Professional Documents

Culture Documents

Imm

Uploaded by

yesalemushOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Imm

Uploaded by

yesalemushCopyright:

Available Formats

Introduction to API Process

Simulation

Pharmaceutical API Process

Development and Design

Module Structure

Process modeling basics

Model applications

Model types

Modeling procedure

Simulation packages

DynoChem

Examples

Heat transfer

Batch reactor with accumulation effects

Model Applications

Effects of process parameter changes

Optimal operating policies for batch

operations

Compare different reactant or solvent feed

strategies

Maximization of yield in crystallization

Minimize side-product formation in batch

reaction

Safety

Loss of cooling

Model Types

Mechanistic (white box)

Empirical (black box)

Combined models (grey box)

Lumped parameter

Distributed parameter

Continuous

Discrete

Hybrid discrete/continuous

Modeling Procedure

1. Problem definition

a. Level of detail

b. Inputs and outputs

2. Identify controlling mechanisms

3. Evaluate problem data

a. Measured data

b. Parameter values

4. Construct model

5. Solve model

Controlling Mechanisms

1. Chemical reaction

2. Mass transfer

a. Diffusion

b. Boundary layer

3. Heat transfer

a. Conduction

b. Convective

c. Radiation

4. Fluid flow

5. Mixing

6. Evaporation

Model Construction

1. System boundary and balance volumes

2. Characterizing variables

3. Balance equations

4. Transfer rate specifications

5. Property relations

Model Components

1. Model equations and variables

a. Overall and component mass balances

b. Energy balance

c. Momentum balance

d. Transfer rates

e. Physical properties

2. Initial conditions

3. Parameters

Software Packages

Examples

gPROMS, DynoChem, Daesim Studio, MATLAB

Desired features

Solution of differential algebraic equation systems

Parameter estimation

Optimization

Model templates, physical properties estimation

Software used for examples in this module

DynoChem

DynoChem Features

Tools for simulation, optimization and

fitting

Excel spreadsheets for data entry and

utility calculations

Model library

Templates for common API Unit Operations

Utilities for physical properties, vessel

characterization

DynoChem Model Structure

Component Definitions

Name, molecular weight, functional groups for

property calculations

Process Definition

Statements

Scenarios

Initial values, parameters

Data sheets

Profiles for measured variables

Statements

Phase

Represents vessel (e.g. header tank,

condenser, receiving vessel) or compartment

(e.g. headspace)

Solid, liquid, gas

Flow

Transfer, feed, remove

Reactions

Take place in phases or flows

Statements (contd.)

Heat transfer

Heat or cool a phase with a jacket (flow)

Heat exchange between phases

Heat duty

Mass transfer

Liquid-liquid (transfer between immiscible

phases)

Gas-liquid (e.g. hydrogen into solvent)

Solid-liquid (e.g. dissolution)

Statements (contd.)

Condense

V-L phase equilibrium (Antoine eqn)

Calculate

Set up user defined equations

Integrate

Integrate variables during a simulation

Solver

Solution method, accuracy

Example 1: Heat Transfer

Through Jacket

(see handout for detailed process

description)

Balance Volumes

1. Bulk liquid

2. Heating fluid

bulk

jacket

jacket

bulk

Assumptions and Controlling

Mechanisms

Assumptions

Neglect agitator work

Neglect heat losses to environment

Neglect evaporation

Constant properties

Controlling Mechanisms

Flow of heating liquid

Heat transfer between jacket and tank

Perfect mixing

Model Variables

Bulk mass

Bulk specific heat

Bulk temperature

Jacket mass flow rate

Jacket specific heat

Jacket inlet temperature

Jacket outlet temperature

bulk

M

bulk p

c

,

bulk

T

jacket p

c

,

jacket

F

in jacket

T

,

out jacket

T

,

Heat Transfer Equations

, p bulk

c specified =

, p jacket

c specified =

jacket

F specified =

bulk

M specified =

)

, bulk p bulk bulk

d

M c T q

dt

=

) q T UA T T c F

lm in jacket out jacket jacket p jacket

= A = ) (

, , ,

) ) ) . J

out jacket bulk in jacket bulk in jacket out jacket lm

T T T T T T T

, , , ,

ln = A

Model Objectives

1. Determine UA by fitting experimental data

2. Estimate time to heat bulk liquid to boiling

point for different jacket temperatures

DynoChem Model Summary

Components

solvent (methanol), htfluid

Process definition (statements)

