings yet

- Six Sigma in Measurement Systems Evaluating The Hidden FactoryDocument30 pagesSix Sigma in Measurement Systems Evaluating The Hidden FactorymaniiscribdNo ratings yet

- Exam 3Document6 pagesExam 3Ralph Castino0% (1)

- 7 QC Tool For Core ElectricalsDocument43 pages7 QC Tool For Core ElectricalsSagar YadavNo ratings yet

- Variation: The Presence of VariationDocument17 pagesVariation: The Presence of VariationHarris ChackoNo ratings yet

- Statistics For Business and Economics: Bab 20Document43 pagesStatistics For Business and Economics: Bab 20balo100% (1)

- ASSIGNMENT ON STATISTICAL PROCESS CONTROL ProdDocument4 pagesASSIGNMENT ON STATISTICAL PROCESS CONTROL ProdsamanthaNo ratings yet

- Quality Control Project: DataDocument13 pagesQuality Control Project: DataWaqar DarNo ratings yet

- SIX SIGMA - An Awareness ProgrammeDocument52 pagesSIX SIGMA - An Awareness ProgrammeKewal SelarkaNo ratings yet

- Analytical Tools For Quality, Six Sigma and Continuous ImprovementDocument25 pagesAnalytical Tools For Quality, Six Sigma and Continuous ImprovementHajiMasthanSabNo ratings yet

- TQM Tools in MFG and Service IndustriesDocument29 pagesTQM Tools in MFG and Service IndustriesSimantoPreeomNo ratings yet

- SQC Notes 2018 AdminDocument9 pagesSQC Notes 2018 AdminAby MathewNo ratings yet

- 0000004421-Chap 9Document42 pages0000004421-Chap 9Srinivas AmaraNo ratings yet

- Critical Thinking Assignment 1Document3 pagesCritical Thinking Assignment 1Rushabh VoraNo ratings yet

- QA Ken Black All Chapters SolutionDocument1,244 pagesQA Ken Black All Chapters SolutionRushabh Vora88% (129)

- GMAT Quant Topic 6 Co-Ordinate Geometry SolutionsDocument20 pagesGMAT Quant Topic 6 Co-Ordinate Geometry SolutionsRushabh VoraNo ratings yet

- On Environmental Factors Responsible For Idbi's PerformanceDocument53 pagesOn Environmental Factors Responsible For Idbi's PerformanceRushabh VoraNo ratings yet

- Eaton Worldwide: Type: - PublicDocument34 pagesEaton Worldwide: Type: - PublicRushabh VoraNo ratings yet

- MBA SIP Project On BSNLDocument16 pagesMBA SIP Project On BSNLRushabh VoraNo ratings yet

- Slide 1: Limits, Fits & ToleranceDocument13 pagesSlide 1: Limits, Fits & ToleranceAnkushNo ratings yet

- Noss Matrix: H-024-1 Jurukimpal Arka Logam BerperisaiDocument4 pagesNoss Matrix: H-024-1 Jurukimpal Arka Logam BerperisaiNorazzah AbdullahNo ratings yet

- Soil NailingDocument5 pagesSoil NailingVishweshwaran MNo ratings yet

- Battery Safety and Environmental Concerns TranscriptDocument13 pagesBattery Safety and Environmental Concerns TranscriptAbhijeet Kumar SinghNo ratings yet

- 2018 Virginia Construction CodeDocument197 pages2018 Virginia Construction CodeДмитрий Касьян100% (1)

- Schwabe 2010Document27 pagesSchwabe 2010giorgis072No ratings yet

- DICOMDocument11 pagesDICOMMichel l'AmieNo ratings yet

- Pip Elsgs11 2014Document6 pagesPip Elsgs11 2014Bijaya Kumar MohantyNo ratings yet

- Oracle Apex 18.1 PDFDocument90 pagesOracle Apex 18.1 PDFJiro B.100% (3)

- Resume - Binay Jha (LTE Engg) - Updated.Document5 pagesResume - Binay Jha (LTE Engg) - Updated.Omprakash BhoiNo ratings yet

- BS 6746 1990Document12 pagesBS 6746 1990JoseHerraizNo ratings yet

- SSM63817 - Smart Key Programming Advice SSM March 2013 v1Document5 pagesSSM63817 - Smart Key Programming Advice SSM March 2013 v1Kent WaiNo ratings yet

- Appendix 6.2-G - Fire Pump Engine SpecsDocument9 pagesAppendix 6.2-G - Fire Pump Engine Specs050678No ratings yet

- NetSure 501 DatasheetDocument2 pagesNetSure 501 DatasheetAnnBlissNo ratings yet

- 042000fl SandellDocument46 pages042000fl SandellabobeedoNo ratings yet

- En 12952Document2 pagesEn 12952Prasanna Balraj0% (1)

- Docu38414 Unisphere Central 4.0 Installation GuideDocument34 pagesDocu38414 Unisphere Central 4.0 Installation GuideJayaprakash Narayan ReddyNo ratings yet

- Chemicals Zetag DATA Powder Zetag 8160 - 0410Document2 pagesChemicals Zetag DATA Powder Zetag 8160 - 0410PromagEnviro.com100% (1)

- 2GCS203014A0060 - Dynacomp Manual PDFDocument112 pages2GCS203014A0060 - Dynacomp Manual PDFmaruf048100% (1)

- Specification: Rev. A English Jun / 2002Document35 pagesSpecification: Rev. A English Jun / 2002Java JavaNo ratings yet

- Sluice GateslknlmDocument7 pagesSluice GateslknlmVed PrakashNo ratings yet

- Project Engineer - 7+ Years - ArshadDocument2 pagesProject Engineer - 7+ Years - ArshadMOHAMMAD ARSHAD ANSARINo ratings yet

- Pwil CorporatebrochureDocument32 pagesPwil Corporatebrochureasr2972No ratings yet

- Specifications For Oil, Gas, Water, Sewer PipesDocument3 pagesSpecifications For Oil, Gas, Water, Sewer PipesShams TabrezNo ratings yet

- Litra Master Plan: Details of Plan and MissionsDocument1 pageLitra Master Plan: Details of Plan and MissionsellonndlovuNo ratings yet

- Piping Design Engineer Interview Questions - Part 1Document5 pagesPiping Design Engineer Interview Questions - Part 1Dayo IdowuNo ratings yet

- Globalone API V 2.6.3Document91 pagesGlobalone API V 2.6.3jeevanowhereNo ratings yet

- Project Cost ControlDocument15 pagesProject Cost ControlMuhammad Sageer100% (3)

- PCS-902 - X - Instruction Manual - EN - Overseas General - X - R2.01 PDFDocument556 pagesPCS-902 - X - Instruction Manual - EN - Overseas General - X - R2.01 PDFAyub HasersNo ratings yet

- Apple TalkDocument2 pagesApple Talkvaseline02No ratings yet