Professional Documents

Culture Documents

Ashok - 07b11a0338

Uploaded by

mdakram145Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ashok - 07b11a0338

Uploaded by

mdakram145Copyright:

Available Formats

Simple example

At an average power consumption of 100 mW, you need slightly more than 1 cm3 of lithium battery volume for 1 year of operation, assuming you can use 100% of the charge in the battery.

Energy density of rechargeable batteries is less than half that of primary batteries.

So, someone needs to either replace batteries in every node every ~ 9 months, or recharge every battery every 3 to 4 months. In most cases, this is not acceptable

An electrical battery is one or more electrochemical cells that convert stored chemical energy into electrical energy. Since the invention of the first battery (or "voltaic pile") in 1800 by Alessandro Volta and especially since the technically improved Daniel cell in 1836, batteries have become a common power source for many household and industrial applications.]

Macro Batteries - too big

Zinc air (3500 J/cm3)

High power density Doesnt stop

Alkaline (1800 J/cm3)

Standard for modern portable electronics

Lithium (1000 - 2880 J/cm3)

Standard for high power portable electronics

Micro Batteries - on the way

Lithium Ni/NaOH/Zn

NUCLEAR MICRO-BATTERY THIN FILM MICRO-BATTERIES

The world of tomorrow that science fiction dreams of and technology manifests might be a very small one. It would reason that small devices would need small batteries to power them. Examination of the research paths and possible applications of nano-scale nuclear power devices will provide perspective on the technological and societal trajectory of nanoscale nuclear power devices.

nano-nuclear batteries commonly called betavoltaics and self-reciprocating cantilevers. The operation of betavoltaics is governed by several parameters. As shown in Figure the betavoltaic effect is the generation of electrical potential due to net positive charge flow of the particle induced electron hole pairs (EHPs).

When EHPs diffuse into the depletion region of the semiconductor pn-junction, the electrical field of the depletion region sweeps them across the depletion region. Net power can be extracted because the resulting current is from n- to p-type semiconductor

Figure Betavoltaic effect a) Schematic diagram of betavoltaic battery b) Potential diagram for a betavoltaic effect

Figure Betavoltaic microbattery based on a pn-junction device on a bulk-icromachined inverted pyramid array. Left three are views of the inverted pyramid array and the far right shows the configuration of Liquid 63NiCl/HCl solution in the inverted pyramid array The energy conversion efficiency of the particles in these betavoltaics is 0.5-1.0% producing on the order of nano-Watts of output power.

Thin film batteries are built layer by layer by vapor deposition. The resulting battery is formed of parallel plates, much as an ordinary battery construction, just much thinner. The figure shows an example of a thin film battery layout where films are deposited symmetrically onto both sides of a supporting substrate.

The full stack of films is only 10 to 15 m thick, but including the support at least doubles the overall battery thickness. When the support is thin, the entire battery can be flexible.

Schematic illustration of a thin film battery. The arrows indicate the discharge reaction where a Li ion diffuses from the lithium metal anode to fill a vacancy in an intercalation compound that serves as the cathode. The compensating electron is conducted through the device.

Schematic cross section of a thin film battery fabricated by vapor deposition onto both sides of a substrate support.

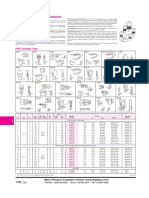

Hearing Aid Batteries Watch Batteries, Lithium Coin Batteries Alkaline Button Batteries

The several examples presented here demonstrate that there are tremendous opportunities in microbattery design. Electrode geometries and cell configurations not yet considered are likely to yield current distributions significantly better than the examples described here.

While significant increases in both power and energy density are obtainable from microbatteries relative to conventional batteries, the inherent difficulty in achieving a uniform current distribution may limit some devices. The several examples presented here demonstrate that there are tremendous opportunities in microbattery design. Electrode geometries and cell configurations not yet considered are likely to yield current distributions significantly better than the examples described.

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- BMHS Specifications of EquipmentDocument43 pagesBMHS Specifications of Equipmentmdakram145No ratings yet

- Uninterruptible Power Supply - UPSDocument68 pagesUninterruptible Power Supply - UPSRawandNo ratings yet

- 15 Small Battery Certification PDFDocument11 pages15 Small Battery Certification PDFdarkestmatterNo ratings yet

- Magic in The: AdīthsDocument11 pagesMagic in The: Adīthsmdakram145No ratings yet

- Instruction Manual: For Installation, Operation & MaintenanceDocument32 pagesInstruction Manual: For Installation, Operation & MaintenancevinayNo ratings yet

- Procedure For B & D RegistrationDocument6 pagesProcedure For B & D RegistrationA K MittalNo ratings yet