Phase bulk liquid

Heat bulk liquid with jacket

Scenarios (initial values and parameters)

Bulk liquid: Initial temperature, solvent mass,

specific heat

Jacket: Inlet temperature, flow, specific heat

UA (to be determined by fitting data)

Jacket and Bulk temperature profiles

0

20

40

60

80

100

120

12/8/06 6:57 AM 12/8/06 7:04 AM 12/8/06 7:12 AM 12/8/06 7:19 AM 12/8/06 7:26 AM 12/8/06 7:33 AM

Time, min

s

e

e

l

e

g

e

n

d Jacket

Temperature C

Bulk liquid

Temperature C

Data Sheets

Simulation Tool

Requires UA value

Obtain by fitting simulated temperature

profile to plant data

0

20

40

60

80

100

120

0 5 10 15 20 25 30 35

Jacket Temperature (Imp)

Bulk liquid Temperature (Exp)

Bulk liquid Temperature

(UA=400)

Bulk liquid Temperature

(UA=100)

Fitting Tool

Least squares fitting (Levenberg-Marquardt)

Scenarios

Compare heating time with different jacket

parameters

Heating time

20

30

40

50

60

70

0 10 20 30 40 50 60

Time (minutes)

T

e

m

p

e

r

a

t

u

r

e

(

C

)

Jacket Temperature=104

Jacket Temperature=120

Jacket Temperature=88

Example 2: Fed-batch

reaction with safety constraint

(see handout for detailed process

description)

Balance Volumes

1. Bulk liquid

2. Heating fluid

3. Header tank

header

jacket

bulk

header

jacket

bulk

1 feed

Process Description

Exothermic reaction

substrate + reagent product

Isothermal operation, fed-batch

Objective

Minimize time to produce given amount of

product

Manipulated variable

Feed rate of reagent

Model Variables

concentration of species X in reactor;

volume of material in reactor;

maximum volume;

feed rate;

concentration of X in header tank;

kinetic rate constant;

reactor temperature (normal process operation);

Maximum temperature of synthetic reaction

(temperature attained after cooling failure);

maximum allowable temperature;

heat of reaction;

Reaction heat generation;

density;

heat capacity of material in reactor

bulk X

c

,

bulk

V

max

V

in

q

header X

c

,

k

bulk

T

MTSR

max

T

r

H A

p

bulk p

c

,

r

q

Safety Constraint

MTSR (maximum temperature of synthetic reaction)

max

T T T MTSR

ad bulk

A + =

bulk

T

Safety Constraint

Cooling failure Stop feed Reaction

continues till unreacted components are

exhausted

Maximum attainable temperature

Without safety constraint, batch operation

(add all B at t=0) is optimal

extent of reaction after feed is stopped

Srinivasan et al., (2003), Computers and Chemical Engineering, 27(2003) 1-26

p r bulk reagent bulk substrate bulk

c H t c t c T t MTSR p ) ( )) ( ), ( min( ) (

, ,

A + =

Feed Profile

Max flow (1, 3): Volume and safety constraints

are inactive

Controlled flow (2): Safety constraint is active

No flow (4): Volume at maximum value

time

Min

in

q

Max

in

q

in

q

con

in

q

Max

in

q

1

2

3

4

Srinivasan et al., (2003), Computers and Chemical Engineering, 27(2003) 1-26

Reaction Equations

B A bulk

c kc V rate =

r r

H rate q A - =

Heat transfer equations as in Example 1

p r bulk reagent bulk substrate bulk

c H t c t c T t MTSR p ) ( )) ( ), ( min( ) (

, ,

A + =

DynoChem Model Summary

Components

solvent, coolant, reagent, substrate, product

Process definition (statements)

Phase bulk liquid

Heat bulk liquid with jacket

Phase header tank

Transfer to bulk liquid from header tank

Reactions in bulk liquid

Calculate MTSR

DynoChem Model Summary

Scenarios (initial values and parameters)

Bulk liquid: Initial temperature, solvent mass,

specific heat, substrate moles, reagent moles

Header tank: Temperature, solvent mass,

reagent moles

Jacket: Inlet temperature, flow, specific heat,

UA

Feed and Temperature Profiles for Fed Batch Reactor

0

10

20

30

40

50

60

70

80

0 200 400 600 800 1000 1200 1400

Time, min

s

e

e

l

e

g

e

n

d

Qin L/hr

Temperature C

Data Sheet for Simulation

Adjust feed profile to satisfy MTSR and volume

constraints

Isothermal temperature profile is imposed through data

sheet (DynoChem calculates required jacket temperature internally)

Simulation Results

Volume (l)

60

70

80

90

100

110

0 200 400 600 800 1000 1200 1400

Time (min)

Volume (l)

Maximum flow

Controlled flow

No flow

Simulation Results

MTSR

76.5

77

77.5

78

78.5

79

79.5

80

80.5

0 200 400 600 800 1000 1200 1400

Time (min)

T

e

m

p

e

r

a

t

u

r

e

(

C

)

MTSR

Safety constraint active

Volume constraint active

Safety and volume constraints inactive

Scenarios

Increase reactor volume, reduce cycle time

0

10

20

30

40

50

60

70

0 200 400 600 800 1000 1200 1400

Time (min)

P

r

o

d

u

c

t

(

m

o

l

)

Run1

Run2

60

70

80

90

100

110

120

0 200 400 600 800 1000 1200 1400

Time (min)

V

o

l

(

l

)

Run1

Run2

Volume constraint no longer active

References

Katalin Hangos and Ian Cameron, Process

Modeling and Model Analysis, Academic Press,

2001, London.

P.E. Burke, Experiences in Heat-Flow

Calorimetry and Thermal Analysis, in W. Hoyle

(ed), Pilot Plants and Scale-Up of Chemical

Processes, Royal Society of Chemistry, 1997,

Cambridge.

You might also like

- Emerging Technology SyllabusDocument6 pagesEmerging Technology Syllabussw dr100% (4)

- Marcet Boiler Lab ReportDocument10 pagesMarcet Boiler Lab ReportErmias AsfawNo ratings yet

- Heat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersFrom EverandHeat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersRating: 4 out of 5 stars4/5 (13)

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- Partnership Digest Obillos Vs CIRDocument2 pagesPartnership Digest Obillos Vs CIRJeff Cadiogan Obar100% (9)

- The New Art of Photographing Nature - ExcerptDocument15 pagesThe New Art of Photographing Nature - ExcerptCrown Publishing GroupNo ratings yet

- Lab Report 2: Phase Change: Name Class Matrix No. Lecturer'S NameDocument18 pagesLab Report 2: Phase Change: Name Class Matrix No. Lecturer'S NameGnabryNo ratings yet

- Crossflow Heat Exchanger Ex PDFDocument5 pagesCrossflow Heat Exchanger Ex PDFprinesst0% (1)

- Pressure VesselDocument507 pagesPressure Vesselpradip11100% (1)

- EP07 Measuring Coefficient of Viscosity of Castor OilDocument2 pagesEP07 Measuring Coefficient of Viscosity of Castor OilKw ChanNo ratings yet

- EPMS System Guide For Subcontractor - V1 2Document13 pagesEPMS System Guide For Subcontractor - V1 2AdouaneNassim100% (2)

- Ford Focus MK2 Headlight Switch Wiring DiagramDocument1 pageFord Focus MK2 Headlight Switch Wiring DiagramAdam TNo ratings yet

- 6 Adiabaticcalorimetry PDFDocument14 pages6 Adiabaticcalorimetry PDFEvelyn TapiaNo ratings yet

- The Heat Transfer Through Jacket: Introduction To API Process Simulation, Example 1Document4 pagesThe Heat Transfer Through Jacket: Introduction To API Process Simulation, Example 1Tamer Abd ElrasoulNo ratings yet

- Week # 05 - Lecture # 10 - HENDocument21 pagesWeek # 05 - Lecture # 10 - HENHadia SAULATNo ratings yet

- The Limit of DSC As A Preliminary Tool To Determine The Safety Parameters?Document6 pagesThe Limit of DSC As A Preliminary Tool To Determine The Safety Parameters?sameer sahaanNo ratings yet

- Process Control and Engineering LAB ManualDocument46 pagesProcess Control and Engineering LAB Manual1DS20CH001 AbhishekNo ratings yet