- Instruction Manual: For Installation, Operation & MaintenanceDocument32 pagesInstruction Manual: For Installation, Operation & MaintenancevinayNo ratings yet

- Certificado UL BateriaDocument20 pagesCertificado UL BateriadavidNo ratings yet

- Primary Cell Types - Dry Cell - Alkaline Cell - Lithium CellDocument4 pagesPrimary Cell Types - Dry Cell - Alkaline Cell - Lithium Cellnivas28100% (1)

- Intertek Button Battery 2020 UpdateDocument2 pagesIntertek Button Battery 2020 UpdatecanacNo ratings yet

- Technical Instructions For The Safe Transport of Dangerous Goods by AirDocument4 pagesTechnical Instructions For The Safe Transport of Dangerous Goods by AirtsanotasnoNo ratings yet

- VLocPro21 A 40Document42 pagesVLocPro21 A 40Claudio VazquezNo ratings yet

- Rayovac 303 357-1W CatalogDocument22 pagesRayovac 303 357-1W CatalogMedSparkNo ratings yet

- X300 Series Transmitter Product Sheet Overview 27 Apr 2017Document2 pagesX300 Series Transmitter Product Sheet Overview 27 Apr 2017S.SasiNo ratings yet

- MST Transponder Instruction ManualDocument76 pagesMST Transponder Instruction ManualŞef Utas AwijNo ratings yet

- Polyswitch Circuit Protection Products Catalog PDFDocument254 pagesPolyswitch Circuit Protection Products Catalog PDFRuben JimenezNo ratings yet

- Manual Delivery Flash PB-03035 v00 PB1000 OP - Alfa Laval BWTSDocument544 pagesManual Delivery Flash PB-03035 v00 PB1000 OP - Alfa Laval BWTSCvetan IvanovNo ratings yet

- Iec 63338 Ed1 2021-01-08 2021-04-02 21a/727a/np, 21a/733/rvnDocument25 pagesIec 63338 Ed1 2021-01-08 2021-04-02 21a/727a/np, 21a/733/rvnB.Bor (Alfen)No ratings yet

- Dukane Safety Data Sheets for Lithium BatteriesDocument6 pagesDukane Safety Data Sheets for Lithium BatteriesmILTONNo ratings yet

- LithiumBattery EnglishDocument7 pagesLithiumBattery EnglishgojarooNo ratings yet

- Instruction Manual: EN IWDocument42 pagesInstruction Manual: EN IWJátékra CsakNo ratings yet

- Mag 8000 Oi en En-UsDocument165 pagesMag 8000 Oi en En-UsJamesh BabuNo ratings yet

- Li Battery DelecrationDocument1 pageLi Battery Delecration420zebraNo ratings yet

- Pacemaker BatteriesDocument12 pagesPacemaker Batteriesrohit860No ratings yet

- Bulk Uploading SampleDocument342 pagesBulk Uploading SampleHuzaifa Bin SaadNo ratings yet

- GIGABYTE AERO 15X V8 ManualDocument105 pagesGIGABYTE AERO 15X V8 ManualAdyanto PutraNo ratings yet

- International Standards BatteriesDocument10 pagesInternational Standards BatteriesshasailuNo ratings yet

- Stratopi Can User Guide 1217995Document34 pagesStratopi Can User Guide 1217995megatornadoNo ratings yet

- Panasonic lithium battery featuresDocument1 pagePanasonic lithium battery featuresAdrianm MzrtinezNo ratings yet

- Lithium Manganese Dioxide - Application Guide - UltraLife (BR - CR - Design - App - Doc)Document13 pagesLithium Manganese Dioxide - Application Guide - UltraLife (BR - CR - Design - App - Doc)MedSparkNo ratings yet

- 80-7061N Issue 3 RT9 Service ManualDocument34 pages80-7061N Issue 3 RT9 Service ManualParvez ShahedNo ratings yet

- Catalogo de Pilas BulltronicDocument110 pagesCatalogo de Pilas Bulltroniccristobal_tl2277No ratings yet

- TVU One Setup and Operating Guide V 6.1 PDFDocument85 pagesTVU One Setup and Operating Guide V 6.1 PDFhieu phamNo ratings yet

- International Standard: Safety of Primary and Secondary Lithium Cells and Batteries During TransportDocument7 pagesInternational Standard: Safety of Primary and Secondary Lithium Cells and Batteries During Transportp sangeerthNo ratings yet

- VTU Engineering Chemistry 15che12 NotesDocument94 pagesVTU Engineering Chemistry 15che12 NotesVTU PRO67% (3)