- Penerapan Metode Tuning Pid Ziegler-Nichols Dalam Pengendalian Temperature Crude Studi Kasus Di Epc Project PT Tripatra Engineers andDocument13 pagesPenerapan Metode Tuning Pid Ziegler-Nichols Dalam Pengendalian Temperature Crude Studi Kasus Di Epc Project PT Tripatra Engineers andDzhokarNo ratings yet

- EXPERIMENT NO.2-WPS OfficeDocument5 pagesEXPERIMENT NO.2-WPS OfficeJohn Paul MorilloNo ratings yet

- HMT Lab ManualDocument24 pagesHMT Lab ManualMian Abdul RehmanNo ratings yet

- Revised-HT lab-Record-AUGUST-2023Document61 pagesRevised-HT lab-Record-AUGUST-2023Satwik SahuNo ratings yet

- Thermal Analysis TechniquesDocument34 pagesThermal Analysis TechniquesMujahid AmeenNo ratings yet

- LAB2 Ex 1Document4 pagesLAB2 Ex 1Ben LopezNo ratings yet

- HT Lab Manual Cycle 2 MLRITDocument34 pagesHT Lab Manual Cycle 2 MLRITchinna kranthiNo ratings yet

- Differential Scanning Calorimetry PresentationDocument16 pagesDifferential Scanning Calorimetry PresentationNebu MathewNo ratings yet

- Martinez HEAT EXCHANGERDocument26 pagesMartinez HEAT EXCHANGERVernix FoNo ratings yet

- Exp 05 Grp8 20110153Document11 pagesExp 05 Grp8 20110153Rahul KumarNo ratings yet

- Experiment No. 4 TGA AnalysisDocument2 pagesExperiment No. 4 TGA AnalysisSIDDHARTH BHASNEYNo ratings yet

- Experiment No. 1Document6 pagesExperiment No. 1Yhuloopz AlvarezNo ratings yet

- Lecture Note 4 - Building Process ModelDocument43 pagesLecture Note 4 - Building Process ModelKASHVINWARMA A/L BASKARANNo ratings yet

- Me 6512 Thermal Engineering Lab Manual 2013 RegulationDocument94 pagesMe 6512 Thermal Engineering Lab Manual 2013 RegulationSujith JNo ratings yet

- Specific Heat of Liquids and Solids: Standard Test Method ForDocument6 pagesSpecific Heat of Liquids and Solids: Standard Test Method ForJean-Patrice DeliaNo ratings yet

- Lesson 1 Introduction To Transient AnalysisDocument10 pagesLesson 1 Introduction To Transient AnalysisMilan P. VasicNo ratings yet

- Differential Scanning CalorimetryDocument38 pagesDifferential Scanning CalorimetrySukhwant SinghNo ratings yet

- Unsteady State Heat Transfer Module - NuDocument7 pagesUnsteady State Heat Transfer Module - NuJady chess24No ratings yet

- Dr. S P Sivapirakasam Associate Professor Department of Mechanical Engineering NIT TiruchirappalliDocument28 pagesDr. S P Sivapirakasam Associate Professor Department of Mechanical Engineering NIT Tiruchirappallisuman pandianNo ratings yet

- ShallDocument19 pagesShallSajad SaladNo ratings yet

- Specific Heat Capacity of Water Exp 4 ThermodynamicsDocument14 pagesSpecific Heat Capacity of Water Exp 4 Thermodynamicshayder alaliNo ratings yet

- Laboratory B: Three-Dimensional Forced Convection Heat LossDocument13 pagesLaboratory B: Three-Dimensional Forced Convection Heat LosscfellowNo ratings yet

- Therm0chimica Acta: KeywordsDocument9 pagesTherm0chimica Acta: Keywordssameer sahaanNo ratings yet

- Experiment 5 Thermal ConductivityDocument9 pagesExperiment 5 Thermal Conductivitybeasturs1No ratings yet

- Linear ConductionDocument9 pagesLinear Conductionaymanjader315No ratings yet

- A2 Physics Practicals 56873595 Practical 10 Specific Heat Capacity of A LiquidDocument2 pagesA2 Physics Practicals 56873595 Practical 10 Specific Heat Capacity of A LiquidSachitra Wijethunga100% (2)

- Thermal Cyclers: Key Thermal Cycling Concepts and Ramp RatesDocument4 pagesThermal Cyclers: Key Thermal Cycling Concepts and Ramp RatesRPNo ratings yet

- PCR April '00 V1.0 Part 1 NicDocument84 pagesPCR April '00 V1.0 Part 1 Nicvg04No ratings yet

- Experiment 1 LinearDocument6 pagesExperiment 1 LinearDeniseLimNo ratings yet

- Lab 3 MeasurementDocument11 pagesLab 3 MeasurementMenny RossNo ratings yet

- Aim: Apparatus:: To Perform Thermo-Gravimetric Analysis of Calcium OxalateDocument10 pagesAim: Apparatus:: To Perform Thermo-Gravimetric Analysis of Calcium OxalateravideyNo ratings yet

- MKL3 PresentationDocument10 pagesMKL3 PresentationMatthew NelsonNo ratings yet

- AgitatorDocument8 pagesAgitatorDennice RuedasNo ratings yet

- Lecture 1 Intro Energy TargetsDocument56 pagesLecture 1 Intro Energy Targets翁宝怡No ratings yet

- Heat and Mass Transfer Lab ReportDocument14 pagesHeat and Mass Transfer Lab ReportKelly KellNo ratings yet

- Heat Transfer Studies in Laminar FlowDocument7 pagesHeat Transfer Studies in Laminar FlowvinodNo ratings yet

- Book-3 - Psychrometrics - 2013 Code Update - Atlanta Mar 2015 - FinalDocument77 pagesBook-3 - Psychrometrics - 2013 Code Update - Atlanta Mar 2015 - FinalMilton RemacheNo ratings yet

- Cooling CurvesDocument21 pagesCooling CurvesXhané TNo ratings yet

- ME 315 - Heat Transfer Laboratory Experiment No. 5 Pool Boiling in A Saturated LiquidDocument10 pagesME 315 - Heat Transfer Laboratory Experiment No. 5 Pool Boiling in A Saturated LiquidmustafaNo ratings yet

- Forced ConvectionDocument6 pagesForced ConvectionTirth VyasNo ratings yet

- Comparison Between Active and Passive Thermal Cycling stress-ED-v1 0-EnDocument8 pagesComparison Between Active and Passive Thermal Cycling stress-ED-v1 0-EnGetssy PrathibaNo ratings yet

- Heat Transfer Lab ReportDocument10 pagesHeat Transfer Lab ReportJonathan WilliamsNo ratings yet

- 1 2 3 4 5 6 7 8 9 MergedDocument72 pages1 2 3 4 5 6 7 8 9 Mergedtenguria samriddhNo ratings yet

- Adiabatic & Reaction Calorimetry PDFDocument24 pagesAdiabatic & Reaction Calorimetry PDFpedroNo ratings yet

- Stepan Boltsmann ApparatusDocument9 pagesStepan Boltsmann ApparatusService MMINo ratings yet

- Soft Computing in the Design and Manufacturing of Composite Materials: Applications to Brake Friction and Thermoset Matrix CompositesFrom EverandSoft Computing in the Design and Manufacturing of Composite Materials: Applications to Brake Friction and Thermoset Matrix CompositesNo ratings yet

- Heat Transfer in Polymer Composite Materials: Forming ProcessesFrom EverandHeat Transfer in Polymer Composite Materials: Forming ProcessesNicolas BoyardNo ratings yet

- ConversionDocument1 pageConversionMikko EsalaNo ratings yet

- Tank VentingDocument2 pagesTank Ventingpradip11No ratings yet

- DDFDocument90 pagesDDFpradip11No ratings yet

- Tank VentingDocument2 pagesTank Ventingpradip11No ratings yet

- Tabel Konversi SatuanDocument1 pageTabel Konversi SatuanSutopo AhmadNo ratings yet

- Bostik India Private Limited: Equipment Master Equipment Technical DataDocument17 pagesBostik India Private Limited: Equipment Master Equipment Technical Datapradip11No ratings yet

- BalDocument1 pageBalpradip11No ratings yet

- Untitled 1Document1 pageUntitled 1pradip1179No ratings yet

- Specs Piping FittingsDocument2 pagesSpecs Piping Fittingspradip11No ratings yet

- Storage Tank Design CalculationDocument12 pagesStorage Tank Design Calculationhtutswe80% (15)

- Unload 1Document7 pagesUnload 1Javad MonfaredNo ratings yet

- Nitrogen SystemDocument3 pagesNitrogen Systempradip11No ratings yet

- DHA - Jebel Ali Emergency Centre + RevisedDocument5 pagesDHA - Jebel Ali Emergency Centre + RevisedJam EsNo ratings yet

- Agrinome For Breeding - Glossary List For Mutual Understandings v0.3 - 040319Document7 pagesAgrinome For Breeding - Glossary List For Mutual Understandings v0.3 - 040319mustakim mohamadNo ratings yet

- Concise Selina Solutions Class 9 Maths Chapter 15 Construction of PolygonsDocument31 pagesConcise Selina Solutions Class 9 Maths Chapter 15 Construction of Polygonsbhaskar51178No ratings yet

- Current Harmonics: Electric Power System Power QualityDocument3 pagesCurrent Harmonics: Electric Power System Power QualityAlliver SapitulaNo ratings yet

- Institutions and StrategyDocument28 pagesInstitutions and StrategyFatin Fatin Atiqah100% (1)

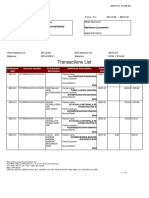

- Transactions List: Marilena Constantin RO75BRDE445SV93146784450 RON Marilena ConstantinDocument12 pagesTransactions List: Marilena Constantin RO75BRDE445SV93146784450 RON Marilena ConstantinConstantin MarilenaNo ratings yet

- Vest3000mkii TurntableDocument16 pagesVest3000mkii TurntableElkin BabiloniaNo ratings yet

- Art Appreciation Chapter 3 SummaryDocument6 pagesArt Appreciation Chapter 3 SummaryDiego A. Odchimar IIINo ratings yet

- This Is A Short Presentation To Explain The Character of Uncle Sam, Made by Ivo BogoevskiDocument7 pagesThis Is A Short Presentation To Explain The Character of Uncle Sam, Made by Ivo BogoevskiIvo BogoevskiNo ratings yet

- Aharonov-Bohm Effect WebDocument5 pagesAharonov-Bohm Effect Webatactoulis1308No ratings yet

- Not CE 2015 Version R Series 1t-3.5t Operating Manua 2015-08Document151 pagesNot CE 2015 Version R Series 1t-3.5t Operating Manua 2015-08hocine gherbiNo ratings yet

- Study and Interpretation of The ScoreDocument10 pagesStudy and Interpretation of The ScoreDwightPile-GrayNo ratings yet

- DL Manual - Com Vs Controller Gs Driver p100 Operating ManualDocument124 pagesDL Manual - Com Vs Controller Gs Driver p100 Operating ManualThiago Teixeira PiresNo ratings yet

- B-GL-385-009 Short Range Anti-Armour Weapon (Medium)Document171 pagesB-GL-385-009 Short Range Anti-Armour Weapon (Medium)Jared A. Lang100% (1)

- Req Equip Material Devlopment Power SectorDocument57 pagesReq Equip Material Devlopment Power Sectorayadav_196953No ratings yet

- Role of Communication at Mahabharatha WarDocument19 pagesRole of Communication at Mahabharatha WarAmit Kalita50% (2)

- Index: © Christopher Pitt 2018 C. Pitt, The Definitive Guide To AdonisjsDocument5 pagesIndex: © Christopher Pitt 2018 C. Pitt, The Definitive Guide To AdonisjsZidi BoyNo ratings yet

- The Intel 8086 / 8088/ 80186 / 80286 / 80386 / 80486 Jump InstructionsDocument3 pagesThe Intel 8086 / 8088/ 80186 / 80286 / 80386 / 80486 Jump InstructionsalexiouconNo ratings yet

- Flipkart Labels 06 Jul 2022 09 52Document37 pagesFlipkart Labels 06 Jul 2022 09 52Dharmesh ManiyaNo ratings yet

- Advanced Herd Health Management, Sanitation and HygieneDocument28 pagesAdvanced Herd Health Management, Sanitation and Hygienejane entunaNo ratings yet

- Tax Havens IMF PDFDocument59 pagesTax Havens IMF PDFClassic PhyXNo ratings yet

- 1572 - Anantha Narayanan FFS CalculationDocument1 page1572 - Anantha Narayanan FFS CalculationAnantha NarayananNo ratings yet

- Energy Production From Speed BreakerDocument44 pagesEnergy Production From Speed BreakerMuhammad Bilal67% (3)

- Sage TutorialDocument115 pagesSage TutorialChhakuli GiriNo ratings yet